Mg及其合金具有比重轻、比强度高、刚度大和减震性良好等一系列优点,在汽车行业和航空航天等领域具有广阔的应用前景[1]。然而,与立方结构金属相比,Mg是典型的hcp结构,室温下可启动的滑移系少,塑性变形能力较差[2]。为了克服Mg塑性较差的缺点,近年来关于Mg变形机制的研究已成为重要的研究课题[3],而位错运动特性是进一步在微观尺度研究位错相互作用及其结构变化,在细观尺度定量描述滑移变形机制的重要基础[4]。分子动力学(molecular dynamics,MD)可通过模拟原子运动、记录原子运动轨迹以及利用统计力学方法计算得到多体系统的静态和动态特性[5],因而成为研究位错运动特性的有效计算方法[6]。

目前,仅有Groh等[7]和Fan等[8,9]基于MD探讨了Mg常见滑移系上的位错运动特性。其中,Groh等[7]研究了在100~500 K下的基面和柱面<a>刃、螺位错,以及100 K下一阶锥面<a>刃位错的运动规律,计算了在黏滞拖曳机制控制下定量表征位错可动性的拖曳系数。Fan等[8]模拟了初始温度为0 K的二阶锥面(Py-II)<c+a>刃位错的运动,发现位错运动速率随外加剪切应力增大而增大,且不同剪切方向对应的位错运动速率存在差异。进一步研究[9]发现,温度对Py-II<c+a>刃位错的临界分切应力(CRSS)有明显影响。总体上,在这些Mg的常见滑移系中,关于Py-II<c+a>刃位错运动特性的研究相对较少,尤其缺乏对其在常见加工温度下位错运动速率与外加剪切应力相关性及位错可动性的研究。Py-II<c+a>位错滑移是协调c轴方向应变的重要机制[10],研究这一机制对改善Mg及其合金的力学性能具有重要意义。

本工作采用MD方法模拟在给定温度和一定外加剪切应力范围内Mg中Py-II<c+a>刃位错运动,研究外加剪切应力的大小及方向对位错运动速率和芯结构的影响,探讨相关位错滑移行为的物理本质,并计算黏滞拖曳机制下的位错可动性,以期补充Mg常见滑移系的位错运动特性结果,为变形机制的研究提供参考。

1 模拟方法

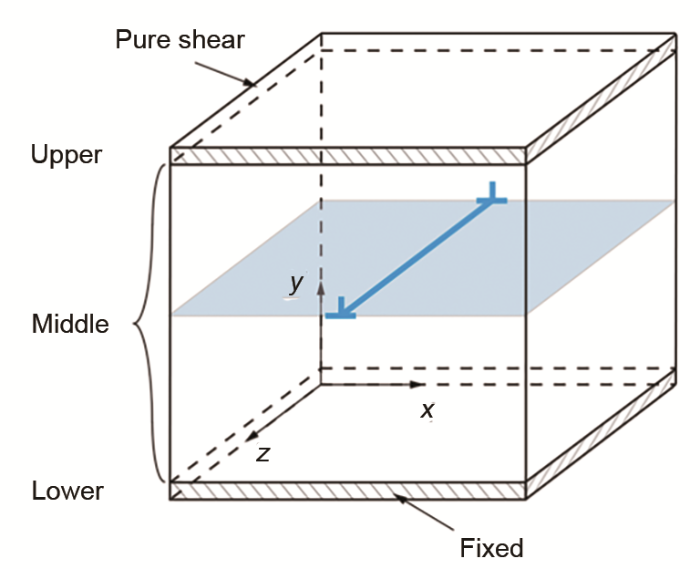

本研究重点考察黏滞拖曳机制控制下的位错运动特性。为此,需要模拟单个位错在不同外加剪切应力下的运动。模拟采用开源软件Lammps[14],所建刃位错运动模型如图1所示。参考文献[15]的设置,将模型沿y方向分为顶部、中部和底部3个区域。其中,顶部区域内的原子不能沿y方向运动,但可在xz平面内运动;底部区域内原子固定不动;中部区域内的原子可以沿任意方向运动。y方向设定为固定边界条件,x和z方向为周期性边界条件(periodic boundary condition,PBC)。对于Py-II<c+a>刃位错,x方向平行于刃位错的Burgers矢量方向[

图1

图1

刃位错运动模型示意图

Fig.1

Schematic of the model for the motion of an edge dislocation

Color online

基于上述刃位错模型和Kim等[16]的修正型嵌入原子势,模拟了温度为300 K下的位错运动。首先,采用共轭梯度法进行能量最小化弛豫。然后,在等温等压(NPT)系综下进行温度和压力调控,使体系温度达到目标温度且稳定、PBC方向(即x和z方向)上的应力趋近于零,升温速率约为1.0 K/ps,在后续保温过程中增大固定边界方向(即y方向)的模型尺寸(增大量约为0.27 nm)以充分消除升温后该方向的正应力。最后,在微正则(NVE)系综下,通过向顶部区域的原子施加外力的方式,分别施加沿x轴正、负方向的剪切应力(目标值为0~250 MPa,时间步长为0.002 ps),使位错沿不同方向滑移(正、负剪切分别导致c轴压缩和拉伸),同时采用Berendsen恒温器进行温度控制[17],实际温度波动范围不超过±5 K。为避免加载速率过高而使晶体产生强烈的惯性效应[18],外加剪切应力增速控制在1.0 MPa/ps以下,达到目标应力值后运行至少100 ps以获得剪切应力和温度都相对稳定的位错运动速率。

2 结果与讨论

2.1 有效剪切应力

在位错运动过程中,尽管大部分外力做功转变为系统内原子的动能和势能,但还有少部分以内能的形式耗散,因而实际驱动位错运动的剪切应力(即有效剪切应力(τeff))往往与外加剪切应力(τapp)存在一定差异[19]。在定量分析位错运动特性时,有必要考察τeff偏离τapp的程度。

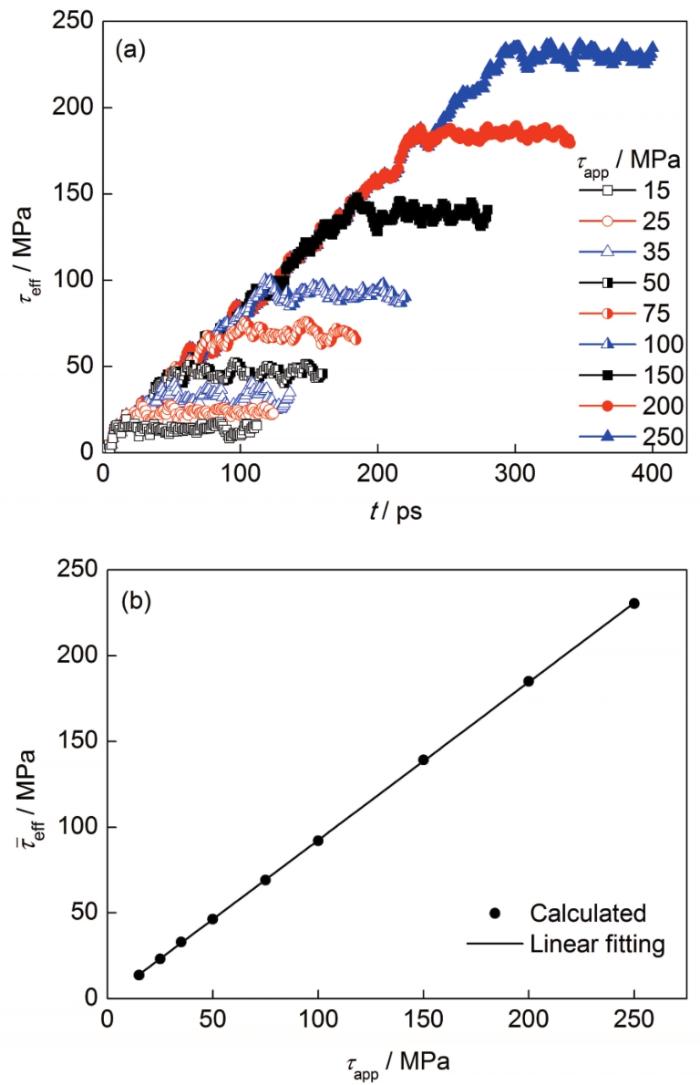

图2a以正剪切为例,给出了不同τapp下模型内的τeff随模拟时间(t)的变化曲线。其中,τeff在数值上等于根据Virial定理计算的体系的剪切应力分量(τxy)[20]。可以看出,τeff进入相对稳定阶段后(如τapp=50 MPa时,t=60~160 ps),没有出现由于惯性效应所导致的大幅振荡,稳态阶段的τeff略低于τapp。由图2b所示稳态阶段平均有效剪切应力(

图2

图2

正剪切下有效剪切应力(τeff)和平均有效剪切应力(

Fig.2

Variations of effective shear stress (τeff) (a) and average effective shear stress (

2.2 位错运动特性

图3

图3

不同τapp (正剪切)下位错芯的位移(d)-时间(t)曲线

Fig.3

Displacement (d)-t curves for the dislocation core under different τapp (positive shear) (The arrows indicate the starting points when τeff enters into a relatively stable stage as shown in Fig.2a)

为了定量分析

图4

图4

正、负剪切时位错运动速率(v)随

Fig.4

Dislocation velocity (v) as a function of

根据位错运动理论,黏滞拖曳机制控制位错运动时,v与施加在位错上的剪切应力呈线性关系[21]。排除外力做功时内能耗散的干扰,考虑实际驱动位错运动的剪切应力

式中,b是位错Burgers矢量模;B是拖曳系数,定量表征黏滞拖曳机制控制下的位错可动性,即B越大则可动性越低;

2.3 位错芯结构的演化

位错运动特性与位错结构的演化密切相关。研究发现,在能量最小化弛豫后,Py-II<c+a>刃位错已经分解成2个以内禀型层错区相连的不全位错(Burgers矢量模均为1/2<c+a>的刃型位错),形成扩展位错。图5是分别施加正、负剪切时,不同τapp作用下Py-II<c+a>刃位错在稳态阶段的位错芯结构。这些截面图对应于沿模型z方向一个周期内(共4层)的原子。原子畸变程度及所属晶体结构类型的判别均采用Ovito软件完成[22,23]。可以看出,在外加载荷作用下,扩展位错的基本特征没有改变,但在位错运动过程中2个不全位错的结构始终存在不同程度的差异。基于此类截面图,结合刃位错多余半原子面特征,可以进一步确定2个不全位错的中心位置,其间距即为扩展位错宽度(l),该值可定量体现位错芯结构变化的重要特征[24]。这些结果初步显示,在位错运动过程中,l随τapp的变化而发生明显变化,而且相同τapp下不同剪切方向所对应的l值亦存在差异。

图5

图5

不同τapp下的位错芯结构

Fig.5

Dislocation core structures under τapp=50 MPa (a1, b1), τapp=150 MPa (a2, b2) and τapp=250 MPa (a3, b3) (l—width of extended dislocation, b—modulus of Burgers vector)

(a1~a3) positive shear (b1~b3) negative shear

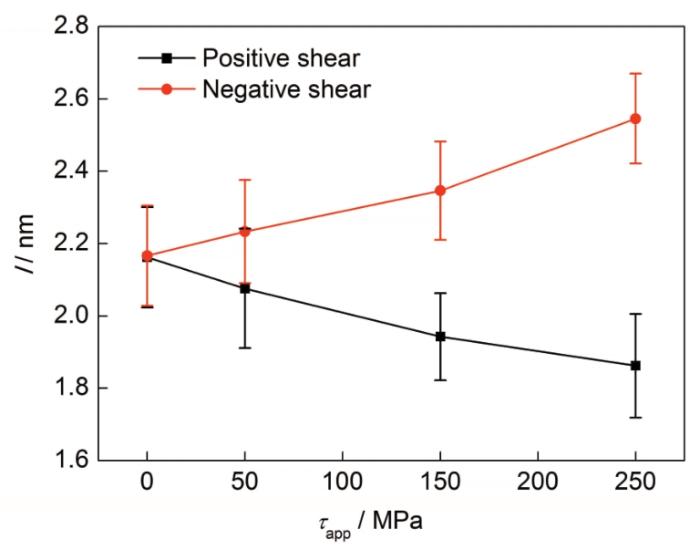

为了系统分析τapp的大小及方向对位错芯结构的影响规律,以进一步理解位错运动特性,图6给出了分别施加正、负剪切应力时不同τapp作用下Py-II<c+a>刃位错芯结构的l值变化情况。这些l值是τeff进入稳定阶段70 ps后,在30 ps内(如τapp=50 MPa时,t=130~160 ps)每1.0 ps提取一次所获l值的平均值,图中所示误差范围为对应时间段内的标准差。可以看出,尽管原子热运动导致l值显著波动,但该值随τapp大小及方向的变化呈现出一定的规律,即:在正剪切过程中随τapp的增大而减小,负剪切时则随τapp的增大而增大;相应地,正、负剪切所对应的l值差异随τapp的增大而变得更加显著。根据位错运动阻力的相关理论,扩展位错的晶格阻力与其宽度呈负相关[25]。上述结构演变特征可以在一定程度上解释位错的运动特性。例如,相同τapp下负剪切所得v高于正剪切的结果可以归结于前者导致较大的l,相应的晶格阻力较小;正、负剪切所得v的差异随τapp的增加而扩大的现象则是由于正、负剪切所得l的差值增加,相应的晶格阻力差异增大。

图6

图6

正、负剪切过程中扩展位错宽度(l)随τapp的变化

Fig.6

Variations of l with τapp under positive shear and negative shear

3 结论

(1) Py-II<c+a>刃位错的运动速率随外加剪切应力的增大而线性增大,符合黏滞拖曳机制控制的位错运动特征。

(2) Py-II<c+a>刃位错表现出较为明显的拉-压非对称性,且其可动性显著低于基面或柱面刃位错:同等剪切应力水平下,正剪切(对应于c轴压缩)的位错运动速率低于负剪切(对应于c轴拉伸),相应的拖曳系数分别为1.69×10-4和1.55×10-4 Pa·s。

(3) Py-II<c+a>刃位错的扩展位错宽度在正剪切时随外加剪切应力增加而减小,在负剪切时则呈现相反的趋势。较高外加应力水平下正、负剪切所得位错运动速率差异增大,本质上与扩展位错宽度差异扩大有关。

参考文献

Large plasticity in magnesium mediated by pyramidal dislocations

[J].Lightweight magnesium alloys are attractive as structural materials for improving energy efficiency in applications such as weight reduction of transportation vehicles. One major obstacle for widespread applications is the limited ductility of magnesium, which has been attributed to [Formula: see text] dislocations failing to accommodate plastic strain. We demonstrate, using in situ transmission electron microscope mechanical testing, that [Formula: see text] dislocations of various characters can accommodate considerable plasticity through gliding on pyramidal planes. We found that submicrometer-size magnesium samples exhibit high plasticity that is far greater than for their bulk counterparts. Small crystal size usually brings high stress, which in turn activates more [Formula: see text] dislocations in magnesium to accommodate plasticity, leading to both high strength and good plasticity.

On the strength of dislocation interactions and their effect on latent hardening in pure magnesium

[J].

Chapter 88 dislocation-obstacle interactions at the atomic level

[J].

Dislocation motion in magnesium: A study by molecular statics and molecular dynamics

[J].

Towards resolving the anonymity of pyramidal slip in magnesium

[J].

Temperature effects on the mobility of pyramidal <c+a> dislocations in magnesium

[J].

{11

Dynamic properties of screw dislocations in Cu: A molecular dynamics study

[J].

Atomistic simulations of dislocation mobility in Al, Ni and Al/Mg alloys

[J].

Fast parallel algorithms for short-range molecular dynamics

[J].

An atomic-level model for studying the dynamics of edge dislocations in metals

[J].

Modified embedded-atom method interatomic potentials for Mg-X (X=Y, Sn, Ca) binary systems

[J].

Molecular dynamics with coupling to an external bath

[J].

Towards further understanding of stacking fault tetrahedron absorption and defect-free channels—A molecular dynamics study

[J].

Mobility law of dislocations with several character angles and temperatures in FCC aluminum

[J].

General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions

[J].Three distinct forms are derived for the force virial contribution to the pressure and stress tensor of a collection of atoms interacting under periodic boundary conditions. All three forms are written in terms of forces acting on atoms, and so are valid for arbitrary many-body interatomic potentials. All three forms are mathematically equivalent. In the special case of atoms interacting with pair potentials, they reduce to previously published forms. (i) The atom-cell form is similar to the standard expression for the virial for a finite nonperiodic system, but with an explicit correction for interactions with periodic images. (ii) The atom form is particularly suited to implementation in modern molecular dynamics simulation codes using spatial decomposition parallel algorithms. (iii) The group form of the virial allows the contributions to the virial to be assigned to individual atoms.

Dislocation kinetics at high strain rates

[J].

Visualization and analysis of atomistic simulation data with ovito-the open visualization tool

[J].Atomistic molecular dynamics (MD) simulations generate a wealth of information related to the dynamics of proteins. If properly analyzed, this information can lead to new insights regarding protein function and assist wet-lab experiments. Aiming to identify interactions between individual amino acid residues and the role played by each in the context of MD simulations, we present a stand-alone software called gRINN (get Residue Interaction eNergies and Networks). gRINN features graphical user interfaces (GUIs) and a command-line interface for generating and analyzing pairwise residue interaction energies and energy correlations from protein MD simulation trajectories. gRINN utilizes the features of NAMD or GROMACS MD simulation packages and automatizes the steps necessary to extract residue-residue interaction energies from user-supplied simulation trajectories, greatly simplifying the analysis for the end-user. A GUI, including an embedded molecular viewer, is provided for visualization of interaction energy time-series, distributions, an interaction energy matrix, interaction energy correlations and a residue correlation matrix. gRINN additionally offers construction and analysis of Protein Energy Networks, providing residue-based metrics such as degrees, betweenness-centralities, closeness centralities as well as shortest path analysis. gRINN is free and open to all users without login requirement at http://grinn.readthedocs.io.

Robust structural identification via polyhedral template matching

[J].

Dislocations in a simple cubic lattice

[J].

An atomic-scale modeling and experimental study of <c+a> dislocations in Mg

[J].