金属材料被广泛应用于民生、重大结构工程、高精密设备和重大装备等领域。强度与塑性是金属材料基本力学性能[1],高强度金属材料可提高承载能力,高塑性决定材料的变形能力, 兼具高强度-高塑性的金属结构材料是材料研究学者们永恒的追求[2~4]。然而,强度与塑性受位错可动性制约,金属材料的强度与塑性之间往往存在矛盾关系,称为强度-塑性倒置,即:高强度材料通常塑性较差,良好的塑性材料强度较低,这也成为了材料学领域需要持续解决的重大基础科学问题和难题[4]。强度-塑性倒置关系中,强度通常指材料的拉伸屈服强度,塑性通常指拉伸均匀延伸率而不是断裂伸长率[1]。为了获得高均匀延伸率,加工硬化率需要大于流动应力,以防止局部颈缩变形[5]。提高材料加工硬化率的本质是提高位错累积速率和位错存储密度,其关键是要在材料变形过程中持续激活新的位错源,使位错快速增殖及存储。由此提出关键问题:如何设计、加工制造显微结构可以增加位错源从而同步提高强度和塑性?

研究人员通过材料热机械加工,引入了非均匀显微结构[6,7],如非均匀晶粒、梯度晶粒和梯度孪晶及其2者耦合、层状晶粒、核壳晶粒等,实现了传统金属材料强度与塑性的协同提高。随着多主元合金(multi-principal element alloys)及高熵合金(high-entropy alloys)的研制,出现了材料显微结构调控的另一维度[8,9]。最近有研究[10~15]表明,在多主元合金晶粒内部引入局部化学有序(local chemical order,LCO)结构及局部化学成分波动(local chemical fluctuation,LCF)结构,实现了加工硬化率的大幅提升,获得了高强韧的力学性能。然而,如何通过合金化学成分设计在晶粒内部实现化学成分波动或者化学有序结构的可控构筑,进而实现超高强韧性能至今仍未明确。本文提出负混合焓(负焓)合金化学术思想,明晰利用负焓合金化设计加工多尺度微观结构,实现多主元合金强度-塑性协同提升。进一步地,本文提出3个负焓合金化效应,为高强韧性合金的设计提供新范式和新准则。

1 利用晶格畸变原理设计高性能多主元合金

经典的合金化加工制造思想是在固溶体合金成分设计中引入与基体原子半径相差较大的元素来提高晶格畸变,从而提高合金的强度,即晶格畸变强化思路。从传统固溶体合金到新金属研制,利用晶格畸变产生固溶强化在冶金领域有着悠久的历史[16]。多主元合金的出现即是将利用晶格畸变效应提高强度的作用发挥到了极致。这是因为多主元合金组成元素较多,并且每种元素含量相近,具有较大的原子半径差。基于此,材料研究学者形成了通过不断提高晶格畸变效应开发超高强度新型多主元合金的研究思路[17~20]。多主元合金的研究始于18世纪后期。随后,1981年,英国剑桥大学Cantor教授制备了FeCrNiMnCo单相fcc结构多主元合金,并于2004年将结果公开发表[8]。同时期,台湾清华大学叶钧蔚教授也独立发表了多主元合金研究成果,并从热力学角度分析了这类合金形成单相固溶体的原因,提出高熵合金的概念[9]。

早期研究[21,22]普遍认为高熵合金中的元素在单相结构中呈理想随机分布。然而,随着研究的深入,学者们发现即使单相高熵合金中的元素分布也并非完全理想随机分布。例如,Lei等[23]通过在难熔高熵合金中引入间隙O原子,成功构筑了具有局部有序氧复合物的新型结构。虽然该合金仍保持单相bcc结构,但其晶粒内部的元素分布已明显呈现非均匀特征。2019年,Ding等[10]首次系统揭示了fcc结构CoCrFeNiMn/Pd高熵合金中存在的明显成分波动现象,阐明了其与传统固溶体合金的本质差异。随后,Zhang等[14]利用能量过滤透射电镜衍射技术,在CoCrNi多主元合金中观察到化学短程有序(chemical short-range order,SRO)结构。2021年,Chen等[12]通过原子级分辨元素能谱技术,不仅精确解析了VCoNi合金中SRO的原子占位信息,还建立了SRO与位错相互作用的机制模型,为多主元合金中SRO结构的表征提供了新方法。这些突破性进展表明,高熵合金中的元素分布既非完全随机也非理想均匀,其实际混合熵显著低于理论值。对于多相或含金属间化合物的合金体系[24],元素偏聚行为更为显著,其混合熵进一步降低,已不符合高熵体系的基本特征和初始定义。基于此,逐渐采用多主元合金或者成分复杂合金(compositionally complex alloys)及复杂浓缩合金(complex concentrated alloys)等更准确的术语。本文后续统一采用多主元合金这一表述。值得注意的是,在多主元合金体系中,即使合金呈现单相fcc或bcc结构,传统固溶体概念中的“溶质、溶剂”区分已不再准确适用,将其归类为固溶体亦不严格。因此,有学者也将多主元合金称为浓固溶体[12]。

2 利用负焓合金化原理设计高性能多主元合金

利用晶格畸变虽然可以提高多主元合金的强度,但通常损失其塑性或者使其不具备拉伸塑性[17~20]。因此,这种单相结构合金的晶格畸变微观结构设计往往不能突破材料强度-塑性倒置关系。近年来,通过调控多主元合金显微结构[10,12,14,15],如异质晶粒结构、孪晶诱导塑性变形、相变诱导塑性变形、LCF、LCO及化学长程有序纳米析出相结构等,在一些体系中实现了强度-塑性的协同提升。特别是在bcc结构难熔多主元合金中引入LCF或者LCO结构能够大幅提高难熔多主元合金的塑性[11,25~27],从而实现材料高强韧的力学性能。这种化学成分调控方法已成为当前高强韧金属材料领域的研究热点。但如何规范、设计和加工这些显微结构尚不清晰。

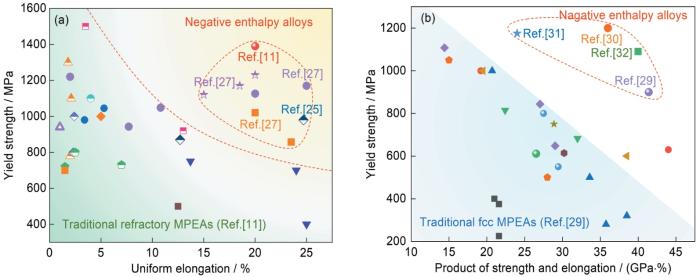

本课题组从热力学第一定律出发,提出材料显微结构设计、加工和力学性能优化的负焓合金化原理。混合焓与混合熵是表征材料热力学状态的基本参数,决定材料的混合自由能。混合焓是衡量原子间化学亲和性的一个重要指标,负混合焓与正混合焓(负焓与正焓)导致最近邻元素之间偏好或避免成键,从而形成局域化学有序结构[11,27]。本课题组[11,27]提出负焓合金化策略,随着合金混合焓的降低,单相无序结构中逐渐形成原子尺度化学成分波动、亚纳米尺度化学SRO结构,直到形成纳米尺度化学中程有序(chemical medium-range order,MRO)结构及化学长程有序(chemical long-range order,LRO)的金属间化合物结构。因此,负焓合金形成以单相结构耦合化学成分波动,局部化学有序结构乃至金属间化合物为异质结构的复杂显微结构,衍生出界面效应和尺寸效应。重要的是,这种负焓复杂显微结构能够在晶粒内部提供位错源,高效率规范位错运动行为,提高位错密度,调控加工硬化,从而使材料获得高塑性。此外,随着混合焓降低,合金内高键能比例增加,合金模量增加。

2.1 负焓合金化方法

负焓合金化作为一种材料设计新原理,为实现传统材料难以企及的强度-塑性协同效应提供了新的维度。然而,如何通过准确选择负焓化学成分实现负焓合金设计,并确定最优的混合焓范围,是当前研究的基础科学问题,也是关键问题。基于本课题组的工作基础及相关领域进展,本文介绍几种典型负焓合金的设计策略:针对不同合金类型选择合适的负焓合金化元素,阐明不同混合焓对应的微观结构特征。

在多主元合金体系中,系统的混合熵(ΔSmix)通常包括构型熵、振动熵、电子随机性熵及磁熵等。其中,构型熵占据主导,往往用构型熵表示合金的混合熵。对于元素理想随机分布的多主元合金,ΔSmix计算公式为[21]:

式中,R为理想气体常数,R = 8.314 J/(K·mol);ci (i = 1, 2, …, n)为合金中i元素的原子分数。

在多主元合金体系中,混合焓(ΔHmix)是反映合金元素之间化学亲和性的热力学参数,可由下式计算[21]:

式中,cj 为元素j的原子分数,ΔHij 为二元液态i-j合金的混合焓[28]。当ΔHij 为负值时,表明元素i和j具有较强的亲和性。因此,当在合金体系中引入与其他元素具有负焓的元素时,称之为负焓合金化,此时合金整体混合焓降低。

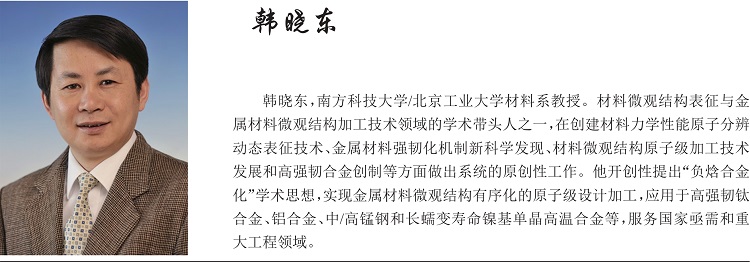

以研究最为广泛的fcc结构多主元合金体系(主要包含Cr、Mn、Fe、Co、Ni等3d过渡金属元素)为例,其次考察bcc结构难熔多主元合金体系(主要由Ti、Zr、Hf、V、Nb、Ta、Cr、Mo和W等元素构成),如图1所示,这2类合金体系中各原子对的混合焓均接近于零,因而其整体混合焓趋近于零,表现出典型的合金元素高熵随机分布特征。值得注意的是:在bcc结构难熔多主元合金体系中,Al/Pt/Ru/Re-X (X = Ti、Zr、Hf、V、Nb、Ta)原子对呈现显著负焓特征,且不同原子对的负焓存在明显差异;在fcc结构多主元合金体系中,Al/Ti/Nb-X (X = Cr、Fe、Co、Ni)原子对同样表现出差异性负焓特性。这表明,Al/Pt/Ru/Re和Al/Ti/Nb元素可分别作为bcc结构难熔多主元合金和fcc结构多主元合金体系中的负焓合金化元素。通过精确调控这些元素的含量,可实现合金混合焓从近零到较大负值的大范围连续调控,为优化材料性能提供了新的维度。

图1

图1

fcc结构多主元合金和bcc结构难熔多主元合金中常见元素的混合焓

Fig.1

Mixing enthalpies of common elements in fcc-structured (a) and bcc-structured refractory (b) multi-principal element alloys (MPEAs)

2.2 超高强韧bcc结构难熔多主元负焓合金

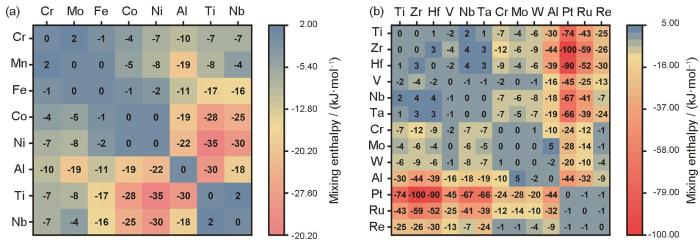

为了在bcc结构难熔多主元合金体系中引入有序结构,选择添加的元素与合金主元可能形成负焓原子对的思路。Al元素与多种难熔元素之间的混合焓为负值,选择Al元素作为负焓合金化元素(图1b)。基于负焓合金化设计策略,本课题组设计并制备了HfNbTiVAl10负焓合金[11]。利用球差校正透射电镜及原子分辨能谱在原子尺度揭示了HfNbTiVAl10合金中化学元素呈现非均匀分布,证明了负焓导致化学成分波动(chemical fluctuation,CF)。该合金在塑性变形时,负焓原子的尺度波动能够有效减慢位错运动,降低位错运动自由程,促进位错发生交滑移及激活更多滑移系,实现高位错密度及大加工硬化能力,使材料的屈服强度与均匀拉伸塑性同步提高(屈服强度约1390 MPa、均匀延伸率约为20%)。此外,对负焓合金HfNbTiTaAl x (x = 0、5、10、12、15,原子分数,%,下同)的研究表明,随着负焓元素Al含量增加,合金混合焓逐渐减小(2.5~-11.7 kJ/mol)[27],合金微观结构逐渐由无序结构转变为短程有序、中程有序及长程有序复杂结构,证明了负焓是局部有序结构演化的本质原因。HfNbTaTiAl12负焓合金实现了屈服强度与拉伸塑性同步提高(屈服强度约为1160 MPa,均匀延伸率约为24.5%),屈服强度-均匀延伸率曲线突破传统“香蕉状”曲线(图2a[11,25,27])。

图2

图2

bcc结构难熔多主元合金及fcc结构多主元合金的力学性能[11,25,27,29~32]

Fig.2

Mechanical properties of bcc-structured refractory MPEAs and fcc-structured MPEAs

(a) comparisons of yield strength and uniform elongation of bcc-structured refractory MPEAs (Compared with traditional refractory MPEAs[11], negative enthalpy alloys[11,25,27] exhibit excellent mechanical properties)

(b) comparisons of yield strength and product of strength and elongation of fcc-structured MPEAs (Compared with traditional MPEAs[29], negative enthalpy alloys[29-32] exhibit excellent mechanical properties)

2.3 高强韧fcc结构多主元负焓合金

fcc结构金属材料是应用最为广泛的金属材料,晶体滑移系最多,位错容易增殖,具有优异的塑性。但是其强度通常较低,尤其是铸造fcc结构金属,无法通过机械加工细化晶粒组织。通过负焓合金化原理,有可能解决铸造fcc结构金属强度与塑性长期存在的倒置问题。依据负焓合金化设计策略,本课题组设计了Co40 - x Cr20Fe20Ni20Al x (x = 6、11、13、15)系列fcc结构多主元合金[29],命名为CCFNA x 合金。随着混合焓的降低,铸态CCFNA x 合金的模量和强度得到了明显提升。令人惊讶的是,相比于CCFNA6合金,CCFNA11合金的屈服强度提升66.7%,塑性基本不变,展示出了优异的强塑性协同(屈服强度约为500 MPa,均匀延伸率约为29%),证明了负焓合金化策略的有效性。经过热机械处理后,该合金的强塑性协同效果进一步提高,屈服强度提高80%,达到900 MPa,均匀延伸率维持在约28%。相比于其他fcc结构合金,铸态及热机械处理态CCFNA11合金均表现出优异的力学性能。通过三维原子探针分析其化学成分分布,结果表明,CCFNA11铸态合金中就存在纳米尺度CF。热机械处理后,这种CF结构依旧存在。这种纳米尺度CF结构有效调控大流变应力下的位错持续增殖,从而提高材料加工硬化率,使其具有优异的力学性能。许多研究[30~32]通过调控合金化学成分,在fcc结构中引入多尺度化学成分波动及局部有序结构,实现了高强度与高塑性的优异结合。通过分析可知,这些合金的混合焓均小于零[30~32],并且形成复杂显微结构,属于负焓合金范畴(图2b[29~32])。

3 负焓合金化的3重效应

负焓合金化的本质在于基于热力学第一定律,利用元素间的偏好性和排斥性,调控元素间的化学相互作用,设计、加工制造材料微观结构中的有序度、有序分布及局域电子态,从而调控材料的力学性能。本节总结负焓合金化至少带来的3重效应。

3.1 键能与慢扩散效应

首先,随着负焓元素加入(混合焓小于零),元素间化学亲和性增加,从而提高键能(图3①),导致材料模量提高[11,27]。例如,在HfNbTiVAl x 难熔多主元合金中,随着负焓元素Al含量的增加,合金混合焓降低,材料模量明显提高(ΔE = KΔHmix,其中,ΔE为模量增量,K为负焓模量强化系数):HfNbTiVAl x (x = 0、5、10)合金模量由约105.6 GPa (x = 0)提升到约134.9 GPa (x = 10)[11],这种负焓诱导的模量强化系数(|K|)约为3.1 mol·GPa/kJ。模量的提高在很大程度上可以提升材料屈服强度(Δσ = MΔHmix,其中,Δσ为屈服强度增量,M为负焓屈服强度强化系数)。例如,HfNbTiVAl x (x = 0、5、10、15)合金屈服强度由约1.1 GPa (x = 0)提升到约1.5 GPa (x = 15)[11];HfNbTiTaAl x (x = 0、5、10、12、15)合金的屈服强度由约0.9 GPa (x = 0)提升到约1.2 GPa (x = 15)[27]。因此,负焓合金化能够显著提高材料强度,且与负混合焓成正相关关系,称为负焓强化。HfNbTiVAl x 合金中负焓屈服强度强化系数(|M|)约为31 mol·GPa/kJ[11]。其次,随着键能的提升,要实现负焓原子的扩散,在打破化学键时须克服更高的能垒。因此,利用负焓合金化策略可以调整原子的扩散行为,降低与其配对原子的扩散能力,称为慢扩散效应(图3①) (或相反)。这种慢扩散效应可用于设计非晶合金的玻璃化形成能力,从而优化非晶合金力学性能。例如,Li等[33]设计了一系列(Zr0.6336Cu0.1452Ni0.1012Al0.12)100 - x Er x 非晶合金,由于Er-X (X = Cu、Ni、Al)原子对的混合焓比X-X更负[28],因此Er元素的加入可以获得较大负焓的金属玻璃。(Zr0.6336Cu0.1452Ni0.1012Al0.12)97.4Er2.6金属玻璃的压缩强度远高于Zr0.6336Cu0.1452Ni0.1012Al0.12金属玻璃。同时,相比于Zr0.6336Cu0.1452Ni0.1012Al0.12金属玻璃,(Zr0.6336Cu0.1452Ni0.1012Al0.12)97.4Er2.6金属玻璃的压缩塑性提高了7倍,约为35.1%。

图3

图3

混合焓与显微结构特征关联关系[11,12,15,27]

Fig.3

Correlation between the mixing enthalpy and microstructure characteristics of alloys[11,12,15,27] (With the decrease of the mixing enthalpy of alloy, at least three effects are presented, including the bond energy and slow diffusion effect, the local chemical ordering effect, and the interface and the size effect; where -n represents the negative mixing enthalpy; band b1 represent the Burgers vectors of dislocation)

3.2 局部化学有序效应

负焓元素的加入会导致合金中的化学元素在原子尺度非均匀分布。这是由于负焓元素的加入会形成局域化学亲和性差异,这种差异往往体现在最近邻原子间的偏好成键,从而形成原子聚集,产生原子尺度非均匀化学成分波动(< 0.5 nm)[11] (图3②[11]),进而形成有序结构。原子尺度化学亲和性差异会导致局域电子密度发生较大变化。这些局域电子密度波动通过与位错交互作用,产生显著的强化效果。这种局域化学亲和性效应促使局域电子密度发生变化,能够造成位错运动的能量波动振幅增大,从而使合金强度增加,也可以促进位错发生交滑移,使材料的位错增殖能力提高,从而提升加工硬化能力,提高均匀塑性。当负焓元素含量增加或有多种负焓元素原子时,局域化学亲和性效果将非常显著,从而形成SRO结构及MRO结构。SRO结构尺寸约为1 nm,MRO结构尺寸在1~5 nm之间(图3②[12,15])。这种SRO/MRO结构可以看作是为降低体系应变能的化学亲和性团簇的低能量原子排布方式。SRO/MRO参与调控位错运动行为,通过钉扎位错运动及促进位错发生交滑移和双交滑移,使合金加工硬化率提高,获得优异的强塑性能。随着合金混合焓持续降低,这些有序结构的纳米尺度团簇尺寸增加,形成LRO结构,也称为金属间化合物析出相,其尺寸一般大于8 nm (图3②[27])。通常,位错扫过这样的微观结构,需要耗费非常高的能量。因此,金属间化合物析出相能够阻碍位错运动,造成位错快速堆积,从而大幅提高材料强度。其次,这种金属间化合物析出相尺寸也可以在大尺度范围内进行调整,位错也可以切过小尺寸LRO,从而保持材料塑性。

3.3 界面和尺寸效应

如前所述,随着负焓元素的加入,合金内部将形成原子尺度CF、SRO、MRO及LRO结构,这一过程在晶体晶格内部引入了不同尺度的高密度化学界面结构(图3③)。此外,利用负焓合金化和正焓策略可以调控合金的界面结构,实现特定化学元素偏聚于界面。随着体系负焓的降低,晶体内部局部化学有序度增加,有序结构的尺寸及体积也将逐渐增加,从原子尺度CF直至形成纳米尺度长程有序相析出结构(图3③),位错的运动行为将受这些衍生的界面之间的狭小空间约束,从而表现出尺寸效应。因此,界面和尺寸效应贯穿于整个负焓合金化设计策略,从而实现材料性能调控。例如,本课题组[34]在第二代镍基单晶高温合金中微量添加Os元素作为关键合金化元素,通过调控γ'相尺寸与体积分数,制造小尺寸γ通道,实现了相界面效应与尺寸效应的协同强化。结果表明,改性合金在1100 ℃、137 MPa和980 ℃、250 MPa蠕变条件下的寿命均提升约1倍,在760 ℃、800 MPa极端条件下寿命提升达5倍。其中760 ℃、800 MPa下约1273 h的拉伸蠕变寿命是所有材料的最高纪录[34]。这一成果验证了负焓合金化衍生的界面效应和尺寸效应,获得了超高强韧镍基单晶高温合金,为航空发动机用镍基单晶高温合金的微观结构加工提供了新思路和新理论。

4 结论与展望

本文叙述了近年来多主元合金发展现状及强韧化研究思路,综述了调控合金显微结构协同提升多主元合金强塑性实例,进而提出负混合焓(负焓)合金化设计、加工高强韧显微结构的学术思想,阐明负焓合金化思想及其在多种材料中的应用效果,最后凝练总结出负焓合金化的3重效应。首先,负焓合金化引起的原子间结合力的增强,导致材料模量(屈服强度)提高及扩散减慢,这是一个普适性的规律,设计高强合金可以考虑添加增大负混合焓的合金化元素。其次,负焓合金化的本质是利用元素间的化学亲和性差异效应,产生跨原子尺度到亚微米尺度化学成分有序结构的多尺度设计和加工,从而获得多级有序结构及可控分布。这种负混合焓局部化学有序结构是普遍存在的,其与位错交互作用的形式是多变的,可以促进位错增殖,可以说,在形成金属间化合物之前的负焓效应,一般可以促进合金的塑性提升[11,27]。第三,负焓合金化在材料晶格内产生极高密度多级界面结构,通过设计、加工界面结构,可以产生较强的界面效应和尺寸效应,使材料强度和塑性都得到提升[34]。因此,负焓合金化策略为高强韧合金的微观结构设计和加工提供了新范式。负焓合金化策略的设计实践在于负焓元素的加入,得益于负焓合金的巨大成分设计空间,混合焓元素和混合焓值可在大范围内调控,从而能够大幅优化合金的力学性能,打破金属材料“强-塑”倒置关系,为实现超高强度与塑性协同提供新维度,推动高强韧合金发展,负焓合金化发展高强韧合金的新领域正在开启。

参考文献

Strengthening materials by engineering coherent internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

Uniting tensile ductility with ultrahigh strength via composition undulation

[J].

Trade-off model for strength-ductility relationship of metallic materials

[J].

Achieving alloys with concurrent high strength and high ductility

[J].Increasing the yield strength of metallic materials is observed to almost always substantially reduce their tensile ductility. Here we unravel the origin of this perplexing “strength-ductility trade-off”, and conclude that this dilemma does not necessarily preclude concurrent high strength and high ductility. We discuss several strengthening and work hardening mechanisms that regulate dislocation behavior, including traditional ones that have been pushed to their extreme in recent years, as well as new ones that take advantage of the heightened structural and chemical heterogeneities; all these mechanisms are rendered more powerful by emerging complex concentrated alloys that bring in multiple principal elements. These mechanisms, while offering elevated strength, contribute to sustainable strain hardening under high flow stresses, delaying strain localization to allow prolonged uniform elongation. The current status in the pursuit for concurrent high strength and high ductility is reviewed. The goal we set for high yield strength ~2 GPa (rivaling super steels) together with large uniform elongation ~30% (much like un-strengthened elemental metals) is projected to be soon within reach. These take-home messages shed light on some existing puzzles regarding the strength-ductility synergy, and offer new insight into the innovative design of alloys.

如何使合金兼具高强度与高塑性

[J].

Extra strengthening and work hardening in gradient nanotwinned metals

[J].

Gradient and lamellar heterostructures for superior mechanical properties

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Tuning element distribution, structure and properties by composition in high-entropy alloys

[J].

Negative mixing enthalpy solid solutions deliver high strength and ductility

[J].

Direct observation of chemical short-range order in a medium-entropy alloy

[J].

Chemical short-range order in Fe50Mn30Co10Cr10 high-entropy alloy

[J].

Short-range order and its impact on the CrCoNi medium-entropy alloy

[J].

Chemical medium-range order in a medium-entropy alloy

[J].High-/medium-entropy alloys (H/MEA) have the inherent local chemical order. Yet, as a structural link between the incipient short-range order and mature long-range counterpart, the chemical medium-range order (CMRO) is conjectural and remains open questions as to if, and what kind of, CMRO would be produced and if CMRO is mechanically stable during plastic deformation. Here, we show compelling evidences for CMRO in an AlCrCoNi MEA. Specifically, the electron diffraction under both [[Formula: see text]] and [[Formula: see text]] zone axis show the definite spots for CMRO of lattice periodicity. CMRO entities are seen directly of medium-ranged in sizes by using dark-field imaging, along with the tendency towards like-pair avoidance and unlike-pair preference based on atomic-resolution EDS mapping. These findings substantiate CMRO with a realistic structural picture in view of crystal periodicity and chemical species occupation, shedding light on understanding the microstructural link at an extended length scale beyond the short-range order.© 2022. The Author(s).

Ductile CoCrFeNiMo x high entropy alloys strengthened by hard intermetallic phases

[J].

Origin of strong solid solution strengthening in the CrCoNi-W medium entropy alloy

[J].Solid solution strengthening is one of the most conventional strategies for optimizing alloys strength, while the corresponding mechanisms can be more complicated than we traditionally thought specifically as heterogeneity of microstructure is involved. In this work, by comparing the change of chemical distribution, dislocation behaviors and mechanical properties after doping equivalent amount of tungsten (W) atoms in CrCoNi alloy and pure Ni, respectively, it is found that the alloying element W in CrCoNi alloy resulted in much stronger strengthening effect due to the significant increase of heterogeneity in chemical distribution after doping trace amount of W. The large atomic scale concentration fluctuation of all elements in CrCoNi-3W causes dislocation motion via strong nanoscale segment detrapping and severe dislocation pile up which is not the case in Ni-3W. The results revealed the high sensitivity of elements distribution in multi-principle element alloys to composition and the significant consequent influence in tuning the mechanical properties, giving insight for complex alloy design.

Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy

[J].

A novel HfNbTaTiV high-entropy alloy of superior mechanical properties designed on the principle of maximum lattice distortion

[J].This paper reports a synergistic design of high-performance BCC high-entropy alloy based on the combined consideration of the principles of intrinsic ductility of elements, maximum atomic size difference for solid solution strengthening and the valence electron concentration criterion for ductility. The single-phase BCC HfNbTaTiV alloy thus designed exhibited a high compressive yield strength of 1350 MPa and a high compressive ductility of >45 % at the room temperature. This represents a 50 % increase in yield strength relative to a HfNbTaTiZr alloy. This is attributed to the maximized solid solution strengthening effect caused by lattice distortion, which is estimated to be 1094 MPa. The alloy was also able to retain 53 % of its yield strength and 77 % of its ductility at 700 °C. These properties are superior to those of most refractory BCC high-entropy alloys reported in the literature.

Solid-solution phase formation rules for multi-component alloys

[J].

Prediction of high-entropy stabilized solid-solution in multi-component alloys

[J].

Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes

[J].

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Tailoring planar slip to achieve pure metal-like ductility in body-centred-cubic multi-principal element alloys

[J].Uniform tensile ductility (UTD) is crucial for the forming/machining capabilities of structural materials. Normally, planar-slip induced narrow deformation bands localize the plastic strains and hence hamper UTD, particularly in body-centred-cubic (bcc) multi-principal element high-entropy alloys (HEAs), which generally exhibit early necking (UTD < 5%). Here we demonstrate a strategy to tailor the planar-slip bands in a Ti-Zr-V-Nb-Al bcc HEA, achieving a 25% UTD together with nearly 50% elongation-to-failure (approaching a ductile elemental metal), while offering gigapascal yield strength. The HEA composition is designed not only to enhance the B2-like local chemical order (LCO), seeding sites to disperse planar slip, but also to generate excess lattice distortion upon deformation-induced LCO destruction, which promotes elastic strains and dislocation debris to cause dynamic hardening. This encourages second-generation planar-slip bands to branch out from first-generation bands, effectively spreading the plastic flow to permeate the sample volume. Moreover, the profuse bands frequently intersect to sustain adequate work-hardening rate (WHR) to large strains. Our strategy showcases the tuning of plastic flow dynamics that turns an otherwise-undesirable deformation mode to our advantage, enabling an unusual synergy of yield strength and UTD for bcc HEAs.© 2023. The Author(s), under exclusive licence to Springer Nature Limited.

Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys

[J].

Negative enthalpy alloys and local chemical ordering: A concept and route leading to synergy of strength and ductility

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Multiscale hierarchical heterostructure yields combined high strength and excellent ductility in a Co-Cr-Fe-Ni-Al negative enthalpy alloy

[J].

Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys

[J].

Exceptional strength-ductility synergy in a casting multi-principal element alloy with a hierarchically heterogeneous structure

[J].

Discontinuous precipitation enables an exceptional cryogenic strength-strain hardening synergy in a heterostructured medium entropy alloy

[J].

Effect of Er on properties of Zr-based bulk metallic glasses

[J].

Mixing enthalpy alloying leads to interface and size effects towards superb creep resistance of nickel-based single crystalline superalloys

[J].

Negative enthalpy doping stabilizes P2‐type oxides cathode for high‐performance sodium‐ion batteries

[J].

Negative mixing enthalpy route guides strong and ductile soft magnetic high-entropy alloys with high saturation magnetization

[J].