与传统的Fe-Cr-Ni-Mo高强钢相比,低C (<0.06%,质量分数,下同)含Cu (1.0%~1.5%)的低合金高强钢(high strength low alloy,HSLA),具有高的强度、良好的韧性及优异焊接性[1,2],被广泛用于建造舰船、近海石油平台等[3~6]。含Cu的HSLA钢中C含量较低,可以有效提高合金钢的焊接性能,而添加的Cu在回火过程中会析出富Cu团簇,具有沉淀强化的作用,从而弥补低C造成的强度损失[1]。近年来,关于HSLA钢中Cu的强化机理研究较多[1,5,7~9]。Dhua等[7]研究了回火温度对HSLA-100合金钢力学性能的影响,发现随着回火温度的增加,强度呈现先增加后降低的趋势,并在450 ℃回火时合金钢的屈服强度获得最大值,为1168 MPa。研究[10~13]表明,HSLA钢中富Cu团簇的强化效果与其尺寸、数量密度等密切相关。通常在峰值时效时,富Cu团簇的尺寸较小、数量密度最大。当回火温度增加或回火时间延长时,富Cu团簇的尺寸逐渐增加,而数量密度明显降低,其沉淀强化效果减弱,合金钢的强度下降[5,13]。

值得注意的是,含Cu的HSLA钢经峰值时效处理后,其冲击性能较低,难以满足实际应用要求。与强化机理的研究相比,目前关于HSLA钢中的Cu对冲击性能影响的研究相对较少,其作用机制还不清楚。Hunter[14]在研究回火工艺对NUCu-140合金钢(0.05%C和1.64%Cu)冲击性能的影响时,发现合金钢经过450 ℃回火处理获得最佳强化效果时,-40 ℃冲击功仅为10 J,并认为晶界处网状分布的Fe3C是导致冲击功下降的主要原因,其断裂方式为沿晶断裂。然而Kapoor等[15]利用Auger电子能谱仪(AES)原位观察发现,Cu在晶界的偏聚是导致合金钢(Fe-0.06C-3Cu-4Ni-1.5Al-0.07Nb)沿晶断裂的主要原因。而Dhua等[7]对获得峰值强度(450 ℃回火)的HSLA-100钢进行-85 ℃的冲击实验,冲击功仅为14 J,其冲击断口形貌以河流花样为主,为穿晶准解理断裂。上述含Cu合金钢冲击断裂行为的差异,主要与所研究合金钢的成分组成相关。如NUCu-140合金钢中不含Mo、Cr等强碳化物形成元素,因而在较低回火温度时(如450 ℃)晶界处形成了数量较多的渗碳体(Fe3C),且主要沿着晶界分布,从而造成了合金钢冲击时的沿晶断裂;而文献[15]采用的合金钢Cu含量较高(3.0%),导致Cu在晶界处偏聚的浓度较高,从而引起了合金钢在冲击断裂时的沿晶开裂。然而对于含Cu的HSLA钢(如HSLA-100、HSLA-115),一般均含有Mo、Cr等强碳化物形成元素,在形成合金碳化物的同时,可降低渗碳体(M3C)的析出数量,且其Cu含量一般为1.0%~2.0%,晶界处Cu的偏聚浓度较低,即使在峰值回火处理后进行低温冲击实验,合金钢也不会出现沿晶开裂现象,其冲击断裂方式为穿晶准解理断裂[7,9]。然而关于Cu对HSLA钢冲击性能的影响机制鲜有报道,有文献[7]认为富Cu团簇的析出,在强化基体的同时,会降低合金钢的冲击性能,但缺少相应微观组织的观察。因此,Cu对冲击性能的作用机制还有待深入研究。

1 实验方法

本实验设计了2种HSLA钢,即不含Cu和含1.4%Cu,分别标记为0Cu和1.4Cu。以0Cu钢作为对比合金,对比分析富Cu团簇的析出对HSLA钢冲击韧性的影响。2种合金钢均采用真空感应炉熔炼,浇铸成25 kg的铸锭。铸锭先经过热锻,而后锻坯经过1150 ℃保温2 h后开轧,终轧温度为800 ℃,最终轧为12 mm厚的板材,合金钢的化学成分如表1所示。

表1 2种HSLA钢的化学成分

Table 1

| Steel | Content | C | Ni | Mn | Mo | Cr | Si | S | P | Nb | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Cu | Mass fraciton / % | 0.037 | 4.03 | 0.97 | 0.50 | 0.99 | 0.21 | 0.005 | 0.006 | 0.040 | 0.010 | Bal. |

| Atomic fraction / % | 0.170 | 3.89 | 0.99 | 0.29 | 1.07 | 0.42 | 0.009 | 0.011 | 0.024 | 0.009 | Bal. | |

| 1.4Cu | Mass fraciton / % | 0.041 | 4.01 | 1.00 | 0.56 | 0.95 | 0.22 | 0.005 | 0.007 | 0.05 | 1.40 | Bal. |

| Atomic fraction / % | 0.190 | 3.88 | 1.02 | 0.32 | 1.02 | 0.44 | 0.009 | 0.013 | 0.03 | 1.23 | Bal. |

从热轧后的板材上截取适当尺寸的试样进行热处理,淬火温度为880 ℃,保温40 min后水淬,回火温度在400~650 ℃之间,保温120 min后水冷。从回火态的试样上沿轧制方向取料,分别加工成标准Charpy-V型缺口冲击试样和棒状的拉伸试样。冲击试样的尺寸为10 mm×10 mm×55 mm;拉伸试样螺纹段直径为10 mm,平行段直径为5 mm、长30 mm。冲击实验在RKP450冲击试验机上进行,实验温度分别为室温(RT)、0、-20、-40和-50 ℃;拉伸实验在AK-1000KNG拉伸试验机上进行。采用JSM-6301F场发射扫描电镜(SEM)观察冲击断口形貌和断口附近纵截面的裂纹扩展路径,工作电压为20 kV。金相样品经过机械研磨、抛光后,采用过饱和的苦味酸溶液热侵蚀(温度为70~80 ℃)后,用GX51型金相显微镜(OM)观察原始奥氏体晶粒;显微组织观察的样品采用4% (体积分数)硝酸酒精侵蚀,并利用SEM进行观察。电子背散射衍射(EBSD)样品首先经过研磨、抛光,而后利用电解的方法去除表面的应力层,电解液为10% (体积分数)的高氯酸酒精溶液,电解电压为20 V,时间为15~20 s。EBSD实验在MERLIN Compact场发射SEM上进行,步长为0.12 μm。

APT技术是目前空间分辨率最高的分析测试手段之一,可在原子尺度上了解合金微区化学成分的不均匀性[19,20]。APT样品制备方法为:利用线切割从回火态样品上切取0.5 mm×0.5 mm×15 mm的细丝,磨平后采用2步电解抛光法制备APT针尖样品,粗抛电解液采用25%的高氯酸+75%的冰醋酸(体积分数)混合溶液,电压为10~20 V,精抛液为4%的高氯酸+96%乙二醇丁醚(体积分数)混合溶液,电压为5~10 V[1]。利用LEAP 5000XR三维原子探针的激光模式对样品进行分析,激光波长为335 nm,能量为40×10-12 J,脉冲频率为200 kHz,每次激光脉冲的离子收集速率为1%,实验温度为50 K。获取的APT实验数据利用IVAS 3.8.2软件进行三维重构,并对元素分布、团簇及其成分进行分析[19]。富Cu团簇的等浓度面采用5% (原子分数),其等效半径(R)与数量密度(NV)可分别由

式中,Nppt为析出相中的原子数目;ρth为析出相中原子的密度(对于bcc晶体结构的马氏体合金钢,取ρth为单个Fe原子的密度为84.3 nm-3[1] );η为所采用的LEAP 5000XR三维原子探针的探测重构系数,约为0.52;N为析出相的数量;Ntotal为重构样品中的原子总数。

2 实验结果

2.1 力学性能

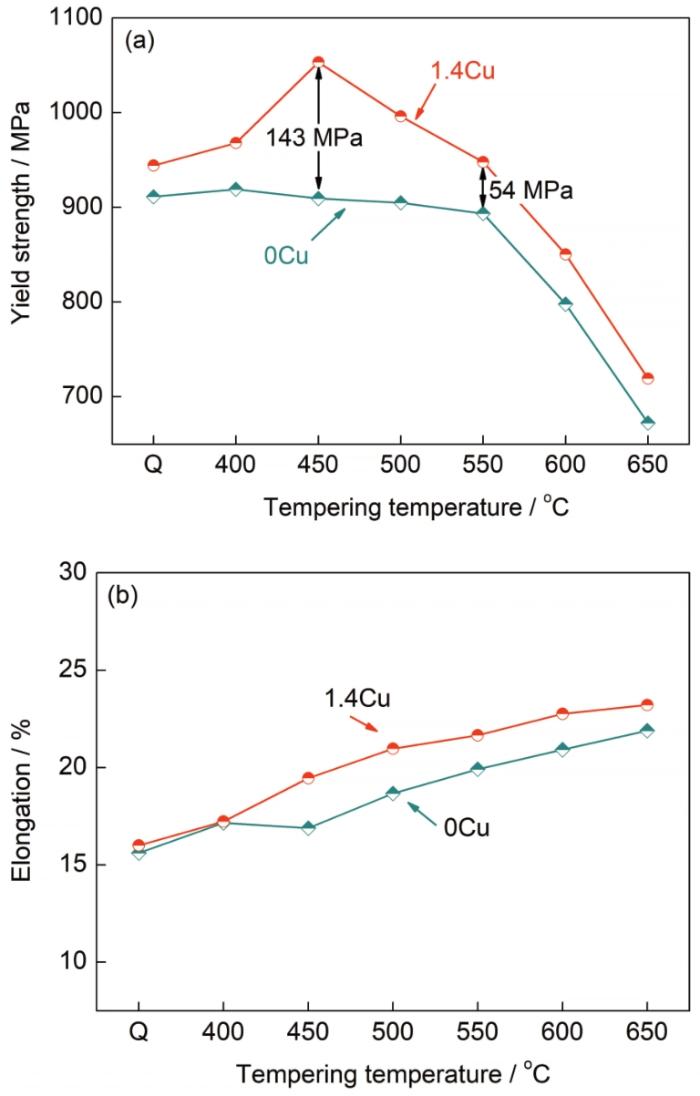

图1为不同温度回火后0Cu和1.4Cu钢的屈服强度和延伸率变化曲线。可知,淬火态时1.4Cu钢的屈服强度略高于0Cu钢,分别为940和910 MPa。不同温度回火处理后,1.4Cu钢的屈服强度高于0Cu钢,并随着回火温度的增加呈现不同的变化趋势。随着回火温度的增加,0Cu钢的屈服强度基本保持不变,当回火温度超过550 ℃时,其屈服强度显著下降。与0Cu钢不同,1.4Cu钢的屈服强度随着回火温度的增加,呈现先增加后降低的趋势,并在450 ℃回火时获得最佳强化效果,约为1053 MPa,此时0Cu钢的强度为910 MPa,相差143 MPa。值得注意的是,经过550 ℃回火后,1.4Cu和0Cu钢的屈服强度分别为948 和894 MPa,2者仅相差54 MPa (图1a),可见Cu的强化作用显著减弱。值得注意的是,0Cu钢与1.4Cu钢的延伸率相差不大,并均随着回火温度的升高而逐渐增加(图1b)。

图1

图1

不同温度回火后0Cu与1.4Cu钢的屈服强度和延伸率

Fig.1

Yield strengths (a) and elongations (b) of 0Cu and 1.4Cu steels tempered at different temperatures (Q—as quenching)

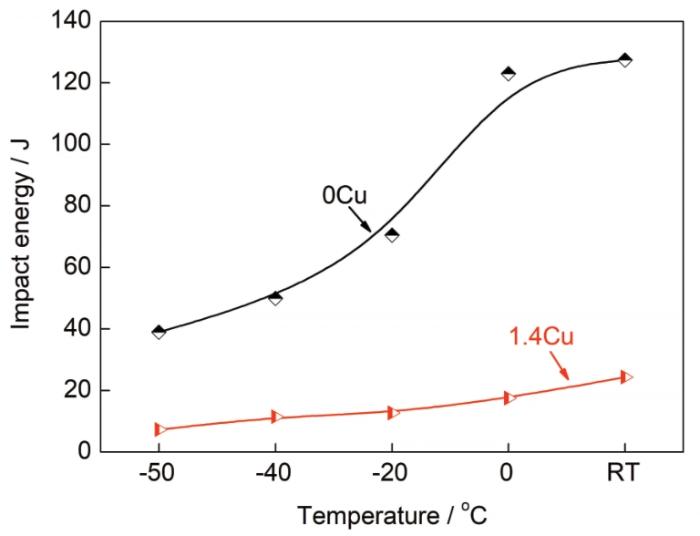

图2为450 ℃回火处理后0Cu和1.4Cu钢在不同温度下的冲击性能曲线。可知,室温下1.4Cu钢的冲击功仅为24 J,而0Cu钢的室温冲击功高达127 J。在整个实验温度范围内1.4Cu钢的冲击功均较低,推测其韧脆转变温度(DBTT)高于室温,而0Cu钢的DBTT约为-20 ℃。可见,在获得最佳强化效果时,1.4Cu钢的冲击性能较差。

图2

图2

450 ℃回火处理后0Cu和1.4Cu钢在不同温度下的冲击性能

Fig.2

The temperature dependent impact energy curves of 0Cu and 1.4Cu steels tempered at 450 ℃ (RT—room temperature)

2.2 微观组织

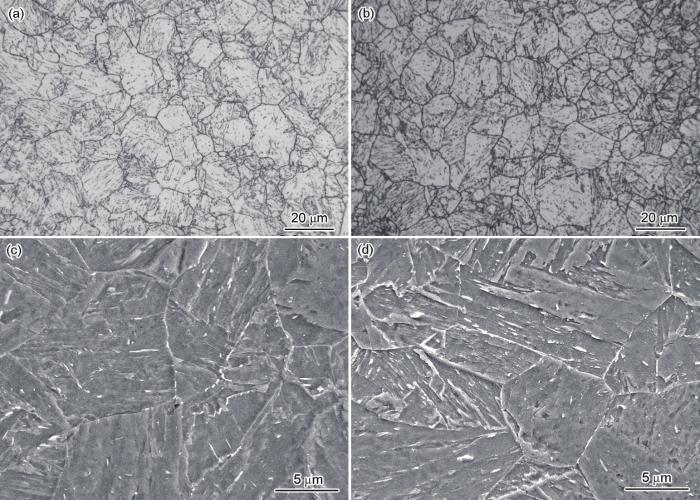

图3

图3

0Cu和1.4Cu钢经450 ℃回火处理后的原始奥氏体晶粒和显微组织的SEM像

Fig.3

SEM images of prior austenite grains (a, b) and microstructures (c, d) of 0Cu (a, c) and 1.4Cu (b, d) steels tempered at 450 ℃

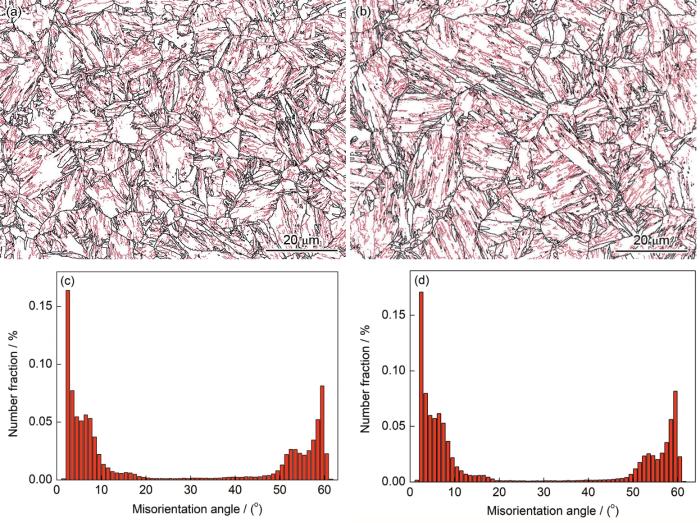

图4

图4

450 ℃回火处理后0Cu和1.4Cu钢的晶界图与取向差角度分布图

Fig.4

Misorientation distributions of grain boundaries (a, b) and misorientation angle distribution maps (c, d) of 0Cu (a, c) and 1.4Cu (b, d) steels tempered at 450 ℃ (The black lines and red lines denote the high angle grain boundaries (misorientation angle>15°) and low angle grain boundaries (misorientation angle 2°~15°), respectively)

Color online

2.3 APT分析

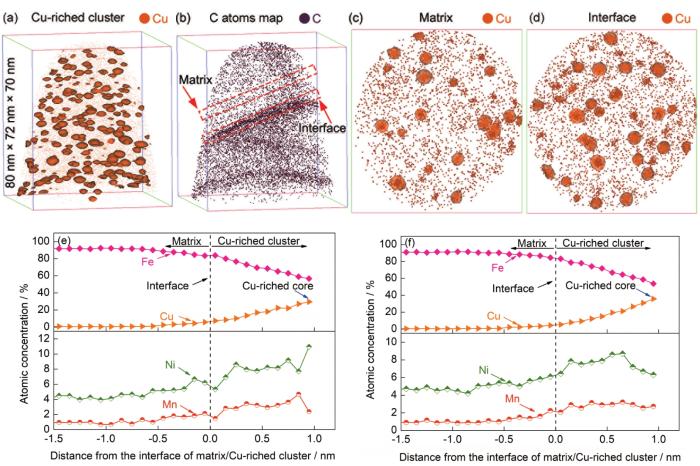

含Cu的HSLA钢在回火过程中将会析出纳米富Cu团簇,为了更好地统计富Cu团簇的尺寸、数量密度以及元素组成,利用APT对1.4Cu钢中富Cu团簇进行了表征,结果如图5所示。可知,经过450 ℃回火处理后,1.4Cu钢中析出了大量的富Cu团簇(5%等浓度面),呈球状分布(图5a)。值得注意的是,C元素的空间分布并不均匀,局部存在明显富集(图5b),通过APT多角度的观察可知此处为界面,在马氏体合金钢中通常会观察到这种C在界面富聚的现象[18]。分别沿基体和界面截取58 nm×57 nm×5 nm的三维空间(图5b红色虚线框),以观察分析富Cu团簇在基体和界面的分布,如图5c和d所示。可知,基体和界面处富Cu团簇的平均等效半径分别为1.56和1.7 nm,即界面处富Cu团簇的尺寸略大,并且界面处的富Cu团簇数量更多。图5e和f分别为基体和界面处富Cu团簇的成分分布,其中横坐标0对应着富Cu团簇与基体的界面,即所选择的等浓度面,负数区域代表基体,正数区域代表富Cu团簇内部[19]。可知,基体和界面处富Cu团簇心部Cu的原子分数分别为30%和36% (图5e和f中蓝色箭头所示),这表明界面处富Cu团簇心部的Cu含量略高于基体,这和界面处富Cu团簇的尺寸略大相一致。此外,基体和界面处的富Cu团簇中均含有一定的Fe和少量的Ni、Mn元素。与基体相比,界面的能量较高,Cu元素在界面处的扩散速率更快,使得富Cu团簇在界面上的析出数量更多、尺寸略大。

图5

图5

1.4Cu钢450 ℃回火处理后富Cu团簇与C元素的空间分布、基体和界面处Cu的分布及富Cu团簇的成分分析

Fig.5

The Cu-riched clusters (a), C element distribution (b), Cu element distributions at matrix (c) and interface (d), and the proxigram composition profiles of 5%Cu (atomic fraction) isoconcentration surfaces at matrix (e) and interface (f) in APT 3D reconstruction for 1.4Cu steel tempered at 450 ℃

Color online

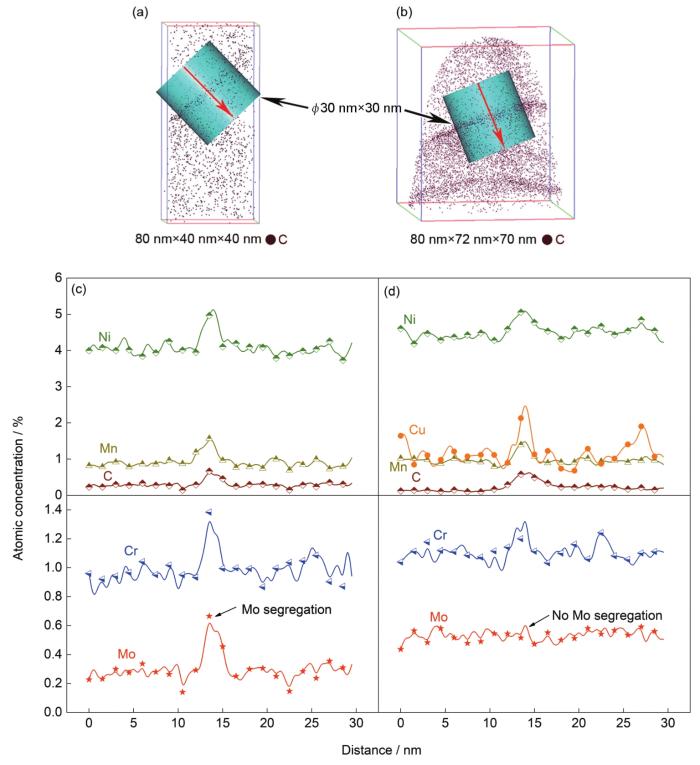

图6

图6

0Cu与1.4Cu钢中C元素的空间分布和界面处合金元素的一维浓度分布

Fig.6

C atoms distribution maps (a, b) and one-dimensional (1-D) composition profiles, obtained with a diameter of 30 nm cylindrical area, across the interfaces delineated with C atoms in an APT 3D reconstruction (c, d) of 0Cu (a, c) and 1.4Cu (b, d) steels tempered at 450 ℃

Color online

3 分析与讨论

3.1 Cu的析出行为及其对Mo界面偏聚的影响

根据文献[25]可知,合金钢中的合金元素易扩散到界面(晶界及亚结构界面)处偏聚,以降低体系的自由能。HSLA钢经过淬火和回火处理后,获得回火马氏体组织,具有丰富的亚结构,一般认为晶界处的能量较高,因而合金元素在晶界处的偏聚程度较高。如Yu等[21]研究发现,在400 ℃回火1 h的HSLA钢(0.04%C和1.15%Cu)中,C、Mo、Cu在晶界处富集,其中晶界处C偏聚的浓度峰值高达1.6% (原子分数),是基体C含量的十几倍之多。在本工作中,经过450 ℃回火处理后的0Cu和1.4Cu钢均观察到C、Cr、Ni、Mn等合金元素在界面处的富集,其中C偏聚的浓度峰值均约为0.6% (原子分数),而基体C含量为0.17% (原子分数),因此界面处C偏聚的浓度峰值约为基体的3倍,远低于上述文献报道的晶界C的偏聚程度。Lim等[26]在400 ℃回火的4340钢中,也观察到了C在晶界和板条界偏聚现象,其中晶界处C偏聚的浓度峰值约为基体的9倍,而板条界面处C偏聚的浓度峰值约为基体的3倍,因此可以推断本工作所观察到的界面为板条界。与文献[18]类似,本工作中0Cu钢450 ℃回火态的板条界面存在C、Ni、Mn、Mo等元素的偏聚。与0Cu钢相比,1.4Cu钢在板条界面上观察到了Cu的偏聚,但未有Mo的偏聚。由此可见,Cu元素的加入对板条界元素的偏聚行为产生了影响,即Cu在界面析出的同时,抑制了Mo在板条界面的偏聚。图7为450 ℃回火态1.4Cu钢界面处Mo和Cu元素的空间分布及界面处富Cu团簇的一维浓度分布图。可知,Mo元素在界面处的浓度分布并不均匀(图7a),Cu原子偏聚的位置,Mo含量较低(图中黑色点线所示),这说明Cu与Mo之间存在相互排斥。图7c为横穿富Cu团簇的一维浓度分布图(图7b中圆柱所穿过区域),可知在富Cu团簇中Mo的含量较低,而在富Cu团簇与基体界面处,Mo元素含量较高,进一步证实了上述结果。

图7

图7

1.4Cu钢450 ℃回火后界面处Mo、Cu元素的空间分布图及界面处富Cu团簇的一维浓度图

Fig.7

The distributions of Mo (a), Cu (b) elements at the interface and the 1-D composition profiles of Cu-riched cluster at the interface (c) for 1.4Cu steel tempered at 450 ℃

Color online

为了研究界面处Cu对Mo元素界面偏聚行为的影响,采用Thermo-Calc软件计算了450 ℃时Cu、Mo元素在1.4Cu钢中的迁移率,即在给定的时间和能量条件下,Cu、Mo的扩散距离,其中Cu为3.52×10-32 m/(J·s),而Mo为1.29×10-41 m/(J·s)。可见,Cu的迁移率显著大于Mo,说明Cu的扩散能力更强。此外,Mo在α-Fe中的固溶度([Mo]α-Fe)较大,其与温度的关系为[27]:

式中,T为587~1174 K。可知,在450 ℃ (723 K)时[Mo]α-Fe=2.3% (原子分数),而合金钢中的Mo含量为0.32% (原子分数),显然Mo可以完全固溶在基体。由此可见,一方面Mo可以完全固溶在基体,而Cu因固溶度低而具有强烈的析出倾向;另一方面,Cu的迁移扩散能力显著大于Mo。所以,Cu率先扩散至界面处,并形成富Cu团簇。而Cu-Mo的混合热为+19 kJ/mol,即Cu、Mo合金元素相互排斥[28]。因而,富Cu团簇在界面析出后,将抑制Mo向界面发生富集,与此同时,随着Cu团簇的长大,团簇中早期含有的一定量的Mo将同Ni、Mn一样被排出,从而造成在富Cu团簇周围观察到Mo偏聚的现象。

3.2 Cu对HSLA钢力学性能的影响

合金钢的力学性能与其成分、组织、析出相和亚结构等密切相关。根据实验结果可知,0Cu和1.4Cu钢经过回火处理后,均为回火马氏体组织,并且2种合金钢的原始奥氏体晶粒尺寸相同。本工作中,2种合金钢具有相同的化学组成(除Cu外),因此具有相同的碳化物析出行为。然而,1.4Cu钢经过回火处理后,析出了大量尺寸细小的富Cu团簇。由此可见,富Cu团簇的析出是导致2种合金钢力学性能差异的主要原因。与0Cu钢相比,含Cu的HSLA钢在450 ℃回火时获得了最佳强化效果,屈服强度由0Cu钢的910 MPa提升到1053 MPa,增加了143 MPa (图1a)。当回火温度为550 ℃时,1.4Cu钢的屈服强度仅比0Cu钢高54 MPa,富Cu团簇的强化效果显著下降。富Cu团簇对HSLA钢强度的影响与其尺寸和数量密度的变化有关[23],测定1.4Cu钢450和550 ℃回火后富Cu团簇的R与NV,可知,450 ℃回火处理后,富Cu团簇的尺寸小(R=1.56 nm)、数量密度大(NV=1.25×1024 m-3),在所研究的温度范围内获得了最佳的强化效果,使得屈服强度增加了143 MPa,这主要源于富Cu团簇引起的化学强化(chemical strengthening)、共格强化(coherency strengthening)以及模量强化(modulus strengthening)[24,29,30],提高的强度幅度与文献[24,29]报道相一致。当回火温度增加到550 ℃时,富Cu团簇的尺寸显著增加(R=4.05 nm),而数量密度则急剧下降,由450 ℃的1.25×1024 m-3下降到550 ℃的1.23×1023 m-3。显然,随着富Cu团簇粗化和数量减少,其强化效果减弱(强度仅增加54 MPa)。与强度相反,2种合金钢的延伸率均随着回火温度的增加而增加。这是由于随着回火温度的增加,2种合金钢的基体逐渐回复,位错密度下降,并且1.4Cu钢中富Cu团簇粗化,强化效果减弱,强度下降的同时会提高延伸率。此外,1.4Cu钢经过450 ℃回火获得最佳强化效果时,其延伸率与0Cu钢相近,2种合金钢的拉伸断裂方式均为韧窝的韧性断裂(图8)。这是由于此时富Cu团簇的尺寸较小,与基体保持共格关系,错配度较小,位错切过时不易产生应力集中[31],因而延伸率与0Cu钢相近。

图8

图8

0Cu和1.4Cu钢450 ℃回火处理后的室温拉伸断口形貌

Fig.8

Fractographs of 0Cu (a) and 1.4Cu (b) steels tempered at 450 ℃ for 120 min after tensile test at room temperature

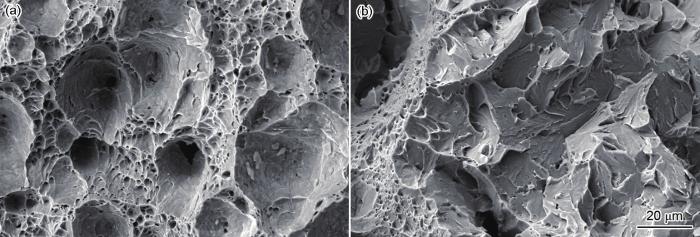

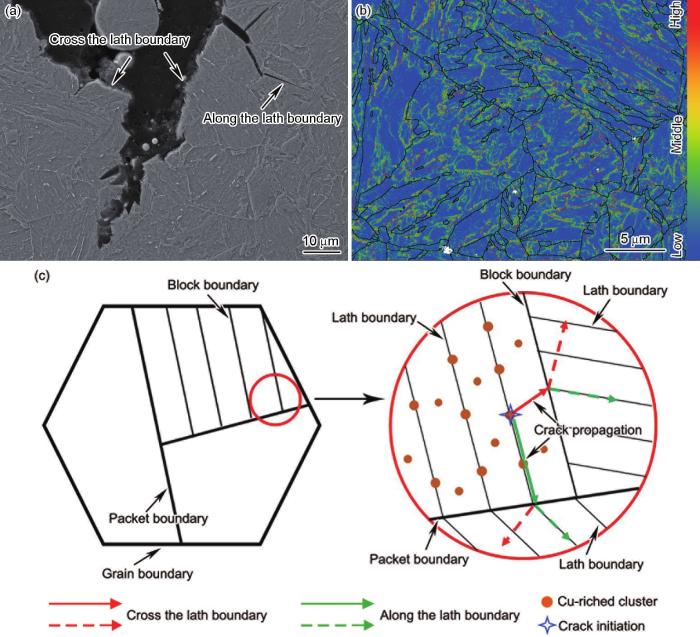

根据文献[16]可知,马氏体合金钢亚结构中的板条块(block)一般认为是控制其冲击韧性的最小结构单元,因为block的界面通常为大角度晶界,而板条界(lath)一般为小角度晶界,因此普遍采用大角度晶界分割区域的等效直径作为马氏体合金钢的有效晶粒尺寸。利用截线法从EBSD结果(图4)获得2种合金钢的有效晶粒尺寸,均为1.9 μm,表明Cu对HSLA合金钢的有效晶粒尺寸没有影响。然而,与0Cu钢室温冲击功(127 J)相比,1.4Cu钢的冲击功仅为24 J,下降明显。文献[32,33]认为富Cu团簇在晶界处的析出是含Cu的HSLA钢冲击功下降的主要原因,然而本工作中观察到HSLA钢的断裂行为为穿晶准解理断裂,这与文献[16,34]报道相一致。图9为0Cu和1.4Cu钢室温冲击断口形貌。可知,0Cu和1.4Cu钢冲击断口形貌差异明显:0Cu钢的冲击断裂方式为韧窝的韧性断裂(图9a);而1.4Cu钢的冲击断口形貌则以河流花样为主,同时存在少量浅小韧窝,其断裂方式为穿晶准解理断裂(图9b)。冲击断口附近纵截面观察结果表明,1.4Cu钢在冲击断裂过程中裂纹扩展的路径有2种:穿过板条扩展和沿板条界扩展,未观察到沿晶界扩展现象,如图10a所示。图10b为1.4Cu钢450 ℃回火处理后应变分布图。可知,在小角晶界处(红色细线,取向差为2°~15°)存在明显的应力集中。与1.4Cu钢类似,0Cu钢的小角度晶界处也存在较明显的应力集中。在马氏体合金钢中,小角度晶界往往为马氏体板条界。APT实验结果表明,2种合金钢板条界处均存在C、Cr、Ni、Mn等合金元素的富集,将会导致应力集中。但与0Cu钢相比,1.4Cu钢板条界处还存在大量的富Cu团簇,因此1.4Cu钢板条界面的应力集中程度更高,这将有利于裂纹在板条界面上富Cu团簇处萌生起裂。图10c为1.4Cu钢在冲击断裂过程中裂纹的扩展示意图。可知,裂纹在1.4Cu钢板条界处萌生(图10c中蓝色星形所示)后,将沿着板条或横穿板条扩展。Mo元素在板条界面处未偏聚,则相对降低了界面处的结合强度[35],有利于裂纹沿着板条界扩展(图10c中绿色箭头所示)。此外,在板条内析出了富Cu团簇,对基体起到显著的沉淀强化作用,但不利于基体的冲击韧性[7],在驱动力较大时,板条界处萌生的裂纹将能够横穿板条扩展[16] (图10c中红色箭头所示)。冲击断裂过程中,不仅变形速率快,而且变形驱动力大,因而裂纹的2种扩展形式能够同时存在。由于马氏体板条块是控制冲击韧性的结构单元,所以,当裂纹沿着或横穿板条扩展到马氏体板条块界时,将会发生偏转。而后,裂纹的扩展路径同样存在着上述2种可能:沿板条或穿过板条扩展(图10c中绿色和红色虚线箭头所示)。

图9

图9

0Cu与1.4Cu钢450 ℃回火处理后的室温冲击断口形貌

Fig.9

Fractographs of 0Cu (a) and 1.4Cu (b) steels tempered at 450 ℃ for 120 min after impact test at room temperature

图10

图10

1.4Cu钢室温冲击断口横截面的SEM像、应变分布图和裂纹在板条界面处萌生扩展示意图

Fig.10

SEM image of the area adjacent to the fracture (a), the strain distribution map (b) and the schematics illustrating the crack propagation initiated at lath boundary (c) of 1.4Cu steel tempered at 450 ℃ for 120 min after Charpy impact test

Color online

式中,E为弹性模量,

4 结论

(1) Cu在淬火态HSLA钢中以固溶态形式存在,而回火处理后,则以富Cu团簇的形式在基体和界面处析出。Cu对回火态HSLA钢的原始奥氏体晶粒、显微组织和有效晶粒尺寸均无明显影响,但对其强度和冲击韧性影响较大,这和富Cu团簇在基体和界面处的析出有关。

(2) 1.4Cu钢经450 ℃回火处理后,析出的富Cu团簇尺寸较小(R=1.56 nm)、数量密度较大(NV=1.25×1024 m-3),获得了最佳强化效果,其屈服强度比0Cu钢提高了143 MPa。此时1.4Cu钢的室温冲击功仅为24 J,其冲击功显著低于0Cu钢(127 J),前者的断口是以河流花样为主的准解理脆性断裂,而后者为韧窝的韧性断裂。

(3) 板条界处析出的富Cu团簇,一方面会增加应力集中,促进裂纹的萌生;另一方面会抑制Mo元素在板条界上偏聚,降低界面的结合强度,促进了裂纹的扩展。而基体中析出的富Cu团簇,因提升了基体的强度,导致韧性降低,促进了裂纹的扩展。因而,富Cu团簇在板条界面和基体的析出是导致含Cu的HSLA钢冲击性能下降的主要原因。

参考文献

Multicomponent high-strength low-alloy steel precipitation-strengthened by sub-nanometric Cu precipitates and M2C carbides

[J].

Structure and properties of a low carbon Cu bearing high strength steel

[J].

Influence of aging and thermomechanical treatments on the mechanical properties of a nanocluster-strengthened ferritic steel

[J].

Influence of thermomechanical treatments on the microstructure and mechanical properties of HSLA-100 steel plates

[J].

Aging characteristics and strengthening behavior of a low-carbon medium-Mn Cu-bearing steel

[J].

Aging behaviour in copper bearing high strength low alloy steels

[J].

Influence of tempering on the microstructure and mechanical properties of HSLA-100 steel plates

[J].

Effect of tempering temperatures on the mechanical properties and microstructures of HSLA-100 type copper-bearing steels

[J].

Ageing behavior of a Cu-bearing ultrahigh strength steel

[J].

Crystallographic model for BCC-to-9R martensitic transformation of Cu precipitates in ferritic steel

[J].

Transmission electron microscope investigations of the structure of copper precipitates in thermally-aged Fe-Cu and Fe-Cu-Ni

[J].

The temporal evolution of the decomposition of a concentrated multicomponent Fe-Cu-based steel

[J].AbstractThe nucleation (to a limited extent), growth and coarsening behavior of Cu-rich precipitates in a concentrated multicomponent Fe–Cu-based steel aged at 500 °C from 0.25 to 1024 h is investigated. The temporal evolution of the precipitates, heterophase interfaces, matrix compositions and precipitate morphologies are presented. With increasing time, Cu partitions to the precipitates, Ni, Al and Mn partition to the interfacial region, whereas Fe and Si partition to the matrix. Coarsening time exponents are determined for the mean radius, 〈R(t)〉, number density, NV(t), and supersaturations, which are compared to the Lifshitz–Slyzov–Wagner (LSW) model for coarsening, modified for concentrated multicomponent alloys by Umantsev and Olson (UO). The experimental results indicate that the alloy does not strictly follow UO model behavior. Additionally, we delineate the formation of a Ni–Al–Mn shell with a stoichiometric ratio of 0.51:0.41:0.08 at 1024 h, which reduces the interfacial free energy between the precipitates and the matrix.]]>

The strengthening mechanism of Cu bearing high strength steel as-quenched and tempered and Cu precipitation behavior in steel

[J].High strength low alloy (HSLA) steels are widely used in the construction of ship structures, oil pipelines, offshore platforms and so on because of their good strength, toughness and weldability. HSLA steel is generally designed with low carbon and Cu alloying. Tempered lath bainite or martensite and nano-precipitate phase of Cu can be obtained by quenching and ageing process after rolling to ensure the excellent matching of strength, low temperature toughness and weldability of HSLA steel. At present, increasing attention has been focused on the precipitation behavior and strengthening mechanism of Cu particles in HSLA steel which was aged at the peak hardness of ageing curve. However, in practical engineering applications, overageing heat treatment is generally used to make HSLA steel achieve a good match of strength and toughness. In this work, the microstructure and nano-sized Cu precipitates of an industrial production HSLA steel plate with thickness of 35 mm were characterized by SEM, EBSD, HRTEM and APT. Meanwhile, the strengthening mechanism of the tested steel was investigated. The results show that Cu precipitates in the tested steel processed by overageing are mainly in the range of 6~50 nm, Cu particles exhibiting short rod or spherical shape within 30 nm are 9R structure, and other particles size larger than 30 nm exhibiting long rod or spherical shape are fcc structure. The segregation of trace Mn and Ni in rod particles on the interface between Cu particles and matrix is more obvious. After ageing at a higher temperature range, the yield strength of the tested steel decreases linearly with the increase of tempering temperature. The main strengthening mechanism of the HSLA steel is fine grain strengthening, followed by dislocation strengthening and precipitation strengthening. The calculated results show that every 1%Cu added in the tested steel can produce about 90 MPa precipitation strengthening increment under the condition of overageing heat treatment. The strength difference between the surface and the center of the tested steel plate is about 40 MPa, which is mainly due to the difference of grain size and dislocation density of steel.

调质态含Cu高强钢的强化机理及钢中Cu的析出行为

[J].对含Cu低合金高强度钢板淬火并经高温时效后,采用SEM、EBSD、HRTEM和APT等手段对其微观组织和纳米尺度Cu的析出相进行了表征,对其厚度截面的室温拉伸性能进行了测定,并对钢板厚度方向近表面和心部的强化机理进行了分析。结果表明,高温时效后钢中Cu的析出相尺寸在6~50 nm范围内,30 nm以内的为9R结构的短棒状或球状粒子,30 nm以上的为fcc结构的长棒状粒子,棒状粒子中微量的Mn、Ni在Cu粒子与基体界面上的偏聚更明显。在较高温度范围内进行时效后,钢的屈服强度随着时效温度的升高而呈大致线性下降趋势,钢的主要强化机制为细晶强化,其次为位错强化和析出强化,经计算,钢中每1% (质量分数)的Cu在过时效状态下能够产生约90 MPa的析出强化增量。钢板厚度截面存在强度差异,表面与心部强度相差约40 MPa,这主要是由于晶粒尺寸及位错密度差异所导致。

Effects of increased alloying element content on NiAl-type precipitate formation, loading rate sensitivity, and ductility of Cu- and NiAl-precipitation-strengthened ferritic steels

[J].

Effects of microstructure on crack resistance and low-temperature toughness of ultra-low carbon high strength steel

[J].

Strategies for strengthening-ductility and hierarchical co-precipitation in multicomponent nano-precipitated steels by Cu partitioning

[J].

Cu precipitation on dislocation and interface in quench-aged steel

[J].The Cu precipitation in a quench-aged high-strength low-alloy steel is studied at the atomic scale by atom probe tomography and high-resolution transmission electron microscopy. The results indicate that the Cu precipitates greatly correlate with carbides in the aspect of distributional character, i.e., the two phases are prone to coprecipitate on the dislocations and/or interfaces (low angle boundaries of the martensite laths). The crystallographic defects have a significant effect on the sizes, morphology and composition of Cu precipitates with Ni and Mn segregation shell.

Study on the precipitation of γ' in a Fe-Ni base alloy during ageing by APT

[J].γ' [Ni3(Al,Ti)], precipitated during ageing, is thought to have the main contribution on the strength. Thus, it is very important to understand the characterization of the precipitation. However, few previous studies are focused on atomic scale evolution of the precipitated phase. Atom probe tomography (APT) is a unique microscopy technique that provides 3D analytical mapping of materials at near atomic resolution and a high detection sensitivity for all elements. The present research is focused on the microstructure evolution at ageing temperature at different time scales using APT. A Fe-Ni base austenite alloy were aged at 620 ℃ for different time after solution treated at 980 ℃ for 2 h. Hardness testing indicates that a sharp increase is observed when the ageing time is less than 6 h. The hardness is up to 205 HV from the initial 145 HV at the ageing time 6 h. After that the hardness increases slowly. The hardness is 251 HV at 120 h. APT results reveal that Ti-rich nanoclusters precipitate obviously at the initial stage of ageing, which contain Fe, Cr, Ni, Mo and Al elements. As the ageing time increases, more Ni and Al atoms are segregated in the Ti-rich nanoclusters while the Fe, Cr and Mo are ejected from the nanoclusters. When the ageing time is up to 120 h, the Ni/(Ti+Al) ration is approximately close to 3. The precipitates can be identified as γ' phase. The results reveal that the formation of γ' involves nucleation and growth. Effect of the number density and the size of the γ' precipitates on the hardening of the alloy has been estimated.]]>

Fe-Ni基合金时效过程中γ'相析出的原子探针层析技术研究

[J].γ'相的析出行为及其对材料硬度的影响。结果表明,当时效时间小于6 h时,合金硬度增加较快,由时效前的145 HV迅速增加至205 HV,随后硬度增加速率缓慢;时效120 h时,硬度为251 HV。APT结果表明,合金经固溶处理后,合金元素均匀分布在基体中。在时效最初阶段,Ti发生了较为明显的偏聚,形成含有Fe、Ni和Al等元素的富Ti纳米团簇。随着时效时间延长,富Ti纳米团簇中的Ni和Al原子的含量逐步增多,而Fe、Cr及Mo等原子的含量不断减少;当时效至120 h时,团簇中Ni与Ti+Al比值近似于3,即已完全形成γ'相,表明γ'相析出是形核-长大过程。合金硬度的变化与时效过程中γ'相的数量密度和体积分数有关。]]>

Invited review article: Atom probe tomography

[J].The technique of atom probe tomography (APT) is reviewed with an emphasis on illustrating what is possible with the technique both now and in the future. APT delivers the highest spatial resolution (sub-0.3-nm) three-dimensional compositional information of any microscopy technique. Recently, APT has changed dramatically with new hardware configurations that greatly simplify the technique and improve the rate of data acquisition. In addition, new methods have been developed to fabricate suitable specimens from new classes of materials. Applications of APT have expanded from structural metals and alloys to thin multilayer films on planar substrates, dielectric films, semiconducting structures and devices, and ceramic materials. This trend toward a broader range of materials and applications is likely to continue.

Study on Cu precipitate of the low C high strength steel containing Cu and Ni during isochronal tempering

[J].followed by water quenching, and tempered isochronally for 60 min at different temperatures. The hardness was conducted, the microstructure and Cu precipitate were analyzed by HRTEM and APT. During tempering, Cu precipitation happened, Cu precipitate Moire fringe formed and the Cu precipitate transformed to fcc structure; the lath boundary gradually bulged out and migrated, a repeat of bulging and migration of local parts of lath boundary resulted in migration of the whole boundary, and lath martensite transformed to equiaxed ferrite finally. At 500℃, the strengthening peaked by Cu precipitates. During 400-500℃, the number of Cu clusters changed greatly when the Cu isoconcentration set at different values, this indicated that the Cu precipitates were on the stage of nucleation; while the number of Cu clusters changed little during 500-650 ℃, this indicated that the Cu precipitates were on the stage of coarsening. The Cu, C, Mo and P segregated at the grain boundary. The boundary could provide Cu solutes and nucleation sites for Cu precipitation, leading to the segregation of Cu clusters at the grain boundary. The Ni, Mn and Al segregated at the heterophase interface between Cu precipitate and ferrite matrix forming a core-shell structure.]]>

含Cu和Ni低碳高强度钢等时间回火析出富Cu相的研究

[J].HRTEM和三维原子探针(3DAP)对含Cu和Ni低碳高强度钢等时回火析出的富Cu相进行了研究.结果表明: 回火过程中,基体发生软化, 富Cu相析出, 板条状马氏体逐渐转变成多边形状铁素体; 在500 ℃时富Cu相强化作用达到最大值; 设置不同的Cu等浓度值时, 在400-500 ℃富Cu相的数量变化幅度大, 在500-650 ℃富Cu相的数量基本不变; 在晶界处发生C, Mo, P和Cu的偏聚; 晶界处Cu浓度高于基体, 为富Cu相的形核和长大提供了有利条件; 在析出的富Cu相与基体的过渡层上发生Ni, Mn和Al的偏聚, 这些偏聚元素与富Cu相核心共同形成核-壳结构.]]>

Microstructure characterization of Cu-rich nanoprecipitates in a Fe-2.5Cu-1.5Mn-4.0Ni-1.0Al multicomponent ferritic alloy

[J].

Research development of high strength low alloy (HSLA) steels

[J].

高强度低合金钢(HSLA)的研究进展

[J].

Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels

[J].

Segregation of boron at prior austenite grain boundaries in a quenched martensitic steel studied by atom probe tomography

[J].

Influence of tempering temperature on both the microstructural evolution and elemental distribution in AISI 4340 steels

[J].

Solubility formulac of molybdenum in iron matrix

[J].

钼在α铁基体中的平衡固溶度公式

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Mechanical properties and nanoparticles precipitation behavior of multi-component ultra high strength steel

[J].

Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions

[J].

Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation

[J].Next-generation high-performance structural materials are required for lightweight design strategies and advanced energy applications. Maraging steels, combining a martensite matrix with nanoprecipitates, are a class of high-strength materials with the potential for matching these demands. Their outstanding strength originates from semi-coherent precipitates, which unavoidably exhibit a heterogeneous distribution that creates large coherency strains, which in turn may promote crack initiation under load. Here we report a counterintuitive strategy for the design of ultrastrong steel alloys by high-density nanoprecipitation with minimal lattice misfit. We found that these highly dispersed, fully coherent precipitates (that is, the crystal lattice of the precipitates is almost the same as that of the surrounding matrix), showing very low lattice misfit with the matrix and high anti-phase boundary energy, strengthen alloys without sacrificing ductility. Such low lattice misfit (0.03 +/- 0.04 per cent) decreases the nucleation barrier for precipitation, thus enabling and stabilizing nanoprecipitates with an extremely high number density (more than 10(24) per cubic metre) and small size (about 2.7 +/- 0.2 nanometres). The minimized elastic misfit strain around the particles does not contribute much to the dislocation interaction, which is typically needed for strength increase. Instead, our strengthening mechanism exploits the chemical ordering effect that creates backstresses (the forces opposing deformation) when precipitates are cut by dislocations. We create a class of steels, strengthened by Ni(Al,Fe) precipitates, with a strength of up to 2.2 gigapascals and good ductility (about 8.2 per cent). The chemical composition of the precipitates enables a substantial reduction in cost compared to conventional maraging steels owing to the replacement of the essential but high-cost alloying elements cobalt and titanium with inexpensive and lightweight aluminium. Strengthening of this class of steel alloy is based on minimal lattice misfit to achieve maximal precipitate dispersion and high cutting stress (the stress required for dislocations to cut through coherent precipitates and thus produce plastic deformation), and we envisage that this lattice misfit design concept may be applied to many other metallic alloys.

Cu segregation at Σ5 symmetrical grain boundary in α-Fe: Atomic-level simulations

[J].

Effects of segregated Cu on an Fe grain boundary by first-principles tensile tests

[J].

Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation-strengthened, high-strength low-alloy plate steels

[J].

The respective roles of the packet size and the lath width on toughness

[J].