7xxx系铝合金由于具有轻质、高强度和高硬度等特点,在航空航天等领域获得了广泛的应用[1,2]。随着科学技术的快速发展,对铝合金的综合性能提出了更高的要求。为此,研究人员[3~6]通过合金成分设计、变形加工技术和热处理工艺改进等多种途径提高铝合金的综合性能。改进其生产工艺,特别是相对简便的热处理工艺,成为挖掘铝合金潜力的有效途径[7]。时效处理是决定铝合金组织及性能的关键热处理工序之一,通过调控析出相的析出过程,对铝合金最终组织及性能产生决定性的影响[8,9]。7xxx铝合金是典型的时效强化型铝合金系列,被广泛认可的析出序列为:过饱和固溶体(SSSS)→过饱和溶质原子聚集(GP)区→η'→η[10,11]。

相变动力学曲线是制定铝合金热处理制度和调控显微组织的重要依据[12~14]。铝合金在脱溶转变早期形成的原子团簇和偏析等不易察觉的微观结构变化会导致显著的电阻变化[15]。目前应用电阻法研究铝合金连续相转变的报道很少,一般作为静态研究,难以反映准确的显微组织信息。原位电阻测量可以直接、快速地反映时效行为的波动,是分析铝合金析出动力学的有效方法。Jiang等[16]认为,原位电阻测量结果能够可靠地提供析出相持续预析出和再溶解的整体信息,并将其扩展到固溶处理+完全人工时效(T6)、固溶处理+多级人工时效(T7X)和回归再时效(RRA)条件下7150铝合金在全时效过程中的组织演变。对于AA7010合金厚板,Deschamps和Brechet[17]证明了通过间断淬火和原位电阻测量表征固溶体贫化并获得等温转变(TTT)曲线的可行性,从而揭示了高温相的等温转变动力学。

1 实验方法

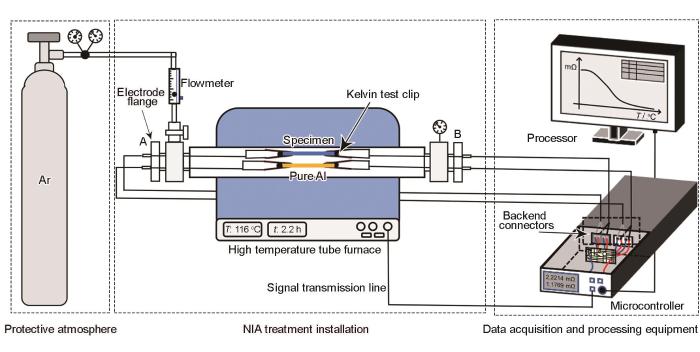

实验采用150 mm厚的7A65铝合金固溶态板材。板材的制备流程以及固溶态组织见前期的研究[20~22]。7A65铝合金厚板的实测化学成分(质量分数,%)为:Zn 7.53,Mg 1.69,Cu 2.07,Zr 0.12,Ti 0.03,Mn < 0.01,Cr < 0.01,Fe 0.04,Si 0.01,Al余量。将轧制方向命名为RD,垂直于轧制方向的横向命名为TD,厚度方向命名为ND。分别从板材表层、H / 4和H / 2 (其中,H为试样厚度)处取样。采用自行搭建的原位电阻测试装置(如图1所示)实时记录7A65铝合金在温度场中电阻的变化。原位电阻测试装置包括加热设备、信号收集与处理设备和气氛保护设备3部分。加热设备内设有可准确控制升降温速率的程序,同时炉体体积小于100 cm2,温度波动± 1 ℃。设备下方通过导管连接Ar气氛保护设备。内部放置不同厚度板材的待测电阻丝和相同尺寸的纯Al电阻丝,电阻丝尺寸为150 mm × 1.5 mm × 1.5 mm。信号收集与处理设备包括信号收集与转换设备和信号处理设备,2者通过串口通信,前者通过后端四线制电路分别连接至待测电阻丝与纯Al电阻丝。待测电阻丝与纯Al电阻丝的电阻差的变化即反映了时效过程中析出相的析出行为。信号收集与转换设备每1 s发射3次激励信号,电阻测量精度可达0.1 μΩ。气氛保护设备内循环气体为Ar气,气体循环速率为500 mL/min。

图1

图1

原位电阻测试装置示意图

Fig.1

Schematic of the in situ resistance test device (NIA—non-isothermal aging, A and B—electrode flanges, T—temperature, t—time)

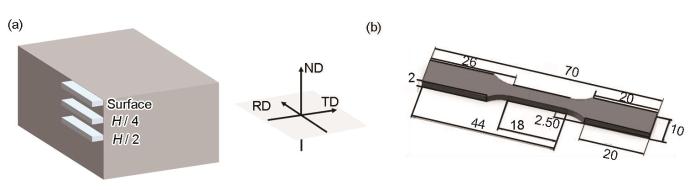

采用JEM-2100F 场发射透射电子显微镜(TEM)观察样品的明场(BF)像、暗场(DF)像、选区电子衍射(SAED)花样和高分辨(HRTEM)像,加速电压为200 kV,点分辨率为0.19 nm。首先将TEM样品机械抛光至70 μm厚,随后采用电解双喷法减薄样品。电解液为25%HNO3 + 75%CH3OH (体积分数),温度控制在-30 ℃以下,电压为20 V。使用Image Pro-Plus软件分析TEM结果,采用面积法估算析出相的体积分数,具体操作步骤为:使用图像处理软件Image Pro-Plus在TEM像上选定一个具有代表性的区域,这个区域包含足够的析出相;使用图像处理软件中的测量工具,分别测量选定区域内基体和析出相的面积;根据二维图像中析出相的面积占总面积的比例,通过将二维面积比例乘以一个合适的因子,估算析出相在三维空间中的体积分数。这个因子取决于析出相在三维空间中的形状和分布,由软件计算得出[23]。使用SMP10电导率计测量同一样品上5个位置的电导率并取平均值。采用FALCON511型Vickers显微硬度计测试试样的显微硬度,载荷为0.98 N、加载时间为15 s,计算其平均值和标准差。通过Instron8801试验机测试板材不同位置和取样方向的拉伸力学性能(如图2所示),拉伸速率为0.5 mm/min,每组分别测试3次取平均值。

图2

图2

拉伸试样的取样位置和试样尺寸示意图

Fig.2

Schematics of sampling location (a) and geometric size (b) for tensile specimen (RD—rolling direction, ND—normal direction, TD—transverse direction, H—specimen thickness. Unit: mm)

使用数字图像相关处理(DIC)技术计算出试样拉伸过程的表面位移场及应变场分布,得到2D全场应变数据分布信息。操作时首先将磨好的拉伸片表面喷上一层白漆,待晾干后在其表面均匀弥散地喷上黑漆,使其呈点状分布。安装上相机和照明灯后进行与拉伸过程同步的DIC拍照测试。

2 实验结果

2.1 7A65铝合金的等温时效析出行为

2.1.1 等温时效析出动力学

通过原位电阻测量装置同步分析合金在等温时效过程中电阻随时间的变化情况。对原位电阻曲线进行非线性拟合,拟合曲线与实测数据的重合率高达99.98%。将固溶态板材的电阻率作为初始电阻率(ρ0),用相对的相转变量(α)评价特定初始微观组织在某一时间节点的时效沉淀行为,其计算公式[24]为:

式中,ρe和ρc分别为该时间节点以及完全时效析出时的电阻率,且ρc可以近似等于0。在时效析出前期,团簇的形成加强了对自由电子的散射,导致电阻率升高,随着析出相的形成,峰值时效时由于消耗溶质原子使得电阻率降低。对于合金来说,时效过程中过饱和溶质原子的析出所转变成的新相的数量、形态及分布均会影响电子的散射概率。通过

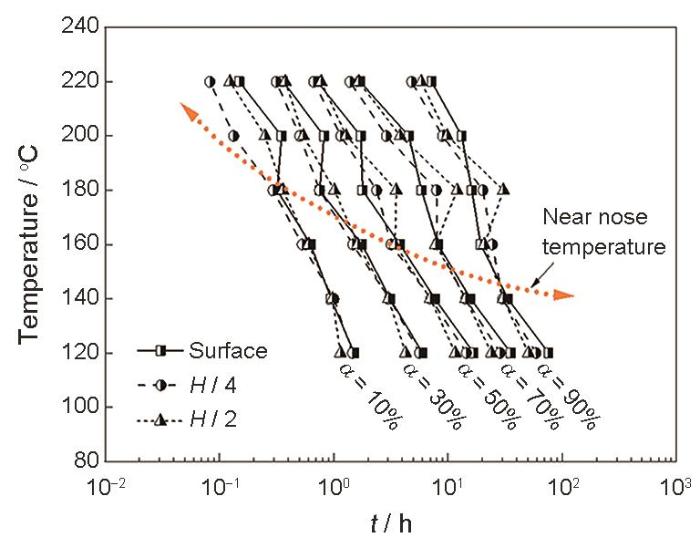

图3

图3

等温时效过程中7A65铝合金板材表面及不同厚度(H)处试样的等温转变(TTT)曲线

Fig.3

Isothermal transition (time-temperature-transformation, TTT) curves at different thicknesses of 7A65 Al alloy plates during isothermal aging process (α—phase transition fraction)

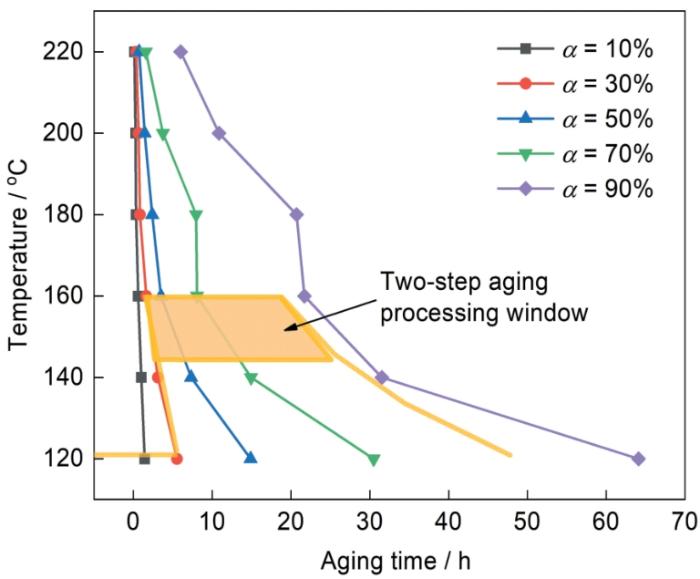

从图3中可以看出,随着时效温度的升高,脱溶相的析出明显提前,且并没有出现“鼻尖”温度,这是因为铝合金时效温度较低,且脱溶驱动力很强,所以温度对形核率和长大速率的影响仍占主导地位。但存在隐藏的近鼻尖温度(near nose temperature),如图3中带双箭头的短点线所示。在这一温度附近的析出相的析出速率明显比两侧更快,证明此位置存在独特的析出脱溶现象。随着析出的持续进行,带双箭头的短点线逐渐往低温方向移动,恰巧构成某一脱溶相x的C曲线的下半部分,即:随着温度的降低,某一析出相x发生大量脱溶现象的时间逐渐后延。由于常规铝合金的时效热处理温度在120~160 ℃之间,而图3表明,在这一温度区间,不同位置的析出相的析出行为差异不大,因此一旦明确析出相x的类型,就可以为后续制定双级时效工艺提供依据。

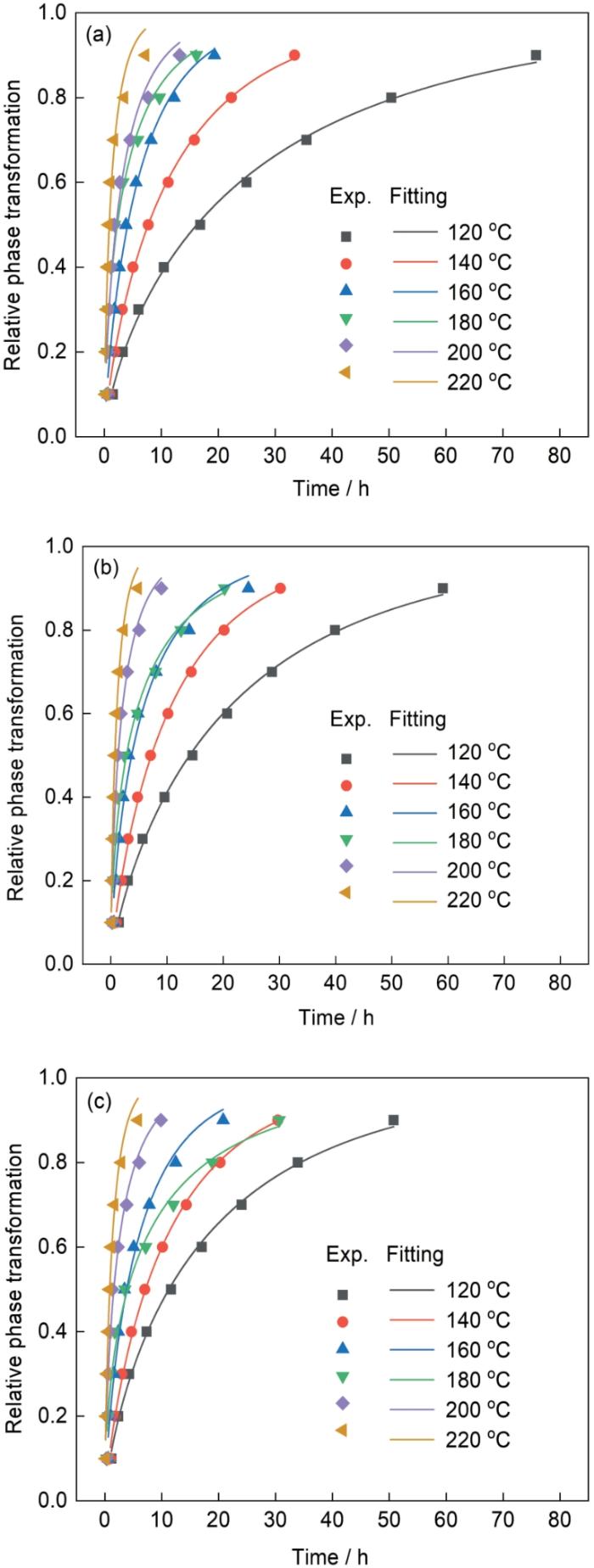

相变动力学研究中主要关注析出相的形核率和长大速率,基于此绘制“S”形相变动力学曲线。考虑到由于固态相变的优先形核机制,“S”形曲线不再遵循Johnson-Mehl方程,而是遵循Avrami经验方程[25],即:

图4

图4

不同温度下7A65铝合金板材表层、H / 4和H / 2处试样的析出动力学曲线

Fig.4

Precipitation kinetics curves of specimens at surface layer (a), H / 4 (b), and H / 2 (c) positions in 7A65 Al alloy plates under different temperatures

表1 不同温度下7A65铝合金板材表层及不同厚度处试样析出动力学曲线的拟合系数(K和n)

Table 1

Temperature oC | Surface | H / 4 | H / 2 | |||

|---|---|---|---|---|---|---|

| K | n | K | n | K | n | |

| 120 | 0.09 | 0.73 | 0.09 | 0.79 | 0.11 | 0.76 |

| 140 | 0.14 | 0.80 | 0.13 | 0.83 | 0.14 | 0.82 |

| 160 | 0.22 | 0.81 | 0.27 | 0.71 | 0.24 | 0.78 |

| 180 | 0.41 | 0.64 | 0.38 | 0.58 | 0.32 | 0.56 |

| 200 | 0.41 | 0.73 | 0.58 | 0.68 | 0.51 | 0.68 |

| 220 | 0.77 | 0.73 | 0.90 | 0.76 | 0.78 | 0.77 |

对比表1的数据可发现,随着温度的升高,K在0.09~0.90的范围内逐渐增大,表明析出相的形核率和长大速率对温度具有较高的敏感性。K越大,脱溶析出的时间越短。板材表层及不同厚度试样的n均先升高后降低再升高,n变化范围为0.56 < n < 0.83。其中,板材180~200 ℃附近的n最小,说明此温度区间附近析出相的形核机制与其他温度不同。因此,随着温度的升高,7A65铝合金时效整体上的形核机制转变过程为:针/棒状相的粗化→位错等缺陷处盘状相的形核→针/棒状相的粗化。由图4可知,形核主导析出占总相变量的比例低于10%,也就说上述形核阶段发生时还处于图3中α = 10%曲线的左侧。而图3表明,180~200 ℃的10%相转变量曲线的确位于未知脱溶相x的C曲线附近。这再次证明了脱溶相x的存在,同时还表明脱溶相x的形核机制为位错等缺陷处盘状相的形核。有研究[13,14]指出,当温度较高时,盘状η'相可以在位错等高畸变能的位置直接非均匀形核,而后迅速长大为η相,因此可以合理地推测脱溶相x为η相。

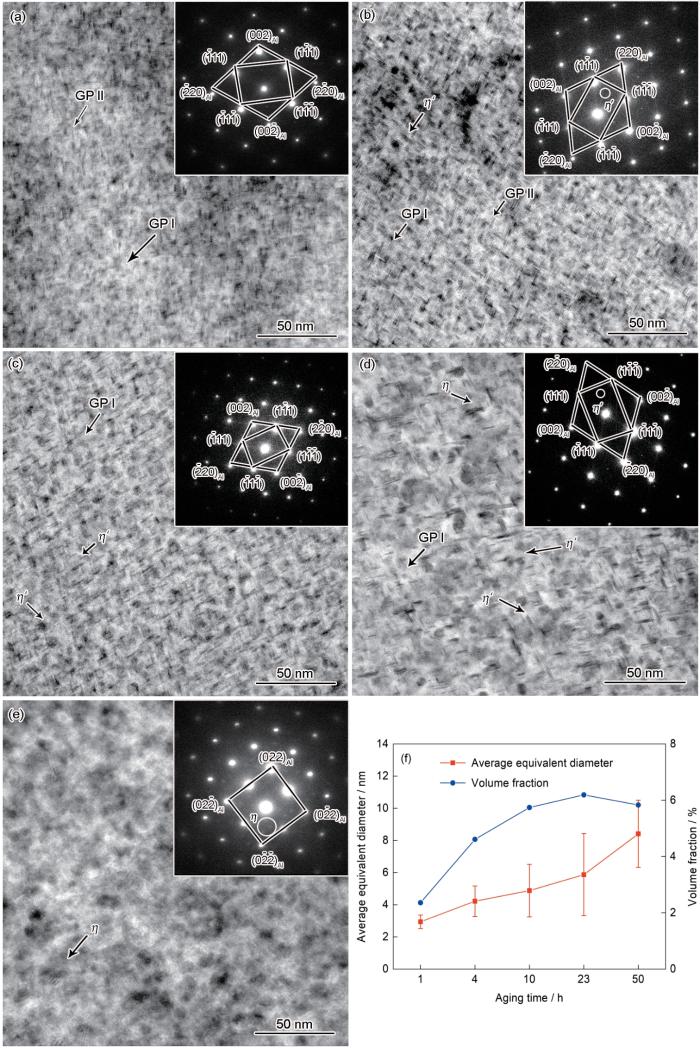

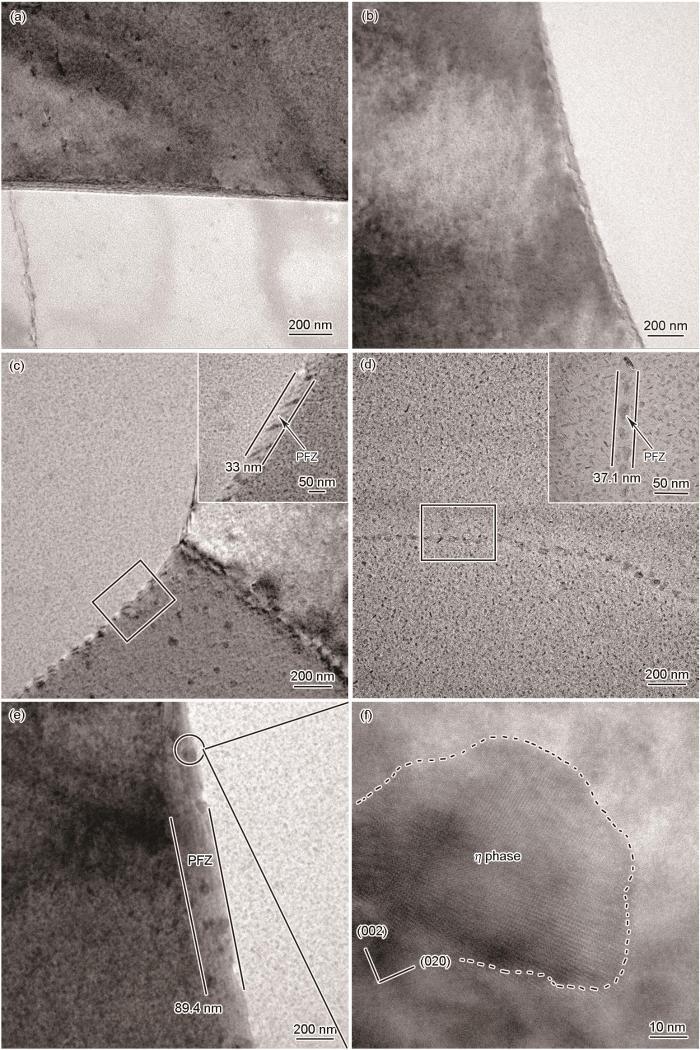

2.1.2 等温时效过程中的微观组织演变

结合7A65铝合金厚板的微观组织演变行为验证了基于原位电阻法解释的时效动力学。以140 ℃为目标温度,图5和6分别给出了板材表层处试样等温时效至α = 10%、30%、50%、70%和90% (对应时间分别为1、4、10、23、50 h)时的晶内和晶界TEM像。从图5可以看出,随着时效的进行,析出相发生“GP Ⅰ区/GP Ⅱ区→η'相→η相”的转变。当α = 10%时(图5a和f),晶粒内部发生溶质原子富集或富空位团簇(VRC)的转变,形成溶质原子团簇,即与基体保持共格关系的GP Ⅰ区和GP Ⅱ区,其等效直径为2.94 nm;此时晶内析出相的密度最低,体积分数只有2.36%,导致SAED花样中只能观察到Al3Zr的衍射斑点。当α = 30%时(图5b和f),晶内析出相的尺寸明显增大且体积分数大幅度提高,分别达到4.22 nm和4.61%。析出相大多呈圆片状或针状。SAED花样显示,此时晶内除了GP区以外还存在η'相,一般认为GP区为η'相的析出前驱体。当α = 50%时(图5c和f),析出相尺寸进一步增大,达到4.88 nm,但体积分数(5.74%)却变化不大。SAED花样显示η'相斑点较为明显,表示其已成为晶内主要析出相,同时GP区的比例有所下降。由于观察角度的原因,此时η'相呈现针状和圆盘状2种形态。当α = 70%时(图5d和f),析出行为接近上述的脱溶相x的C曲线,此时在晶内出现了长达20 nm的盘状η相,这一定程度上证实了脱溶相x为η相的推断。另外,η'相斑点仍然比较明显,表明亚稳η'相是作为η相的前驱体而存在的。此时析出相进一步长大,平均等效尺寸增大至5.87 nm。但由于部分细小的GP区仍然存在,体积分数依旧变化不大。当α = 90%时(图5e和f),长时时效导致盘状平衡相η相的大量出现。此时SAED花样也出现了典型的η相斑点。为了减少总界面能,η相发生小颗粒的溶解和大颗粒的长大,即Ostwald熟化效应,因此析出相平均等效尺寸明显增大而体积分数略微下降,分别为8.41 nm和5.83%。

图5

图5

140 ℃等温时效过程中7A65铝合金板材表层试样晶内析出相的TEM明场像选区电子衍射(SAED)花样及析出相平均等效直径和体积分数

Fig.5

TEM bright field images and selected area electron diffraction (SAED) patterns (insets) (a-e) and average equivalent diameter and volume fraction (f) of the precipitated phase in the surface of the 7A65 Al alloy plate after isothermal aging at 140 oC (GP—Guinier-Preston)

(a) α = 10% (b) α = 30% (c) α = 50% (d) α = 70% (e) α = 90%

图6

图6

140 ℃等温时效过程中7A56铝合金板材表层试样晶界处的TEM像和HRTEM像

Fig.6

TEM (a-e) and HRTEM (f) images of grain boundaries in 7A65 Al alloy plates after isothermal aging at 140 oC (Insets in Figs.6c and d show high magnified views of the grain boundary precipitates. PFZ—precipitate-free zone)

(a) α = 10% (b) α = 30% (c) α = 50% (d) α = 70% (e) α = 90%

2.2 厚板的双级时效工艺

2.2.1 厚板的双级时效工艺的优化

由图3可知,TTT曲线中存在η相的C曲线。而双级时效的最佳组织状态应该是:晶内析出相以η'相为主,η相尽可能少,同时GBP粗大断续分布并伴有较窄的PFZ。因此,制定双级时效的第二级时效工艺时,时效时间应尽量接近但不能超过η相的C曲线。据此,可以利用TTT曲线对7A65铝合金厚板的双级时效工艺进行优化。根据本课题组[21]前期对一级时效工艺的时间和温度的研究,确定最佳的一级时效工艺为121 ℃、6 h。根据TTT曲线的斜率变化以及η相C曲线的位置,确定的板材双级时效工艺的工艺窗口,如图7中梯形区域所示。这里已将图3中不同厚度处的时间数据进行了加权平均。选择的时效温度为145、150、152和160 ℃。根据图5确定板材的双级时效工艺为:121 ℃、6 h + 145 ℃、22 h,121 ℃、6 h + 150 ℃、20 h,121 ℃、6 h + 152 ℃、19 h,及121 ℃、6 h + 160 ℃、16 h。

图7

图7

基于TTT权重曲线确定的7A65铝合金板材的双级时效工艺窗口

Fig.7

Two-stage aging processing windows of 7A65 Al alloy plates determined by TTT weight curves

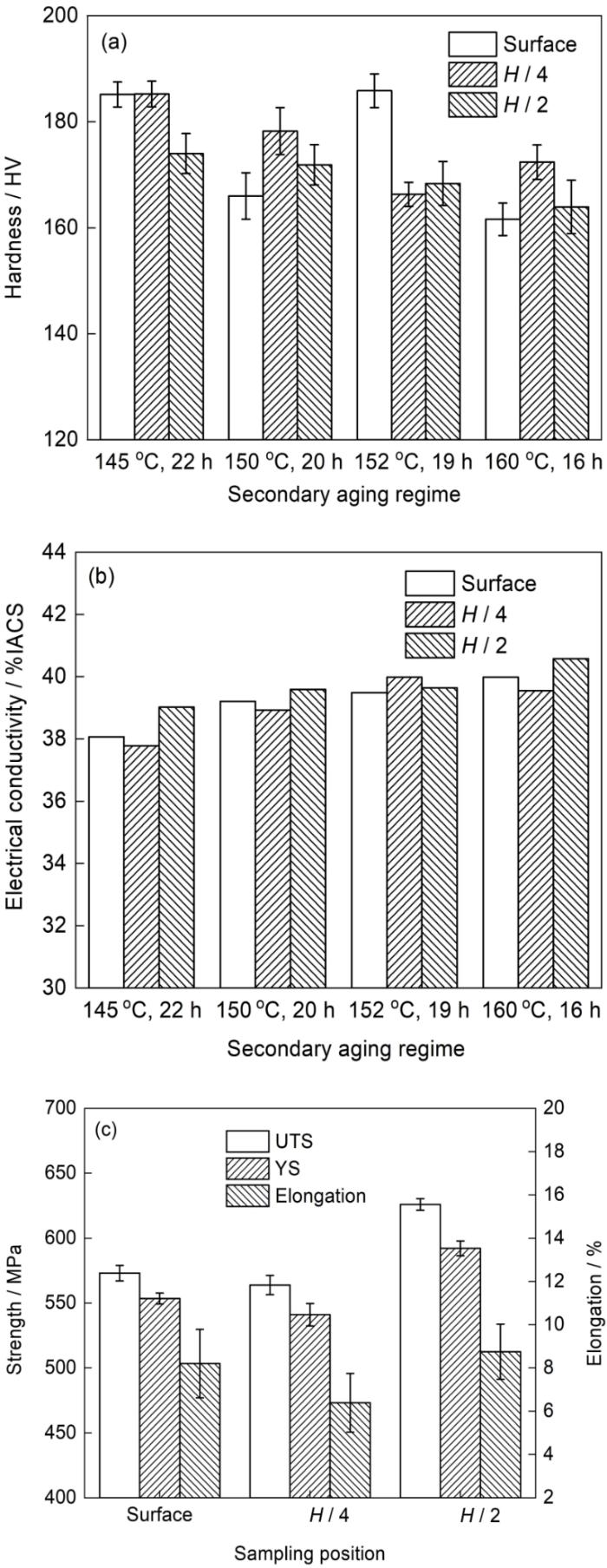

2.2.2 双级时效后板材的性能

对板材分别进行4种双级时效处理后,板材表层及H / 4和H / 2处试样的硬度、电导率和拉伸力学性能如图8所示。从图中可以看出,随着二级时效温度的提高,硬度呈现逐渐降低的趋势,而电导率则恰好相反。这是因为虽然4种工艺的α相同,即相对析出量相等,但在较高的时效温度下析出相主要倾向于发生粗化,而在较低的时效温度下析出相主要倾向于发生形核和长大,所以前者的电导率较高而后者的显微硬度较高。在所有工艺中,同时满足硬度和电导率良好匹配的只有121 ℃、6 h + 152 ℃、19 h。此时板材硬度达到170~180 HV,电导率超过39%IACS。图8c给出了最佳时效工艺下不同位置处板材沿RD的拉伸性能。经过双级时效热处理后,7A65铝合金具有较高的强度,其中H / 2处的强度最高,表层处的强度次之,H / 4处的强度最低;板材 H / 2处的延伸率略高于表层处,H / 4处的塑性最低。

图8

图8

7A65铝合金板材不同厚度处不同双级时效工艺的硬度和电导率对比及最佳双级时效工艺下的拉伸性能

Fig.8

Comparison of hardness (a) and conductivity (b), and tensile properties (c) of 7A65 Al alloy plates at different thicknesses under the optimal two-stage aging process (UTS—ultimate tensile strength, YS—yield strength, IACS—internatonal annealed copper standard)

3 分析与讨论

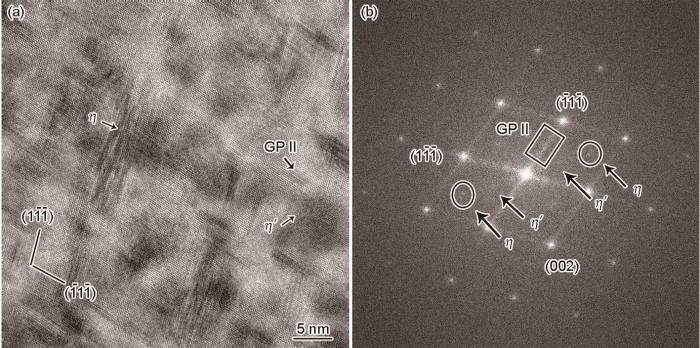

根据图3得知,7A65合金在140 ℃下时效约23 h后7A65合金的TTT曲线会接近η相的C曲线,此时α = 70%。进一步地,图5d中的晶内析出相的HRTEM像和快速Fourier变换(FFT)花样如图9所示。由图9a可见,晶内存在明显的GP Ⅱ区、η'相和η相的晶格条纹像,其中η相与基体(111)面保持完全非共格关系。从图9b中还可看出,对应区域的FFT图内同时出现明显的连续条纹(方框区域)、1/3 (220)和2/3 (220)处的衍射斑点(箭头所指)以及双衍射斑点(圆圈内),这分别对应了图9a中的GP Ⅱ区、η'相和η相,证明了“GP区→η'相→η相”的脱溶序列,同时也提供了η相开始转变的直接证据。

图9

图9

140 ℃时效23 h后7A65铝合金板材表层处试样晶内析出相的HRTEM像和快速Fourier变换

Fig.9

HRTEM image (a) and fast Fourier transform (b) of the precipitated phase in the surface of the 7A65 Al alloy plate after isothermal aging at 140 oC for 23 h

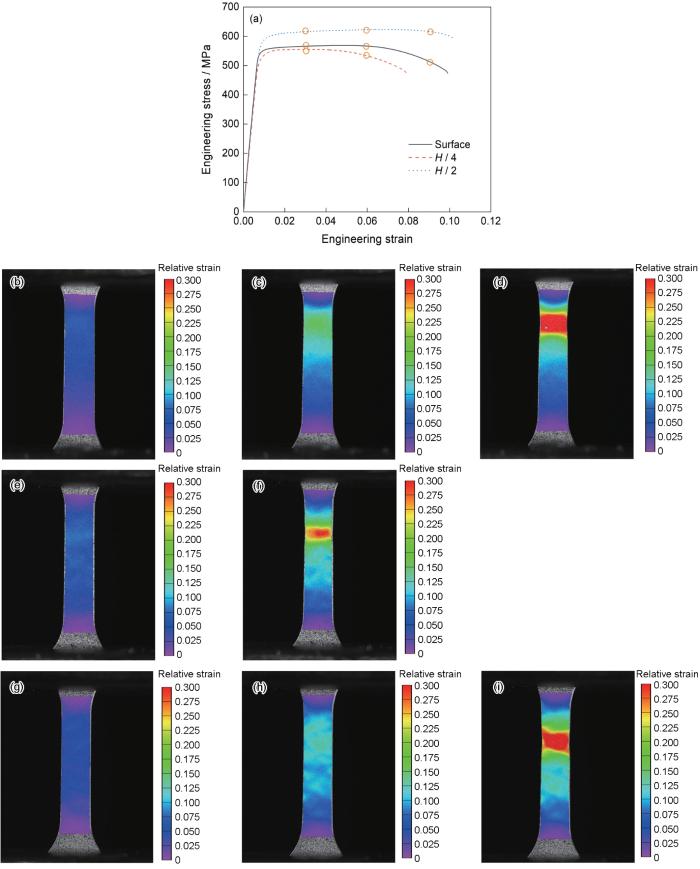

图10给出了最佳双级时效工艺下板材不同厚度的RD工程应力-应变曲线及对应的DIC分析。DIC用以综合评价拉伸过程中试样抵抗应力集中、裂纹扩展和颈缩的能力。分别选取了工程应变为3%、6%和9%的测量点。从图10中可看出,随着拉伸的进行,试样应力集中的部位主要靠近中心,且当局部应变超过0.275时,试样很快发生断裂。对比不同厚度处可以发现,板材表层和H / 2处的试样在延伸率达到6%时依然没有发生明显的应变局域化,且试样在H / 2处具有更佳的均匀塑性变形能力,而在H / 4处却已发生严重的颈缩,因此H / 4处的延伸率最低。同时表层处发生颈缩之后较长时间才出现断裂,而板材H / 2处的试样却很快断裂,因此后者抵抗局部裂纹扩展的能力较差。

图10

图10

最佳双级时效工艺下7A65铝合金板材不同厚度的轧向(RD)工程应力-应变曲线及对应的数字图像相关处理技术(DIC)分析

Fig.10

Typical engineering stress-strain curves along RD (a) and digital image correlation (DIC) analyses of speciments of surface (b-d), H / 4 (e, f), and H / 2 (g-i) positions in 7A65 Al alloy plates at strains of 0.03 (b, e, g), 0.06 (c, f, h), and 0.09 (d, i) under optimal two-stage aging process

式中,Δσs为析出相的强化贡献,f和r分别为析出相体积分数和等效半径,c2为常数。当位错绕过析出相后,留下的位错环相当于增大了r,降低了后续位错的绕过阻力,这造成某一局部区域应变的快速积累,进而引起应力集中。虽然表层也会出现这一情况,但由于发生了不完全再结晶[22],快速积累的局部位错湮灭在亚晶界,因此板材表层抵抗应力集中的能力比H / 4处强。由于局部区域的应变积累导致微裂纹萌生点少,进而裂纹扩展需要更多的时间才能引起断裂,因此板材表层和H / 4处的颈缩现象都比H / 2处明显。板材H / 4处的晶界位置存在大量小角度晶界和高的局部取向差[22],表明变形主要集中在晶界[26],同时双级时效态晶界处存在粗大的GBP和较宽的PFZ,这是引起该位置塑性差的原因。

对于双级时效态的合金,其时效强化首先考虑Orowan机制,将

式中,M为Taylor因子,取值3.06;G为剪切模量,取值为26.9 GPa;b为Burgers矢量模,取值为0.286 nm;μ为Poisson比,取值为0.33[27]。根据图5f的统计数据,计算得出η′相的理论Orowan机制强化增量为184 MPa。通过拉伸测试获得的固溶态屈服强度为302 MPa,而根据图8c计算的平均屈服强度为553 MPa,因此实际屈服强度增量为251 MPa。换言之,理论上的Orowan机制强化增量略小于实际屈服强度增量,这是由于仅统计了η′析出相对强度的贡献,组织中同时存在GP区、η析出相以及其他析出相(如Al3Zr相),且尺寸细小。另外,除了析出相的强化作用,合金的固溶强化、位错强化也不容忽略。除了Orowan绕过机制外,位错剪切机制也起到重要的作用,即双级时效态析出相的主要强化机制包含了位错剪切机制和Orowan绕过机制。值得注意的是,此时板材保持了39%IACS以上的电导率,且具有550 MPa以上的平均屈服强度,同时平均延伸率能达到9%。因此经121 ℃、6 h + 152 ℃、19 h双级时效后,150 mm厚7A65铝合金板材具备了较好的综合性能。

4 结论

(1) 基于原位电阻分析法绘制了TTT曲线,发现合金中存在η相的脱溶C曲线,在140 ℃时效23 h左右会接近η相的C曲线。根据Avrami经验方程,绘制了7A65铝合金厚板的析出动力学曲线。由于由形核主导的相变时间较短,曲线不存在严格的“S”形。随着温度的升高,K在0.09~0.90的范围内逐渐增大,n则先降低后升高,推测形核机制为:针/棒状相的粗化→位错等缺陷处盘状相的形核→针/棒状相的粗化。

(2) 当α位于30%~70%之间时,析出相的体积分数变化不大。但当α超过70%时,Ostwald熟化使得析出相尺寸明显增大且体积分数略微下降。

(3) 根据TTT曲线制定的最佳双级时效工艺为:121 ℃、6 h + 152 ℃、19 h。经时效后,150 mm规格的7A56铝合金板材具备39%IACS以上的电导率和550 MPa以上的平均屈服强度,同时平均延伸率达到9%。此时,合金在变形过程中同时存在位错剪切机制和Orowan绕过机制。

参考文献

Development and applications of aluminum alloys for aerospace industry

[J].

Recent development in aluminium alloys for aerospace applications

[J].

Heat treatment of 7xxx series aluminium alloys—Some recent developments

[J].

Investigation on microstructure and mechanical properties of Al-Zn-Mg-Cu alloys with various Zn/Mg ratios

[J].The effects of Zn/Mg ratios on microstructure and mechanical properties of Al-Zn-Mg-Cu alloys aged at 150 °C have been investigated by using tensile tests, optical metallography, scanning electron microscopy, transmission electron microscopy and atom probe tomography analyses. With increasing Zn/Mg ratios, the ageing process is significantly accelerated and the time to peak ageing is reduced. T′ phase predominates in alloys of lower Zn/Mg ratios while η′ phase predominates in alloys with a Zn/Mg ratio over 2.86. Co-existence of T′ phase and η′ phase with a large number density is beneficial to the high strength of alloys. Such precipitates together with narrow precipitate free zones cause a brittle intergranular fracture. A strength model has been established to predict the co-strengthening effect of T′ phase and η′ phase in Al-Zn-Mg-Cu alloys, including the factors of the grain boundary, solid solution and precipitation.

Effect of pre-deformation on microstructure and mechanical properties of ultra-high strength Al-Zn-Mg-Cu alloy after ageing treatment

[J].Ultra-high strength Al-Zn-Mg-Cu alloy is a promising lightweight structural material, and there is still room to improve its mechanical property. As a typical precipitation strengthening material, controlling the size and distribution of precipitate is an effective way to enhance the mechanical properties of the ultra-high strength Al-Zn-Mg-Cu alloy. The influence of pre-deformation on the microstructures and properties of the ultra-high strength Al-Zn-Mg-Cu alloy after ageing treatment was studied by TEM, XRD, SEM, DSC and tensile tests. The microstructures and the tensile mechanical properties of Al-Zn-Mg-Cu alloy without pre-deformation and with 3% and 4% pre-deformation were compared. It is found that the pre-deformation can promote the ageing precipitation rate and enhance the precipitate density in the Al-Zn-Mg-Cu alloy, and the pre-deformation ratio of 3% can promote the dispersion of the precipitate phase in the grain interiors, but the pre-deformation ratio of 4% may result in coarsening of precipitate. The size of precipitate along the grain boundaries and the width of precipitation free zones decreased in the pre-deformation treated ultra-high strength Al-Zn-Mg-Cu alloys. The tensile strength and yield strength of the pre-deformation treated ultra-high strength Al-Zn-Mg-Cu alloys increased, and the elongation also increased slightly, in which the tensile strength and elongation of 3% pre-deformation alloy combined with 80 ℃ for 12 h and 120 ℃ for 8 h ageing were (813±4) MPa and 10.10%±0.77%, respectively. The results show that the dislocations produced by pre-deformation may provide more heterogeneous nucleation sites for the precipitate formation, and improve the precipitate's distribution.

预变形对超高强Al-Zn-Mg-Cu合金时效组织与力学性能的影响

[J].利用TEM、XRD、SEM、DSC以及室温拉伸等方法,研究了预变形对超高强Al-Zn-Mg-Cu合金组织与性能的影响。通过对比未经预变形和预变形量为3%及4%的Al-Zn-Mg-Cu合金时效态微观组织与拉伸力学性能,发现:预变形可以提高铝合金时效析出速率和密度,变形量为3%时可促进析出相在晶内弥散分布,但增加到4%会导致析出相粗化;经预变形处理后晶间析出相尺寸减小,晶界无析出带宽度降低;抗拉强度和屈服强度提高,伸长率略微提高,经3%预变形以及80 ℃、12 h和120 ℃、8 h时效后的抗拉强度可达到(813±4) MPa,伸长率为10.10%±0.77%。分析认为,预变形产生的位错为析出相形核提供了异质形核的质点,改善了其在晶内与晶间的分布状态。

Enhanced plasticity and corrosion resistance of high strength Al-Zn-Mg-Cu alloy processed by an improved thermomechanical processing

[J].

Influence of heat treatment on corrosion behaviour of Al-Zn-Mg-Cu-Zr-Sc alloy

[J].

Secondary ageing in an aluminium alloy 7050

[J].

Unraveling precipitation evolution and strengthening function of the Al-Zn-Mg-Cu alloys with various Zn contents: Multiple experiments and integrated internal-state-variable modeling

[J].Zn content is one of the most concerned factors in the development of next generation ultra-strength Al-Zn-Mg-Cu alloys owing to its essential role in precipitation strengthening. In the present work, the underlying functions of Zn content in precipitation evolution and strengthening function of Al-Zn-Mg-Cu alloys were systematically investigated by combining multiple experiments and an integrated internal-state-variable model. The experimental results indicated that the increased Zn content in Al-Zn-Mg-Cu alloys would promote the development of precipitates and enhance aging hardening. The diffusion flux of soluble Zn and the coordination of Mg atom controlled the crystallographic microstructures evolution during precipitates nucleation, growth and transition processes. By integrating precipitation development with electrical resistivity and hardness evolutions, an improved internal-state-variable physical model was then developed for the aging responses of Al-Zn-Mg-Cu alloys. The unified model considered the intrinsic characteristics of precipitates such as crystallographic orientation, morphology, component, and distribution. The specific improvements were to balance the combined functions of Zn element and Mg element and consider the plate-like morphology and directed growth as indicated by experiments. This model was also adaptive to heat-treatment variables and chemical compositions, and owned the notable advantages to simultaneously rationalize the observed microstructural characteristics, mechanical and electrical properties following artificial aging of Al-Zn-Mg-Cu alloys. In addition, a preliminary model framework between electrical resistivity and hardness for Al-Zn-Mg-Cu alloys was established.

Effect of multi-stage aging treatments on the precipitation and mechanical properties of Al-Zn-Mg alloys

[J].

Precipitation sequence of η phase along low-angle grain boundaries in Al-Zn-Mg-Cu alloy during artificial aging

[J].

Precipitation kinetics of second-phase particles in supersaturated solid solution of 7050 aluminum alloy

[J].

过饱和7050铝合金固溶体中第二相粒子的析出动力学

[J].

Research on quench sensitivity and microstructure analysis of 7050 aluminum alloy

[J].

7050铝合金淬火敏感性研究和微观组织分析

[J].通过分级淬火方法测定了7050铝合金的TTT曲线, 采用TEM和JMA方程等分析手段研究了固溶、等温淬火和时效过程中微观组织的演变规律及其动力学特性. 结果表明, 合金TTT曲线的鼻尖温度在330 ℃附近, 淬火敏感区间为300~380 ℃, 高温区(400~450 ℃)淬火敏感性低于低温区(210~270 ℃); 等温保温过程中过饱和固溶体主要析出以Al<sub>3</sub>Zr粒子为形核核心的片层状η平衡相及少量针状S相, 随保温时间延长析出相体积分数快速增加, 同时在晶界排列变得连续而粗化、无沉淀析出带(PFZ)宽化, 在远离鼻尖的温度下保温合金析出速率减慢, 在晶界排布连续化和粗化程度降低; JMA方程中反映析出相形态的常数n在0.50~0.65的范围内, 析出相特征以片层状相为主、针状相为辅.

Revisiting the precipitation sequence in Al-Zn-Mg-based alloys by high-resolution transmission electron microscopy

[J].

Characterizing precipitate evolution of an Al-Zn-Mg-Cu-based commercial alloy during artificial aging and non-isothermal heat treatments by in situ electrical resistivity monitoring

[J].

Influence of predeformation and ageing of an Al-Zn-Mg alloy—II. Modeling of precipitation kinetics and yield stress

[J].

Recent advances in ageing of 7xxx series aluminum alloys: A physical metallurgy perspective

[J].

Investigation of mechanical and corrosion properties of an Al-Zn-Mg-Cu alloy under various ageing conditions and interface analysis of η′ precipitate

[J].

Hot deformation behavior of high Zn-containing 7A65 Al alloy

[J].

Study on the inhomogeneity of Al-Zn-Cu-Mg aluminum alloy plates with different thickness

[J].

Enhanced properties and homogeneity of Al-Zn-Mg-Cu alloy thick plate by non-isothermal aging

[J].

The effect of Mn on the high temperature flow stress of Al-Mg-Si alloys

[J].

Investigation of microstructure evolution and quench sensitivity of Al-Mg-Si-Mn-Cr alloy during isothermal treatment

[J].

Relationship between microstructure and mechanical properties of 5083 aluminum alloy thick plate

[J].

Precipitation behavior and mechanical properties of Al-Zn-Mg-Cu matrix nanocomposites: Effects of SiC nanoparticles addition and heat treatment

[J].