近年来,研究人员发现,将脉冲电流应用于金属或合金的变形及热处理过程可以显著优化其微观组织并提高其力学性能及成形性能。Xu等[4]研究发现脉冲电流的非热效应可显著降低AZ31镁合金在轧制过程中动态再结晶(DRX)的临界温度,从而允许不同尺寸晶粒在金属塑性变形过程中相互协调并显著提高合金板材的塑性。王少楠[5]研究发现,电脉冲的热效应和非热效应耦合机制可以提高AZ31镁合金变形过程中的位错攀移速率,从而降低其冲压过程中的变形抗力并显著提高冲压极限。本课题组前期工作[6]发现,变形态合金内部的变形储能对脉冲电流处理后的晶粒细化效果有显著影响,并设计变温多道次等通道挤压(ECAP)实验制备高变形储能AZ61镁合金,利用高密度脉冲电流对合金进行静态处理,最终制备出高强韧化镁合金样品。

然而,目前关于脉冲电流处理的研究仍存在一些不足。首先,虽然脉冲电流对于变形镁合金的影响在多种塑性变形方式中均有报道,但关于脉冲电流对挤压过程中镁合金微观组织的影响尚缺乏深入研究,且研究主要集中在再结晶阶段,而当合金处于能够完全动态再结晶的临界变形条件时,施加脉冲电流对其变形过程中的微观组织演变以及非平衡相变的影响尚不明确。基于此,本工作通过自主搭建的脉冲电流辅助挤压(EPAE)平台开展脉冲电流辅助AZ91镁合金温挤压(250 ℃)实验,系统研究不同峰值电流密度条件下脉冲电流对AZ91镁合金挤压过程中β-Mg17Al12相的动态析出行为、微观组织和织构演变的影响。

1 实验方法

1.1 实验材料与工艺

采用商业AZ91镁合金铸锭作为原材料,其化学成分(质量分数,%)为:Al 8.79,Zn 0.73,Mn 0.2,Si < 0.005,Cu < 0.005,Ni < 0.005,Fe < 0.005,Mg余量。

采用KD-7740数控电火花加工机床将AZ91镁合金切割成直径40 mm、高30 mm的圆柱体试样。挤压前,试样在400 ℃下固溶处理12 h,然后在冷水中快速淬火。EPAE工艺和脉冲电流产生的方波示意图如图1所示。该装置主要分为导电系统。挤压系统、绝缘系统和温度记录系统。挤压时,先通过常规热挤压挤出一部分棒材,然后分别将电源正极和负极连接到挤压杆和挤出棒材,此时开启脉冲电源并继续挤压,同时利用放置在凹模出口处的热电偶记录样品实际挤出温度,最终完成EPAE过程。为保证AZ91镁合金在常规挤压时能够完全动态再结晶,本实验条件设定为:挤压比16∶1,挤压温度250 ℃,挤压速率1 mm/s。挤压前将润滑剂涂抹在AZ91镁合金样品表面以减少摩擦。常规热挤压(EX)和EPAE样品编号及相关实验参数列于表1。

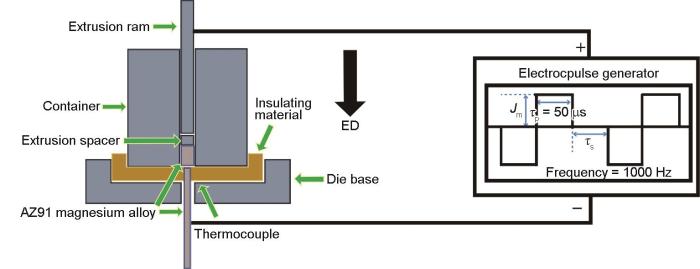

图1

图1

脉冲电流辅助挤压(EPAE)工艺以及脉冲电流产生的方波示意图

Fig.1

Schematic of the EPAE process and square wave generated by electric pulsing (EPAE—electropulse-assisted extrusion, ED—extrusion direction, Jm—peak pulse current density, τp—pulse width, τs—pulse spacing)

表1 AZ91镁合金的挤压工艺参数

Table 1

Sample | Ram velocity mm·s-1 | Extrusion ratio | Frequency Hz | Duration μs | Current intensity A | Current density 107 A·m-2 | Duty ratio |

|---|---|---|---|---|---|---|---|

| 250EX | 1 | 16∶1 | - | - | - | - | - |

| EPAE-1 | 1 | 16∶1 | 1000 | 50 | 10667 | 3.4 | 0.05 |

| EPAE-2 | 1 | 16∶1 | 1000 | 50 | 16000 | 5.1 | 0.05 |

| EPAE-3 | 1 | 16∶1 | 1000 | 50 | 20078 | 6.4 | 0.05 |

1.2 表征方法

用苦味酸腐蚀剂(苦味酸∶乙醇∶去离子水∶醋酸 = 1∶15∶2∶2,体积比)腐蚀样品后,使用VHX-2000光学显微镜(OM)和S8000扫描电子显微镜(SEM)的二次电子(SE)模式观察挤压方向(ED)-横向(TD)平面的微观组织,同时利用SEM的背散射电子成像(BSE)模式分析β-Mg17Al12相的形态及分布。使用15 kV X-MaxN能量色散X射线光谱仪(EDS)和D8 Advanced高分辨率旋转阳极X射线衍射仪(XRD)测定合金的相组成,CuKα,波长λ = 0.15406 nm,扫描速率4°/min。利用LYRA3XMH双光束聚焦离子束扫描电镜(FIB-SEM)上的电子背散射衍射(EBSD)系统进行EBSD表征,工作电压、工作距离和倾斜角度分别为20 kV、15 mm和70°。EBSD样品用砂纸机械研磨成镜面后在-20 ℃的ACⅡ电解液中电化学抛光100~200 s。使用Image-Pro Plus 6.0软件从获得的显微照片中统计不同类型及区域的晶粒和β-Mg17Al12相的平均尺寸和体积分数。

2 实验结果

2.1 铸态及固溶态合金的微观组织

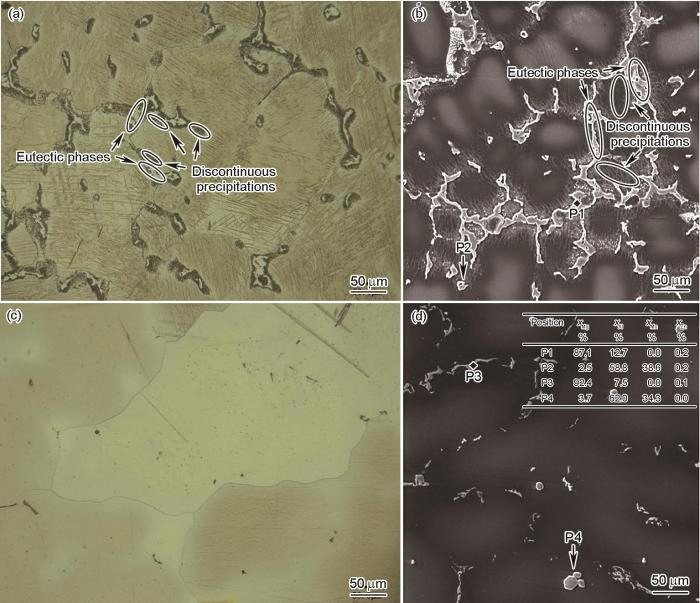

图2为铸态及固溶态AZ91镁合金的OM和BSE像。在铸态AZ91镁合金中可以观察到典型的树枝状组织(图2a和b),其中基体晶粒较为粗大,尺寸约为90 μm,在基体晶界处出现了一些具有网状结构的共晶相和一些非连续析出相(DP相),EDS结果(图2d插图)表明2者皆为β-Mg17Al12相,其中前者在凝固的最后阶段形成,后者在合金冷却到室温时在基体中析出[7]。固溶处理后,平均晶粒尺寸超过500 μm (图2c),共晶相和DP相大量溶解的同时在SEM-BSE像(图2d)及EDS结果中仍能发现少量残余,这是AZ91镁合金中Al元素含量较高导致的,但其在对应的XRD谱(图3a)中并无体现。在铸态和固溶态合金中均观察到微量白色圆形粒状第二相(P2和P4),EDS结果表明其为富Al-Mn相,推测该相为Al8Mn5相。由于形成温度高于α-Mg,因此即使经过长时间的均质处理Al8Mn5相也难以分解[7],但由于其含量较少,同样未在图3a中有所体现。

图2

图2

铸态和固溶态AZ91镁合金样品显微组织的OM及SEM-BSE像

Fig.2

OM (a, c) and SEM-BSE (b, d) images of the as-cast (a, b) and as-soluted (c, d) AZ91 magnesium alloys (Inset in Fig.2d shows the EDS results, xM —atomic fraction of element M)

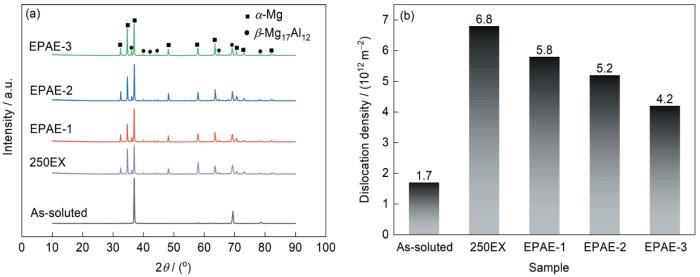

图3

图3

固溶态及挤压态AZ91镁合金的XRD谱及位错密度演变趋势

Fig.3

XRD spectra (a) and evolution of dislocation density (b) of as-soluted and extruded AZ91 magnesium alloys

2.2 挤压态合金的微观组织

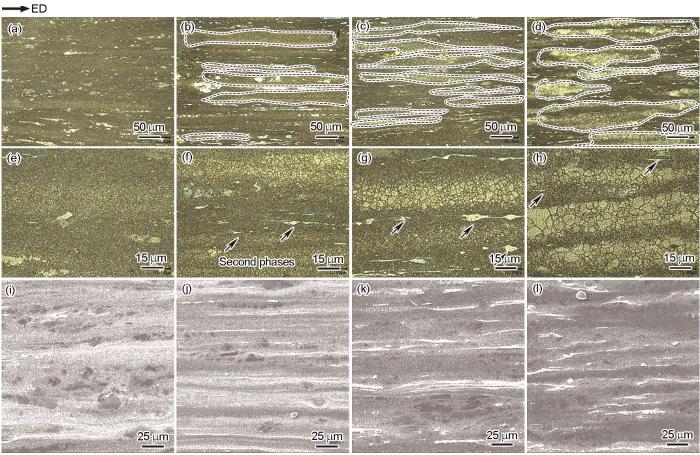

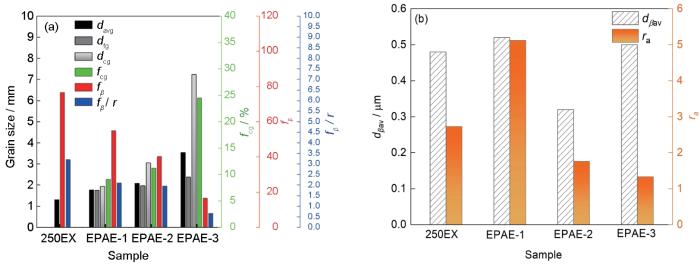

图4为各挤压条件下沿ED的AZ91合金的OM及SEM-BSE像,观察位置位于挤出棒材中心处,相关统计结果及演变规律如表2和图5a所示。根据图4a和e可知,250EX样品的微观组织由尺寸远小于固溶态样品的细小晶粒和均匀分布的第二相颗粒混合组成,说明完全实现DRX的同时发生了动态析出。当施加脉冲电流后,EPAE样品中出现粗晶粒并聚集成条带状分布(图4b~d中虚线标记区域),其与细晶粒条带共同组成双峰结构。由图4f~h可知,EPAE样品的粗晶粒条带内部第二相颗粒分布较少;细晶粒条带内有较多第二相颗粒,并出现了部分粗大的平行于ED的长条状第二相(如箭头所示)。随着电流密度的增大,粗晶粒条带面积分数(fcg)从EPAE-1样品的9.1%上升至EPAE-3样品的24.5%。根据SEM-BSE像(图4i~l)统计可知,样品整体的第二相颗粒体积分数(fβ)从250EX样品的76.9%下降至EPAE-3样品的16.5%。

图4

图4

挤压态AZ91镁合金样品的OM及SEM-BSE像

Fig.4

Low (a-d) and high (e-h) magnification OM images and SEM-BSE images (i-l) of the extrude AZ91 magnesium alloy samples (The black dashed areas in Figs.4b-d are coarse-grained areas, and the black arrows in Figs.4f-h are long-strip second phases)

(a, e, i) 250EX (b, f, j) EPAE-1 (c, g, k) EPAE-2 (d, h, l) EPAE-3

表2 挤压态AZ91镁合金样品中微观组织常数和挤出温度

Table 2

| Sample | davg / μm | dfg / μm | dcg / μm | fcg / % | fβ / % | dβav / μm | ra | fβ / r | Tp / oC |

|---|---|---|---|---|---|---|---|---|---|

| 250EX | 1.07 | - | - | - | 76.9 | 0.48 | 2.73 | 3.20 | 270 |

| EPAE-1 | 1.77 | 1.75 | 1.93 | 09.1 | 54.8 | 0.52 | 5.12 | 2.11 | 309 |

| EPAE-2 | 2.09 | 1.97 | 3.05 | 11.2 | 40.2 | 0.41 | 1.76 | 1.96 | 320 |

| EPAE-3 | 3.54 | 2.37 | 7.23 | 24.5 | 16.5 | 0.50 | 1.33 | 0.66 | 345 |

图5

图5

挤压态AZ91镁合金样品中不同类型晶粒及β-Mg17Al12相的平均尺寸和比例的演变趋势

Fig.5

Evolutions of average size and proportion of different types of grains (a) and β-Mg17Al12 phase (b) in extruded AZ91 magnesium alloy

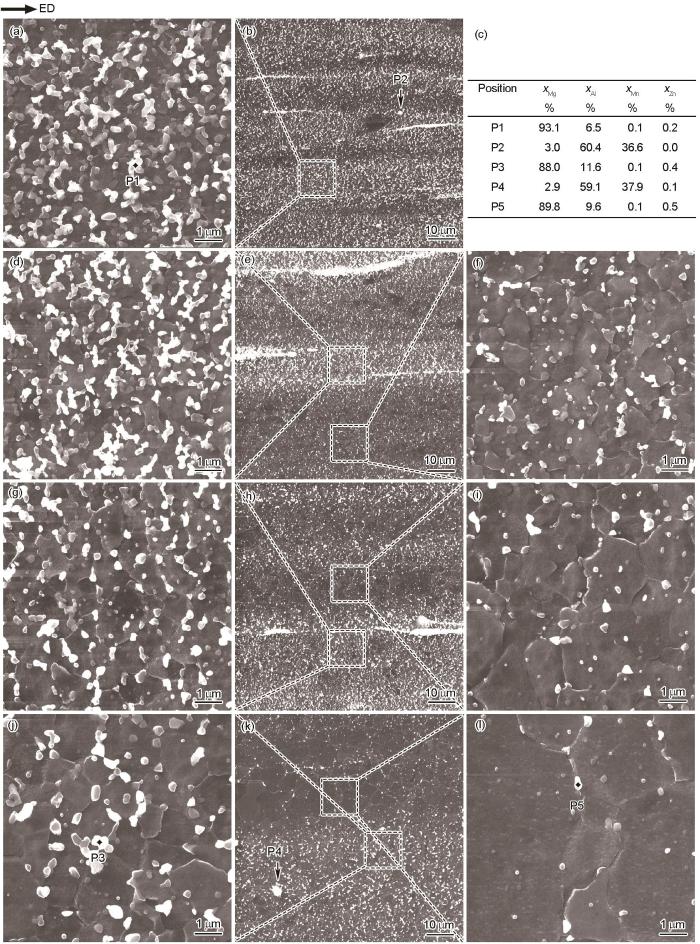

图6为250EX及EPAE样品的SEM-SE像和EDS结果,其中,图6b、e、h和k为各挤压样品低倍图像,图6d、g和j为EPAE样品细晶粒条带区域的放大图像,图6f、i和l为EPAE样品粗晶粒条带区域的放大图像;由于250EX样品显微组织分布较为均匀,因此只用图6a来表示其放大区域。根据SEM-SE像及其对应的晶粒演变规律(图5)和统计数据(表2)可知,250EX样品中平均晶粒尺寸(davg)仅为1.07 μm,同时晶界较为锐利,说明此时合金内部仍存在较高的应变储能。EDS结果(图6c)表明,250EX样品基体上方均匀分布的棒状第二相颗粒为β-Mg17Al12相,极少量白色圆形大颗粒为富Al-Mn相,其组成与图2中Al8Mn5相接近,研究[8]表明,Al8Mn5相在热加工中同样较为稳定,因此推测白色圆形颗粒相仍为Al8Mn5相。施加脉冲电流后,EPAE样品内部逐渐出现粗、细晶粒条带交替排列的双峰结构,随着电流密度的增大,细晶粒和粗晶粒的平均尺寸(dfg和dcg)分别由EPAE-1样品的1.75和1.93 μm增加到EPAE-3的2.37和7.23 μm;同时,细晶粒晶界形态逐渐趋于平直,说明残余应力逐渐减少。此外,根据EDS结果可知,EPAE-3样品中的第二相颗粒仍由β-Mg17Al12相及少量的Al8Mn5相组成,这说明脉冲电流的施加对于第二相的成分无显著影响。在各挤压样品中,无论是在粗晶区域或是细晶区域,相对粗大的β-Mg17Al12相往往集中在晶界处,而晶粒内部的β-Mg17Al12相尺寸相对较小,这可能与Al原子的不均匀分布有关。在常规情况下,挤压前的固溶过程中溶质原子的扩散系数(D1)可以用Arrhenius方程表示[9,10]:

图6

图6

挤压态AZ91镁合金样品的SEM-SE像及EDS结果

Fig.6

SEM-SE images (a, b, d-l) and EDS results (c) of the 250EX (a, b), EPAE-1 (d-f), EPAE-2 (g-i), and EPAE-3 (j-l) AZ91 magnesium alloy samples

(a, d, g, j) SEM-SE images of fine grain region (b, e, h, k) SEM-SE images of the whole region (f, i, l) SEM-SE images of coarse grain region

式中,D0为晶格扩散常数,Q为扩散激活能,Al原子在Mg基体中的D0和Q分别取1.2 × 109 m2/s和1.43 × 103 J/mol;R为理想气体常数,T为固溶温度。固溶过程中溶质原子在基体中的扩散距离(l)可以表示为:

式中,t为固溶时间。结合

图7

图7

EPAE-3样品微观组织形貌

Fig.7

SEM-SE image of the transition region from fine grain to coarse grain (a) and TEM image of fine grain region (b) of the EPAE-3 sample (The black dotted line in Fig.7b is the grain boundary)

式中,ε为微应变,d为位错壁包围的亚晶粒尺寸,b为Burgers矢量模。

式中,β

此外,在变形过程中为再结晶晶粒的形核、长大以及相变过程提供驱动力的变形储能(γDSE),一般以晶格畸变或缺陷的形式储存起来,因此其可以表示为以下形式[12]:

式中,K为常数,G为剪切模量。由

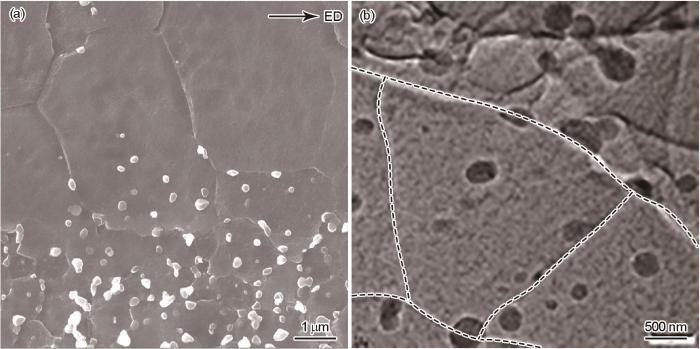

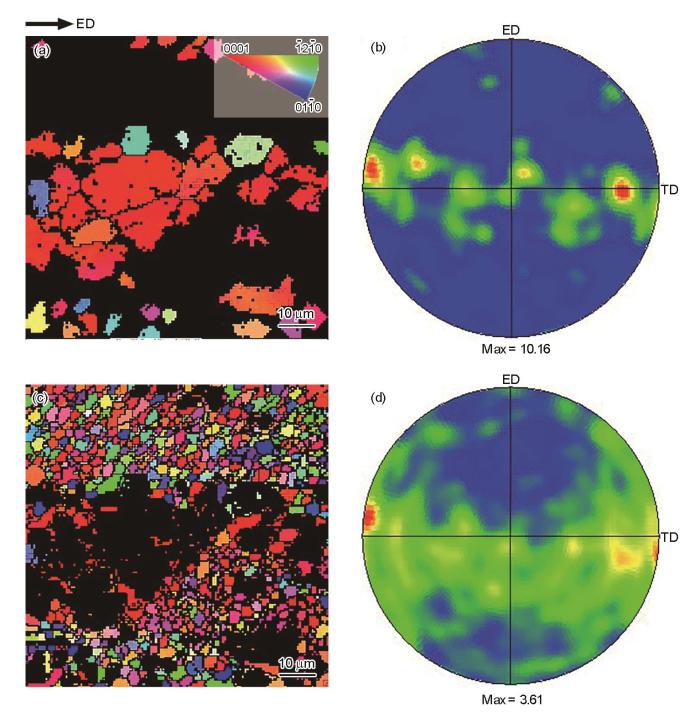

图8为250EX及EPAE-3样品的反极图(IPF)、(0001)极图(PF)和取向差分布。观察图8a和d可以看出,EBSD所表征出的微观结构与OM及SEM结果相似,其中黑色区域是第二相颗粒覆盖导致EBSD无法正常解析所造成的,因此图8a和d中的圆形和条带状的黑色区域(虚线标记区域)分别对应250EX及EPAE-3样品中团簇状第二相颗粒和长条状第二相颗粒。此外,相比于图8a,图8d中红色面积更大,根据色规可以推断,EPAE-3样品中基面取向晶粒的数量更多。图8b和e表明2种样品都具有典型的基面丝织构形态,但图8e中的丝织构轮廓比图8b更加集中,最大织构强度从3.39提高至5.92,这说明挤压态样品中大多数晶粒的(0001)面平行于ED,且EPAE工艺会促进晶粒旋转,从而增强基面织构强度,这与图8a和d的结果相一致。由图8c和f可知,随着脉冲电流的施加,低角度晶界(LAGB)比例(fLAGB)从250EX样品的23.42%显著降低至EPAE-3样品的7.46%。LAGB的产生是挤压过程中位错相互缠结及重排的结果,其可以在随后的变形过程中通过不断吸收可移动位错转变为大角度晶界(HAGB)[13]。因此,EPAE样品中LAGB比例的降低意味着脉冲电流能够促进LAGB对可动位错的吸收及向HAGB的转化,这同样会引起位错密度的降低。

图8

图8

250EX及EPAE-3样品典型的EBSD结果

Fig.8

Typical EBSD results of 250EX alloy (a-c) and EPAE-3 alloy (d-f) (TD—transverse direction, fLAGB—fraction of low angle grain boundary)

(a, d) invers pole figures (IPFs) (b, e) (0001) pole figures (PFs) (c, f) grain boundary misorientation angle distributions

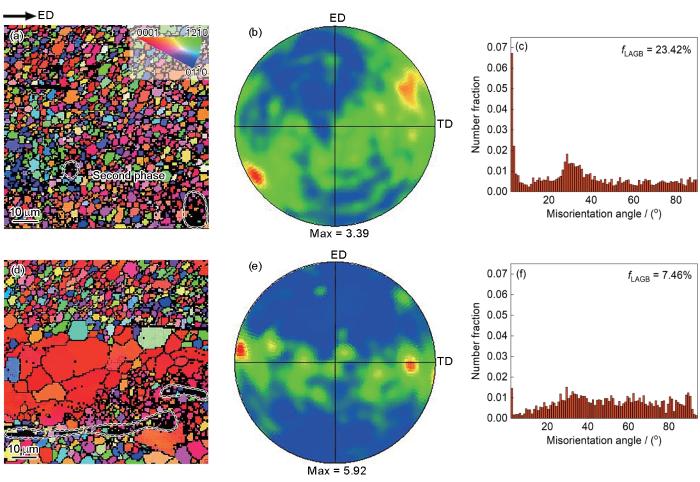

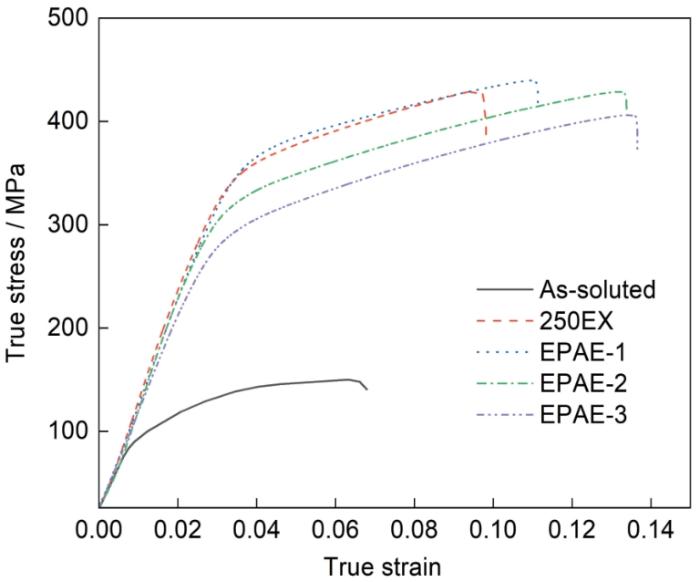

图9为固溶态及挤压态合金样品的室温拉伸真应力-真应变曲线,屈服强度(σy)、抗拉强度(σs)和断裂延伸率(δ)列于表3。可以看出,固溶态样品的强度和塑性较差,经过常规热挤压后,250EX样品的σy、σs和δ分别提升了220 MPa、278 MPa和3%,强度的提高是由于davg减小所带来的细晶强化、ρ提高所带来的位错强化以及大量析出的β-Mg17Al12相所带来的Orowan强化共同作用的结果,塑性的提高则是由于细小晶粒中的晶界滑移促进了拉伸过程中晶粒之间的相容性。施加脉冲电流后,虽然上述各项强化机制均会随着微观组织的变化而有所减弱,但EPAE-1样品的σy、σs和δ仍小幅提升至318 MPa、440 MPa及11.2%,强度的进一步提高可能是具有强基面取向的粗晶所带来的织构强化导致的,而ρ和fβ 的降低意味着样品在拉伸过程中应力集中和位错缠结情况有所减弱,从而促进了塑性进一步提高。随着电流密度的提高,σy、σs最终分别下降至240和406 MPa (EPAE-3样品),δ则进一步提升至13.7%,这表明此时davg增加及ρ和fβ 降低对强度的弱化作用大于织构的强化作用。

图9

图9

固溶态及挤压态样品的室温拉伸真应力-真应变曲线

Fig.9

True stress-strain curves of as-soluted and extruded samples at room temperature

表3 固溶态及挤压态AZ91合金样品的力学性能

Table 3

| Sample | σy / MPa | σs / MPa | δ / % |

|---|---|---|---|

| As-soluted | 81 | 150 | 6.8 |

| 250EX | 301 | 428 | 9.8 |

| EPAE-1 | 318 | 440 | 11.2 |

| EPAE-2 | 267 | 429 | 13.4 |

| EPAE-3 | 240 | 406 | 13.7 |

3 分析讨论

3.1 脉冲电流对动态析出的影响

综上实验结果可知,在AZ91镁合金挤压过程中施加脉冲电流能够抑制β-Mg17Al12相的动态析出并促进其球化。

在镁合金的变形过程中,β-Mg17Al12相的动态析出与溶解过程是同时存在的[14],当析出速率大于溶解速率时,材料即可表现出动态析出状态。因此,本工作中脉冲电流对于动态析出的抑制可看作其对β-Mg17Al12相溶解过程的增强。

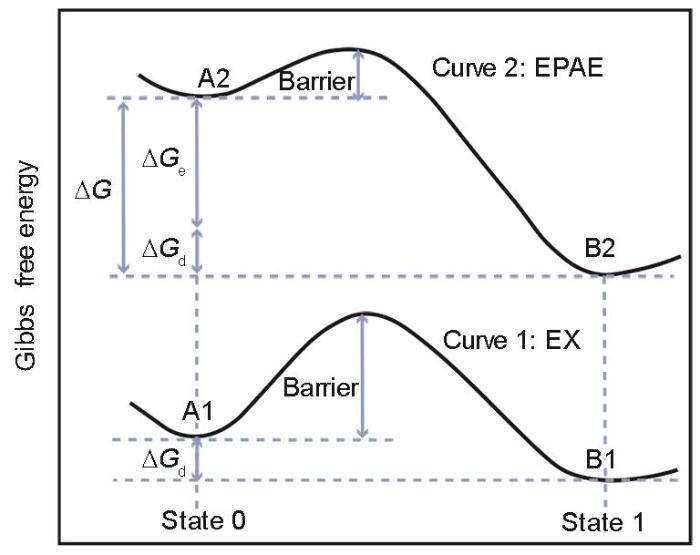

Jeong等[15]研究发现,相比于常规热变形,在脉冲电流辅助拉伸变形中,脉冲电流能够通过其非热效应降低AZ91镁合金中β-Mg17Al12相的溶解温度并促进固溶过程,再结合Shan等[16]的研究,本工作中脉冲电流对β-Mg17Al12相溶解过程的影响可以利用图10中Gibbs自由能的变化来描述,其中曲线1和曲线2分别表示常规热挤压和EPAE工艺中Gibbs自由能的变化,状态0和状态1分别代表挤压过程中β-Mg17Al12相溶解前和溶解后的合金样品状态。曲线1中,尽管状态1 (表示为B1)与状态0 (表示为A1)的自由能差ΔGd = GB1 - GA1 < 0,但由于能量势垒较高,因此β-Mg17Al12相溶解过程仍然较为困难。随着脉冲电流的引入,曲线2中状态1和状态0的Gibbs自由能(分别记为GA2和GB2)同时增大,2者的自由能差可表示为ΔG:

图10

图10

不同挤压条件下β-Mg17Al12相溶解过程中Gibbs自由能变化示意图

Fig.10

Schematic of Gibbs free energy changes during solution of β-Mg17Al12 phase under different extrusion conditions (ΔGd—thedifference in free energy between state 0 and state 1 in Curve 1, ΔG—thedifference in free energy between state 0 and state 1 in Curve 2, ΔGe—additional energy change caused by pulse current)

式中,ΔGe为脉冲电流在与常规热挤压处于相同状态(组成、温度、压力等)的系统中所能引起的附加能量变化。Qin等[17]发现变形金属试样的固态相变过程中ΔGe可写为:

式中,P为与材料相关的正常数,ΔV为再结晶晶核体积,σ1和σ2分别为固溶体和β-Mg17Al12相的电导率,ξ(σ1, σ2)为与晶核和介质电性质的有关的常数,可以表示为[21]:

由于在β-Mg17Al12相溶解过程中,σ1 > σ2[22],从而导致ξ(σ1, σ2) < 0,因此根据

值得注意的是,β-Mg17Al12相溶解过程是一种扩散相变,即使满足热力学条件,如果没有长程扩散,这种相变也不会发生,这意味着脉冲电流对挤压过程中的原子扩散同样有重要影响。由于平衡的原子浓度即意味着平衡的空位浓度,可以采用空位扩散通量来衡量脉冲电流中的热效应和非热效应,其中脉冲电流在单位时间内由热效应引起的空位扩散通量(Jt)可以用下式表示[4]:

式中,C0为空位浓度指前因子;f和τp分别为脉冲电流频率和脉宽;Qv为空位扩散形成能;ΔTp为单个脉冲在单位时间内引起的样品的温升;Nl为原子浓度;R0 - r0为与割阶有关的常数;Tp为本实验中样品的绝对温度。ΔTp可表示如下[23]:

式中,I为峰值电流强度;Re为电阻;cp 为比热容;m为样品质量;t0为单位时间,即1 s。通过上述内容可知,本实验中Jt主要由ΔTp、Tp和D1决定。随着脉冲电流密度的增大,ΔTp与Tp同时增大,则可以计算出EPAE-1~EPAE-3样品的

式中,f′为扩散系统常数,α为晶格常数,ν为原子振动频率,k为Boltzmann常数,Δs为活化熵。研究[24]发现,脉冲电流非热效应引起的能量增加可以提高原子振动频率。一旦原子从脉冲电流中获得足够的能量,其跳跃到空位的可能性将大大增加,这也会增大Δs并提高D0。综上所述,脉冲电流的热效应和非热效应会同时增大D1,此时结合ΔTp与Tp的相对变化可知,Jt会随着脉冲电流密度的提高而增大。

式中,Ni 为第i个原子的密度,Z *eρeJ为电子与原子之间的相互作用关系(其中,Z*为有效化合价,e为电子电荷,ρe为电阻率),J为平均电流密度,本实验中所用到的电流的脉冲形式为双极方波,因此J可以表示为:

式中,Jm为峰值电流密度,τs为脉冲间距,因此Ja可以表示为:

从上式可以看出,本实验中Ja同时受到D1、Jm和Tp的影响,但由于Jm与I成正比,因此

然而,无论是脉冲电流的何种作用,其对于β-Mg17Al12相的析出抑制情况均会受到不同晶粒中应变能差异[29]以及固溶样品中Al溶质原子微观偏析的影响,因此EPAE样品中β-Mg17Al12相的动态析出分布呈不均匀条带状。

此外,根据合金的Gibbs-Thomson效应,变形镁合金中β-Mg17Al12相不同曲率半径对应的α-Mg基体中Al溶质原子的浓度差为[30]:

式中,Cr1和Cr2分别为β-Mg17Al12相曲率半径为r1和r2处所对应的Al合金元素浓度;C1为α-Mg基体中Al溶质原子和表面曲率半径所对应的平衡浓度;Ω为β-Mg17Al12相的摩尔体积;σ为β-Mg17Al12相与α-Mg基体之间的界面能。由上式可知,β-Mg17Al12相曲率半径越小,其附近Al溶质原子浓度越高。而脉冲电流对原子扩散的促进作用会促使棒状β-Mg17Al12相中的Al溶质原子从曲率半径较小的位置(如棒状相的尖端、缺陷处)向曲率半径较大的位置(如棒状β-Mg17Al12相的平整表面)扩散,因此促进了棒状β-Mg17Al12相发生球化。

3.2 脉冲电流及动态析出对晶粒长大的影响

一般来说,晶粒长大过程可以看作是晶界迁移的结果,根据生长动力学,在挤压过程中,晶界移动速率(V)可表示为[31]:

式中,M0为晶界移动常数,

式中,γ是晶界张力,r为晶粒平均半径,α'为与材料相关的常数,

此外,晶粒长大的动力学条件还可用晶界活动性(B)来表示[32]:

式中,Db为晶界扩散系数,可以表示为:

结合式(

对晶粒长大同样有重要影响的还有β-Mg17Al12相。由2.2节可知,EAPE样品中细晶区的β-Mg17Al12相数量多于粗晶区,同时,随着电流密度的增大,dfg的长大程度小于dcg,这表明β-Mg17Al12相对于晶粒的生长存在限制作用。

图7b为EPAE-3样品细晶区的TEM像。可见,有大量动态析出的β-Mg17Al12相分布在晶界处和晶内。其中,主要分布于晶界处的粗大β-Mg17Al12相的平均粒径约为250 nm,晶粒内部相对较小β-Mg17Al12相平均粒径约为95 nm。研究[33,34]发现,晶界处粗大β-Mg17Al12相可以通过对晶界施加钉扎力来阻碍其迁移,进而抑制晶粒长大,而晶粒内部的球形或近球形的β-Mg17Al12相更倾向于阻碍位错的运动,从而在一定程度上抑制DRX晶粒的形核及长大。由

综合3.1及3.2节可以推断,EPAE样品中双峰组织的形成是脉冲电流引起的晶粒长大和β-Mg17Al12相不均匀析出及其钉扎作用共同导致的。

3.3 脉冲电流及动态析出对织构的影响

图11

图11

EPAE-3样品粗晶区和细晶区的典型EBSD结果

Fig.11

Typical EBSD results of EPAE-3 sample in coarse grain region (a, b) and fine grain region (c, d)

(a, c) IPFs (b, d) (0001) PFs

式中,

4 结论

(1) EPAE工艺能够有效抑制β-Mg17Al12相的动态析出并促进其球化,同时促进晶粒的长大。与250 ℃常规热挤压相比,经过峰值电流密度为6.4 × 107 A/m2的EAPE处理的AZ91镁合金中β-Mg17Al12相体积分数从76.9%显著降低至16.5%并发生球化,平均晶粒尺寸从1.07 μm增加到3.54 μm。

(2) EPAE过程中β-Mg17Al12相对晶界的钉扎作用限制了晶粒的长大,其不均匀分布导致了挤压态AZ91镁合金中双峰组织的形成。

(3) 基面<a>滑移对挤压变形过程的主导作用促使挤压态样品呈现基面织构。此外,EPAE工艺可以显著提高合金整体的基面织构强度。相比于250 ℃常规热挤压,峰值电流密度为6.4 × 107 A/m2的EPAE制备的AZ91镁合金样品最大织构强度从3.39增加至5.92。

(4) EPAE工艺对合金组织的改变主要是通过脉冲电流中的热效应和非热效应对AZ91镁合金挤压过程中的Gibbs自由能变化量、原子扩散通量以及位错运动速率的提高来实现的。

参考文献

Magnesium alloys development towards the 21st century

[J].

Magnesium: Properties-applications-potential

[J].

Effect of heat treatment on strain hardening of ZK60 Mg alloy

[J].

Thermal and electromigration effects of electropulsing on dynamic recrystallization in Mg-3Al-1Zn alloy

[J].

Effect of electric pulses on drawability and corrosion property of AZ31 magnesium alloy

[D].

电脉冲对AZ31镁合金冲压性能和腐蚀性能的影响

[D].

Extraordinary mechanical properties of AZ61 alloy processed by ECAP with 160° channel angle and EPT

[J].

Microstructure and mechanical properties of as-extruded AZ80-xSn magnesium alloys

[J].

The effect of Mn-rich precipitates on the strength of AZ31 extrudates

[J].

Acceleration de la diffusion chimique sous irradiation dans le systeme aluminium-magnesium

[J].

Dissolution of eutectic β-Mg17Al12 phase in magnesium AZ91 cast alloy at temperatures close to eutectic temperature

[J].

Microstructure evolution and mechanical properties of an AZ61 alloy processed with TS-ECAP and EPT

[J].

Stored energy, microstructure, and flow stress of deformed metals

[J].

Deformation behavior, microstructure evolution, and dynamic recrystallization mechanism of an AZ31 Mg alloy under high-throughput gradient thermal compression

[J].

Refined microstructure and dispersed precipitates in a gradient rolled AZ91 alloy under pulsed current

[J].

Effect of pulsed electric current on dissolution of Mg17Al12 phases in as-extruded AZ91 magnesium alloy

[J].

Microstructural evolution and precipitate behavior of an AZ61 alloy plate processed with ECAP and electropulsing treatment

[J].

Electropulse-induced cementite nanoparticle formation in deformed pearlitic steels

[J].

Influence of an electric or magnetic field on the liquid-solid transformation in materials and on the microstructure of the solid

[J].

Effect of electric current pulses on grain size in castings

[J].

Segregation of lead in Cu-Zn alloy under electric current pulses

[J].

Effect of electropulsing treatment on microstructure and tensile fracture behavior of aged Mg-9Al-1Zn alloy strip

[J].

The effect of a.c. frequency on precipitation in Al-5.6 at % Zn

[J].

On the temperature rise associated with the electroplastic effect in titanium

[J].

Overview no. 49: On the mechanisms for the electroplastic effect in metals

[J].

Effect of billet diameter on hot extrusion behavior of Mg-Al-Zn alloys and its influence on microstructure and mechanical properties

[J].

Spherical shape of γ-Mg17Al12 precipitates in AZ91 magnesium alloy processed by equal-channel angular pressing

[J].

Effects of initial texture on deformation behavior during cold rolling and static recrystallization during subsequent annealing of AZ31 alloy

[J].This study demonstrates that the initial texture of Mg alloy significantly affects the microstructure developed during cold rolling and the recrystallization behavior during subsequent annealing. In a sample with a texture oriented toward the normal direction (ND sample), thick and large-sized shear bands are intensively formed during cold rolling and the deformation is strongly localized along these bands. In contrast, in a sample with a texture oriented toward the transverse direction (TD sample), many {10-12} twins are formed at the early stage of cold rolling, and then, numerous small-sized shear bands are formed in these twins. Results of nanoindentation tests reveal that the cold-rolled ND sample has internal strain energy that is substantially concentrated along the shear bands, whereas the cold-rolled TD sample has a large amount of internal strain energy that is homogeneously distributed throughout the material; this latter behavior is strongly related to the extensive {10-12} twinning and the resultant microstructural variations in the TD sample. During subsequent annealing, recrystallization occurs locally along the shear bands in the ND sample, which leads to the formation of a bimodal grain structure comprising fine recrystallized grains and coarse unrecrystallized grains. In contrast, during subsequent annealing of the TD sample, static recrystallization occurs homogeneously throughout the material, which results in the formation of a uniform grain structure that mostly comprises equiaxed recrystallized grains.

Spheroidizing kinetics of eutectic carbide in the twin roll-casting of M2 high-speed steel

[J].

The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials

[J].

Strain-induced dynamic precipitation of Mg17Al12 phases in Mg-8Al alloys sheets rolled at 748 K

[J].

Development of Mg-6Al-4Sn-1Zn alloy sheets with ultra-high strength by combining extrusion and high-speed rolling

[J].

Dynamic precipitation and recrystallization mechanism during hot compression of Mg-Gd-Y-Zr alloy

[J].Hot compression tests of Mg-Gd-Y-Zr alloy at different deformation temperatures and strains were carried out with Gleeble-1500 simulator at strain rate of 0.002 s-1. The microstructure evolution of 400 degrees C/0.002 s-1 sample under different strain was analyzed emphatically by transmission electron microscopy and electron backscatter diffraction technology. Dynamic precipitation characteristics and nucleation-expansion mechanism of dynamic recrystallization (DRX) were discussed in detail. The results indicated that the dynamic precipitation takes place prior to DRX, and the morphology, size and distribution of precipitates change with increasing strain. At the later stage of deformation, the large-size hard phase b-Mg5(Gd,Y) can induce the particle-stimulated nucleation (PSN) mechanism under large strain and act as an effective nucleation site for DRX. In addition, we constructed a schematic diagram of the DRX nucleation-expansion mechanism of Mg-Gd-Y-Zr alloy under high temperature deformation. The first layer of DRX grains is formed by discontinuous dynamic recrystallization (DDRX) mechanism characterized by grain boundary bulge out, and the precipitates distributed at the original grain boundary promote DDRX nucleation; The expansion of necklace structure depends on continuous dynamic recrystallization (CDRX) mechanism; Subgrain division can further refine DRX grains. (c) 2021 The Author(s). Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

A study of the electroplastic effect in metals

[J].

Additional results on the electroplastic effect in metals

[J].

Dislocation structure evolution under electroplastic effect

[J].

Texture enhancement during grain growth of magnesium alloy AZ31B

[J].