镍基变形高温合金具有优异的综合力学性能,良好的抗氧化、耐腐蚀性,广泛用于制造国内外各种先进军、民用航空发动机零部件[1,2,3,4]。其中,GH4169合金被大量用于制备航空发动机的高压压气机盘、涡轮盘、轴、机匣、锻造叶片等。目前,GH4169已经成为我国现役和在研的各型号航空发动机中用量最大、用途最广、产品种类与规格最全的变形高温合金材料[5,6,7,8,9,10]。为满足高品质航空盘锻件的要求,20世纪末国外就规定,航空发动机转动件需采用真空感应熔炼+保护气氛电渣重熔+真空自耗重熔三联熔炼工艺制备。三联熔炼工艺能够综合真空感应熔炼精确控制合金成分,电渣重熔脱硫、降低夹杂物含量并提高电极锭致密度,真空自耗重熔细化合金组织、降低成分偏析的优点,但是三联熔炼制备的变形高温合金铸锭内并不能完全杜绝偏析类冶金缺陷,如黑斑,特别是白斑的产生。2017年7月,美国联合航空公司一架波音767-323客机起飞时,配装的一台GE公司CF6航空发动机的Inconel 718高压涡轮二级盘破裂造成事故,事后查明最终原因是合金熔炼过程中产生的偏析类冶金缺陷造成的,并且盘件用的Inconel 718合金棒材就是采用三联熔炼工艺制备。随着技术进步和为了降低成本,国内外制备的GH4169合金真空自耗锭尺寸逐渐增大,发展趋势为直径406 mm→508 mm→610 mm→660 mm。然而,锭型尺寸增加带来的突出问题就是强化元素在选分结晶原理作用下元素偏析倾向加大。研究[11]表明,常规电渣重熔或真空自耗重熔工艺制备的高温合金中,当锭型超过某一临界尺寸,材料中出现偏析类冶金缺陷的风险急剧增大。GH4169合金本身合金化程度较高,更加容易产生宏观偏析(如“黑斑”、“白斑”)[12]和微观偏析(如枝晶偏析等)[13]等冶金缺陷。国内外对GH4169合金组织和性能[14,15]、均匀化处理[16]、冷热加工性能[17,18]、电子束焊接[19]、增材制造[5]、电极锭去应力退火[20,21]等方面开展了深入研究,然而国内近年刚开展变形高温合金三联熔炼棒材的批生产,技术成熟度有待进一步提高。另外,与Inconel 718合金盘件相比,GH4169合金锻造盘件在冶金缺陷出现概率、力学性能波动、残余应力控制等方面均有一定差距。此外,对航空发动机盘件应用的三联熔炼大规格GH4169合金铸锭及棒材中的元素区域偏析问题也鲜有报道。元素偏析对金属制件的力学性能、物理性能均带来有害影响,如不锈钢的成分偏析导致产生晶间腐蚀、合金钢中成分偏析易导致热处理后组织不均匀性等,因此,研究高温合金的元素偏析成因与规律,有重要的现实意义。

本工作在分析三联熔炼GH4169合金大规格铸锭与棒材中的元素偏析与微观组织的基础上,结合计算仿真分析了大规格合金铸锭和棒材中区域偏析的形成原因,同时利用样本方差统计方法分析了GH4169合金棒材内典型元素的分布均匀性,研究了GH4169棒材区域元素偏析差异及其对相关力学性能的影响,以期提高变形高温合金GH4169棒材的冶金质量,满足航空发动机、燃气轮机等领域对高品质高温合金材料的需求。

1 实验方法

GH4169合金通过真空感应熔炼+保护气氛电渣重熔+真空自耗重熔三联熔炼工艺制备,自耗锭直径508 mm。铸锭经过两阶段高温均匀化处理后,采用镦拔+快锻+径锻制成棒材,棒材表面经机加工,并超声无损检测后制成直径240 mm的成品棒材。Inconel 718合金棒材也采用三联熔炼工艺制备,棒材直径为240 mm。GH4169与Inconel 718合金主要化学成分见表1。

表1 三联熔炼GH4169和Inconel 718合金棒材主要化学成分 (mass fraction / %)

Table 1

| Alloy | C | Mo | Cr | Nb | Al | Ti | Co | Ni | P | Si | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GH4169 | 0.027 | 2.96 | 17.84 | 5.38 | 0.54 | 1.01 | <0.1 | 53.6 | 0.0099 | 0.063 | 0.0004 | Bal. |

| Inconel 718 | 0.027 | 2.98 | 18.04 | 5.40 | 0.54 | 1.02 | 0.37 | 53.5 | 0.0079 | 0.061 | 0.0003 | Bal. |

GH4169棒材微观组织分析用腐蚀剂为100 mL HCl+100 mL CH3OH+5 g CuCl2,腐蚀的主要目的是显现出合金中的晶粒组织和析出相,腐蚀浸泡时间为25~30 s,然后取出,用流动的清水把腐蚀面冲洗干净,再用酒精冲洗,最后热风吹干腐蚀面用于观察分析。采用JSM-6510LV型扫描电镜(SEM)观察合金铸锭和棒材腐蚀后的微观组织,通过SEM自带的Penta FET Precision X-Act能谱仪(EDS)测定合金局部成分,借助JXA-iHP200F电子探针(EPMA)检测铸锭中尺度更小的枝晶干和枝晶间的典型元素分布。从GH4169合金棒材上切取透射电镜(TEM)观察用试样,TEM试样制样方法为电解双喷,电解腐蚀剂是10%的高氯酸酒精溶液,使用30 V电压,制样环境为-20 ℃。采用JEM2000F型TEM对GH4169合金基体组织及析出相进行观察和标定,确定析出相与基体间的取向关系。利用HXD-100TMC硬度计测试GH4169合金棒材Brinell硬度,每个部位分别测试3次。采用的硬质合金压头直径为1 mm,实验载荷294.2 N,保持时间20 s,测试完成后测量压痕直径,根据标准公式计算得出硬度。采用 ARL4460型光谱仪并结合数值仿真软件JmatPro、MetFlow检测和分析GH4169和Inconel 718合金棒材的元素分布均匀性,其中用于光谱分析的试样表面平整(粗糙度Ra≤12.5 μm),无夹杂物、微裂纹以及机加工造成的热变色。

力学测试试样采用的热处理制度为965 ℃、1 h,空冷+720 ℃、8 h,以50 ℃/h速率炉冷至620 ℃、8 h,空冷至室温。

2 实验结果与讨论

2.1 三联熔炼GH4169合金铸锭元素偏析行为

2.1.1 铸锭初始组织与元素分布

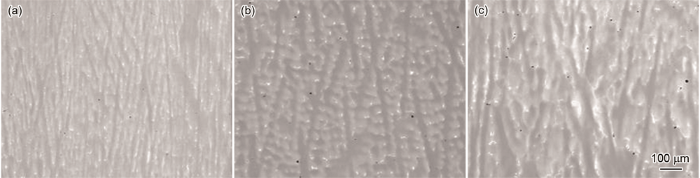

图1

图1

GH4169合金自耗锭不同部位枝晶组织的SEM像

Fig.1

SEM images of dendrite structures in different locations of GH4169 vacuum arc remelting (VAR) ingot

(a) edge (b) R/2 (R refer to the VAR ingot radius 254 mm) (c) center

采用EPMA测定典型元素Ti、Al、Nb和Mo在枝晶间和枝晶干的偏析情况,测试结果列于表2。相应的偏析系数(k)计算结果见表3。偏析系数越接近1说明该元素分布越均匀。表2的测定结果表明,Al元素在枝晶干富集,而Ti、Nb和Mo元素在枝晶间富集,并且在边缘、R/2处和中心3个部位,偏析程度和枝晶臂间距依次增加。从自耗锭边缘→R/2→中心部位,Nb、Ti元素偏析程度依次加重,其中Nb元素偏析程度最严重(0.555→0.446→0.376)。凝固过程中,合金元素在液相和固相中要重新分配。先结晶的固相中,高熔点组元的含量增加,相应地,液相中低熔点组元的含量增加。凝固结束后元素的扩散速率很慢,成分偏析就被保留下来。元素偏析与合金体系、冷速有关。本工作研究的GH4169合金体系已经确定,因此影响偏析的内在原因主要是冷速。在铸锭中心位置的冷速较慢,使得该位置的合金保留在液态的时间较长,原子扩散的时间更长,因此偏析程度更严重。

表2 GH4169合金自耗锭不同部位元素分布 (mass fraction / %)

Table 2

| Position of ingot | Region | Al | Ti | Nb | Mo |

|---|---|---|---|---|---|

| Edge | Interdendritic region Dendritic arm | 0.457 0.491 | 1.249 0.910 | 6.082 3.376 | 3.160 2.768 |

| R/2 | Interdendritic region Dendritic arm | 0.477 0.513 | 1.256 0.846 | 6.442 2.870 | 2.964 2.545 |

| Center | Interdendritic region Dendritic arm | 0.452 0.526 | 1.329 0.752 | 6.639 2.494 | 3.110 2.501 |

表3 GH4169合金自耗锭不同部位元素偏析系数(k)

Table 3

| Position of ingot | Al | Ti | Nb | Mo |

|---|---|---|---|---|

| Edge | 1.074 | 0.729 | 0.555 | 0.876 |

| R/2 | 1.075 | 0.674 | 0.446 | 0.857 |

| Center | 1.164 | 0.566 | 0.376 | 0.804 |

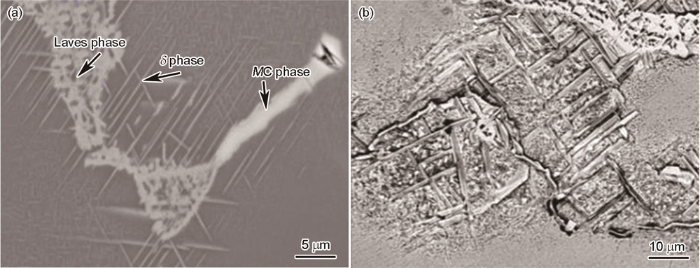

图2

图2

GH4169合金自耗锭中心部位析出相的EPMA像和SEM像

Fig.2

EPMA (a) and SEM (b) images of precipitated phase at center in VAR ingot of GH4169 alloy

表4 GH4169合金自耗锭析出相化学成分 (mass fraction / %)

Table 4

| Phase type | Al | Ti | Cr | Nb | Ni | Mo | Fe | C |

|---|---|---|---|---|---|---|---|---|

| Carbide | - | 4.994 | 1.043 | 87.617 | 2.527 | 1.579 | 0.523 | 9.730 |

| Laves phase | 0.140 | 0.812 | 14.906 | 30.151 | 34.107 | 12.630 | 14.065 | 0.247 |

| δ phase | 0.272 | 1.905 | 11.651 | 15.972 | 58.570 | 2.344 | 11.214 | - |

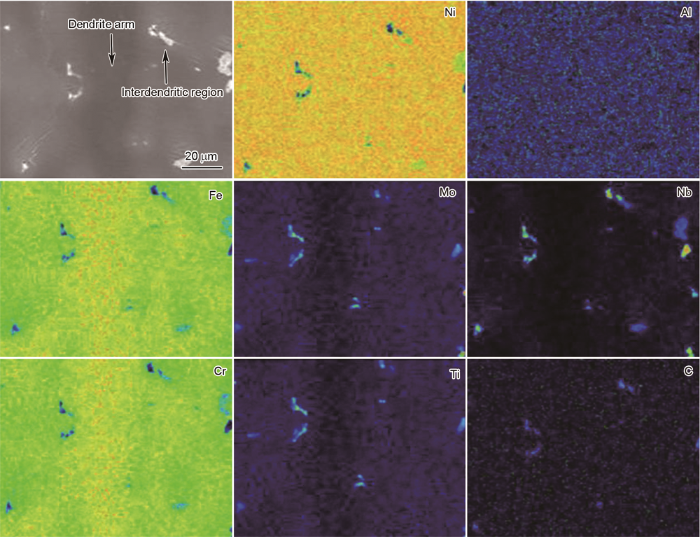

GH4169合金自耗锭中心部位面扫描成分分析结果如图3所示。结果表明,枝晶组织中存在明显的元素偏析。其中,Ni、Al和C元素偏析程度较小,而Nb、Ti和Mo元素偏析程度相对严重。元素的偏析在凝固过程中是不可避免的,先结晶的枝晶干和后结晶的枝晶间位置势必存在成分的不均匀,这些成分的不均匀将导致微观区域中相变临界温度的改变,并对相变动力学产生影响,所以成分的偏析又必然会造成组织的不均匀性。

图3

图3

GH4169合金自耗锭中心部位SEM像和元素分布

Fig.3

SEM image and element distributions at center in VAR ingot of GH4169 alloy

Color online

2.1.2 铸锭成分偏析理论计算分析

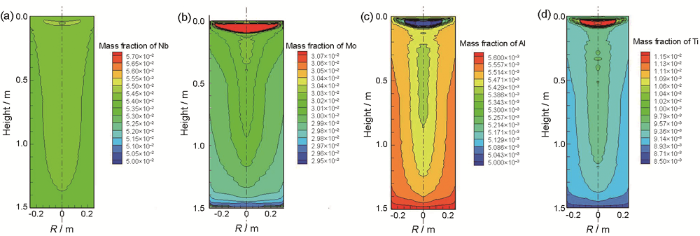

借助MetFlow软件对大规格GH4169合金自耗锭中的元素区域分布进行了计算分析。结合目前冶金厂生产的实际情况,设定GH4169合金铸锭半径254 mm,结晶器采用水冷却和He气冷却(压力为480 Pa)相结合。此外,计算过程中合金的4种元素成分(质量分数,%)设定为:Nb 5.40、Mo 3.00、Al 0.53、Ti 1.00,计算显示的中轴线为GH4169合金铸锭轴线。图4为计算得到的GH4169合金自耗锭中Nb、Mo、Al、Ti元素的分布图。可以看出,自耗锭中区域元素偏析程度较大的为Al元素(局部成分含量最大值达到0.56%,最小值为0.50%),而区域偏析程度最小的是Nb元素(成分含量最大值为5.5%,最小值为5.3%)。同时,Nb、Mo、Ti元素含量最高的部位均处于自耗锭的头部,而Al元素区域偏析状况恰恰与之相反。分析认为,其主要原因在于与Nb、Mo、Ti相比,金属Al的熔点和密度低,在高温电弧熔化后的电磁场Lorentz磁力作用下各组元之间出现凝固差异[22,23]。

图4

图4

GH4169合金自耗锭中典型元素Nb、Mo、Al、Ti分布的计算结果

Fig.4

Calculated distributions of typical elements Nb (a), Mo (b), Al (c) and Ti (d) in VAR ingot of GH4169 alloy

Color online

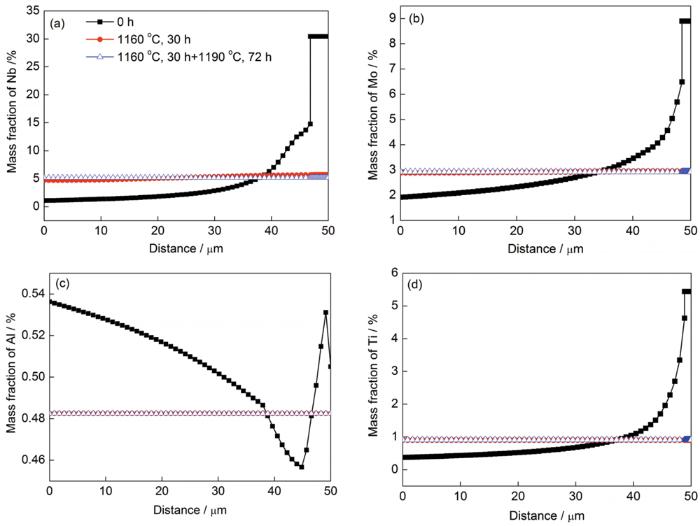

此外,图4中计算结果与前文实验分析存在区别的主要原因在于,通过软件计算得到的是自耗锭中元素的宏观偏析而非微观偏析(如枝晶偏析等),前文由EPMA测定的主要是合金中的微观偏析,2种结论并不矛盾。

2.2 高温均匀化热处理后铸锭元素分布特点

铸锭经1160 ℃、30 h+1190 ℃、72 h两阶段高温均匀化处理,采用JmatPro软件计算铸锭内典型元素Nb、Mo、Al、Ti达到完全均匀的时间。其中,根据前文测定结果,直径508 mm的GH4169合金自耗锭的二次枝晶臂间距约为100 μm (图1)。根据固态扩散理论,高温合金铸锭在高温均匀化过程中,合金元素达到均匀分布时,扩散完成的距离是枝晶臂间距的一半,据此本工作把扩散距离设定为50 μm进行计算。变形高温合金铸锭热传导速率设定为1.5 mm/min,Nb、Mo、Al、Ti 4种典型元素经高温均匀化处理后的成分分布如图5所示。可以看出,初始阶段自耗锭中4种元素偏析严重,在1160 ℃保温30 h后,自耗锭元素偏析程度显著降低,再经过在1190 ℃下72 h保温处理后,4种元素在自耗锭中实现均匀分布,说明本工作所采用的两阶段均匀化处理工艺合理。

图5

图5

GH4169合金自耗锭高温均匀化后成分分布计算结果

Fig.5

Calculated distributions of elements Nb (a), Mo (b), Al (c) and Ti (d) in VAR ingot of GH4169 alloy after homogenization heat treatment

2.3 大规格GH4169棒材组织和成分均匀性

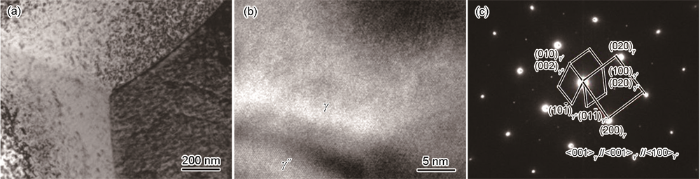

图6

图6

GH4169棒材TEM分析

Fig.6

TEM images of GH4169 billet

(a) TEM image of grain boundary and second phase

(b) HRTEM image of strengthening phase γ'' and matrx γ

(c) SAED pattern of matrix, γ' and γ''

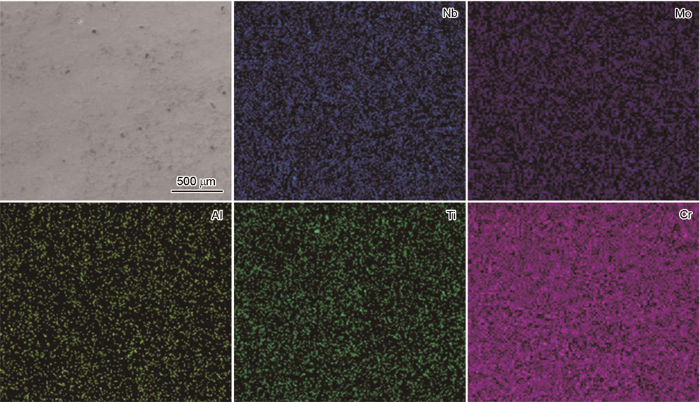

图7为GH4169合金锻态棒材Al、Ti、Nb、Mo和Cr元素分布图。可以看出,5种典型元素均为均匀分布,无明显的偏析区域,说明在2 mm的尺度范围内GH4169合金中元素分布的均匀性较高,微观偏析基本消除。

图7

图7

GH4169棒材典型合金元素分布

Fig.7

Distributions of typical elements Nb, Mo, Al, Ti and Cr in GH4169 billet

Color online

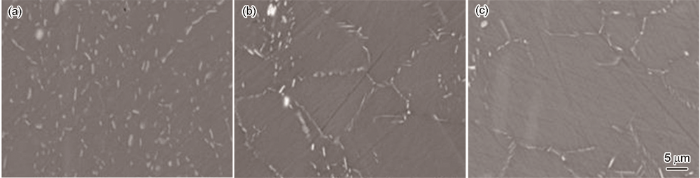

图8为GH4169合金棒材不同区域微观组织的SEM像。可以看出,由于GH4169合金本身的特点,不同部位晶粒尺寸和δ相分布状态存在一定差异。从棒材边缘至心部晶粒尺寸逐渐增大,晶界处均存在棒状分布的δ相。此外,GH4169大规格棒材内部的枝晶组织已完全消除,说明经过高温均匀化和开坯锻造后,细化了棒材晶粒。

图8

图8

GH4169棒材不同位置微观组织的SEM像

Fig.8

SEM images of GH4169 billet at different locations

(a) edge (b) R/2 (c) center

表5 利用EPMA测定的GH4169棒材不同部位的元素分布 (mass fraction / %)

Table 5

| Position of billet | Al | Ti | Mo | Nb | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Edge | 0.453 | 1.089 | 2.758 | 4.875 | 54.393 | 18.798 | 19.266 |

| 0.427 | 1.044 | 2.801 | 4.778 | 54.658 | 18.796 | 19.508 | |

| 0.411 | 1.051 | 2.803 | 4.771 | 54.325 | 18.796 | 19.421 | |

| Average value | 0.430 | 1.061 | 2.787 | 4.808 | 54.459 | 18.797 | 19.398 |

| R/2 | 0.440 | 1.094 | 2.740 | 4.975 | 53.962 | 19.172 | 19.298 |

| 0.502 | 1.122 | 2.742 | 4.835 | 53.877 | 19.225 | 19.312 | |

| 0.488 | 1.109 | 2.716 | 4.870 | 54.178 | 19.098 | 19.268 | |

| Average value | 0.477 | 1.108 | 2.733 | 4.893 | 54.006 | 19.165 | 19.293 |

| Center | 0.482 | 1.165 | 3.008 | 5.029 | 54.515 | 18.818 | 19.203 |

| 0.444 | 1.147 | 3.024 | 5.191 | 54.483 | 18.781 | 18.964 | |

| 0.452 | 1.149 | 2.941 | 5.133 | 54.442 | 18.957 | 19.115 | |

| Average value | 0.459 | 1.154 | 2.991 | 5.118 | 54.480 | 18.852 | 19.094 |

2.4 国内外大规格棒材成分均匀性与性能对比

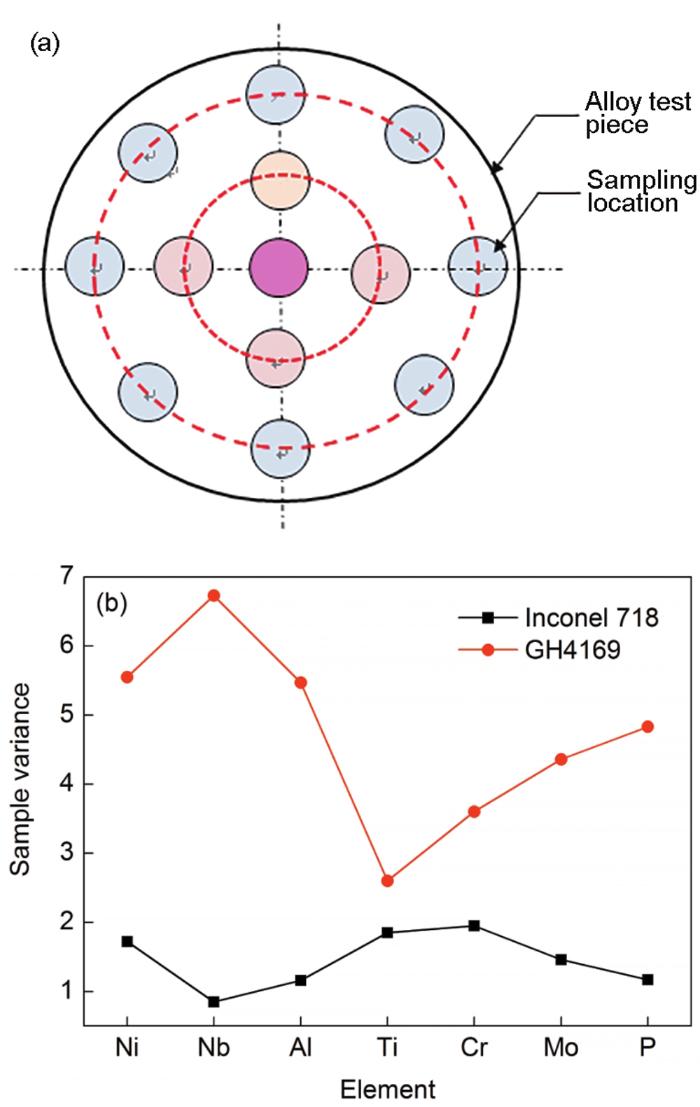

目前,高温合金化学成分分析主要采用湿化学法,该方法虽然结果十分准确,但无法对样品元素的位置信息进行追溯,而且混匀后的试样粉末无法反应区域成分偏析情况,难以评价合金的成分均匀度。为了分析大规格GH4169合金棒材在锻态下元素区域偏析状况,设计了如图9a所示的实验方案。在GH4169合金棒材试样的3个区域:边缘、R/2、心部测定13个样本位置,为减小误差,采用光电光谱仪对每个位置测3次,取元素检测结果的平均值作为一个样本,共13个样本。

图9

图9

棒材横截面不同部位元素测定方法及GH4169棒材与Inconel 718棒材典型元素标准偏差计算结果

Fig.9

Element testing method at different locations in billet cross section (a) and the calculated results of standard deviation for GH4169 and Inconel 718 billets (b)

对不同部位测定结果进行统计分析,采用样本标准偏差表征横截面上元素的均匀性。其中,样本平均值

GH4169和Inconel 718棒材典型元素标准方差计算结果如图9b所示。考虑到光谱分析设备的精确性,并尽量减少误差影响因素,只分析光谱法检测精度最高的主元素。可以看出,与GH4169棒材相比,Inconel 718棒材的元素分布样本标准方差更小,表明元素分布更均匀,如Inconel 718棒材的Nb元素样本标准偏差值为0.85,而GH4169棒材则达到6.73,其次是Inconel 718棒材Al元素的样本标准方差为1.16,而GH4169棒材为5.47。同样,GH4169棒材Mo和Ti元素的分布均匀性也稍低于Inconel 718棒材。此外,在GH4169合金棒材试样中没有观察到“黑斑”、“白斑”等宏观偏析类严重的冶金缺陷,也说明三联熔炼GH4169合金棒材的冶金质量整体水平较高。

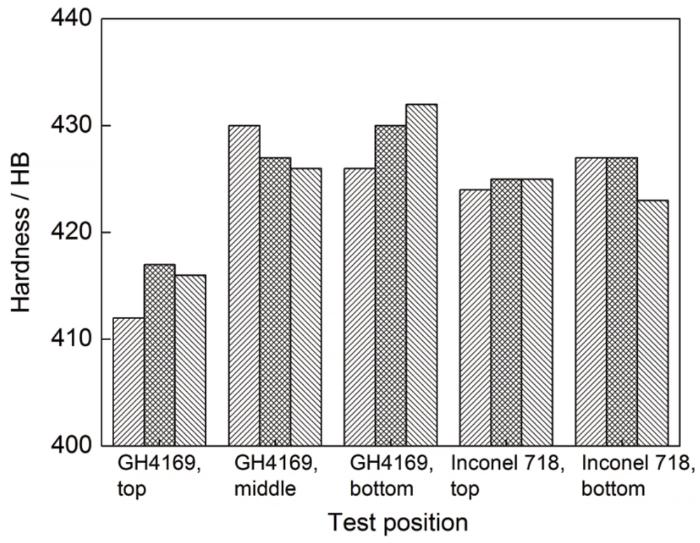

本工作采用的GH4169合金棒材的化学成分均符合标准要求,化学成分无明显差异,且力学性能包括室温和高温拉伸、持久、蠕变测试结果均优于标准规定的指标[28]。在此基础上分别对不同部位取样的GH4169和Inconel 718棒材,经过标准热处理后,进行Brinell硬度检测,每个部位测3个点,以分析硬度分布的均匀性,结果如图10所示。可以看出,GH4169合金棒材顶部硬度分布为412、417和416 HB,中部为430、427和426 HB,底部为426、430和432 HB;而Inconel 718棒材头部3点位置测试的Brinell硬度分别为424、425和425 HB,尾部为427、427和423 HB。可知,Inconel 718棒材硬度波动性小于GH4169棒材,说明Inconel 718棒材在硬度一致性方面相对更好。结合上文中GH4169/Inconel 718合金元素分布均匀性的对比结果,可认为区域元素偏析是造成GH4169棒材硬度波动性的原因之一。

图10

图10

GH4169和Inconel 718棒材不同部位硬度

Fig.10

Brinell hardnesses at different locations of GH4169 and Inconel 718 billets

通常,冶炼锭型越大、熔速增加以及合金化程度增高,都会增大变形高温合金铸锭中元素偏析的程度,而降低自耗重熔熔速、提高冷速等工艺措施有助于降低元素偏析,但是过低的熔速会导致自耗锭表面质量变差,并且增加He气冷却容易导致气体从坩埚壁与铸锭间隙逸出,影响熔池稳定。此外,自耗重熔工艺设定也需考虑到结晶器水冷铜底板的冷却效果随着过程进行不断减弱,进而影响铸锭熔池深度和熔体糊状区的凝固行为,用于冷却的He气流量参数也不能是一个恒定值,需要随着熔炼过程的进行而调整。总之,降低变形高温合金棒材的区域偏析是系统工程,需要严格控制和优化每个工艺环节,包括熔速优化、电极去应力退火、改进结晶器冷却条件、提高合金纯净度、改善均匀化热处理等,达到最终提升棒材质量水平的目的。

3 结论

(1) 三联熔炼工艺制备的GH4169合金大规格(直径508 mm)自耗锭呈现典型的树枝状结构,并且从自耗锭的边缘、R/2处到铸锭中心,二次枝晶臂间距依次增大,表明元素偏析逐渐加重。相对而言,Al组元偏析程度较轻,而Nb、Ti和Mo组元偏析较重,枝晶间凝固时析出较多的MC相、Laves相和δ相等。

(2) 经过高温均匀化热处理和锻造后,GH4169合金棒材中无“黑斑”、“白斑”等宏观偏析缺陷。棒材内部已完全消除了枝晶组织,从边缘至心部晶粒尺寸逐渐增大,晶界处均存在棒状分布的δ相,棒材内部毫米尺度范围内Al、Ti、Nb和Mo等元素分布均匀性较高,微观偏析基本消除。

(3) 统计计算分析结果表明,大规格GH4169合金棒材不同部位的元素区域偏析控制水平与Inconel 718存在差距。

参考文献

Study on the element segregation and Laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and gaussian distribution laser

[J].

Correlation of mechanical properties to microstructure in Inconel 718 fabricated by direct metal laser sintering

[J].

Effect of annealing treatment on microstructure evolution and creep behavior of a multiphase Ni3Al-based superalloy

[J].

Improving creep resistance of nickel-based superalloy Inconel 718 by tailoring gamma double prime variants

[J].

A review of mechanical properties of additively manufactured Inconel 718

[J].

Electron force-induced dislocations annihilation and regeneration of a superalloy through electrical in-situ transmission electron microscopy observations

[J].

Preparation of ultrafine-grained GH4169 superalloy by high-pressure torsion and analysis of grain refinement mechanism

[J].

Recent progress on evolution of precipitates in Inconel 718 superalloy

[J].γ'' phase), secondary strengthening phase (γ' phase), equilibrium phase of γ'' phase (δ phase), MX-type carbonitride and Laves phase. Precipitation mechanisms of secondary phases in Inconel 718 alloy are also reviewed, as well as the effects of different types of precipitates on high-temperature performance of the Inconel 718 alloy. With respect to the high-energy electron beam welding of Inconel 718 alloys, factors contributing to the cracking in heat affected zone are indicated.]]>

Inconel 718高温合金中析出相演变研究进展

[J].γ'' 相)、辅助强化相(γ' 相)、γ'' 相的平衡相(δ相), 以及MX型碳氮化物和Laves相; 论述了镍基合金制备过程中不同类型析出相的析出机制及其对合金高温性能的影响; 指出了镍基合金高能电子束焊接过程中, 焊接热影响区微裂纹形成的影响因素.]]>

Residual stress evolution and its mechanism during the manufacture of superalloy disk forgings

[J].γ″ or γ′ phase during heat treatment has a significant interaction with the distribution and magnitude of residual stress. During the machining process, part of the residual stresses contributing to the equilibrium of the internal forces are removed along with the material. Additional moment caused by re-balance of residual stresses results in the serious consequences of distortion in the remaining body.]]>

高温合金盘锻件制备过程残余应力的演化规律及机制

[J].高温合金盘锻件制备工艺过程中形成的内部残余应力是涡轮盘件尺寸精度和使用稳定性的重要影响因素。本文综述了高温合金盘锻件内部残余应力的中子衍射法和轮廓法测试技术,以及残余应力在固溶淬火、时效热处理和零件加工过程的分布特征、演化规律和内在机制:高温合金盘锻件的内部残余应力主要源于淬火过程的温度梯度,以弦向和径向应力为主,沿截面轮廓呈“内拉外压”特征分布,其数值与淬火态合金的屈服强度相当;时效热处理后小部分残余应力通过塑性变形和蠕变释放;热处理过程中强化相的析出与残余应力演化存在显著交互影响;零件加工过程中,残余应力会随着加工余量脱离本体而被部分释放,残余应力在再平衡过程发生变化所引起的附加力矩是加工变形的主要原因。

Microstructure evolution of Inconel 718 superalloy during hot working and its recent development tendency

[J].δ-phase morphology control and residual stress are explained. Based on the potential application prospect of selective laser melting in additive manufacture of aerocraft engine components, the specialized anisotropic microstructure and mechanical performance resulted from the rapid solidification process in selective laser melting are analyzed. Furthermore, the importance and difficulty of heat treatment in eliminating Laves-phase as well as tailoring substructure and related mechanical behavior are also discussed. The deformation mechanisms of Inconel 718 alloy at high temperature are illustrated in detail, comprising of dislocation planar slip, twinning and dislocation-shearing γ″ precipitates in complex modes. At last, a newly developed wrought nickel superalloy (Allvac 718Plus, with a increase in service temperature of 55 ℃ as compared to that of Inconel 718) is introduced, and some recent progresses aimed at modifying chemical compositions and phase compositions to improve service temperature on the basis of Inconel 718 alloy are also reviewed. The results indicate that the more stable γ″-γ' composite structure is important for the further design of next-generation wrought nickel superalloys.]]>

Inconel 718变形高温合金热加工组织演变与发展趋势

[J].δ相形态控制以及存在的残余应力问题。基于选区激光熔化技术在航空发动机材料增材制造领域的潜在优势和应用前景,分析了选区激光熔化技术制造Inconel 718合金凝固组织和性能的各向异性,探讨了热处理工艺在消除有害相、改变组织结构及力学行为等方面的重要作用和局限性。结合高温服役过程的组织演变,分析了Inconel 718合金变形时涉及位错滑移、孪生、γ″相剪切方式的变形机制。最后,介绍了通过调整Inconel 718合金成分来改变强化相结构,从而进一步提高变形高温合金服役温度的有效尝试(如Allvac 718Plus合金的服役温度提高了55 ℃),指出了通过成分调整来获得热稳定性优异的γ″-γ'复合析出结构是新型变形镍基高温合金的重要发展方向。]]>

Macrosegregation in ESR and VAR processes

[J].

Role of grain structure, grain boundaries, crystallographic texture, precipitates, and porosity on fatigue behavior of Inconel 718 at room and elevated temperatures

[J].

Multiscale characterization of microstructures and mechanical properties of Inconel 718 fabricated by selective laser melting

[J].

Study on freckle of a high-alloyed GH4065 nickel base wrought superalloy

[J].η-phases, block M3B2 borides and MC carbides are formed in the forged condition. It is confirmed by the thermodynamic calculations that the η-phases, M3B2 borides and MC carbides are much easier forming in the freckle than that in matrix. After heat treatment, compared with matrix, the lathy η-phases are still existed in the freckle; the size and quantity of primary γ′ phases increase significantly while the size and morphology of the secondary γ′ phase are basically identical, only with less quantity. It has been found that due to the high content of γ′ phase, the γ′ dissolution temperature in the freckle is higher than that in the matrix. This induces an impeded recrystallization process caused by the coarsened γ′ phases during forging process and the grain size of the freckle region is significantly smaller than that of matrix. Based on this study, the formation of freckle can be effectively controlled by meticulous controlling of the previous smelting process, releasing of electrode residual stress, suitably reducing VAR melting rate, and accelerating VAR cooling.]]>

高合金化GH4065镍基变形高温合金点状偏析研究

[J].η相、块状M3B2型硼化物与MC型碳化物。热力学相计算亦证实了点状偏析区较正常组织区域更容易生成η相、M3B2和MC。热处理后,与正常组织区域相比,点状偏析中仍存在板条状η相,一次γ′相的尺寸和数量明显增加,二次γ′相尺寸和形貌基本相同但数量减少。分析发现,由于点状偏析区的成分变化使得γ′相回溶温度升高,导致锻造中粗大γ′相阻碍再结晶长大,点状偏析区晶粒尺寸小于正常组织区域。采取前道次冶炼精细化控制、释放电极残余应力、适度降低真空自耗重熔熔化速率、加强真空自耗重熔冷却等措施,可以有效降低点状偏析的形成倾向。]]>

Residual stresses in a quenched superalloy turbine disc: Measurements and modeling

[J].

Refining a complex nickel alloy to remove a sulfur impurity during vacuum induction melting: Part I

[J].

Hot deformation characteristics and dislocation substructure evolution of a nickel-base alloy considering effects of δ phase

[J].

Precipitation behavior during high-temperature isothermal compressive deformation of Inconel 718 alloy

[J].

Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718

[J].

Rapid solidification kinetics and mechanical property characteristics of Ni-Zr eutectic alloys processed under electromagnetic levitation state

[J].

Experimental and numerical investigations of the γ'' and γ' precipitation kinetics in Alloy 718

[J].

Superalloys: Alloying and Performance

[M].

Co-growing mechanism of γ/γ' eutectic on MC-type carbide in Ni-based single crystal superalloys

[J].

Recent progress of microstructure evolution and performance of multiphase Ni3Al-based intermetallic alloy with high Fe and Cr contents

[J].

高Fe、Cr含量多相Ni3Al基高温合金组织与性能研究进展

[J].

Coarsening behavior of γ' precipitates in the γ'+γ area of a Ni3Al-based alloy

[J].

Relationships between elastic constants and EAM/FS potential functions for cubic crystals

[J].

立方晶体弹性常数和EAM/FS势函数的关系

[J].

Analysis on quality of GH4169 alloy billet with large specification at home and abroad

[A].

国内外三联冶炼GH4169合金大规格棒材质量分析

[A].