75Cr1钢属于高端锯片用钢,广泛应用于机械、石材等切削加工领域。由于其较高的C、Mn、Cr含量,75Cr1钢具有较高的热裂纹敏感性,给内部质量控制带来了难度[1]。同时,锯片长期在共振、较大侧压力和拉应力下服役,这要求锯片的钢基体具有一定的弹性强度、疲劳强度和冲击韧性。钢中非金属夹杂物会打破钢基体的连续性,并容易造成应力集中而萌生裂纹,钢中残余的低熔点有害元素也会对钢的力学性能产生影响,需要尽可能提高钢的纯净度,并使钢中的夹杂物细小弥散分布,以减轻对钢基体的危害[2~5]。研究[6~9]表明,晶粒细化也有利于提高钢材的力学性能,降低钢的热裂纹敏感性。此外,75Cr1钢在服役过程中长期与冷却介质接触,并且使用环境多为工业环境,因此其在侵蚀性阴离子的作用下容易被腐蚀。而腐蚀又以局部腐蚀为主,局部腐蚀中以点蚀最为常见[10]。非金属夹杂物是点蚀的主要诱发源,夹杂物的尺寸、种类、形貌、数量对点蚀具有很大的影响[11~20]。因此,洁净化、均质化、细晶化是生产高品质锯片钢的关键所在。

稀土与钢中的O和S都具有较强的结合能力,加入钢中后能降低钢中O、S含量,达到净化钢液的目的[21,22]。稀土处理后的钢在夹杂物尺寸、形貌和数量方面均能得到较大的改善,所生成的稀土夹杂物具有较高的熔点且能稳定存在于钢水中[23~25]。与Al2O3等夹杂物相比,稀土夹杂物与钢基体的弹性模量更为接近,在钢的热加工成型过程中有利于减轻钢基和夹杂物界面的应力集中,从而提高钢的耐疲劳性能和韧性[4]。稀土夹杂物还可以在钢液的凝固过程中作为初晶相的形核质点,起到细化晶粒的作用[26,27]。另一方面,稀土元素可以变质硫化物夹杂形成点蚀敏感性较低的稀土氧硫化物或稀土硫化物夹杂,进而提高钢的耐点蚀性能[28~30]。我国有着较为丰富的稀土资源,本工作拟通过向75Cr1钢中加入稀土来净化钢液、改质夹杂,同时达到钢的组织细化和增强耐蚀性能的目的,为制备高品质锯片用钢提供技术参考和理论支撑。

1 实验方法

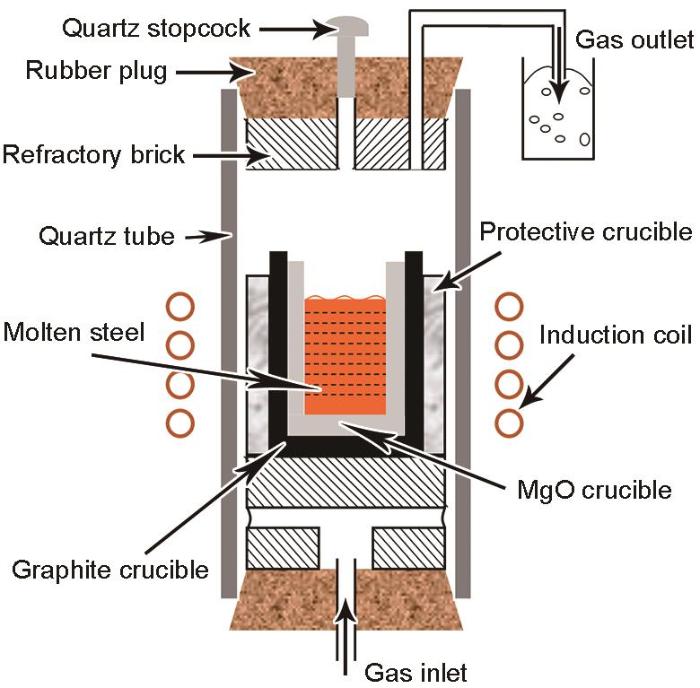

实验所用75Cr1钢来自于某钢厂生产的板坯,板坯化学成分(质量分数,%)为:C 0.76,Si 0.29,Mn 0.6938,Al 0.013,Cr 0.51,Ti 0.0040,Fe余量。考虑到实际生产过程中多为镁质耐火材料,实验所用坩埚为MgO坩埚,外套石墨坩埚,加热设备为高频感应炉,装置如图1所示。实验前将感应炉通入高纯Ar气(99.999%,体积分数) 5 min以驱赶炉膛中的残余气体,然后通电升温至1600℃后保温5 min加入用铁箔包裹的Ce块(99.9%),继续保温5 min使之均匀化,随后停炉冷却。重复实验,5组实验中Ce的添加量(质量分数,下同)分别为0、0.01%、0.03%、0.05%、0.08%,得到5组不同Ce含量的实验用钢。

图1

钢中Ce含量的检测按GB/T 14635—2020进行,准确称取约0.35 g钢样置于烧杯中,加入20 mL盐酸(体积比HCl∶H2O = 1∶1)和10 mL水在60℃溶解,待钢样溶解后加入5 mL HClO₄加热冒白烟至白烟消失,降温冷却至室温后加入5 mL硝酸 (体积比HNO3∶H2O = 1∶1),再次加热到60℃后逐滴加入H2O2至沉淀完全溶解,随后冷却至室温定容,利用DGS-III型电感耦合等离子体原子发射光谱仪(ICP-AES)分析Ce含量。5组钢中Ce含量分别为0、0.0074%、0.0195%、0.0260%、0.0416%,对应的试样分别命名为C1、C2、C3、C4和C5。

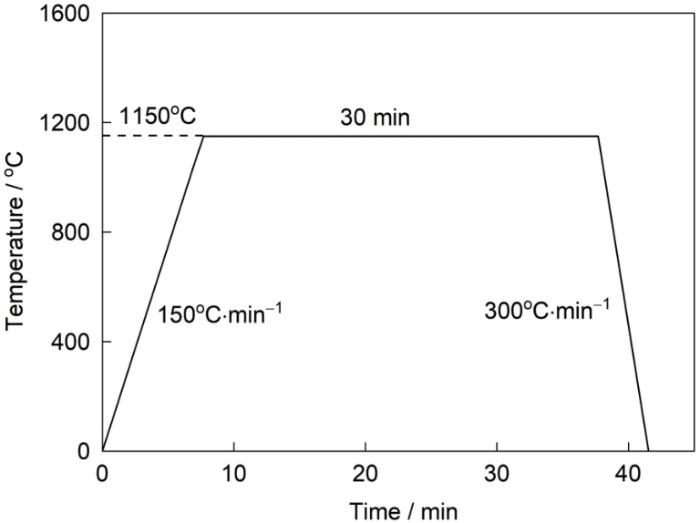

经线切割对样品加工后,钢中O、S含量由LECO TC500氧氮分析仪和LECO CS744碳硫分析仪测定;通过Nova 400 Nano扫描电子显微镜(SEM)和LE350 PentaFETx-3能谱仪(EDS)检测夹杂物的成分、尺寸和数量;利用SEM在1000倍下随机拍摄30张图,再通过Image-Pro-Plus 6.0软件对钢中夹杂物尺寸与数量进行统计。利用Lasertec VL2000DX高温激光共聚焦扫描显微镜(CLSM)在1150℃下原位观察C1、C3和C5实验用钢奥氏体晶粒长大行为,升降温路线如图2所示。同时,使用JMatPro7.0软件计算钢在降温过程中的相分布。

图2

通过电化学极化实验检测钢的耐点蚀性能,试样尺寸为10 mm × 10 mm × 5 mm,背面焊接上铜线,并用环氧树脂进行封装,露出10 mm × 10 mm的表面。在进行电化学测试之前,使用粒度为5 μm的砂纸将试样表面湿磨至光滑无划痕,经抛光后用丙酮脱脂、酒精与蒸馏水冲洗,随后在干燥箱中进行干燥。利用PARSTAT 2273型电化学综合测试仪对上述材料进行电化学极化曲线测试,电极体系为标准的三电极体系,实验溶液为3.5%NaCl (质量分数)溶液,以饱和甘汞电极(SCE)作为参比电极,实验用钢为工作电极,Pt片作为辅助电极。

2 结果与讨论

2.1 钢中O、S含量的变化

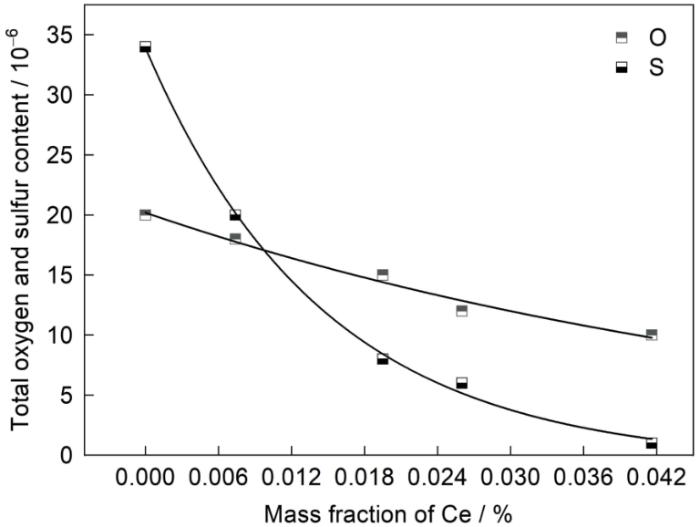

图3

图3

钢中总O、S含量随Ce含量的变化

Fig.3

Variation of total oxygen and sulfur content in steel with Ce content

2.2 夹杂物特征的演变

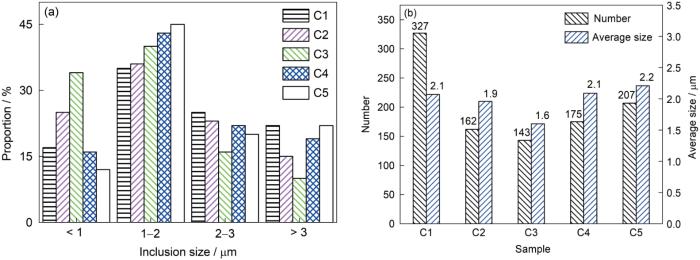

除了总O和S含量,夹杂物的数量、尺寸和形貌也是反映钢洁净度的重要标志。图4所示为钢中夹杂物尺寸与数量分布。可以看出,随着Ce含量的增加(0%~0.0416%),5组钢中小尺寸夹杂物(< 3 μm)所占比例分别为78%、85%、90%、81%和78%,夹杂物平均粒径分别为2.1、1.9、1.6、2.1和2.2 μm,同时夹杂物数量也呈现先减小后增加的趋势。一般而言,钢中总O含量越高,夹杂物的数量和尺寸也相应增加[32,33]。夹杂物尺寸和数量的统计结果表明,随着Ce的加入,钢的洁净度先提高后降低。这与2.1节中随着Ce的加入,O、S含量不断降低的趋势不符。为了更好地解释这一现象,有必要对夹杂物的形貌和成分特征进行分析。

图4

图4

钢中夹杂物尺寸和数量分布

Fig.4

Sizes (a) and number distributions (b) of inclusions in steels (C1: 0%Ce, C2: 0.0074%Ce, C3: 0.0195%Ce, C4: 0.0260%Ce, C5: 0.0416%Ce)

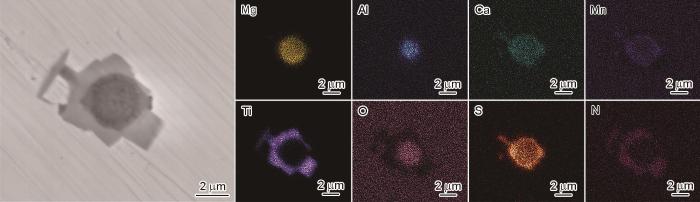

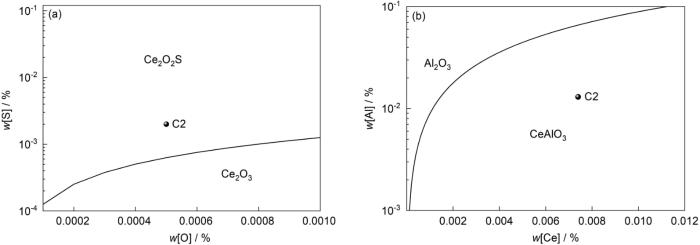

图5所示为未采用稀土处理的C1钢中典型夹杂物的形貌和元素分布。可以看出,钢中典型夹杂物主要是以Ca-Mg-Al-O为核心、外围包裹着MnS和CaS、最外层有TiN析出的夹杂物。C2钢中Ce可以置换出夹杂物中的Al,钢中典型夹杂物发生改性,主要包含2类夹杂,其中一类以Mg-Ca-Ce-O-S为核心,边缘有TiN析出(图6a),表明部分原始Ca-Mg-Al-O夹杂物中的Al已经被Ce完全置换出来,且形成了Ce2O2S;同时钢中也发现了Ca-Mg-Ce-Al-O-S夹杂,表明原始夹杂物中仍有部分夹杂物中的Al未被Ce完全还原,且形成了Ce2O2S-CeAlO3夹杂(图6b)。根据表1中Ce、Al、O、S相互作用的热力学公式(1)~(3)及相关热力学数据[34],可以计算得出1600℃下Ce处理过程中的O-S平衡曲线和Al-Ce平衡曲线,如图7所示。热力学计算[35]表明当前钢液成分下,钢中溶解氧含量在0.0005%以下,从图7a可以看出,Ce含量为0.0074%时,钢中O、S含量成分点处于形成Ce2O2S夹杂物的稳定区。图7b显示,针对原始75Cr1钢中溶解Al含量为0.013%,当钢中溶解Ce含量大于0.0014%时,就可能形成CeAlO3夹杂。实验结果与计算结果展现出很好的一致性。

图5

图5

C1钢中夹杂物的典型形貌及元素分布

Fig.5

Morphology and element distributions of typical inclusions in C1 steel

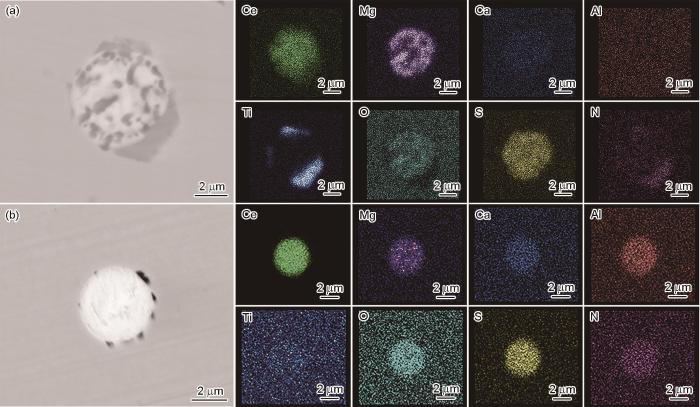

图6

图6

C2钢中典型夹杂物的形貌和元素分布

Fig.6

Morphologies and element distributions of typical inclusions in C2 steel

(a) Ce2O2S (b) Ce2O2S-CeAlO3

| ΔGθ / (J·mol-1) | No. | |

|---|---|---|

| (1) | ||

| (2) | ||

| (3) | ||

| (4) | ||

| (5) | ||

| (6) |

图7

图7

1600℃下钢液中O-S平衡曲线和Ce-Al平衡曲线

Fig.7

O-S equilibrium curve (a) and Ce-Al equilibrium curve (b) in molten steel at 1600oC (w[M]—mass fraction of dissolved element M in liquid steel)

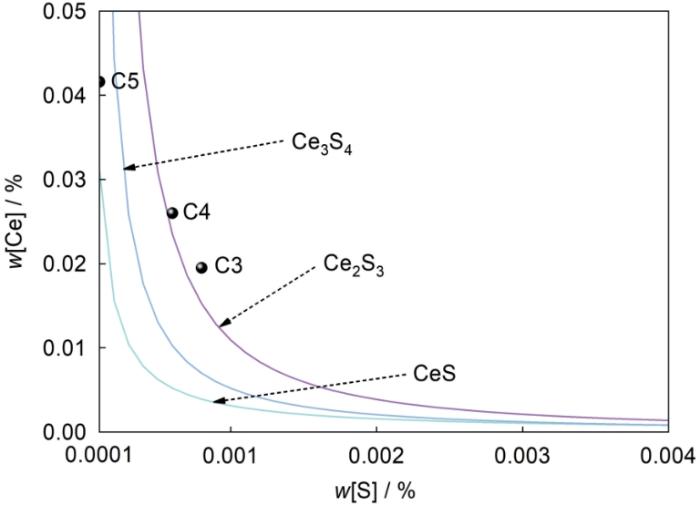

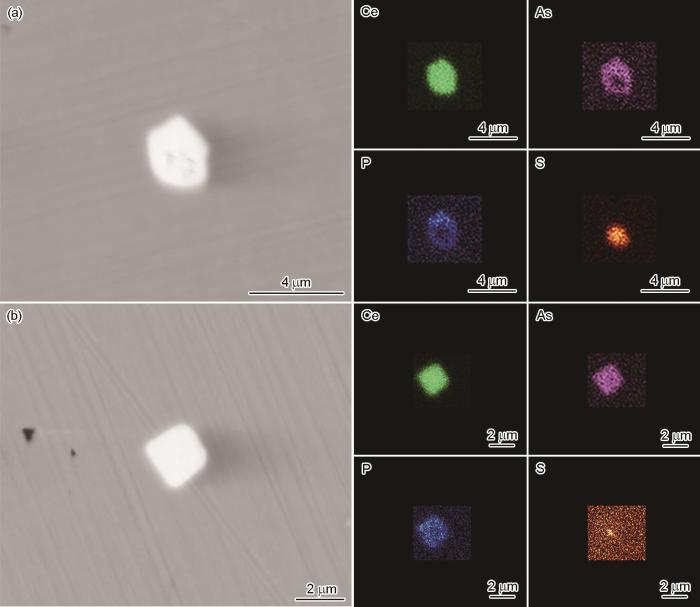

图8所示为C3钢中典型夹杂物的形貌和元素分布。可以看出,夹杂物为Ce x S y 夹杂。这表明Ce含量为0.0195%时,钢中原始的Ca-Mg-Al-O复合夹杂被彻底还原改性。根据表1中的热力学公式(4)~(6)可以计算得出1600℃下Ce处理过程中的Ce-S平衡曲线,如图9所示。O含量较低的情况下,稀土表现出较强的脱硫能力,夹杂物开始转变为稀土硫化物。随着稀土Ce含量进一步增加(0.0260%和0.0416%),钢中O、S含量进一步降低,尤其是S含量降低到较低水平(图3),开始出现稀土的磷化物和砷化物,如图10所示。稀土的磷化物和砷化物中仍然含Ce x S y,随着Ce含量提高,磷化物和砷化物中Ce x S y 含量减少。这也就解释了为何Ce含量从0到0.0416%逐步提高时,钢中O、S含量一直降低,而钢中的夹杂物数量和尺寸先减小后增加,因为Ce含量超过0.0195%时,稀土夹杂物主要以磷化物和砷化物为主,氧硫夹杂减少。此外,从夹杂物的形貌来看,随着Ce含量的增加,夹杂物形貌先从不规则形状转变为球状,当Ce过量后又转变为不规则形状(图6、8和10)。本实验条件下,0.0195%Ce的含量最有利于钢中形成球状的稀土夹杂物,这将有利于减轻稀土夹杂物和钢基体之间的应力集中,提升钢的性能。

图8

图8

C3钢中典型夹杂物的形貌和元素分布

Fig.8

Morphology and element distributions of typical inclusions in C3 steel

图9

图10

图10

C4和C5钢中典型夹杂物的形貌和元素分布

Fig.10

Morphologies and element distributions of typical inclusions in C4 (a) and C5 (b) steels

2.3 热处理过程中奥氏体晶粒长大行为

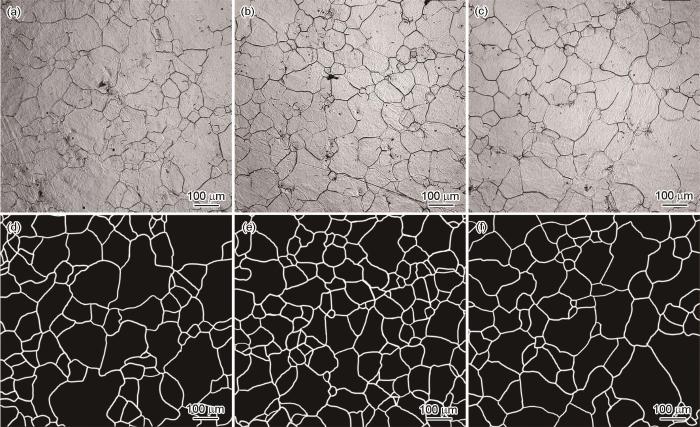

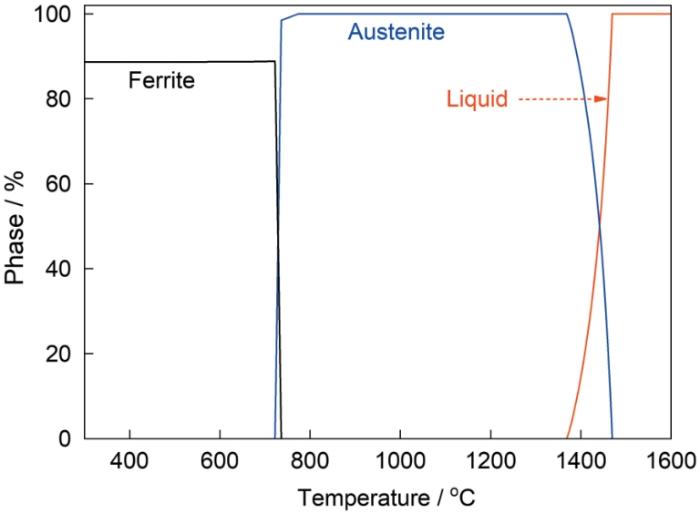

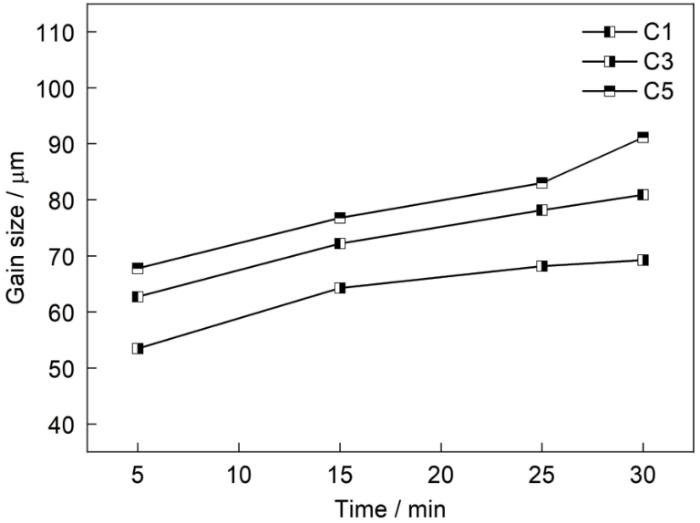

图11a~c为1150℃下保温30 min时不同Ce含量试样的原位CLSM。结合JMatPro7.0计算的75Cr1钢中的物相分布(图12)可以看出,1150℃下钢的显微组织均为奥氏体,且相比C1和C5钢样,C3钢中奥氏体晶粒尺寸更小。为了定量分析奥氏体晶粒尺寸的变化,对显微图片进行了处理(如图11d~f),并利用Image-Pro-Plus6.0软件对晶粒尺寸进行了统计,结果如图13所示。可以看出,在1150℃下保温5~30 min的过程中,C1钢中奥氏体晶粒尺寸从62.7 μm长大到80.9 μm (增加了18.2 μm);C3钢中奥氏体晶粒尺寸从53.5 μm长大到69.0 μm (增加了15.5 μm);C5钢中奥氏体晶粒尺寸从67.8 μm长大到91.1 μm (增加了23.3 μm)。可见,适量的Ce处理可以使初始奥氏体晶粒得到细化,并在热处理的过程中有着更慢的晶粒长大速率。

图11

图11

1150℃下保温30 min时C1、C3和C5钢中显微组织的原位CLSM像和对应的晶界处理图像

Fig.11

In situ CLSM images of tested steels after 30 min holding at 1150oC (a-c) and corresponding processed diagrams of grain boundary (d-f)

(a, d) C1 (b, e) C3 (c, f) C5

图12

图12

不同温度下75Cr1钢中的相分布

Fig.12

Phase distributions in 75Cr1 steel at different temperatures

图13

图13

在1150℃下不同保温时间下奥氏体晶粒平均尺寸

Fig.13

Average austenite grain sizes of steels after different holding time at 1150oC

C3钢样在原位观察中初始奥氏体晶粒最小,也反映出其凝固组织更加细小。从图12中可以看出,75Cr1钢在凝固过程中的初晶相为奥氏体相。从热力学上看稀土氧化物或稀土氧硫化物主要在液态钢中形成,大量细小弥散的夹杂易聚集长大成为大尺寸的夹杂物团簇,从而使得夹杂物不能有效促进形核[36~38]。而稀土硫化物在钢中的浓度积比稀土氧化物或稀土氧硫化物高多个数量级,稀土硫化物夹杂除了在钢液中形成之外,还在钢液凝固过程中析出形成大量细小弥散分布的稀土硫化物夹杂[39]。因此,相比稀土的氧硫化物,弥散分布的稀土硫化物能更好地促进钢液凝固过程中δ-Fe/γ-Fe相的异质形核,且最有利于促进形核的稀土硫化物尺寸为1~2 μm,其次是2~3 μm[40]。相比C1和C5钢,C3钢中夹杂物主要为稀土硫化物,且夹杂物在1~3 μm的占比达56% (图4),平均尺寸为1.6 μm,因此在钢液的凝固过程中能更好地起到细化初晶奥氏体相的作用。

2.4 Ce含量对耐点蚀性能的影响

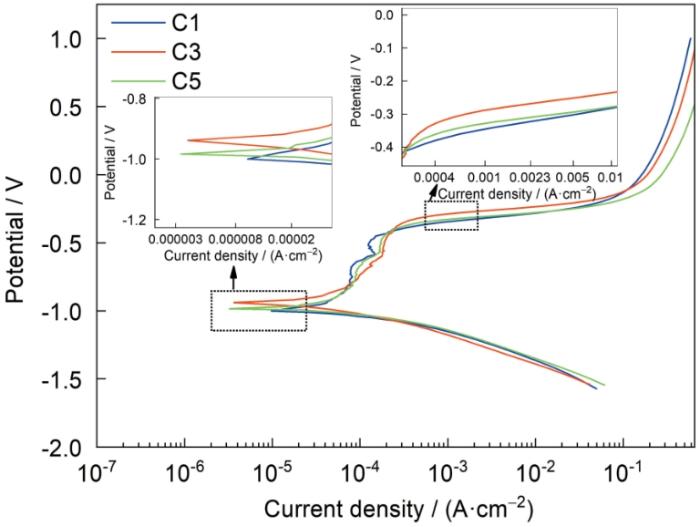

C1、C3、C5钢的极化实验结果如图14所示,并由此得出每个样品的电化学腐蚀参数,如表2所示。可以看出,C1、C3、C5钢的点蚀电位分别为-350、-290和-330 mV,表明在一定范围内添加稀土可以显著提高钢的耐点蚀性能,但过量的稀土添加对点蚀性能提高不利。钢中的S含量和夹杂物的特征(组成、形貌和分布)会对钢的耐点蚀性能产生影响[41],C3钢中夹杂物尺寸细小且形状接近球状,这会减轻钢基体和夹杂物附近的应力集中,从而减少钢基体和夹杂物界面的微裂纹,即有利于消除点蚀薄弱区。适量的稀土处理也能起到很好的脱硫效果,可以对钢中MnS、CaS等易引起点蚀的硫化物夹杂进行改性,使钢中夹杂物类型转变为Ce x S y;稀土夹杂物比同类型夹杂物具有更高的耐点蚀性能[28~30],且夹杂物尺寸得到了细化,数量也减少;因此,C3钢的耐点蚀性能得到提高。C5钢中稀土夹杂物主要是稀土磷化物和砷化物及少量的稀土硫化物夹杂,虽然稀土磷化物相比稀土硫化物有着更低的点蚀敏感性[42],但是因其夹杂物尺寸较大且数量多,增加了夹杂和钢基体之间的接触面及点蚀位点,导致钢的耐点蚀性能下降。

图14

图14

C1、C3和C5钢的极化曲线

Fig.14

Polarization curves of the C1, C3, and C5 steels (Insets show the corresponding local magnified curves)

表2 C1、C3和C5钢在3.5%NaCl溶液中的电化学参数

Table 2

| Sample | Ecorr / mV | icorr / (A·cm-2) | Epit1000 / mV |

|---|---|---|---|

| C1 | -1000 | 8.53 × 10-5 | -350 |

| C3 | -936 | 4.03 × 10-5 | -290 |

| C5 | -986 | 5.07 × 10-5 | -330 |

3 结论

(1) 随着Ce含量的增加,钢液中O、S含量不断降低,钢中典型夹杂物从原始的Ca-Mg-Al-O + MnS + CaS + TiN夹杂物转变为Ce2O2S和Ce2O2S-CeAlO3夹杂,而后转变为稀土硫化物夹杂;O、S含量降低后,夹杂物转变为稀土的磷化物或稀土砷化物;夹杂物的尺寸和数量先减小后增大,夹杂物的形状从不规则形状转变为类球状后又转变为不规则形状。Ce含量为0.0195%的钢样表现出了最高的洁净度。

(2) 含0.0195%Ce的钢在1150℃的等温原位观察过程中有更小的初始奥氏体晶粒尺寸,且保温过程中奥氏体晶粒长大速率更慢,等温30 min后,奥氏体晶粒尺寸最小。这主要归功于Ce处理后钢中夹杂物被改质为稀土硫化物夹杂,且尺寸分布有利于其作为钢液凝固过程中初晶相的异质形核质点,因此原始晶粒尺寸得到细化。

(3) 适量的Ce处理有利于提高75Cr1钢的耐点蚀性能,含0.0195%Ce的钢由于相对低的S含量、以及钢中硫化物夹杂被充分改质成为球状的稀土硫化物夹杂,并且夹杂物数量较少而且尺寸细小,因此具有更加优异的耐点蚀性能。随着稀土含量的进一步增加,由于夹杂物尺寸变大、数量变多,从而降低了钢的耐点蚀性能。

参考文献

Effect of La on microstructure and mechanical properties of 75Cr1 saw blade steel

[J].

La对75Cr1锯片用钢热轧板组织和力学性能的影响

[J].

Effects of non-metallic inclusions on the crack propagation in bearing steel

[J].

Plastic deformation behavior and fracture mechanism of rare earth H13 steel based on in situ TEM tensile study

[J].Fatigue failure caused by crack propagation is one of the main failure modes of H13 die steel. Because H13 die steel is mainly used under operational conditions involving high-pressure cycling or high friction, its crack initiation and propagation behavior play a critical role in fatigue failure. However, to the best of the authors' knowledge, few reports on the direct observation of deformation and crack propagation behavior of H13 die steel exist, which limits the understanding of the fracture mechanism of H13 die steel. In this work, an in situ TEM tensile study combined with post-mortem EBSD analysis was employed to investigate the microstructure evolution and crack propagation behavior of rare earth (RE) H13 steel. Results indicate that the stress concentration at the grain boundaries and coarse granular inclusions in the tensile specimen were the main sources of crack initiation. After crack initiation and during the tensile process, many cracks converged into the main crack. The main crack propagated along the direction perpendicular to the tensile direction, exhibiting zigzag-shaped features. The stress distribution in the area near a crack in a specimen was heterogeneous; the length fraction of V1/V2 inter-variant boundaries in the relatively high-stress area increased from 56.5% to 58.8% compared with the relatively low-stress area, and the length fraction of V1/V3&V5 inter-variant boundaries increased from 16.3% to 21.6%. The increase in the length fraction of V1/V2 inter-variant boundaries indicated an increase in the twin martensite fraction, which effectively relieved the stress concentration at the grain boundaries and reduced crack initiation. During the tensile process, the austenite retained at the grain boundaries underwent stress-induced phase transformation and was partially transformed into V1/V2 and V1/V3&V5 variant pairs. The dislocation propagation in martensite contributed to dislocation pile-up at high-angle grain boundaries and carbide precipitation. Moreover, the dislocation pile-up at the high-angle grain boundaries promoted the stress-induced phase transformation of the retained austenite.

基于原位TEM拉伸的稀土H13钢塑性形变行为和断裂机制

[J].

Application prospects and behavior of RE in new generation high strength steels with superior toughness

[J].

稀土元素在新一代高强韧钢中的作用和应用前景

[J].

Improvement of lanthanum on impact toughness of 34CrNi3Mo steel containing Sn, Sb residual elements

[J].

残余元素锡、锑对34CrNi3Mo钢冲击韧性的影响及稀土镧的改善作用

[J].

Effect of Ce on microstructure and impact properties of S32550 duplex stainless steel

[J].

铈对S32550双相不锈钢微观组织及冲击性能的影响

[J].双相不锈钢兼具奥氏体和铁素体不锈钢的优良性能,多用于船舶、化工、核反应等领域。为了进一步提高S32550双相不锈钢的力学性能和抗腐蚀性能,采用真空感应炉成功冶炼了S32550双相不锈钢,并研究了有无添加稀土铈对其锻造、轧制后的微观组织、夹杂物形貌及冲击性能的影响。结果表明,添加稀土铈可以细化组织晶粒,使形状分布不均匀的铁素体组织与奥氏体组织均匀化;改善夹杂物形貌分布大小,对有害夹杂MnS进行改质,降低硫含量,使多余硫元素与铈反应形成Ce<sub>2</sub>O<sub>2</sub>S、Ce<sub>2</sub>S<sub>2</sub>夹杂弥散分布在钢中;另外,添加稀土铈可以提高S32550双相不锈钢在室温和低温(-40、-20 ℃)下的冲击韧性,在低温下可出现韧窝带,降低冷脆效应对钢材的危害。

Austenite grain growth behaviors of La-microalloyed H13 steel and its effect on mechanical properties

[J].

Enhanced welding properties of high strength steel via rare earth oxide metallurgy technology

[J].With the increase of the strength of steel plate, the welding performance of the steel decreases sharply and the welding crack susceptibility increases. The properties of welding heat-affected zone of high strength steel lower with increasing the welding heat input. The present work aims to improve the toughness of welding heat-affected zone by rare earth oxide metallurgy technology. The effect of 5×10-6 and 23×10-6 rare earth Ce on the impact toughness, microstructure, austenite grains of heat-affected zone and fracture morphology of welded joint were studied. When the steel contains 5×10-6 rare earth Ce, the inclusions are MgO-Al2O3 spinels surrounded with a small amount of CeAlO3 inclusions. In the case of the steel with 23×10-6Ce, Ce can completely modify MgO-Al2O3 inclusions, resulting in the formation of (CeCa)S+MgO-Al2O3+MnS complex inclusions. The simulation welding of high strength steel was performed. The results show that the Charpy impact energy of heat-affected zone of the steel with 23×10-6Ce is higher at four different heat inputs, in comparison with the steel with 5×10-6Ce. The microstructure analysis shows that the fracture morphology of heat-affected zone of the steel with 23×10-6Ce appears dimples, which is an indication of a higher toughness. With increasing the heat input from 25 kJ/cm to 100 kJ/cm, the average grain size of the original austenite in the heat-affected zones of the steels with 5×10-6Ce and 23×10-6Ce was increased by 75.6% and 52.4%, respectively. It indicates that the growth of the original austenite grain during welding is suppressed with increasing the Ce content in the steel. Comparison of the microstructure shows that rare earth Ce can delay the formation of upper bainite structure in the heat-affected zone. Through the high temperature confocal microscope, it was observed that the rare earth inclusions pinned on the original austenite grain boundary, which can effectively restrain the grain growth during the welding process. It provides an evidence showing the mechanism of improvement in the heat-affected zone in the welding of the high strength steel by rare earth Ce. The present study demonstrates the rare earth oxide metallurgy can improve the weldability of the high strength steel.

应用稀土氧化物冶金技术改善高强钢焊接性能

[J].

Mechanism of cracking resistance improved by rare earth oxide of hardfacing specimens of medium-high carbon steel

[J].

稀土氧化物提高中高碳钢堆焊试样抗开裂性机制的研究

[J].

Electrochemical investigations on pitting corrosion inhibition of mild steel by provitamin B5 in circulating cooling water

[J].

Understanding localized corrosion

[J].

The effect of titanium on pitting corrosion resistance of welded supermartensitic stainless steel

[J].

Understanding the corrosion mechanism of spring steel induced by MnS inclusions with different sizes

[J].

Pitting initiation and propagation of X70 pipeline steel exposed to chloride-containing environments

[J].

In situ characterization by localized electrochemical impedance spectroscopy of the electrochemical activity of microscopic inclusions in an X100 steel

[J].

Observation of the pitting corrosion and uniform corrosion for X80 steel in 3.5 wt.% NaCl solutions using in-situ and 3-D measuring microscope

[J].

A new microelectrochemical method to study pit initiation on stainless steels

[J].

Effect of inclusions on pitting corrosion of C70S6 non-quenched and tempered steel doped with Ca and Mg

[J].As one of the energy-saving steels, non-quenched and tempered steel commonly requires the addition of alloying elements to improve its properties. The inclusions related to those elements have significant influence on the properties of the steels. In this work, the potentiodynamic polarization curves of C70S6 non-quenched and tempered steel and its Mg-Ca doped samples were measured by solution modification, and the samples before and after the test were characterized by SEM-EDS. The results show that the MnS inclusions in the samples act as active sites for pitting. The doped Ca and Mg elements make the distribution of inclusions more dispersed and the content of MnS in each inclusion lower, leading to the better pitting resistance of the doped specimens.

Ca、Mg掺杂下夹杂物对C70S6非调质钢点蚀行为的影响

[J].通过溶液调制的方法对C70S6非调质钢及其掺Ca、Mg样品进行了动电位极化曲线测试,并对测试前后的样品进行了SEM-EDS表征,揭示了夹杂物对非调质钢点蚀行为的影响。结果表明,MnS夹杂易作为活性位点诱发点蚀,而掺杂Ca、Mg元素使得夹杂物分布更弥散,MnS含量更低,相应的点蚀抗性也更高。

Effects of inclusions on the resistance to pitting corrosion of S32205 duplex stainless steel

[J].

Cathodoluminescence analysis of nonmetallic inclusions in steel deoxidized and desulfurized by rare-earth metals (La, Ce, Nd)

[J].

Study on behavior of rare earth cerium modifying inclusions in clean steel

[J].

洁净钢中稀土铈变质夹杂物行为研究

[J].

Characterization transformation of inclusions using rare earth Ce treatment on Al-killed titanium alloyed interstitial free steel

[J].

Modification mechanism of cerium on the inclusions in drill steel

[J].Fatigue fracture is the main failure forms of drill steel, and the hard oxide with large size is one of the main reasons for the fatigue fracture of drill steel. Therefore, the miniaturization and softening of inclusion can effectively improve the anti-fatigue performance of drill steel and prolong its service life. Rare earth elements have very good affinity with oxygen and sulfur in molten steel, and the hardness of resulting rare earth compounds is very low. In this work, the rare earth element cerium was added into drill steel to investigate the effect of Ce on the MgAl2O4 and sulfides. The composition, morphology, number, and size of inclusions in drill steel were analyzed by using SEM and EDS. The evolution process and modification mechanism of Ce on MgAl2O4 and sulfides were clarified by experimental results and calculated by thermodynamic software. The type of inclusions in drill steel without Ce addition is MgAl2O4 and (Ca, Mn)S. As the Ce content in drill steel reaches to 0.0078% (mass fraction), the type of inclusions changes to Ce-O and Ce-S. In addition, a few complex inclusions, mixture of Ce-O and MgO, were also found. The size of inclusions in drill steel decreases significantly as the oxides and sulfides were modified into Ce-O and Ce-S. The calculated results show that MgAl2O4 and (Ca, Mn)S in drill steel can be effectively modified into Ce-O and Ce-S as the Ce added into molten steel, and the modification sequence of Ce on the MgAl2O4 is as follows: MgAl2O4→CeAlO3+MgO→Ce2O3+MgO→Ce2O3. The content of Ce in drill steel has great influence on the type of inclusions. The modification mechanism of Ce on MgAl2O4 calculated by Factsage 6.3 agrees well with the experimental observations.

稀土Ce对钎具钢中夹杂物的改质机理研究

[J].

Effects of rare earth addition on microstructure of C-Mn steel

[J].

Effect of Ce on the microstructure, high-temperature tensile properties, and fracture mode of strip casting non-oriented 6.5%Si electrical steel

[J].Non-oriented 6.5%Si electrical steel exhibits excellent high-frequency magnetic properties, such as low iron loss and near-zero magnetostriction. Moreover, the high Si content causes poor deformability due to the solution strengthening effect of Si and the resulting ordering transformations, delaying the commercial application. Strip casting is a near-net forming technology that directly produces thin strips from the melt and reduces the required rolling deformation for the fabrication of thin sheets. This technology could be a viable option for industrializing the production of non-oriented 6.5%Si electrical steel. Despite this, even in the strip casting process, this brittle material is prone to edge cracks. Thus, improving the intrinsic plasticity of strip casting non-oriented 6.5%Si electrical steel is necessary through chemical modification to eliminate the deforming defects. The effect of Ce on the ordered phase of the solidification microstructure, high-temperature tensile properties, and fracture mode of strip casting non-oriented 6.5%Si electrical steel was investigated in this work. The results showed that the addition of Ce introduced high-melting Ce2O2.5S and Ce4O4S3 during strip casting, which promoted heterogeneous nucleation and refined the solidification microstructure of the as-cast strip. The presence of Ce did not affect the ordering condition of the as-cast strip. In decreasing order, the tensile temperatures corresponding to the ordered degree of the as-cast strip were 650, 400, and 800oC. With the tensile temperature increasing, the yield and tensile strengths of the as-cast strip decreased, whereas the elongation gradually increased. When the tensile temperature exceeded 500oC, the purification and microstructure refining effects of Ce improved grain-boundary cohesion and prevented intergranular cracking. Moreover, the occurrences of dynamic recovery and recrystallization eventually made the as-cast strip doped with Ce fractured by dimples, leading to a considerably enhanced tensile ductility. According to the findings, the rare-earth treatment should be considered as an effective method for increasing the ductility of strip casting non-oriented 6.5%Si electrical steel.

稀土Ce对薄带连铸无取向6.5%Si钢组织、高温拉伸性能和断裂模式的影响

[J].

Discussion of inclusions as heterogeneous nuclei of primary austenite of medium-high carbon steel during hardfacing

[J].

夹杂物在中高碳钢堆焊金属中成为初生奥氏体非均质形核核心的探讨

[J].

Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel

[J].

Micro-electrochemical properties of CeS inclusions in stainless steel and inhibiting effects of Ce3+ ions on pitting

[J].

Cerium addition to CaS inclusions in stainless steel: Insolubilizing water-soluble inclusions and improving pitting corrosion resistance

[J].

Effect of rare earth on microstructure and property of X80 pipeline Steel

[D].

稀土对X80管线钢组织和性能的影响

[D].

Assessment of oxygen control and its effect on inclusion characteristics during electroslag remelting of die steel

[J].

Evolution of desulfurization and characterization of inclusions in dual alloy ingot processed by electroslag remelting

[J].

Effect of adding cerium on microstructure and morphology of Ce-based inclusions formed in low-carbon steel

[J].Intra-granular Acicular Ferrite (IAF), as one of the most well-known desirable microstructure of ferrite with a chaotic crystallographic orientation, can not only refine the microstructure and retard the propagation of cleavage crack but also provide excellent combination of strength and toughness in steel. The effect of adding cerium on microstructure and controlling proper cerium-based inclusions in order to improve properties in low-carbon commercial steel (SS400) were investigated. The type of inclusions can be controlled by changing S/O ratio and Ce content. Without Ce modification, MnS is a dominate inclusion. After adding Ce, the stable inclusion phases change from AlCeO to CeOS. The optimum amount of cerium, 0.0235 wt.%, lead in proper grain refinement and formation of cerium oxide, oxy-sulfide and sulfide inclusions. Having a high amount of cerium results in increasing the number of inclusions significantly as a result it cannot be effective enough and the inclusions will act like barriers for others. It is found that the inclusions with a size of about 4∼7 μm can serve as heterogeneous nucleation sites for AF formation. Thermodynamic calculations have been applied to predict the inclusion formation in this molten steel as well, which show a good agreement with experimental one.

Precipitation mechanism and thermal stability of primary carbide in Ce microalloyed H13 steel

[J].Ce microalloyed H13 hot die steel is widely used in manufacturing hot extrusion and die casting mold of magnesium-aluminium alloy because of its excellent combination of hot strength and impact toughness. The C content in Ce microalloyed H13 steel is approximately 4% (mass fraction), and the alloy elements content such as Cr, Mo, V et al are about 8%. Therefore, it is easy for primary carbide to precipitate during the solidification of the molten steel due to the segregation of alloy elements. Most researchers study the precipitation mechanism of primary carbide in the two-dimensional perspective. A few people are involved in the three-dimensional morphology of the primary carbide, especially the thermal stability of the primary carbide in the three-dimensional perspective in the Ce microalloyed H13 steel. Therefore, the precipitation mechanism and thermal stability of the primary carbide were systematically studied in this work. First, the SEM and inclusion automatic analysis system were used to analyze the morphology, number density and size of the inclusions in Ce microalloyed H13 steel. The three-dimensional morphology of the primary carbide in sample was observed after electrolyzed in a non-aqueous solution. The voltage was 20 V, the electrolysis time was about 3 min and the electrolyte was composed of 1% tetramethylammonium chloride, 10% acetylacetone, and 89% methanol (volume fraction). Three samples were heated to 1150, 1200 and 1250 ℃ for 1 h to investigate the thermal stability of the primary carbide. Finally, Factsage 7.2 software was used to calculate the precipitation mechanism and thermal stability of the primary carbide. Elemental Ce can effectively react with O, S, P and As elements to form the corresponding Ce-O, Ce-S and Ce-P-As inclusions. There is a huge difference between the two-dimensional and three-dimensional morphologies of the primary carbide, the two-dimensional morphology is strip and the three-dimensional morphology is irregular flake. Ti-V-rich carbide precipitates first, and then acts as the nucleation core of V-rich carbide. When the heating temperature reaches 1250 ℃, the V-rich carbide has completely dissolved, and the Ti-V-rich carbide begins to dissolve. The three-dimensional morphology of the wrapped Ti-V-rich carbide is completely exposed after the V-rich carbide disappears completely. The Ce-O inclusion is formed before solidification, and the primary carbide precipitates at the end of the solidification of molten steel. As the Ce content in molten steel increases, the stability diagram of Ce2O2S and Ce-S increases gradually. The precipitation temperature of Ti-V-rich carbide is approximately 1360 ℃, and the V-rich carbide starts to precipitate at about 1200 ℃. The calculated results are keeping well with the experimental observations. The damage of primary carbide in Ce microalloyed H13 steel can be partly reduced by higher heating temperature, but cannot be completely removed.

Ce微合金化H13钢中一次碳化物的析出机理及热稳定性研究

[J].

Dispersion of primary inclusions of Ce2O3 and CeS in Fe-0.20 mass%C-0.02 mass%P alloy

[J].

Agglomeration characteristics of various inclusions in Al-killed molten steel containing rare earth element

[J].

Thermodynamics of rare earths in steelmaking

[J].

Refinement of solidification structure of H13 steel by rare earth sulfide

[J].

Effects of cerium on resistance to pitting corrosion of spring steel used in fasteners of high-speed railway

[J].