镁合金是最轻的工程结构金属材料,具有优异的比强度和比刚度,在航空航天、汽车、轨道交通等领域具有广泛的应用前景[1~8]。然而,镁合金具有hcp结构,在室温下可启动的滑移系不足,因此其室温塑性及成型性较差。通常采用提高合金含量的方法提高镁合金强度,在合金中形成高密度的纳米第二相以阻碍位错运动。但高合金元素含量会使合金在凝固过程中易形成粗大的共晶相,提高强度的同时损失了塑性,从而限制了镁合金的应用进程。近年来,新型低合金含量镁合金受到了研究者的广泛关注[9~14]。其中,低合金含量Mg-Zn-Ca(-Al)系合金板材由于其弱化的基面织构展现出了优异的室温冲压成型性,使镁合金板材在车身覆盖件应用方面替代钢和6XXX系铝合金成为可能。然而,与高合金含量镁合金相比,该体系镁合金强化手段有限,屈服强度一般低于180 MPa,限制了其进一步应用。目前,在不损失成型性的前提下,如何提高低合金含量镁合金的强度仍是亟待解决的难题。

为了充分利用低合金含量镁合金中有限的溶质原子,在实际应用过程中,热机械加工工艺的调控尤为重要。烘烤硬化在钢、铝合金中应用较为广泛,作用机制包括在位错核心附近形成“Cottrell气团”等,阻碍位错运动从而提高合金高强度。烘烤硬化的突出优点是可以在板材成型后,经过短时的烤漆处理即可使合金强度显著提升。近期,Bian等[15]针对低合金含量镁合金的研究表明,烘烤硬化处理有望成为提高低合金镁合金强度的有效手段。然而,目前烘烤硬化对低合金镁合金的强度贡献及作用机制尚不完全明晰。本工作旨在综述烘烤硬化在低合金含量镁合金中的研究进展及其作用机理。

1 位错偏聚诱导烘烤硬化

烘烤硬化,也称烤漆硬化现象,在汽车制造过程中被首次发现,具体表现为车身(钢/铝合金)经过涂装高温固化处理后,其流变应力显著提高[16,17]。对于钢板而言,这是由于其经过冲压、拉延等处理成型后,组织中会引入大量的残余位错,在随后的烤漆热处理(150~200 ℃,20~30 min)过程中,基体中固溶的间隙或置换原子会择优向位错核处偏聚[15,18],聚集的原子形成“Cottrell气团”,钉扎位错,从而提高了合金强度。该机制最初由Cottrell和Bilby[19]于1949年提出,随后Blavette等[20]于1999年通过三维原子探针(APT)技术验证了该机制,并在Fe-Al合金中观察到溶质原子(B)在位错上偏聚的现象。对于铝板而言,常见的烘烤硬化板为6XXX系合金,由于其快速的时效硬化响应,烘烤硬化主要来源于基体中析出的大量溶质团簇或析出相。烘烤硬化板材的加工流程为:(1) 轧制处理;(2) 对钢材进行退火处理、对铝合金进行T4固溶处理以充分固溶溶质原子;(3) 冲压与拉延,以实现工件的成型;(4) 涂装与烤漆。利用该原理,多种钢材和铝材(如低碳钢、6XXX系铝合金等[21~26])既能在冲压、拉延等变形时保证良好的成型性,又能利用随后的烘烤硬化处理提高强度(> 40 MPa),为节约成本及轻量化提供了重要手段。

随着高分辨透射电镜(HRTEM)及APT技术的发展,越来越多的研究发现在镁合金中也存在溶质原子在位错处偏聚的现象。例如,Hu等[27]利用原子尺度的高角度环形暗场-扫描透射显微镜(HAADF-STEM)表征技术,在Mg-2.5Zn-6.8Y (质量分数,%,下同)合金中发现基面<a>位错核周围存在“Cottrell气团”。该合金经过300 ℃压缩变形40%后,由Zn/Y原子组成的“Cottrell气团”在相界面上的位错核附近形成。Xiao等[28]在Mg-2.57Ag合金中也观察到Ag原子在1/6<2

虽然在一些镁合金中已观察到溶质原子在位错处偏聚的现象,但是利用烘烤硬化机制提高镁合金强度目前仍存在挑战。烘烤硬化对合金强度的提高与合金元素的种类密切相关。在生产制造过程中,烘烤硬化处理对温度和时间均有严格的限制,要求溶质原子能够在短时间内快速实现位错偏聚。例如,Bian等[15]研究表明,拉伸预应变为2%的Mg-1.3Al-0.8Zn-0.7Mn-0.5Ca (AZMX1110)合金经170 ℃、20 min短时烘烤硬化处理后流变应力提高了约40 MPa,屈服强度约为238 MPa,抗拉强度约为272 MPa,断裂延伸率高达26.3%。此外,该镁合金在T4固溶处理后具有良好的成型性,埃里克森杯突值(index Erichsen,IE)可达约7.8 mm,性能远高于AZ31合金(IE约2.7 mm),进一步说明烘烤硬化处理可有效地解决镁合金的强度、成型性呈倒置关系这一问题。然而,相比之下,烘烤硬化处理后AZ31合金的流变应力不仅没有提高,反而降低了约12 MPa,屈服强度仅约为186 MPa。Bian等[15]进一步采用APT表征AZMX1110合金中的原子分布,发现Al、Zn、Ca原子偏聚于基面<a>位错处(图1[15]),基体中存在的大量Al、Zn、Ca原子共团簇是该合金烘烤硬化响应较高的原因。从热力学角度出发,Al-Ca和Zn-Ca的结合焓分别为-20和-22 kJ/mol,表明3者之间有强烈的互相吸引倾向;此外,由于位错核附近同时存在拉应力和压应力区,因此原子半径小于Mg (约0.16 nm)的Al (约0.143 nm)和Zn (约0.133 nm)及原子半径大于Mg的Ca (约0.197 nm)原子共偏聚可以大幅降低体系能量,钉扎位错的移动,从而提高合金强度[15]。从动力学角度出发,短时间内保温即可使大量溶质原子扩散至位错区域,这也是实现有效烘烤硬化的重要条件。Hua等[30]随后报道了一种具有自然时效硬化能力的低合金含量Mg-1.0Zn-0.45Ca-0.33Sn-0.2Mn合金。结果表明,经2%拉伸预应变且室温放置48 h后,该固溶态合金的流变应力从约138 MPa提升至约163 MPa。而在相同的室温放置时间下,未经拉伸预应变的T4态样品并未表现出明显的强度提升。此外,Hua等[30]还发现,随着预变形量的不断提高,自然时效响应速率会随之提高。预应变达到8%后放置仅24 h,合金的流变应力相应提高了约30 MPa。TEM结果表明,自然时效过程中,基体中的固溶原子在预变形引入的位错处偏聚,从而提高了镁合金强度。由此可见,经T4固溶和预应变处理后,Mg-Zn-Ca(-Al)系合金具有快速时效硬化响应特性,为实现有效烘烤硬化提供重要保障。

图1

图1

2%拉伸预应变态和烘烤硬化态AZMX1110合金的透射电镜-三维原子探针(TEM-APT)联用表征结果[15]

Fig.1

Correlative TEM-APT characterization of 2% pre-strained and bake-hardened (BH) AZMX1110 alloys[15] (APT—atom probe tomography, insets in Figs.1a and d are the selected area electron diffraction (SAED) patterns)

(a) two-beam bright field-TEM (BF-TEM) image of 2% pre-strained sample obtained under the g =

(b) APT map obtained from the same tip shown in Fig.1a

(c) overlay of Fig.1b and the corresponding region in Fig.1a

(d) two-beam BF-TEM image of bake-hardened sample obtained under the g =

(e) APT map obtained from the same tip shown in Fig.1d (a-d represents four dislocations)

(f) overlay of Fig.1e and the corresponding region in

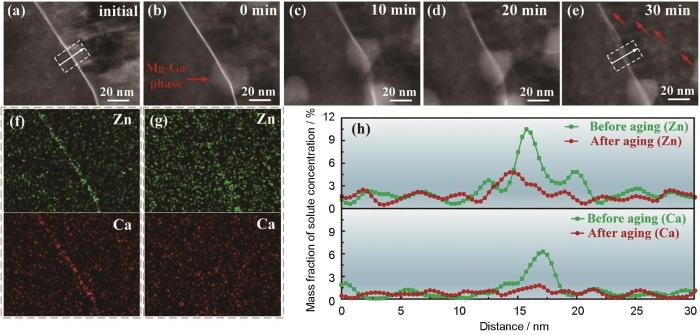

需要说明的是,Mg-Zn-Ca(-Al)系合金实现烘烤硬化的前提之一是在变形后先进行高温固溶处理,从而在Mg基体中保留充分的溶质原子。然而,高温(如约450 ℃)固溶过程中,Mg基体中的晶粒会发生粗化,损失一部分晶界强化效果。近期,Hua等[31]研究表明,利用溶质再分配,低合金含量镁合金无需高温固溶处理也能获得显著的烘烤硬化效果。首先对Mg-1.0Zn-0.45Ca-0.33Sn-0.2Mn (ZXTM1000)合金进行轧制和300 ℃短时退火,随后对合金进行2%预拉伸变形和175 ℃、30 min烘烤硬化处理,发现即使没有进行固溶处理,合金的烘烤硬化响应也能达到30 MPa (图2a[31],详细性能见表1[31~36])。烘烤硬化态ZXTM1000合金的屈服强度约达到297 MPa,断裂延伸率约达到21.9%,与其他镁合金相比具有明显优势(图2b[31])。TEM和APT结果[31]表明,ZXTM1000合金位错处存在明显的Zn、Ca原子共偏聚现象。TEM原位加热实验 (图3[31])表明,随着烘烤硬化的进行,晶界处偏聚的溶质Zn、Ca原子逐渐扩散到基体中的位错处,完成了溶质的再分布,从而解释了为什么Mg基体中在缺乏足量的溶质原子时,仍能在烘烤硬化处理后产生足量的位错偏聚。该工作巧妙利用了低含量的Zn、Ca原子,为实现低合金含量镁合金的显著烘烤硬化效果提供了新的思路。

图2

图2

退火态、直接时效态、预应变态和烘烤硬化态的ZXTM1000合金的拉伸工程应力-应变曲线及烘烤硬化态样品与其他镁合金的屈服强度、断裂应变对比图[31]

Fig.2

Tensile engineering stress-strain curves of annealed, directly aged, pre-strained, and bake-hardened ZXTM1000 alloys (a) and tensile yield strength as function of elongation for various rolled and extruded Mg alloys (b)[31]

表1 低合金含量烘烤硬化镁合金与烘烤硬化钢/铝合金的力学性能[31~36]

Table 1

| Alloy | Processing | YS MPa | UTS MPa | EL % | BH mechanism | Ref. |

|---|---|---|---|---|---|---|

| Mg-1.0Zn-0.45Ca-0.33Sn-0.2Mn | Annealed | 265 | 291 | 24.6 | Solute segregation at dislocations | [31] |

| BH | 297 | 301 | 21.9 | |||

| Mg-2.0Zn-0.5Ca | T4 | 95 | 208 | 12.0 | Solute segregation at dislocations and twin boundaries | [32] |

| BH | 200 | 244 | 17.0 | |||

| Mg-1.61Zn-0.57Mn-0.54Ca-0.46Al | T4 | 234 | 288 | 21.1 | GP zone strengthening | [33] |

| BH | 293 | 316 | 19.2 | |||

| AA6016 Al alloy | PA | 122 | 234 | 27.8 | Mg-Si cluster strengthening | [34] |

| BH | 223 | 291 | 22.7 | |||

| AA6111 Al alloy | T4 | 150 | 268 | 19.2 (UL) | Precipitate strengthening | [35] |

| PFHT | 280 | 325 | 10.9 (UL) | |||

| BH | 289 | 331 | 10.5 (UL) | |||

| B180H1 Steel | BH | 241 | 352 | 38.0 | Solute segregation at dislocations | [36] |

图3

图3

预应变态ZXTM1000合金原位加热过程中的HAADF-STEM像及EDS分析[31]

Fig.3

High-angle annular dark field-scanning transmission electron microscope (HAADF-STEM) images (a-e) and EDS results (f-h) of pre-strained ZXTM1000 alloy during in situ heating[31] (White arrows in Figs.3a and e represent areas of EDS line scanning results in Fig.3h; red arrows in Fig.3e show the solute segregation at dislocations after in situ heating for 30 min)

(a) pre-strained (b) reaching at 175 oC (c) heating at 175 oC for 10 min (d) 175 oC for 20 min (e) 175 oC for 30 min

(f, g) EDS mappings of pre-strained (f) and after heating (g) samples

(h) EDS line scanning results of white arrows in

2 孪晶界偏聚诱导烘烤硬化

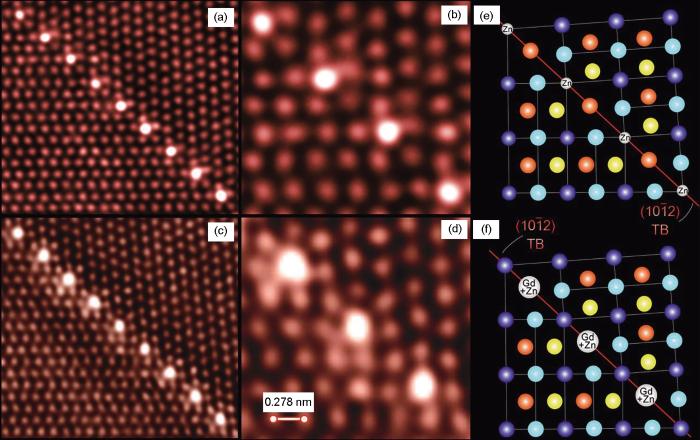

镁合金基面滑移只能提供2个独立滑移系,而较高的临界剪切应力又使得非基面滑移开启困难。因此,镁合金通常会借助临界剪切应力较低的孪晶以协调变形。在镁合金变形初期,可以观察到大量的孪晶及孪晶界[37]。位错作为一维晶格缺陷,其吸引溶质原子偏聚的特性有助于降低体系能量。同样地,作为二维晶格缺陷的晶界和孪晶界也会诱导溶质原子偏聚[38]。2013年,Nie等[39]使用具有原子分辨率的HAADF-STEM技术在Mg-6.1Gd-1.0Zn-0.7Zr合金中的共格孪晶界上发现了周期性Zn、Gd原子共偏聚。该合金经过500 ℃固溶处理后,在单轴压缩应变为6.5%的截断样品中观察到大量{10

图4

图4

Mg-4.7Zn合金和压缩退火后Mg-6.1Gd-1.0Zn-0.7Zr合金孪晶界上的周期性溶质偏聚[39]

Fig.4

Periodic segregation of solutes in twinning boundaries (TBs)[39]

(a, c) HAADF-STEM images showing {

(b, d) close-ups of Figs.4a and c, respectively

(e, f) schematic illustrations of Figs.3b and d, respectively (Blue (in the paper plane) or purples (out of the paper plane) balls represent atoms in the A layer, yellow (in the paper plane) or orange (out of the paper plane) balls represent atoms in the B layer)

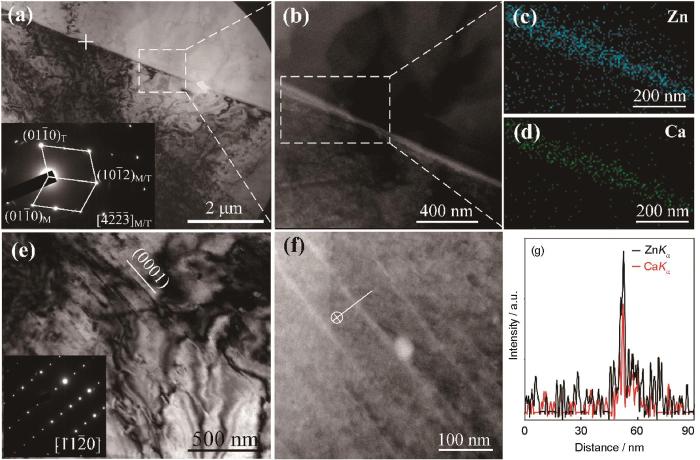

利用原子级分辨技术,研究人员对镁合金中孪晶界处偏聚的元素进行了系统表征[41~50]。如何诱导溶质原子在孪晶界处的偏聚,从而提高烘烤硬化镁合金性能,仍然是目前的热点问题。根据位错偏聚诱导烘烤硬化的原则,即溶质原子在Mg基体中具有较快的扩散速率、共偏聚原子半径分别大于和小于Mg原子及共偏聚溶质原子间适当的结合倾向,Zn、Ca、Al等合金元素仍然是实现孪晶界偏聚诱导硬化的有效添加元素。Li等[51]于2020年在热轧态的Mg-1.6Zn-1.1Al-0.4Ca-0.6Mn合金中发现了Zn、Ca溶质原子共偏聚于孪晶界,并通过原子分辨率的HAADF-STEM表征解释了Zn、Ca原子在完全共格{10

上述工作表明,Zn、Ca原子在Mg的孪晶界上存在强烈的偏聚倾向,且对孪晶界钉扎作用显著。Li等[32]于2022年成功地在Mg-2.0Zn-0.5Ca合金中利用孪晶界偏聚实现了高烘烤硬化响应。结果表明,在对该合金进行T4和2%预拉伸应变处理后,组织中出现了{10

图5

图5

烘烤硬化态Mg-2.0Zn-0.5Ca合金的TEM分析[32]

Fig.5

TEM analyses of the bake-hardened Mg-2.0Zn-0.5Ca alloy[32]

(a, e) BF-TEM images of twin boundary, taken from the [

(b, f) HAADF-STEM images of the white rectangle region in

(c, d) EDS mappings of the white rectangle region in

(g) line EDS scanning result of the white line in

3 Guinier-Preston (GP)区诱导烘烤硬化

值得一提的是,低合金含量Mg-Ca合金中,添加少量的Zn[55,56]和Al[57]元素可以将峰时效时间由30 h缩短至2 h,同时还提高了时效硬化能力。Zn或Al元素的添加使合金峰时效组织由粗大、稀疏的Mg2Ca相,转变为高密度的单原子层盘状Mg-Al-Ca/Mg-Zn-Ca GP区,是合金提高时效硬化响应的主要原因[55~57]。当位错切过GP区时,会受到其共格应变场的阻碍,从而有效地提高合金的强度[58]。此外,由于GP区与Mg基体间存在完全共格关系,且其尺寸细小,难以成为微孔的形核核心,因此不会导致合金塑性显著降低[59]。综上所述,GP区强化是低合金含量Mg-Al-Ca/Mg-Zn-Ca合金体系中提高强度、保持塑性的重要手段。Li等[60]通过APT和TEM表征发现,早期时效过程中,Mg-Ca合金中的Ca团簇密度不断降低,而Zn的添加有助于形成高密度Zn-Ca团簇,且在时效早期Zn-Ca团簇的密度不断增加。随着时效时间延长至峰时效,Mg-Zn-Ca合金中高密度的Zn-Ca团簇演化为大量的单原子层Mg-Zn-Ca GP区,而Mg-Ca二元合金中形成了粗大、稀疏的Mg2Ca相。该研究合理地解释了Zn添加对Mg-Ca合金时效硬化动力学和响应的影响机制。

Mg-Al-Ca/Mg-Zn-Ca合金中GP区的发现在近10年来极大地推动了低合金快速时效硬化领域的研究进展[58,61~69]。Nakata等[59]研究表明,挤压态Mg-1.3Al-0.3Ca-0.4Mn合金在200 ℃下仅需30 min即可达到峰时效,屈服强度提升高达100 MPa左右。相比之下,Li等[70]的研究表明,Mg-1.6Zn-0.5Ca-0.4Zr合金板材也具有较快的时效硬化响应,但是其时效屈服强度增值仅为46 MPa。Bhattacharyya等[71~73]随后系统地研究并解释了上述现象。通过弹粘塑性自洽(EVPSC)模型分别分析了经固溶和峰时效处理后,挤压态Mg-1.31Al-0.33Ca-0.46Mn合金沿不同方向的拉伸和压缩变形行为[71],发现Mg-Al-Ca GP区对柱面滑移的阻碍力要远大于基面滑移。这一差异归因于GP区对柱面滑移的额外化学键合抗力,或者是GP区引起的共格应变场对位错从基面到柱面进行交滑移的阻力[71]。Bhattacharyya等[73]随后的研究表明,轧制态Mg-1.2Al-0.4Ca-0.5Mn合金经过固溶和峰时效处理后,由于织构较弱,沿轧制方向进行拉伸变形的过程中产生易产生基面滑移和孪生。然而,挤压态Mg-1.31Al-0.33Ca-0.46Mn合金经过固溶和峰时效后,在沿挤压方向拉伸变形过程中易产生柱面滑移[71~73]。因此,即使在GP区密度完全相同的情况下,由于织构较弱,轧制Mg-Zn-Ca(-Al)系板材合金的时效硬化响应可能要明显低于挤压合金。

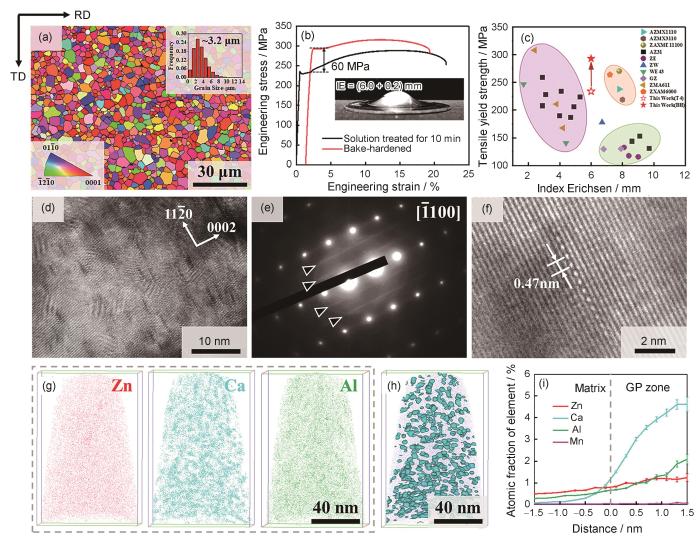

在烘烤硬化过程中,如果形成高密度Mg-Al-Ca/Mg-Zn-Ca GP区,则可得到40~60 MPa的时效强化效果。然而,通过GP区、位错偏聚及孪晶界偏聚实现高额烘烤硬化响应,均需高温固溶处理以在Mg基体内保留足量的溶质原子。在高温固溶处理过程中,轧制获得的细晶组织(约3 μm)不可避免地粗化至10~50 μm。取镁合金的Hall-Petch系数为205 MPa·μm0.5[74,75]进行计算,得出细晶强化效果会相应地降低50~90 MPa,是有限的烘烤硬化难以弥补的。因此,在固溶处理过程中稳定细晶组织,同时获得显著的烘烤硬化性能是提高烘烤硬化镁合金强度的重要手段。Meng等[33]研究表明,Mg-1.61Zn-0.57Mn-0.54Ca-0.46Al (ZMXA2110)合金具有高密度、热稳定的核壳结构Al-Mn相(β-Mn结构),因而获得了优异的细晶组织热稳定性,即在450 ℃固溶处理下保持晶粒尺寸< 3.4 μm超过30 min (图6a[33])。由于固溶态ZMXA2110合金具有细晶组织和弱织构,其具有优异的屈服强度(高达约230 MPa)和良好的杯突成型性(图6b[33])。经历拉伸预应变2%和200 ℃、30 min的烘烤处理后,固溶态ZMXA2110合金的流变应力提高约60 MPa,屈服强度约达293 MPa (表1[31~36]),综合性能超过了大部分板材镁合金(图6b和c[33])。TEM和APT结果(图6d~i[33])表明,高密度的Mg-Al-Zn-Ca GP区是烘烤硬化响应的主要来源。该工作成功地在镁合金中同时利用了细晶强化和烘烤硬化机制,为开发高强度、低合金含量镁合金板材提供了新思路。

图6

图6

固溶态和烘烤硬化态Mg-1.61Zn-0.57Mn-0.54Ca-0.46Al (ZMXA2110)合金TEM和APT分析及力学性能[33]

Fig.6

TEM and APT analyses and mechanical properties of the Mg-1.61Zn-0.57Mn-0.54Ca-0.46Al (ZMXA2110) alloy[33]

(a) electron backscattered diffraction (EBSD) image of ZMXA2110 alloy under solution treatment at 450 oC for 10 min (Inset is the distribution of grain size. RD—rolling direction, TD—transverse direction)

(b) strain-stress curves of solution treated and bake-hardened ZMXA2110 alloy (Inset is the Erichsen cupping test result of the solution treated ZMXA2110 alloy. IE—index Erichsen)

(c) tensile yield strength and IE value of ZMXA2110 alloy and other Mg sheet alloys

(d-f) TEM (d) and high resolution TEM (HRTEM) (f) images and SAED (e) pattern of bake-hardened ZMXA2110 sample which were obtain along the [10

(g-i) atom maps (g), APT map of Mg and iso-concentration surface of 1.0%Ca (atomic fraction) (in cyan) (h), and concentration proxigram histogram corresponding to the iso-concentration surface in

4 总结与展望

综上所述,烘烤硬化处理是提高低合金含量镁合金性能的有效手段。通过低温短时烘烤热处理,诱导溶质原子在位错、孪晶界等缺陷处快速偏聚,或析出形成高密度GP区,从而阻碍位错运动,提高镁合金强度。随着高分辨透射电镜及三维原子探针技术的发展,对烘烤硬化作用机制的研究也在不断深入。本工作重点总结了低合金含量镁合金体系中的烘烤硬化响应机制,探讨了溶质原子种类及合金中引入的缺陷类型对烘烤硬化强度提升的影响机制。为推动低合金含量镁合金走向大规模应用,充分利用烘烤硬化提升镁合金性能,仍需要在以下方面取得进一步的突破。

(1) 开发新型高烘烤硬化响应低合金含量镁合金体系。目前,可烘烤硬化的低合金含量镁合金体系较为单一,研究主要集中于Mg-Zn-Ca(-Al)系镁合金。这是由于Zn、Al、Ca元素扩散速率快,且与Mg原子及其互相之间结合能力强,在低温短时的烘烤处理过程中,上述元素可在缺陷处迅速偏聚或析出,从而使合金具有较高的烘烤硬化响应效果。然而,为了推动镁合金在汽车制造过程中大规模应用,亟需进一步系统性地研究并开发具有性能特色且应用于不同场景的系列烘烤硬化镁合金,如高成型性、高耐蚀性镁合金。

(2) 深入探究低合金含量镁合金烘烤硬化机制,进一步提高低合金含量镁合金强度。低合金含量镁合金初始强度普遍偏低,目前通过烘烤处理后可实现约60 MPa的强度提升,合金服役拉伸性能已接近6XXX系铝合金。然而,烘烤过程中,溶质原子的利用还可进一步提高。目前,铝合金的预时效处理对烘烤硬化性能影响的研究已较为普遍,然而相关研究在镁合金中仍然较为少见。此外,微合金化元素的添加对镁合金溶质偏聚及GP区析出的影响研究亟待开展。

(3) 利用烘烤硬化过程中的溶质再分配,提高低合金含量镁合金的晶粒稳定性。镁合金具有较高的Hall-Petch系数,因此其细晶强化效率高。在高温固溶处理下稳定低合金含量镁合金的细晶组织,有助于同时实现烘烤硬化和细晶强化,从而使合金具有较高的服役强度。目前Mg-Zn-Ca-Al-Mn系合金可以实现在450 ℃固溶处理温度下稳定地获得晶粒尺寸约3.4 μm的细晶组织。鉴于此,亟需开发具有类似稳定性的合金体系,并进一步突破该热稳定性,以期实现更高的服役强度。

参考文献

Current research and future prospect on microstructure stability of superplastic light alloys

[J].There have been numerous attempts to achieve superplasticity in light alloy materials for improving the formability and manufacture efficiency of them. However, the superplasticity of light alloy is difficult to realize for the uniform fine equiaxed grains, which are generally required by superplasticity, tend to rapidly grow during high temperature deformation. That means the superplasticity of light alloys not only requires an equiaxed fine-grained structure, but also needs to ensure the high-temperature structural stability. Thus, adding a second phase or alloying elements become one of the current research hotspots on superplasticity of light alloy materials. Currently, the main strategies for improving stability of the fine-grained structure of superplastic light alloy materials can be summarized as: introduction of second-phase particles pinning grain boundaries, phase structure of dual-phase alloys to inhibit growth between each other and reinforcement of composite materials inhibiting grain growth as well as utilizing solute segregation of single-phase alloys. This paper summarizes the research status of superplastic microstructure stability of light alloys including second-phase-containing alloys, duplex alloys, metal matrix composites and single-phase alloys. Finally, the paper proposes the development trend of superplastic light alloy materials from the perspective of industrial applications and cost-reduction requirements. Increasing the variety of alloying element, decreasing the content of alloying element, simplifying the process of manufacture and achieving low temperature superplasticity and high strain-rate superplasticity will be the development trend of superplastic light alloy materials.

超塑性轻合金组织稳定性的研究进展及展望

[J].金属材料超塑性一般要求具有均匀细小的等轴晶粒,并且在高温超塑变形过程中能够保持晶粒尺寸稳定性,避免晶粒快速长大。轻合金的超塑性不仅要具备等轴细晶组织,还需要通过引入第二相或合金元素等来保证材料的高温组织稳定性,这也是当前金属材料超塑性的研究热点之一。目前提高超塑性材料细晶组织稳定性的策略主要包括:析出第二相粒子钉扎晶界,双相合金的相结构之间抑制彼此生长,复合材料的增强体抑制晶粒长大以及单相合金的溶质原子偏聚等。本文概述了含析出第二相合金、双相合金、金属基复合材料和单相合金等轻合金超塑性组织稳定性的研究现状,并从工业应用需求及降低生产成本的角度,提出了超塑性材料的发展趋势。

Current research and future prospect on low-alloyed high-performance wrought magnesium alloys

[J].Wrought magnesium alloys have a wide range of applications by controlling the microstructure and optimizing the deformation process to improve the mechanical properties. Low-alloyed magnesium alloys have great advantages in formability, corrosion resistance, and light weight. Moreover, low alloying and high performance have become important trends in the development of wrought magnesium alloys. This study reviews the research progress of low-alloyed, high-strength, high-plasticity, and superplastic wrought magnesium alloys regarding alloy composition design, strengthening and toughening mechanisms, and processing technology. From the perspective of improving production efficiency and expanding application scope, the development trend of low-alloyed wrought magnesium alloys is proposed.

低合金化高性能变形镁合金研究现状及展望

[J].变形镁合金通过调控微观组织、优化变形工艺,提高材料的力学性能,从而具有广泛的应用前景。低合金化镁合金在成形性、耐腐蚀性及轻量化等方面具有较大优势。低合金、高性能成为变形镁合金发展的重要趋势之一。本文重点概述了低合金化高强、高塑、超塑性变形镁合金在合金成分设计、强韧化机制及加工技术等方面的研究进展,并从提高生产效率、扩大应用范围的角度,展望了低合金化变形镁合金的发展趋势。

Grain refinement mechanism and research progress of magnesium alloy incorporating Zr

[J].Grain refinement stands out as the primary strengthening mechanism in magnesium alloys. Zr emerges as the most effective grain refiner for magnesium alloys in the absence of Al, Si, etc. Typically, Zr is introduced in the form of an Mg-Zr master alloy. The crucial factor for achieving effective grain refinement in magnesium alloys incorporating Zr lies in regulating the morphology of Zr elements in the Mg-Zr master alloy, distinguishing between particle Zr and solute Zr. This study presents the theoretical groundwork for grain refinement. Drawing upon the growth restriction theory and heterogeneous nucleation theory, the refinement mechanism of soluble Zr and particle Zr on magnesium alloys is discussed. The discussion also identifies the engineering application bottleneck associated with Zr-refined magnesium alloys. A comprehensive review of advancements in Zr-refined magnesium alloy research is conducted, encompassing particle Zr and solute Zr. This review highlights the synergistic design strategy proposed for Zr-refined magnesium alloys. Ultimately, the anticipated development trends for Zr-refined magnesium alloys is prospected.

含Zr镁合金晶粒细化机理与研究进展

[J].

Research progress on the mechanisms controlling high-temperature oxidation resistance of Mg alloys

[J].This paper briefly reviews the progress on high-temperature oxidation mechanisms of pure Mg and Mg alloys, the thermodynamics and kinetics of high-temperature oxidation of Mg alloys, and the antioxidation mechanism of Mg alloys. The potential of applying advanced characterization techniques in studying the high-temperature oxidation of Mg alloys is envisaged. Finally, the development trends of the oxidation-resistant Mg alloy are also summarized. The main viewpoints are as follows: The protection of magnesium alloys at high temperatures is provided by the formation of a continuous, dense oxide scale that is a specific thickness and prevents the outward diffusion of magnesium vapor and the inward diffusion of oxygen; the oxidation resistance of Mg alloys is usually closely related to the thermal stability of the second phases; when the trace alloy elements are not enough to form the corresponding surface oxide scale, the oxidation resistance can be improved by creating a substitutional solid solution and using the reactive element effect; the size of the oxide grain size decreases and then enhances the oxidation resistance once the surface active elements is enriched on the surface of the alloys; the selective oxidation and synergistic effect of alloying elements are critical to the oxidation resistance of Mg alloys; the addition of nano or microparticles into the Mg alloys improve the high-temperature oxidation resistance of the Mg alloy by reducing the size of specific oxidation sensitive regions. In the future, the research on the high-temperature oxidation of Mg alloys can be based on the following aspects: Investigating the processes and nature of the oxidation resistance of Mg alloys using cutting-edge characterization techniques; constructing the underlying connections between the alloying elements and the oxide scale grain size and mechanical properties; designing and optimizing multi-alloying element composition systems.

镁合金抗高温氧化机理研究进展

[J].

Microstructure evolution mechanism of new low-alloyed high-strength Mg-0.2Ce-0.2Ca alloy during extrusion

[J].

新型低合金化高强Mg-0.2Ce-0.2Ca合金挤压过程中的组织演变机理

[J].基于Pandat相图设计了一种新型的Mg-0.2Ce-0.2Ca (质量分数,%)三元合金,经常规挤压变形后的屈服强度约364 MPa、总合金化含量约0.4%,实现了高强度、低合金化。对挤压过程中不同阶段的组织进行表征,发现Mg-0.2Ce-0.2Ca合金中的孪晶存在于挤压的整个阶段,表现出了高的孪晶迁移阻力,并且在挤压变形的中后期,部分动态再结晶晶粒沿着孪晶变体交割区域形核,导致孪晶界面比例显著降低。Mg-0.2Ce-0.2Ca合金在挤压变形的早期阶段即存储了大量<c + a>位错,这些位错的运动阻力大,因此位错主导的回复再结晶机制直至挤压变形的后期才大量启动,并直接促进了该阶段镁合金中高比例超细晶粒的形成。分析认为,Mg-Ce-Ca合金挤压过程中微观组织演变的主要原因是Ca元素的添加提升了Mg基体孪晶运动阻力,且Ce、Ca元素的共添加诱导了多系滑移。

Effect of rare earth element Ce on the bulk texture and mechanical anisotropy of as-extruded Mg-0.3Al-0.2Ca-0.5Mn alloy sheets

[J].

稀土元素Ce对挤压态Mg-0.3Al-0.2Ca-0.5Mn合金板材体织构及力学各向异性的影响

[J].针对Mg-0.3Al-0.2Ca-0.5Mn合金在热挤压过程中容易形成对称性差的强基面织构从而导致力学性能各向异性的问题,本工作通过稀土元素Ce合金化的方法优化其基面织构进而改善材料的力学性能。利用中子衍射技术,结合SEM和EBSD等微观测试手段,研究稀土元素Ce对Mg-0.3Al-0.2Ca-0.5Mn挤压态镁合金板材的微观组织、体织构和力学各向异性的影响。结果表明,随着Ce含量的增加,挤压态镁合金板材中的第二相颗粒逐渐从Al<sub>8</sub>Mn<sub>5</sub>转变为Al<sub>8</sub>Mn<sub>4</sub>Ce和Al<sub>11</sub>Ce<sub>3</sub>,且第二相颗粒数量明显增多。0.05%Ce (质量分数)的添加并未明显改变合金板材的基面织构,而添加0.5%Ce后合金板材沿着挤压方向(ED)的双峰基面织构向双峰非基面织构转变,同时沿横向(TD)分布的丝织构组分明显减少,从而使得沿着ED和TD的拉伸屈服强度比值接近于1,合金板材各向异性显著降低。

Magnesium extrusion alloys: A review of developments and prospects

[J].Magnesium (Mg) alloys have received a significant interest in the past 20 years, owing to a nonlinearly increasing demand for lightweight structural materials. Magnesium extrusions alloys to date have had lower industrial uptake than their counterpart aluminium extrusion alloys, predominantly due to lower extrudability and formability, tension-compression yield asymmetry and no clear advantage in the specific strength. Any improvement in extrusion alloy properties requires a better understanding of the effects of alloy composition and processing conditions; and how these dictate the final alloy microstructure. This review sheds insightful information on the processing-microstructure-property relationships of extruded magnesium alloys. Historical and recent progress in magnesium extrusion alloys is critically reviewed, including the advances in extrudability, mechanical properties and microstructural characterisation. The challenges associated with the 'gap' in properties between the magnesium and aluminium extrusion alloys are identified, and prospects discussed regarding the development of high performance magnesium extrusion alloys.

A review of superplastic magnesium alloys: Focusing on alloying strategy, grain structure control and deformation mechanisms

[J].In response to the urgent demand for lightweight, magnesium (Mg) alloys have garnered considerable attention owing to their low density. Nonetheless, the intrinsic poor room-temperature formability of Mg alloys remains a major obstacle in shaping precise complex components, necessitating the development of superplastic Mg alloys. Excellent superplasticity is usually acquired in high-alloyed Mg alloys with enhanced microstructural thermal stability facilitated by abundant optimized second-phase particles. While for cost-effective low-alloyed Mg alloys lacking particles, regulating solute segregation has emerged as a promising approach to achieve superplasticity recently. Moreover, the potential of bimodal-grained Mg alloys for superplastic deformation has been revealed, expanding the options for designing superplastic materials beyond the conventional approach of fine-grained microstructures. This study reviews significant developments in superplastic Mg alloys from the view of alloying strategies, grain structure control and deformation mechanisms, with potential implications for future research and industrial applications of superplastic Mg alloys.

Development of weak-textured and high-performance Mg-Zn-Ca alloy sheets based on Zn content optimization

[J].

Enhanced ductility of Mg-1Zn-0.2Zr alloy with dilute Ca addition achieved by activation of non-basal slip and twinning

[J].

Achieving high ductility and low in-plane anisotropy in magnesium alloy through a novel texture design strategy

[J].

Texture evolution during static recrystallization of cold-rolled magnesium alloys

[J].

A heat-treatable Mg-Al-Ca-Mn-Zn sheet alloy with good room temperature formability

[J].

Designing a magnesium alloy with high strength and high formability

[J].Although magnesium alloys, as the lightest structural alloys, offer significant potential for automotive applications, their applications remain limited due to their poor formability at room temperature. Since the strategies used for improving formability usually result in a degradation of strength, there are no high strength magnesium alloys showing good formability. Here we report an alloy design concept that can simultaneously provide high strength and good formability. Such designed alloy when subjected to an appropriate processing technique shows a combination of strength and formability that surpasses those of the existing magnesium alloys reported so far. The alloy design concept used in the present study is based on the utilization of alloying elements that can induce precipitation, as well as maximize the segregation of other texture-controlling alloying elements. Such developed alloy is expected to broaden the application of Mg alloy sheets, which are now starting to gain acceptance by automotive industries.

Bake-hardenable Mg-Al-Zn-Mn-Ca sheet alloy processed by twin-roll casting

[J].

Dislocation theory of yielding and strain ageing of Iron

[J].

Three-dimensional atomic-scale imaging of impurity segregation to line defects

[J].Clouds of impurity atoms near line defects are believed to affect the plastic deformation of alloys. Three-dimensional atom probe techniques were used to image these so-called Cottrell atmospheres directly. Ordered iron-aluminum alloys (40 atomic percent aluminum) doped with boron (400 atomic parts per million) were investigated on an atomic scale along the <001> direction. A boron enrichment was observed in the vicinity of an <001> edge dislocation. The enriched region appeared as a three-dimensional pipe 5 nanometers in diameter, tangent to the dislocation line. The dislocation was found to be boron-enriched by a factor of 50 (2 atomic percent) relative to the bulk. The local boron enrichment is accompanied by a strong aluminum depletion of 20 atomic percent.

Effects of Zn addition on the natural ageing behavior and bake hardening response of a pre-aged Al-Mg-Si-Cu alloy

[J].

Zn添加对预时效态Al-Mg-Si-Cu合金自然时效和烘烤硬化性的影响

[J].

Study of Mn and P solute distributions and their effect on the tensile behavior in ultra low carbon bake hardening steels

[J].With the increasing requirement of vehicle weight reduction and energy conservation from automobile industry, the investigation and development of high strength steel sheet has been stressed extensively. Bake hardening steel, as a new kind of automotive steel, exhibits low strength and good formability before drawing, after which increases obviously in the yield strength during baking process, and is then widely used in the outer plate of modern cars. Mn and P are often added to sheet steel to increase the strength, and their distributions have significant effect on drawability, bake hardening property and surface quality of bake hardening steels. In this paper, the distributions of Mn and P and their effect on tensile behavior in bake hardening steels were studied. For investigation, two kinds of bake hardening steels (BH–Mn and BH–P steels) were heated to 800 ℃, held for 2 min and cooled by water quenching. Three dimensional atom probe (3DAP) technique, internal friction experiments and tensile tests were carried out to analysis the effect of Mn and P distribution patterns on the interstitial atom distribution and Cottrell atmosphere in the matrix, so as to obtain the influence of solute istributions on tensile behavior. The results indicate that P segregates mainly in bake hardening steel, and part of P segregates together with C, which strongly pin the dislocations and is the main reason that induces the yield point elongation during tensile process. In BH–Mn steel, Mn hardly segregates in the matrix and C segregates very little, so the strength of BH–Mn steel is lower than that of BH–P steel, whereas the plasticity is better than BH–P steel. The segregation of P together with C and its pinning of dislocations will influence Snoek–Ke–Koster internal friction, and mkes the disappearance of Snoek–Ke–Koster peak.

Mn和P在超低碳烘烤硬化钢中的分布形态及其对拉伸行为的影响研究

[J].

The effects of preaging treatments on aging kinetics and mechanical properties in AA6111 aluminum autobody sheet

[J].

Bake-partitioning in a press-hardening steel

[J].

Effects of natural aging after pre-aging on clustering and bake-hardening behavior in an Al-Mg-Si alloy

[J].

Competition between grain boundary segregation and Cottrell atmosphere formation during static strain aging in ultra low carbon bake hardening steels

[J].

Cottrell atmospheres along dislocations in long-period stacking ordered phases in a Mg-Zn-Y alloy

[J].

Solute segregation assisted nanocrystallization of a cold-rolled Mg-Ag alloy during annealing

[J].

Effect of dislocation configuration on Ag segregation in subgrain boundary of a Mg-Ag alloy

[J].

Pre-strain mediated fast natural aging in a dilute Mg-Zn-Ca-Sn-Mn alloy

[J].

Rapid dislocation-mediated solute repartitioning towards strain-aging hardening in a fine-grained dilute magnesium alloy

[J].

Enhanced strength-ductility synergy achieved through twin boundary pinning in a bake-hardened Mg-2Zn-0.5Ca alloy

[J].

Achieving extraordinary thermal stability of fine-grained structure in a dilute magnesium alloy

[J].

Design of solute clustering during thermomechanical processing of AA6016 Al-Mg-Si alloy

[J].

Forming characteristics of artificial aging Al-Mg-Si-Cu sheet alloys

[J].

Summary of steel sheet in Cherry Car Co.

[J].

奇瑞轿车用钢板

[J].

Excellent synergy of formability and strength of a Mg-Zn-Y-Ca-Zr alloy by tailoring segregation-assisted weak elliptical ring texture

[J].

Periodic segregation of solute atoms in fully coherent twin boundaries

[J].The formability and mechanical properties of many engineering alloys are intimately related to the formation and growth of twins. Understanding the structure and chemistry of twin boundaries at the atomic scale is crucial if we are to properly tailor twins to achieve a new range of desired properties. We report an unusual phenomenon in magnesium alloys that until now was thought unlikely: the equilibrium segregation of solute atoms into patterns within fully coherent terraces of deformation twin boundaries. This ordered segregation provides a pinning effect for twin boundaries, leading to a concomitant but unusual situation in which annealing strengthens rather than weakens these alloys. The findings point to a platform for engineering nano-twinned structures through solute atoms. This may lead to new alloy compositions and thermomechanical processes.

Unusual solute segregation phenomenon in coherent twin boundaries

[J].Interface segregation of solute atoms has a profound effect on properties of engineering alloys. The occurrence of solute segregation in coherent twin boundaries (CTBs) in Mg alloys is commonly considered to be induced by atomic size effect where solute atoms larger than Mg take extension sites and those smaller ones take compression sites in CTBs. Here we report an unusual solute segregation phenomenon in a group of Mg alloys-solute atoms larger than Mg unexpectedly segregate to compression sites of {10[Formula: see text]1} fully coherent twin boundary and do not segregate to the extension or compression site of {10[Formula: see text]2} fully coherent twin boundary. We propose that such segregation is dominated by chemical bonding (coordination and solute electronic configuration) rather than elastic strain minimization. We further demonstrate that the chemical bonding factor can also predict the solute segregation phenomena reported previously. Our findings advance the atomic-level understanding of the role of electronic structure in solute segregation in fully coherent twin boundaries, and more broadly grain boundaries, in Mg alloys. They are likely to provide insights into interface boundaries in other metals and alloys of different structures.

$\left\{ 10\bar{1}1 \right\}$ twin boundary structures in a Mg-Gd alloy

[J].

Effect of twin boundary segregation on damping properties in magnesium alloy

[J].

Removing basal-dissociated<c + a> dislocations by $\left\{ 10\bar{1}2 \right\}$ deformation twinning in magnesium alloys

[J].

Segregation potency at $\left\{ 10\bar{1}2 \right\}$ and $\left\{ 10\bar{1}1 \right\}$ twin boundaries in Mg with Zn and Ca co-addition: A first-principles study

[J].

Room temperature deformation-induced solute segregation and its impact on twin boundary mobility in a Mg-Y alloy

[J].

Origin of twin-like $\left\{ 33\bar{6}4 \right\}$ tilt boundary and associated solute segregation in a high strain rate deformed Mg-Y alloy

[J].

Atomic-scale insights into grain boundary-mediated plasticity mechanisms in a magnesium alloy subjected to cyclic deformation

[J].

Atomic segregation at twin boundaries in a Mg-Ag alloy

[J].

Control of twin boundary mobility by solute segregation in Mg binary alloys

[J].

Formation and solute segregation for an asymmetric tilt boundary on $\left\{ 10\bar{1}2 \right\}$ twin boundaries

[J].

Role of Zn on the room temperature formability and strength in Mg-Al-Ca-Mn sheet alloys

[J].

Segregation-driven exceptional twin-boundary strengthening in lean Mg-Zn-Ca alloys

[J].

Precipitation and hardening in magnesium alloys

[J].

Improved bake-hardening response of Al-Zn-Mg-Cu alloy through pre-aging treatment

[J].

Precipitation hardening of Mg-Ca(-Zn) alloys

[J].

Age-hardening response of Mg-0.3at.%Ca alloys with different Zn contents

[J].

Enhanced precipitation hardening of Mg-Ca alloy by Al addition

[J].

Rational design of a lean magnesium-based alloy with high age-hardening response

[J].

Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys

[J].

Role of Zn on the rapid age-hardening in Mg-Ca-Zn alloys

[J].

High-speed extrusion of heat-treatable Mg-Al-Ca-Mn dilute alloy

[J].

Optimization of Mn content for high strengths in high-speed extruded Mg-0.3Al-0.3Ca (wt%) dilute alloy

[J].

Improving mechanical properties and yield asymmetry in high-speed extrudable Mg-1.1Al-0.24Ca (wt%) alloy by high Mn addition

[J].

Improving formability of Mg-Ca-Zr sheet alloy by microalloying of Zn

[J].

Improving room-temperature stretch formability of a high-alloyed Mg-Al-Ca-Mn alloy sheet by a high-temperature solution-treatment

[J].

Precipitation in lean Mg-Zn-Ca alloys

[J].

Atomic structures of ordered monolayer GP zones in Mg-Zn-X (X = Ca, Nd) systems

[J].

Revisited precipitation process in dilute Mg-Ca-Zn alloys

[J].

Enhanced age-hardening in a lean Mg-Al-Ca-Mn alloy by trace silver addition

[J].

Simultaneous achievement of high thermal conductivity, high strength and formability in Mg-Zn-Ca-Zr sheet alloy

[J].

Determining the strength of GP zones in Mg alloy AXM10304, both parallel and perpendicular to the zone

[J].Microalloyed, age-hardenable Mg alloys can exhibit an excellent balance between strength and ductility. One such alloy, AXM10304 (Mg-1.31A1-0.33Ca-0.46Mn in wt. %), possesses high extrudability with mechanical properties comparable to 6xxx-series Al alloys at considerably lower density. The mechanical properties are due to the presence of a high number density of disc-shaped GP zones parallel to the basal planes. The present work focuses on providing a mechanistic understanding of the effect of these GP zones, on both basal and prismatic slip. Using crystal plasticity simulations in conjunction with analytical strength modeling, the anisotropy in shear resistance of disc-shaped GP zones is quantitatively evaluated for the first time. It is shown that the passage of dislocations parallel to the zone (basal slip) experience a lower resistance compared to the case when the shearing occurs perpendicular to the zone (prismatic slip). This is not simply a geometrical effect; in fact, the geometry of basal discs favors the strengthening of basal slip when dislocations are not required to bow around the obstacles. Rather, it is hypothesized that the GP zone coherency strain fields contribute less resistance to basal slip as compared to prismatic slip. Furthermore, the possibility of a chemical effect is only present for the prismatic. Despite the fact that the harder mode (prismatic slip) is strengthened more than the soft, it is shown that the net strengthening effects still cause a decrease in the overall anisotropy of the individual grains, which may help to explain why the ductility is good, despite the high strength. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Origins of high strength and ductility combination in a Guinier-Preston zone containing Mg-Al-Ca-Mn alloy

[J].

Why rolled Mg-Al-Ca-Mn alloys are less responsive to aging as compared to the extruded

[J].

Solute strengthening of prismatic slip, basal slip and $\left\{ 10\bar{1}2 \right\}$ twinning in Mg and Mg-Zn binary alloys

[J].

Mechanistic investigation of a low-alloy Mg-Ca-based extrusion alloy with high strength-ductility synergy

[J].