当前材料结构与组织表征手段主要以电子、X射线和中子作为探针。电子束具有电荷和自旋,较易聚焦,具有亚纳米尺度的空间分辨率;但由于电子间强烈的排斥作用,穿透能力较弱,只能获取薄层样品的信息。同步辐射X射线由于能量高而穿透深度强于电子束,通量高而具有超快的时间分辨能力;但空间分辨能力弱于电子束。中子不带电,只与原子核相互作用,穿透深度极大,且可分辨轻元素、同位素和相邻元素;有自旋,可与磁性材料中的磁矩相互作用;时间分辨能力和空间分辨能力均弱于X射线和电子束。

由于上述特点,中子表征技术是研究大型块体材料和工件的理想手段。中子的高穿透性可以非破坏性地获取材料内部信息,反映平均效应,具有统计意义;同时,也保证了在各类复杂样品环境中得以运用,为原位研究提供了保障。另外,中子的独特元素分辨能力有利于研究金属中H、N、O等轻元素,以及合金和固溶体中的临近元素,特别对于高/中熵合金中相邻元素的原子占位精确表征具有重要意义[1]。结构材料的力学特性决定于材料的化学成分、原子结构、微观组织和介观结构等,是多尺度、多维度因素共同作用的结果。中子能量和波长具有可调性,运用不同实验方法可覆盖原子到宏观多个尺度,涵盖了材料科学研究中绝大部分物理化学过程。近些年来,先进中子源和中子谱仪的建设与复杂样品环境的研发取得了长足进步,为金属结构材料的研究提供了前所未有的机遇。本文将系统介绍各类中子表征技术及其在金属结构材料研究中的应用。

1 中子源与中子散射技术简介

中子表征实验在中子源的相应谱仪上开展。现代中子源主要有2类:核反应堆和加速器,后者因高通量、优异的脉冲结构和高安全性成为中子源发展的趋势。中子谱仪是为了实现某种中子表征技术而设计、建设的特定实验仪器。中子是物质波,与材料中原子的相互作用可分为3类:透射、反射和散射。无能量转移的过程称为弹性散射过程,存在能量转移的过程称为非弹性散射过程。常用的中子表征技术包括衍射(diffraction)、小角散射(small-angle neutron scattering)、Bragg边成像(Bragg-edge imaging,BEI)、中子照相(neutron radiography & tomography)、反射(reflection)、准弹性中子散射(quasi-elastic neutron scattering)与非弹性中子散射(inelastic neutron scattering)等。其中衍射和小角散射过程的主要信号来自弹性过程,准弹性散射较为特殊,下文将详细叙述。关于中子表征技术的完整理论描述可参阅文献[2]。

1.1 中子源

反应堆中子源利用核裂变反应产生中子,其中子束流连续分布。代表性装置有法国劳厄-朗之万研究所(Institut Laue-Langevin,ILL)反应堆、美国橡树岭国家实验室的高通量同位素反应堆(High Flux Isotope Reactor,HFIR)、澳大利亚核科学和技术组织的轻水反应堆(Open Pool Australian Lightwater Reactor,OPAL)、日本原子能研究开发机构的研究用反应堆(Japan Research Reactor-3,JRR-3)、中国先进研究堆(China Advanced Research Reactor,CARR)和中国绵阳研究堆(China Mianyang Research Reactor,CMRR)。加速器中子源又称散裂中子源,其利用高能加速器加速质子,轰击重金属靶产生原子核散裂反应形成脉冲中子。代表性装置有英国卢瑟福

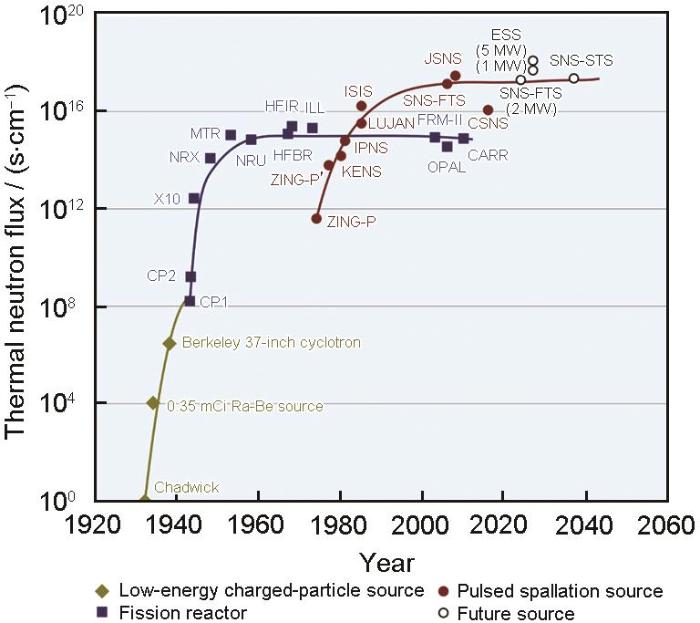

图1

图1

反应堆与散裂中子源的发展[3]

Fig.1

Evolution of reactor and spallation neutron sources around the world[3] (CP1—Chicago Pile 1, CP2—Chicago Pile 2, X10—X-10 Graphite Reactor, NRX—National Research Experimental, MTR—Materials Testing Reactor, NRU—National Research Universal, HFBR—High Flux Beam Reactor, HFIR—High Flux Isotope Reactor, ILL—Institut Laue-Langevin, ZING-P—Spallation Pulsed Neutron Source Prototype, KENS—KEK Neutron Scattering Research Facility, IPNS—Intense Pulsed Neutron Source, LUJAN—Lujan Center at Los Alamos National Laboratory, ISIS—ISIS Neutron and Muon Source, FRM-Ⅱ—The Research Neutron Source Heinz Maier Leibnitz, OPAL—Open Pool Australian Lightwater Reactor, CARR—China Advanced Research Reactor, SNS-FTS—Spallation Neutron Source-First Target Station, JSNS—Japan Spallation Neutron Source, CSNS—Chinese Spallation Neutron Source, ESS—European Spallation Source, SNS-STS—Spallation Neutron Source-Second Target Station)

1.2 中子衍射

与X射线衍射和电子衍射相似,中子衍射亦遵守Bragg定律:

式中,dhkl 为某一晶面(hkl)的晶面间距,θ为Bragg角,λ为中子波长。反应堆中子源使用恒定波长的中子,通过扫描θ角来测量衍射强度并获得衍射谱,该方法称为角度色散(angular dispersion)法,这与实验室X射线衍射实验完全类似。而散裂中子源通常使用飞行时间(time of flight,TOF)法,通过测量不同波长的中子到达探测器所需的时间和衍射后中子强度来获取衍射谱。上述2类衍射谱的横轴均可转化为散射矢量 Q (Q = 4πsin(θ / λ))。如图2a的散射几何所示,入射波矢量与散射波矢量之差为 Q。相对于出现在较高Q处的Bragg峰,极小Q (< 0.1 nm-1)处的散射强度反映了体系的空间不均匀性(图2b)。散裂中子源上专门开展工程材料测试[4]的原理如图2c所示。2组探测器可以同时获得材料2个方向(即 Q1与 Q2)的衍射谱,从而同时探测多个取向晶粒群,其细节是反应堆中子源无法实现的。

图2

图2

散射光路,小角散射与衍射谱,及飞行时间法光路的示意

Fig.2

Schematics of scattering with scattering vector Q (a), small-angle scattering signal and diffraction spectrum (b), and the time-of-flight diffraction geometry used in the pulsed spallation sources (Scattering vectors Q1 and Q2 are observed by the two detector banks) (c)

1.3 中子照相与Bragg边成像

与X射线照相类似,中子照相利用中子束穿过物体时的强度衰减变化对被测物体进行透视成像。近些年,随着计算机技术的发展,可以利用二维相机式探测器记录成像信息,通过旋转样品获得一系列二维投影图片,再进行数字互相关联实现结构的三维重构,称之为断层扫描技术(computed tomography,CT)。随着新型探测器的不断发展,该技术的空间分辨率和时间分辨率分别达到了微米和毫秒级别。借助中子的高穿透能力,中子照相技术在锂电池内部电极退化、锂离子扩散等问题的研究中得到了广泛应用[5]。然而,这些均基于材料的化学、几何等特征,未能提供晶体学信息。

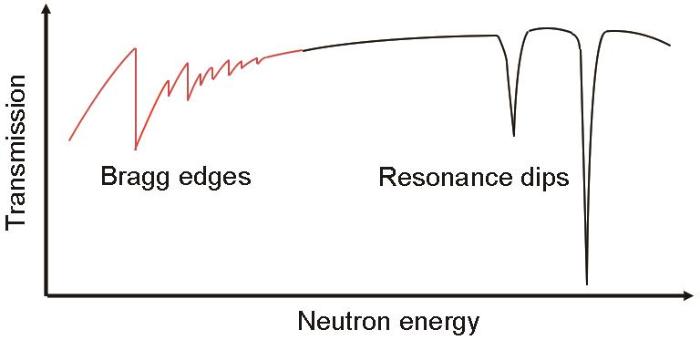

Bragg边成像也可以称为能谱中子成像,是近些年发展起来的新兴中子表征技术。它是基于透射率与中子能量的相互关系,定量“成像”出材料的晶体学信息。依赖于中子能量的透射率谱(Tr(E))可以表示为:

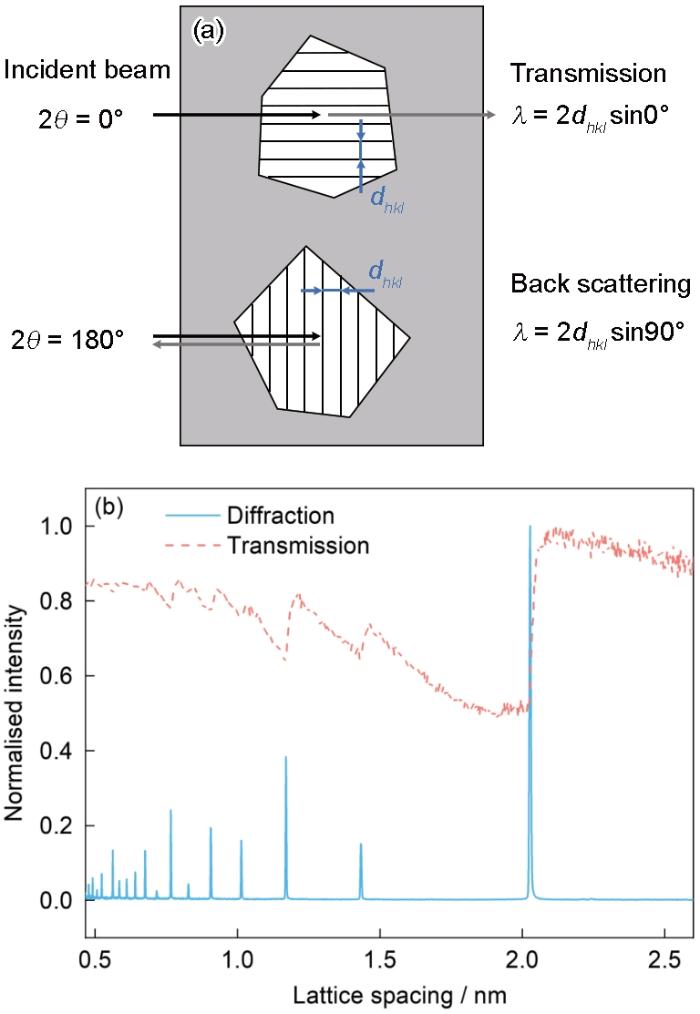

式中,I(E)和I0(E)分别是透射与入射中子强度。当该材料包含结晶成分时,如图3a所示,入射束方向与该晶体的某个晶面平行,θ为0°。根据

图3

图3

Bragg边出现的示意图及对应的纯Fe的衍射峰

Fig.3

Schematic of Bragg-edge (a) and diffraction and transmission spectra of bcc iron (b) (θ—Bragg angle, dhkl —lattice spacing of (hkl) plane, λ—wavelength)

图4

1.4 非弹/准弹性散射

非弹性中子散射是指入射中子与样品中的原子作用过程中存在能量和动量转移,常用来研究原子振动;准弹性中子散射较特殊,不存在能量和动量转移,在能谱结构上却表现出有限线宽,可用来研究原子扩散和分子随机转动。该类实验一般利用三轴谱仪或飞行时间谱仪开展,测量得到二阶微分中子散射截面与材料的散射函数S(Q, E)直接相关(其中E为能量转移),分析S(Q, E)可获得材料的动力学性质[11]。

1.5 面向工程材料的中子科学平台

面向工程材料研究领域,中子谱仪不仅需要具备优异的性能,还需要建设丰富的样品环境,保证满足不同应用场景下材料所需要的外场调控。在此方面,欧美及日本长期处于领先地位,ISIS的ENGIN-X谱仪、SNS的VULCAN谱仪及J-PARC的TAKUMI谱仪具备高通量且完备的样品环境装置,已经开展了大量的材料表征研究。中子源大科学装置上工程材料谱仪与能量分辨中子谱仪的相关参数及特色样品环境见表1[4,12~22]。我国也在该领域不断追赶,截至2023年,CARR的RSD谱仪、中南大学和CARR共建的ESSD谱仪、CSNS的能量分辨中子成像谱仪ERNI、及上海交通大学和CMRR共建的冷中子工程应力谱仪“河图”(HETU)相继开放,CSNS的通用粉末衍射仪(GPPD)谱仪也完成了残余应力测试改造。此外,CSNS的工程材料衍射谱仪EMD也已经出束,样品环境正在调试。

| Source | Instrument | Parameter | Main sample environment |

|---|---|---|---|

SNS | VULCAN[12] (ED) | Δd / d = 0.25% | Loading frame (100 kN, 30 Hz) Furnace (RT-1773 K) Liquid N2 cooling jar free (80 K-RT) Additive manufacturing system |

| VENUS (BEI) | Under construction | ||

J-PARC | TAKUMI[13] (ED) | Δd / d = 0.2% | High temperature loading frame (50 kN, RT-1273 K) Cryogenic loading frame (50 kN, 10 K-RT) Fatigue machine (60 kN, 30 Hz) Eulerian cradle |

Δλ / λ = 0.2% SR: 10 μm (camera-type detector), 100 μm (counting-type detector) | Furnace (RT-1173 K) Polarization analysis system | ||

| ISIS | ENGIN-X[4] (ED) | Δd / d = 0.26% | High temperature loading frame (100 kN, RT-1373 K) Cryogenic loading frame (50 kN, 10 K-RT) |

IMAT[16] (BEI) | Δλ / λ = 0.7% SR: 50 μm (camera-type detector), 200 μm (counting-type detector) | Furnace (RT-1273 K) | |

| CSNS | EMD[17] (ED) | Δd / d = 0.25% | 3D scanner Tensile ring (100 kN, RT-1473 K, 50 Hz) |

ERNI[18] (BEI) | Δλ / λ = 0.4% SR: 15 μm (camera-type detector), 50 μm (counting-type detector) | Fatigue testing (10 kN, 10Hz) High temperature loading frame (RT-1673 K, 60 kN) Cryogenic loading frame (6-473 K, 50 kN) | |

CMRR | RSND[19] (ED) | Δd / d = 0.20% Flux: 4.7 × 106 n·s-1·cm-2 | Stress ring (15 kN) Furnace (RT-773 K) Temperature-tension-torsion instrument (173-727 K, 100 kN, 50 N·m) Cryogenic loading frame (15 K-RT, 2.5 kN) |

HETU[20] (ED) | Δd / d = 0.19% Flux: 3.0 × 107 n·s-1·cm-2 | Loading frame (15 kN) Cyrostat (93 K-RT) and furnace (RT-1273 K) Eulerian cradle | |

| CARR | RSD[21] (ED) | Δd / d = 0.2% Flux: 2.7 × 107 n·s-1·cm-2 | Furnace (RT-1100 K) |

| ESSD[21] (ED) | Δd / d = 0.2% Flux: 4.0 × 107 n·s-1·cm-2 | Loading frame (100 kN) Cyrostat (77 K-RT) and furnace (RT-1300 K) | |

TNI[22] (Imaging) | Δλ / λ = 3% SR: 50 μm (camera-type detector) Flux: 1.0 × 109 n·s-1·cm-2 | Polarization analysis system |

Note: J-PARC—Japan Proton Accelerator Research Complex, CMRR—China Mianyang Research Reactor, CARR—China Advanced Research Reactor, ED—engineering diffractometer, BEI—Bragg-edge imaging, Δd / d and Δλ / λ—instrument resolutions, RT—room temperature, SR—spatial resolution

2 基于中子衍射的材料表征

运用原位中子衍射技术,能够在温度、力学加载、磁场、静水压等复杂外场条件下研究材料的晶体结构、相组成、织构、弹性应变、晶粒或位错胞尺寸、位错密度及位错类型等关键物理参量。该技术在解析材料微观结构与内部力学机理方面发挥着重要的作用,下面将介绍几种典型结构材料的研究范例。

2.1 钢铁材料

固态相变是金属材料组织调控和力学性能优化的关键手段之一。直接观测热处理过程中微观组织的定量演化,是理解相变规律并精准调控组织的重要依据。随着中子通量的不断提高,时间分辨率得以优化,使原位追踪制造加工过程中的组织演化成为现实。对于钢铁材料的微观组织表征,原位研究主要集中在铁素体相变[23]、奥氏体逆相变[24]、贝氏体/马氏体相变[25,26]过程中的内部应力演化,淬火配分工艺中C的配分行为[27],织构演化[28]与变形组织的回复、再结晶现象[29],热机械控制工艺(thermomechanical controlled processing,TMCP)中组织的动态演化[30,31]等。Tomota等[32]利用中子衍射技术原位表征了连续冷却过程中低碳钢内部应力的演化行为,通过原位中子衍射与Eshelby夹杂理论,定量揭示了铁素体相变过程中由晶格体积差异产生的相变应变、奥氏体-铁素体热膨胀差异引起的热应变以及C扩散至奥氏体引起的相应变这3者的关系。Plotkowski等[33]原位表征了低温转变钢(LTT250)在增材制造期间的瞬态相变与晶格热应变演化。这些工作都为研究钢铁材料的微观结构演化、应力分配和热力学分析奠定了基础。

人们对扩散型相变的认识已经相对成熟,对于切变型相变,虽然涉及了变体选择调控、膨胀收缩的各向异性等微观局部信息的研究,但在这些局部信息平均后的体信息层面上仍存在一些尚未理解的问题,部分实验结果也无法从体积变化或相应力的角度来解释[34]。经典马氏体相变理论认为一组原子通过剪切移动来改变晶体结构,但每个原子的移动路径尚不清楚。唯象学对马氏体相变过程的描述将存在的应变分解成3个基本应变[35]:① Bain位移(fcc→bcc);② 塑性变形(协调马氏体内部滑移、孪晶等产生的非均匀应变);③ 刚性转动(无畸变、不转动的惯习面)。除此之外,在母相的界面处也通过透射电子显微镜(TEM)观察到了位错的存在[36],即相变应变中的剪切成分通过奥氏体或马氏体的塑性变形得到缓和,但是其中的静水压成分非常难以协调。导致这一问题的主要原因是Bain应变残留在马氏体内的Block单元(具有相同晶体取向的马氏体的集合)内,最近有研究[37]也证明了这一点。如果相变过程引起体积膨胀(正向),那么生成相将产生静水压应力(反向),母相将产生静水拉应力以保持内部应力平衡,这一问题在微观力学上是显而易见的。然而,在衍射实验获得的数据中[38,39],有许多互相矛盾的结果。

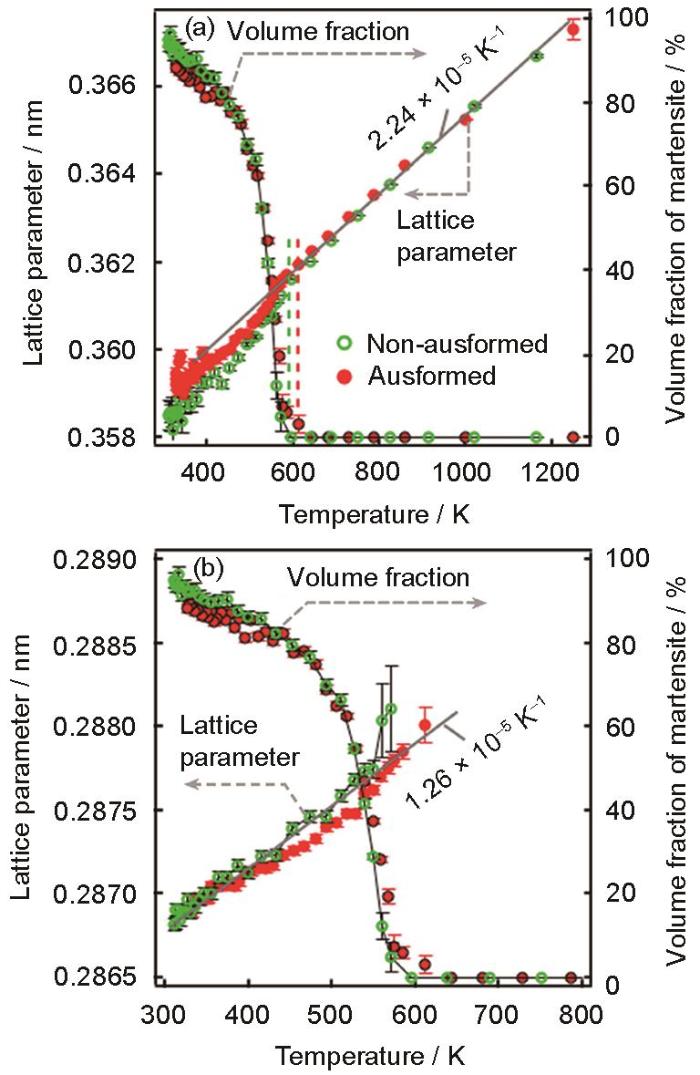

日本京都大学Tsuji团队与J-PARC工程材料谱仪团队联合开发了热机械模拟仪(型号:Thermecmastor-Z),实现了高温淬火。借助此设备,作者团队表征了Fe-C[34,40]、Fe-Ni[41]等合金在连续冷却过程中马氏体相变、等温马氏体/贝氏体相变过程中的组织演化。例如,使用0.4C低合金钢,实现了追踪高温奥氏体在淬火时的瞬态相变过程[34]。通过在高温变形过程中引入位错,原位表征了位错对相变的影响。以2 s的时间间隔切取中子衍射数据,经过数据拟合分别得到了奥氏体与马氏体的晶胞参数变化(图5[34])。奥氏体晶胞参数随着相变的进行而减小(静水压应力),这一结论与Eshelby[42]及Mori等[43]的微观力学理论相互矛盾。而在导入位错后(位错密度计算值:4.4 × 1014 m-2),晶胞参数的减小量也随之减少(图5b[34])。在马氏体相变开始温度(Ms)前后的等温相变过程中[40],发现奥氏体晶胞参数呈现与连续冷却相变相同的变化趋势,且减少量随相变温度的降低而增加。这一系列结果都预示着晶格缺陷可能掩盖了晶胞参数变化与相应力之间的真正关系。研究[41]表明,通过在相变后进行回火处理去除晶格缺陷,马氏体与奥氏体晶胞参数的变化关系出现倒转,即低晶格缺陷状态下,相变应变引起的内应力在马氏体中表现为静水压应力,奥氏体受到静水拉应力并与马氏体所受相应力互相平衡。然而,仅考虑位错或孪晶作为晶格缺陷,很难解释这一结果,因为剪切成分只影响衍射峰的宽化。作为晶格缺陷的原子空位可能是唯一能解释的因素,因为原子空位的增加导致体积膨胀且晶胞参数减小。近些年,尽管有相变诱导空位理论[44,45]被提出,但是钢铁材料中具体的原子空位形成机制仍不明确。

图5

此外,通过原位表征TMCP过程中的微观组织,是揭示超细晶组织形成机理的直接证据。Shibata等[46]通过模拟实际低碳钢生产工艺,利用原位中子衍射研究了TMCP过程中微观组织的形成过程。结果表明,相较于没有变形的样品,压缩变形开始后出现了铁素体相,证明动态铁素体转变发生在母相奥氏体的加工过程中。关于动态铁素体转变的物理机制也曾提出过各种假设,如切变(displacive transition)、块状转变(massive transition)等。该研究明确了动态铁素体相变是一种扩散型转变。此外,还定量评估了TMCP过程中母相奥氏体的晶格缺陷密度(位错密度)的变化。高通量下的中子衍射技术对TMCP过程中组织形成理论带来了新的认知。

2.2 非铁系合金

近年来,随着制造工艺的不断迭代,精细化调控的组织使得变形、疲劳等现象变得更加复杂,仅仅通过传统表征手段很难定量地揭示宏观力学响应。对于内应力(弹性应变)的评价,无论是X射线还是中子射线,都可以通过材料中组成相的晶面间距变化来计算应变,并通过线弹性本构方程(广义Hooke定律)计算应力。详细的多尺度残余应力分类、表征原理与方法可以参见综述文章[47]。

中子衍射技术在非铁系金属中的研究要追溯到1982年,Schmank和Krawitz[48]尝试利用中子衍射来测量Al弯曲试样的应力梯度。紧接着MacEwen等[49]对Zircaloy-2合金的柱面和底面晶粒群在拉伸与压缩变形后的残余应力进行了测量,发现各个取向晶粒群的残余应力与不同取向中发生柱面滑移和拉伸孪晶的难易程度相关联,并指出利用中子衍射测量块体材料的残余应力比传统X射线衍射更具优势。随后,运用原位中子衍射的研究较多关注在金属复合材料中的应力分配问题,例如,Allen等[50]报道了Al/SiC复合材料在变形中的两相间应力传递;Prangnell等[51]通过测量Al/SiC复合材料在卸载后的残余应力,发现Al的晶粒群取向不同也会导致应力分配。铜合金的相应力分配与晶粒群取向间的应力分配现象也显著影响着材料的变形[52],后者对于推导各种变形机制的贡献有重要作用。

Mg及镁合金是最典型的hcp结构金属。Mg具有较大的中子散射长度和较低的吸收率,因此是中子衍射的理想材料之一。1999年,Gharghouri等[53]运用原位中子衍射研究了Mg-7.7%Al (原子分数)合金的变形机制,对比了不同取向晶粒的应力分配以及衍射峰强度变化对{10

图6

图6

{10

Fig.6

Schematic of the parent {10

关于镁合金中相应力的报道很少,主要是由于塑性变形过程中晶粒取向的各向异性较大,很难用单一取向来计算相应力。Gong等[64]通过结合各取向晶粒的Young's模量、晶格应变和体积分数开发了一种准确计算hcp结构金属中基体Mg以及长周期堆垛有序结构(LPSO)相在合金中贡献的内应力的方法。另一方面,衍射峰的宽化主要由位错引起,镁合金中存在多种Burgers矢量的位错,这加大了位错密度计算的难度。Máthis等[81]和Ungár等[82]应用X射线衍射解析分别报道了纯Mg和锆合金中位错密度的解析方法(修正Williamson-Hall法)。首先运用Convolutional multiple whole profile程序拟合衍射谱求出对比度因子,然后通过比较对比度因子实验值和不同Burgers矢量位错在各种比例组合下对比度因子计算值,求出各种位错类型的概率以及位错密度。这种解析方法也适用于中子衍射测量Mg及其合金的位错密度[56,83]。近年,修正Williamson-Hall法使用较广,该方法的原理解读可参阅文献[84,85]。

相较于Mg及镁合金,对于同样是hcp结构的Zr和Ti的中子衍射研究相对较少。Zr和Ti比较相似,柱面滑移是优先滑移系。锆合金由于具有良好的力学性能、热中子俘获截面小以及在热水中具有耐腐蚀性,因此被广泛应用在核反应堆的压力管材料。研究者[86~89]运用原位中子衍射对锆合金做了系统的研究,其中单相Zircaloy-2合金压延板材的变形各向异性主要由初始织构和拉伸孪晶的极性引起[86],同时研究了高温变形中各个变形机制的温度依赖性[89]、双相锆合金的相应力分配行为[88]以及高温相变过程中存在的织构记忆效应[87]。Abdolvand等[90]运用结晶塑性有限元(crystal plasticity finite element method)分析了锆合金中滑移和孪晶2种主要变形模式的贡献。中子衍射在Ti中的研究主要集中在纯Ti[91~93],钛合金[94,95]的报道较少。这是由于Ti的相干散射长度为-3.44 × 10-15 m,当钛合金中其余合金元素的相干散射长度为正值时(如Al元素),合金的总相干散射长度会降低,所以大部分钛合金的衍射强度都比较低,这也是中子衍射在钛合金特别是高合金化β钛合金或形状记忆钛合金中应用较少的原因。Ti的力学行为与Zr相近,在此不再详叙。

fcc结构金属的变形机制会相对简单。例如Al有较高的层错能,所以Al及铝合金只有一种位错滑移。中子衍射对Al及铝合金的研究主要集中在相应力的分析,例如早期用来研究Al/SiC复合材料的相应力[48,49]。近年来,随着增材制造技术的兴起,利用原位中子衍射分析增材制造铝合金变形机制的研究[96~98]逐渐增多。主要通过分析变形过程中的应力分布和位错密度变化来研究增材制造方法的优劣。而对于层错能较低的金属(如孪晶诱发塑性(TWIP)钢),除了位错滑移,还有可能出现层错、孪晶以及ε马氏体转变。高/中熵合金是由多种主要元素组成的新型合金,由于其元素组成和成分调节范围很广,使得可调控的力学性能范围潜力较大,其中改变层错能是一种重要的强化手段。中子衍射在高熵、中熵合金中的应用也迅速增长,主要集中在原位测量变形过程中的位错密度[99~102]、层错概率[100~104]、应变诱导马氏体转变的体积分数[101,102]等组织演化,以及考虑相应力分配来理解合金的宏观变形行为[105]。由于层错能会随着变形温度降低而减小,使得高熵合金在低温下反而有更加优异的力学性能[106]。如Shi等[107]在77 K下的双相高熵合金中发现了bcc相存在巨大晶格应变。现阶段TAKUMI谱仪和ENGIN-X谱仪都具备极低温变形的样品环境。极低温的原位中子衍射也逐渐成为一种常规的研究手段,近年在高熵合金[100,101,107,108]、纯Ti[93]、铜合金[109]、镁合金[56,65]等非铁系材料的研究中都有重要贡献。

相比于金属材料,陶瓷/半导体具有迥然不同的力学性能。其中,Ag2S是一种典型的无机半导体材料,具有类似金属的塑性、可弯曲性,还具备半导体材料的高迁移率特征,有望在柔性电子中获得广泛应用。Ag2S常温常压下为单斜结构,温度可诱发超离子转变,Ag+在bcc结构“骨架”中无序扩散,具有“液体”特征。Wang等[110]对其室温相与高温相的变形机制开展了研究,室温相及高温相具有优异的塑形变形能力(真应变超过50%),远超传统半导体材料。随着应力不断增加,可以清晰观察到室温相出现了与金属材料类似的变形三阶段,即“grain-to-grain屈服”。与晶粒群取向相关的应力分配、衍射峰宽化及织构演化证明了位错滑移导致其加工硬化能力增加,从而使得室温塑性提高。而高温相中Ag+的无序扩散被抑制,此时bcc结构中的位错增殖加剧,2种变形模式相互竞争,使得高温相的塑性变形能力增加。

3 Bragg边成像

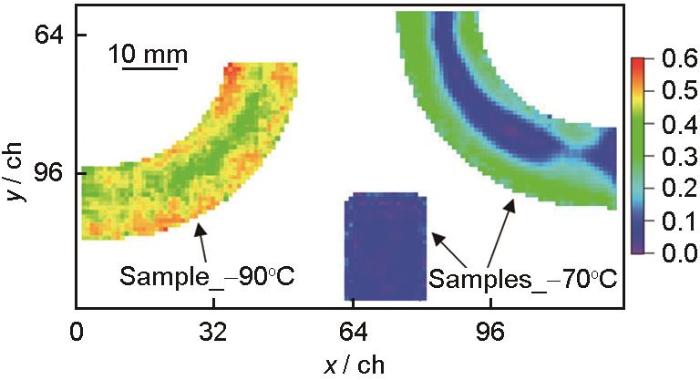

目前Bragg边成像法在技术开发方面仍充满挑战,但因为具有能够一次性对大面积(10 cm × 10 cm)和复杂形状的样品进行定量分析的优点,使其成为一种极具吸引力的研究方法。J-PARC的RADEN (螺鈿)谱仪是世界上第一台专用于脉冲型中子源的成像装置,除了传统的白光中子成像,还可以运用能量分辨成像技术,包括Bragg边成像、极化中子成像和共振吸收成像等。RADEN谱仪的波长分辨率约为0.2%,实现了约100 μm空间分辨率的Bragg边成像[14]。Su等[111]将Bragg边成像法应用于塑性加工后的铁素体钢和双相不锈钢,通过将Bragg边成像技术的结果(包括织构变化、相体积分数和晶粒尺寸)与中子衍射和电子背散射衍射等成熟方法进行比较,成功验证了该技术的可靠性。随后将Bragg边成像法用于相变组织表征[14,112],图7[14]展示了亚稳奥氏体合金大尺寸弯曲变形样品经过不同深冷处理后,马氏体相体积分数的定量二维分布。值得一提的是,当合金中粒径尺寸达到微米级时,Bragg边成像是一种有效的统计手段。由于衍射线强度变化与晶体的结晶度相关(主要是消光的影响),亦或是多重散射影响透射强度,因此可以利用这一点来计算合金中的晶粒尺寸。

图7

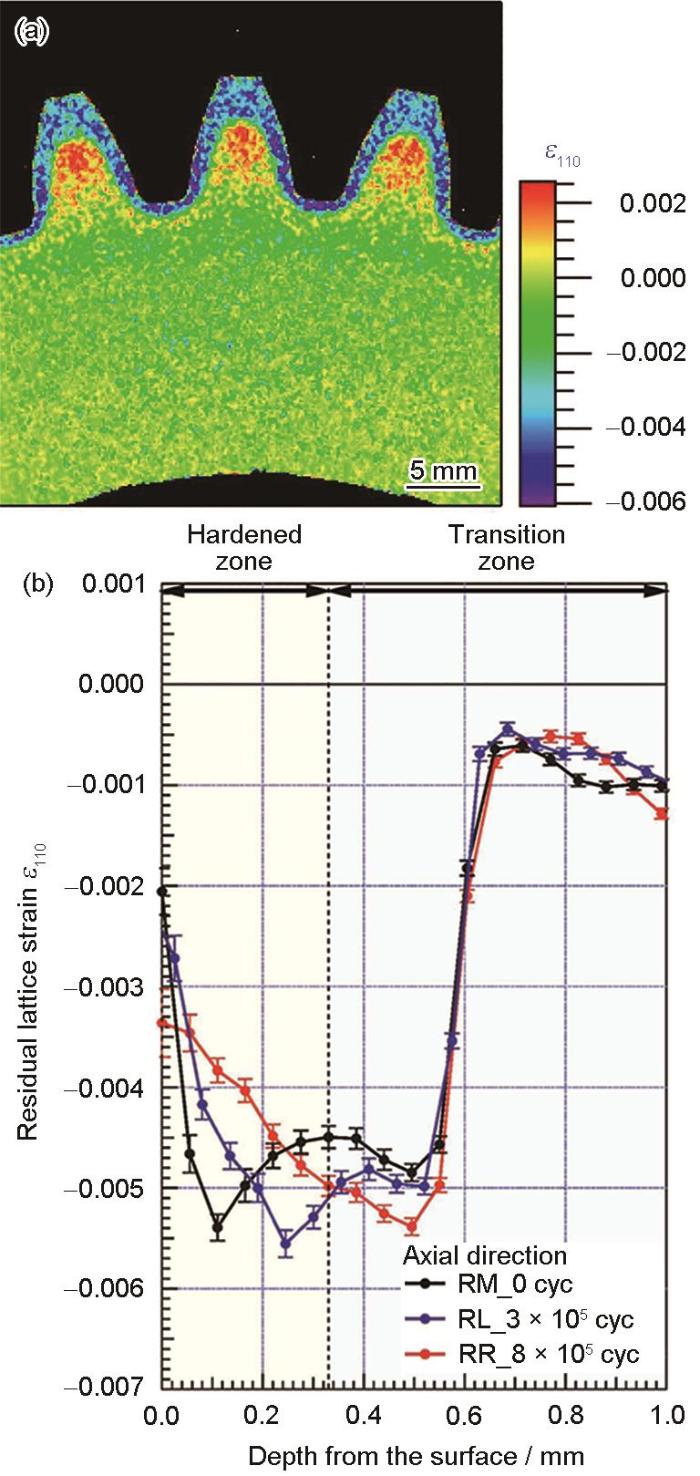

通过Bragg边位置的相对变化推导得到的残余应变可以进行应变成像(计算原理可参考衍射法)。Santisteban等[113]通过Bragg边透射光谱,首次实现了钢板中冷加工孔周围残余应变的可视化。在此基础上,Tremsin等[114]利用扭力钢螺栓紧固件进行原位透射成像,获得了亚毫米级空间分辨率的应变分布。Su等[115]对感应硬化齿轮在疲劳加载过程中引起的残余应力的松弛或重新分布进行了研究,在弯曲疲劳循环加载中,齿轮齿根的残余应力主要集中在受压侧,表明残余应力的松弛与疲劳损伤之间存在相关性,见图8[115]。在获得二维应变分布的基础上,开发CT技术[116]可对大尺寸部件残余应变的三维空间分布进行更深入的研究。此外,动态循环加载引起残余应力/应变重新分布对于准确预测疲劳寿命和有效控制零部件加工过程至关重要,这对现有中子源、检测器等多方面是一个技术上的挑战。

图8

图8

基于Bragg边透射成像所测的残余应变[115]

Fig.8

Residual lattice strains obtained via Bragg-edge imaging[115]

(a) a 2D map of residual lattice strain (ε110)

(b) distributions on the compressive side of the teeth root in the axial direction (RM, RL, and RR represent the right side of the tooth on the middle, the left, and the right sides, respectively)

4 其他中子散射技术的应用

4.1 小角散射

金属材料中的微观析出物对材料的强度有很大影响,评价其形态、分布至关重要。然而,由于观察区域受限,很难获得析出物的统计学信息。另一方面,衍射峰的宽化可以统计弹性相干散射大小,但对于工程材料的晶粒尺寸表征,这种方法通常不适用。原因在于,当粒径大于1 μm时,其对衍射峰线宽的影响变得很小,很难将其与位错引起的宽化分离出来,而且如果存在位错、孪晶、微应力等,局部晶粒取向会发生改变,这会导致相干散射的区域发生变化。由于析出物、夹杂物的体积分数较低,其衍射峰强度较弱,因此通过衍射峰的峰形分析粒径变得非常困难。而小角散射是发生在小散射矢量的弹性相干散射(见图2a和b),本质是获得不均匀结构(散射体)与母相之间的散射衬度差异,可以定量统计第二相的尺寸分布、形貌、体积比等方面的组织信息,是研究材料纳米结构的重要实验手段之一[125~127]。

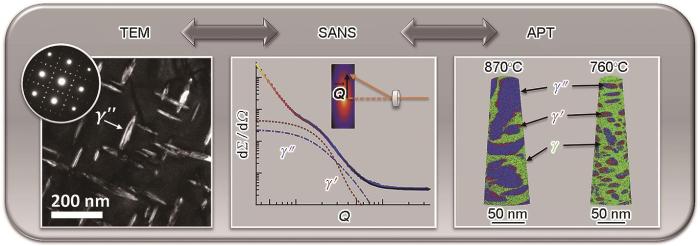

最近,Lawitzki等[128]利用小角中子散射技术成功区分并量化了镍基高温合金(Inconel718)中的γ'与γ"相的体积分数,并通过TEM与三维原子探针所获得的形态与成分信息构建了结构模型,精准分析了析出动力学的特征,如图9[128]所示。为了定量评估在工业上具有重要应用的中/高碳钢中发生的渗碳体球化现象,Su等[129]研究了高温退火条件下不同成分的珠光体钢的球化机理。Chen等[130,131]通过引入不同尺寸的纳米析出相,揭示了5系Al-Mg合金塑性变形过程中可剪切与不可剪切纳米析出相对Portevin-Le Chatelier效应的不同影响机制。此外,对于氧化物弥散强化合金中纳米颗粒尺寸、分布与成分的研究也不胜枚举。

图9

4.2 对分布函数分析

对于完美晶体,其原子结构可以由Bragg衍射方法精确确定。然而,当结构缺陷导致局域原子结构偏离长程平均原子结构时,衍射方法就无法准确描述材料的原子结构。玻璃态和液体可以看作极端情况,它们完全不具备长程有序的原子结构。此时,需要采用对分布函数(pair distribution function,PDF)来分析材料的局域原子结构,该方法与衍射法确定的长程结构一同构成了完整的原子结构图像。PDF (G(r))是衍射数据的Fourier变换,可用下式表示:

式中,S(Q)为结构因子,r为空间距离。G(r)的峰位代表了原子间距,峰的面积正比于原子对配位数,峰的宽度代表了无序程度。PDF数据一般在散裂中子源和高能同步辐射光源的谱仪采集,如CSNS的多物理谱仪(MPI)[132],通过“实空间精修”方法确定局域原子结构[133]。该方法最初常用来研究非晶合金[134]。2021年,Lan等[135]揭示了非晶态材料的中程序(0.5~2 nm)结构。该方法已广泛用于高熵合金[136~138]、超离子导体[139]、塑晶[140]等具有化学无序、原子占位无序、取向无序等体系。PDF分析直接表明高熵合金中随着原子尺寸差异的增大,局域原子畸变加剧,例如三元合金TiVNb和五元合金TiVZrNbHf的局域原子畸变分别为4.29%和6.96%[137]。

4.3 非弹/准弹性散射

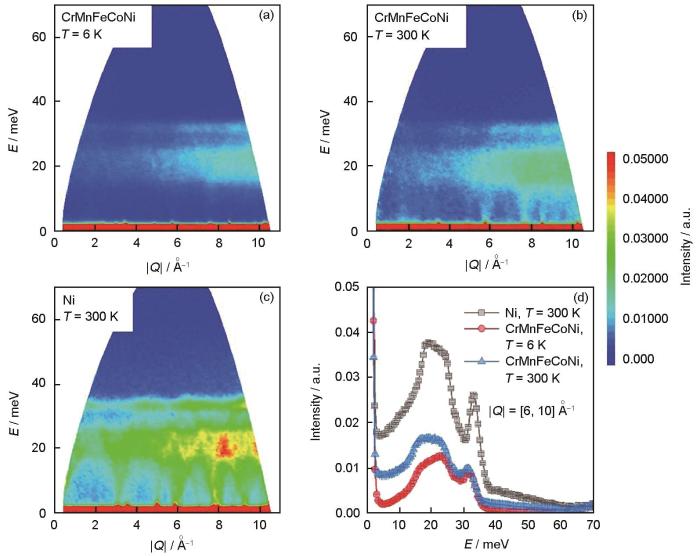

非弹性中子散射研究表明(图10[141]),相较于结构原型单质金属Ni,CrMnFeCoNi高熵合金的声子呈现明显软化,且在低能处(约15 meV)存在较大区别[141]。由于H原子具有巨大的非相干散射截面,该技术已被用来研究H原子在金属中的高频振动和扩散过程[142]。H原子在金属中的振动能级与金属原子和H原子之间的距离有关,距离越长相互作用越弱,振动能级也就越低。Hynes等[142]用2个经验关系来描述这一规律,即线性的Sakamoto关系和指数型的Rose关系。拟合准弹性中子散射数据,可以确定H原子在金属中扩散激活能、扩散系数、弛豫时间、扩散路径等决定扩散过程的重要微观参量[143,144]。例如,利用准弹性中子散射技术确定了各类锆合金中H的扩散激活能约为0.5 eV。

图10

图10

CrMnFeCoNi合金的非弹性中子散射谱[141]

Fig.10

Inelastic neutron scattering in CrMnFeCoNi alloy[141] (The dynamic structural factor, denoted as S(Q, E),is produced as a function of Q and energy transfer E. T—temperature)

(a, b) S(Q, E) contour plots of CrMnFeCoNi at 6 and 300 K

(c) S(Q, E) contour plot of Ni at 300 K

(d) sliced spectra at 6 Å-1 ≤ |Q| ≤ 10 Å-1

5 结论与展望

中子散射技术是人类了解物质微观结构和运动状态的重要工具之一,是材料研究的前沿核心技术,在诸多领域扮演了不可替代的角色,逐渐为各国所重视。经过长期的原位中子散射研究,在钢铁材料相变理论方面,通过分析相转变过程中相应力的演化,发现了晶格缺陷对相应力的潜在影响机制;在镁合金的变形行为方面,通过相应力、孪晶体积分数及位错密度的定量评估,揭示了镁合金的强化机理;在大面积复杂形状金属材料的残余应力测量方面,通过Bragg边成像分析,显示了其具有良好的空间及波长分辨率进行残余应变和微观结构的可视化。

(1) 时间分辨中子散射技术。中子通量相对于同步辐射X射线仍然较低,因此中子衍射技术的时间分辨能力在分钟甚至更长。在该时间尺度上,可以研究某些关键材料的大尺度范围的平均微观组织演化规律和内部力学机制。

(2) 极端环境下材料的服役问题。中子相对于同步辐射X射线的最大优势是穿透深度大,可构建复杂样品环境。因此,针对某些苛刻服役环境,设计样品环境研究材料服役行为大有可为。

(3) 通过电子衍射、同步辐射X射线衍射和中子衍射联用,实现材料的跨尺度精确表征。

参考文献

Magnetic moment and chemical order in off-stoichiometric Ni-Mn-Ga ferromagnetic shape memory alloys

[J].

Neutron scattering studies of heterogeneous catalysis

[J].Understanding the structural dynamics/evolution of catalysts and the related surface chemistry is essential for establishing structure-catalysis relationships, where spectroscopic and scattering tools play a crucial role. Among many such tools, neutron scattering, though less-known, has a unique power for investigating catalytic phenomena. Since neutrons interact with the nuclei of matter, the neutron-nucleon interaction provides unique information on light elements (mainly hydrogen), neighboring elements, and isotopes, which are complementary to X-ray and photon-based techniques. Neutron vibrational spectroscopy has been the most utilized neutron scattering approach for heterogeneous catalysis research by providing chemical information on surface/bulk species (mostly H-containing) and reaction chemistry. Neutron diffraction and quasielastic neutron scattering can also supply important information on catalyst structures and dynamics of surface species. Other neutron approaches, such as small angle neutron scattering and neutron imaging, have been much less used but still give distinctive catalytic information. This review provides a comprehensive overview of recent advances in neutron scattering investigations of heterogeneous catalysis, focusing on surface adsorbates, reaction mechanisms, and catalyst structural changes revealed by neutron spectroscopy, diffraction, quasielastic neutron scattering, and other neutron techniques. Perspectives are also provided on the challenges and future opportunities in neutron scattering studies of heterogeneous catalysis.

An inert-gas furnace for neutron scattering measurements of internal stresses in engineering materials

[J].

Application of neutron imaging in observing various states of matter inside lithium batteries

[J].

The energy-selective option in neutron imaging

[J].

Wavelength tunable device for neutron radiography and tomography

[J].

Conceptual monochromatic digital neutron radiography using continuous cold neutron beam

[J].

Energy sliced neutron tomography using neutron resonance absorption spectrometer

[J].

Non-destructive study of bulk crystallinity and elemental composition of natural gold single crystal samples by energy-resolved neutron imaging

[J].Energy-resolved neutron imaging enables non-destructive analyses of bulk structure and elemental composition, which can be resolved with high spatial resolution at bright pulsed spallation neutron sources due to recent developments and improvements of neutron counting detectors. This technique, suitable for many applications, is demonstrated here with a specific study of similar to 5-10 mm thick natural gold samples. Through the analysis of neutron absorption resonances the spatial distribution of palladium (with average elemental concentration of similar to 0.4 atom% and similar to 5 atom%) is mapped within the gold samples. At the same time, the analysis of coherent neutron scattering in the thermal and cold energy regimes reveals which samples have a single-crystalline bulk structure through the entire sample volume. A spatially resolved analysis is possible because neutron transmission spectra are measured simultaneously on each detector pixel in the epithermal, thermal and cold energy ranges. With a pixel size of 55 mu m and a detector-area of 512 by 512 pixels, a total of 262,144 neutron transmission spectra are measured concurrently. The results of our experiments indicate that high resolution energy-resolved neutron imaging is a very attractive analytical technique in cases where other conventional non-destructive methods are ineffective due to sample opacity.

Neutron scattering of magnetocaloric and barocaloric materials

[J].

磁卡与压卡材料的中子散射

[J].

First in situ lattice strains measurements under load at VULCAN

[J].

Current status of engineering materials diffractometer at J-PARC

[J].

The energy-resolved neutron imaging system, RADEN

[J].

The first application of a Gd3Al2Ga3O12:Ce single-crystal scintillator to neutron radiography

[J].

Time-of-flight neutron imaging on IMAT@ISIS: A new user facility for materials science

[J].

The new engineering material diffractometer (EMD) at CSNS

[R].

Progress of GPPD & ERNI and their applications at CSNS

[R].

The neutron scattering platform of China Mianyang Research Reactor (CMRR) and recent applications

[J].

中国绵阳研究堆CMRR中子散射平台及应用

[J].

HETU: A new high-resolution stress and texture neutron diffractometer at China Mianyang Research Reactor

[J].

Current status and future prospect of neutron facilities at China advanced research reactor

[J].

中国先进研究堆中子科学平台发展现状及展望

[J].

The current status of neutron imaging project at CARR

[R].

The lattice parameters of austenite and ferrite in Fe-C alloys as functions of carbon concentration and temperature

[J].

Reverse austenite transformation behavior in a tempered martensite low-alloy steel studied using in situ neutron diffraction

[J].

Effect of prior martensite on bainite transformation in nanobainite steel

[J].

In-situ synchrotron diffraction studies on transformation strain development in a high strength quenched and tempered structural steel—Part I. Bainitic transformation

[J].

Effect of Si on bainitic transformation kinetics in steels explained by carbon partitioning, carbide formation, dislocation densities, and thermodynamic conditions

[J].

Principal preferred orientation evaluation of steel materials using time-of-flight neutron diffraction

[J].

Revealing the role of dislocations on the stability of retained austenite in a tempered bainite

[J].

High-tech composites to ancient metals

[J].

Quantitative analysis of microstructure evolution, stress partitioning and thermodynamics in the dynamic transformation of Fe-14Ni alloy

[J].Dynamic transformation (DT) of austenite (γ) to ferrite (α) in the hot deformation of various carbon steels was widely investigated. However, the nature of DT remains unclear due to the lack of quantitative analysis of stress partitioning between two phases and the uncertainty of local distribution of substitutional elements at the interface in multi-component carbon steels used in the previous studies. Therefore, in the present study, a binary Fe-Ni alloy with α + γ duplex microstructure in equilibrium was prepared and isothermally compressed in α + γ two-phase region to achieve a quantitative analysis of microstructure evolution, stress partitioning, and thermodynamics during DT. γ to α DT during isothermal compression and α to γ reverse transformation on isothermal annealing under unloaded condition after deformation were accompanied by Ni partitioning. The lattice strains during thermomechanical processing were obtained via in-situ neutron diffraction measurement, based on which the stress partitioning behavior between γ and α was discussed by using the generalized Hooke's law. A thermodynamic framework for the isothermal deformation in solids was established based on the basic laws of thermodynamics, and it was shown that the total Helmholtz free energy change in the deformable material during the isothermal process should be smaller than the work done to the deformable material. Under the present thermodynamic framework, the microstructure evolution in the isothermal compression of Fe-14Ni alloy was well explained by considering the changes in chemical free energy, plastic and elastic energies, and the work done to the material. In addition, the stabilization of the soft α phase in Fe-14Ni alloy by deformation was rationalized since the γ to α transformation decreased the total Helmholtz free energy by decreasing the elastic and dislocation energies.

In situ neutron diffraction study on ferrite and pearlite transformations for a 1.5Mn-1.5Si-0.2C steel

[J].

Operando neutron diffraction reveals mechanisms for controlled strain evolution in 3D printing

[J].Residual stresses affect the performance and reliability of most manufactured goods and are prevalent in casting, welding, and additive manufacturing (AM, 3D printing). Residual stresses are associated with plastic strain gradients accrued due to transient thermal stress. Complex thermal conditions in AM produce similarly complex residual stress patterns. However, measuring real-time effects of processing on stress evolution is not possible with conventional techniques. Here we use operando neutron diffraction to characterize transient phase transformations and lattice strain evolution during AM of a low-temperature transformation steel. Combining diffraction, infrared and simulation data reveals that elastic and plastic strain distributions are controlled by motion of the face-centered cubic and body-centered cubic phase boundary. Our results provide a new pathway to design residual stress states and property distributions within additively manufactured components. These findings will enable control of residual stress distributions for advantages such as improved fatigue life or resistance to stress-corrosion cracking.© 2023. Springer Nature Limited.

Real time observation of martensite transformation for a 0.4C low alloyed steel by neutron diffraction

[J].

Dislocation activities at the martensite phase transformation interface in metastable austenitic stainless steel: An in-situ TEM study

[J].

Internal residual stress originated from Bain strain and its effect on hardness in Fe-Ni martensite

[J].

In situ investigation of the evolution of lattice strain and stresses in austenite and martensite during quenching and tempering of steel

[J].

Into the quenching & partitioning of a 0.2C steel: An in-situ synchrotron study

[J].

Evolution of austenite lattice parameter during isothermal transformation in a 0.4 C low alloyed steel

[J].

Lattice parameters of austenite and martensite during transformation for Fe-18Ni alloy investigated through in-situ neutron diffraction

[J].

The determination of the elastic field of an ellipsoidal inclusion, and related problems

[J].

Average stress in matrix and average elastic energy of materials with misfitting inclusions

[J].

Positron annihilation study of lattice defects induced by hydrogen absorption in some hydrogen storage materials

[J].

Excess vacancies induced by disorder-order phase transformation in Ni3Fe

[J].

Nature of dynamic ferrite transformation revealed by in-situ neutron diffraction analysis during thermomechanical processing

[J].

Multiscale residual stress evaluation of engineering materials/components based on neutron and synchrotron radiation technology

[J].Multiscale residual stress exists throughout the manufacturing process of engineering components, from design and production to processing and servicing. This stress can impact the machining accuracy, structural load capacity, and fatigue lifespan of these components. Therefore, accurate measurement and regulation of residual stress are critical for ensuring the longevity and reliability of engineering components. However, precise characterization of residual stress is challenging owing to its multilevel and cross-scale distribution traits and dynamic evolution under various conditions, such as temperature and load. Compared with laboratory X-ray measurement methods, neutron diffraction (ND), synchrotron-based high-energy X-ray diffraction (HE-XRD), and synchrotron-based X-ray microbeam diffraction (μ-XRD) techniques offer increased penetration depth and better time and spatial resolutions. In addition, the ability to attach environmental devices enables nondestructive and accurate in situ characterization of three types of residual stresses: macroscopic residual stress, intergranular or interphase microscopic stress, and intragranular ultramicroscopic stress. ND is currently the only nondestructive method capable of accurately measuring three-dimensional (3D) stress at centimeter-level depths within engineering components. HE-XRD, due to its high flux, excellent collimation, and millimeter-level penetration depth for metals, can be utilized for in situ studies of intergranular and interphase stress evolution and partitioning during deformation. The μ-XRD employs a submicron focused beam and differential aperture technology to analyze depth information of a sample. By conducting point-by-point scanning, it can capture 3D distribution of microscopic stress inside a single grain. Furthermore, our group has developed a novel method and device for depth stress characterization based on differential aperture technology under synchrotron-based high-energy monochromatic X-ray transmission geometry, and can measure stress gradients with high precision from the surface to the interior of engineering materials at millimeter-level depths. This study presents the measurement principles, application ranges, and applications of the above-mentioned multiscale stress characterization technologies based on the neutron/synchrotron facilities as well as envisaging the future development of related technologies.

基于中子与同步辐射技术的工程材料/部件多尺度残余应力评价

[J].多尺度残余应力贯穿于工程部件设计、生产、加工和服役的全生命周期,对工程部件的长寿命可靠服役具有重要意义。残余应力具有多层次、跨尺度的分布特征,在温度、载荷等服役环境作用下发生动态演化,给精确表征带来了很大困难。相较于传统实验室X射线残余应力测量方法,中子衍射、同步辐射高能X射线衍射和同步辐射微束衍射技术在穿透深度、时间分辨率、空间分辨率、环境装置等方面具有显著优势,能够实现宏观残余应力、晶间/相间微观应力、晶内超微观应力3类残余应力的原位无损精确表征。本文详细介绍了上述基于中子/同步辐射大科学装置的多尺度应力表征技术的测量原理、应用范围和典型应用案例,并对相关技术的发展进行了展望。

Measurement of a stress gradient through the bulk of an aluminum alloy using neutrons

[J].

The use of time-of-flight neutron diffraction to study grain interaction stresses

[J].

The analysis of internal strains measured by neutron diffraction in Al/SiC metal matrix composites

[J].

An examination of the mean stress contribution to the Bauschinger effect by neutron diffraction

[J].

Measuring texture-component-dependent stress of CuZn39Pb2 by neutron diffraction

[J].

Study of the mechanical properties of Mg-7.7at.% Al by in-situ neutron diffraction

[J].

In-situ neutron diffraction study on tensile behavior of LPSO Mg-Zn-Y alloys

[J].

Neutron diffraction monitoring of as-cast Mg97Zn1Y2 during compression and tension

[J].

Rediscovery of Hall-Petch strengthening in bulk ultrafine grained pure Mg at cryogenic temperature: A combined in-situ neutron diffraction and electron microscopy study

[J].

Strengthening of αMg and long-period stacking ordered phases in a Mg-Zn-Y alloy by hot-extrusion with low extrusion ratio

[J].

Contributions of multimodal microstructure in the deformation behavior of extruded Mg alloys containing LPSO phase

[J].

Investigation of deformation mechanisms involved in the plasticity of AZ31 Mg alloy: In situ neutron diffraction and EPSC modelling

[J].

In situ neutron diffraction investigation of deformation twinning and pseudoelastic-like behaviour of extruded AZ31 magnesium alloy

[J].

Investigation of deformation twinning in a fine-grained and coarse-grained ZM20 Mg alloy: Combined in situ neutron diffraction and acoustic emission

[J].

On the correlation between deformation twinning and Lüders-like deformation in an extruded Mg alloy: In situ neutron diffraction and EPSC.4 modelling

[J].

Deformation behavior of solid-solution-strengthened Mg-9 wt.% Al alloy: In situ neutron diffraction and elastic-viscoplastic self-consistent modeling

[J].

Deformation behavior of as-cast and as-extruded Mg97Zn1Y2 alloys during compression, as tracked by in situ neutron diffraction

[J].

Compressive deformation behavior of AZ31 alloy at 21K: An in-situ neutron diffraction study

[J].

Effect of extrusion ratio in hot-extrusion on kink deformation during compressive deformation in an αMg/LPSO dual-phase magnesium alloy monitored by in situ neutron diffraction

[J].

Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction

[J].

Effect of the loading mode on the evolution of the deformation mechanisms in randomly textured magnesium polycrystals—Comparison of experimental and modeling results

[J].

Dependence of twinned volume fraction on loading mode and Schmid factor in randomly textured magnesium

[J].

Internal strain and texture evolution during deformation twinning in magnesium

[J].

Reorientation and stress relaxation due to twinning: Modeling and experimental characterization for Mg

[J].

In situ neutron diffraction and polycrystal plasticity modeling of a Mg-Y-Nd-Zr alloy: Effects of precipitation on individual deformation mechanisms

[J].

In-situ observation of twinning and detwinning in AZ31 alloy

[J].

Twinning-detwinning behavior during the strain-controlled low-cycle fatigue testing of a wrought magnesium alloy, ZK60A

[J].

Internal stress relaxation and load redistribution during the twinning-detwinning-dominated cyclic deformation of a wrought magnesium alloy, ZK60A

[J].

Deformation dynamics study of a wrought magnesium alloy by real-time in situ neutron diffraction

[J].

Investigation of deformation dynamics in a wrought magnesium alloy

[J].

Unraveling cyclic deformation mechanisms of a rolled magnesium alloy using in situ neutron diffraction

[J].

A study of residual stresses in Zircaloy-2 with rod texture

[J].

Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling

[J].

The evolution of non-basal dislocations as a function of deformation temperature in pure magnesium determined by X-ray diffraction

[J].

Grain to grain slip activity in plastically deformed Zr determined by X-ray micro-diffraction line profile analysis

[J].

Evolution of dislocation and twin densities in a Mg alloy at quasi-static and high strain rates

[J].

Recent progress of line-profile analyses for neutron or X-ray diffraction

[J].

ハルヨステファヌス中性子・X線回折ラインプロファイル解析の最近の進歩

[J].

A Method to calculate the dislocation density of a TWIP steel based on neutron diffraction and synchrotron X-ray diffraction

[J].The modified Williamson-Hall method, which has been widely used to calculate dislocation densities of high-strength steels and other structural alloys, is re-examined in this work, and is further applied to calculate the dislocation density of a deformed twinning-induced plasticity (TWIP) steel by using its neutron diffraction patterns and synchrotron X-ray diffraction patterns. This paper aims not only to promote the proper use of the method but also to shed light on its underlying pre-requisites and assumptions, and is thus expected to help avoid any errors during its usage.

基于中子衍射和同步辐射X射线衍射的TWIP钢位错密度计算方法

[J].本文详细梳理并介绍了被广泛应用于高强钢及其它结构金属材料位错密度计算的修正Williamson-Hall法,并结合中子衍射和同步辐射X射线衍射实验结果,以一种孪生诱发塑性(TWIP)钢为例,计算其在变形后的位错密度演化。本文详细介绍如何正确使用该方法以及如何避免常见的一些错误,并介绍其背后的原理及假设。

Development of internal strains in textured Zircaloy-2 during uni-axial deformation

[J].

Texture inheritance and variant selection through an hcp-bcc-hcp phase transformation

[J].

Deformation of high β-phase fraction Zr-Nb alloys at room temperature

[J].

Temperature dependence of the activity of deformation modes in an HCP zirconium alloy

[J].

Incorporation of twinning into a crystal plasticity finite element model: Evolution of lattice strains and texture in Zircaloy-2

[J].

Lattice strain evolution during tensile and compressive loading of CP Ti

[J].

Experimental and theoretical studies of intergranular strain in an alpha titanium alloy during plastic deformation

[J].

In-situ neutron diffraction study of lattice deformation behaviour of commercially pure titanium at cryogenic temperature

[J].

Stress relaxation behavior and mechanisms in Ti-6Al-4V determined via in situ neutron diffraction: Application to additive manufacturing

[J].

Study on formation mechanism of {332} <113> deformation twinning in metastable β-type Ti alloy focusing on stress-induced α" martensite phase

[J].

Stress partitioning behavior of an AlSi10Mg alloy produced by selective laser melting during tensile deformation using in situ neutron diffraction

[J].

Quantifying internal strains, stresses, and dislocation density in additively manufactured AlSi10Mg during loading-unloading-reloading deformation

[J].

Multiscale constitutive modeling of additively manufactured Al-Si-Mg alloys based on measured phase stresses and dislocation density

[J].

Deformation of CoCrFeNi high entropy alloy at large strain

[J].

Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction

[J].

Stacking fault driven phase transformation in CrCoNi medium entropy alloy

[J].Phase transformation is an effective means to increase the ductility of a material. However, even for a commonly observed face-centered-cubic to hexagonal-close-packed (-to-) phase transformation, the underlying mechanisms are far from being settled. In fact, different transformation pathways have been proposed, especially with regard to nucleation of the phase at the nanoscale. In CrCoNi, a so-called medium-entropy alloy, an -to- phase transformation has long been anticipated. Here, we report an loading study with neutron diffraction, which revealed a bulk -to- phase transformation in CrCoNi at 15 K under tensile loading. By correlating deformation characteristics of the phase with the development of the phase, it is shown that the nucleation of the phase was triggered by intrinsic stacking faults. The confirmation of a bulk phase transformation adds to the myriads of deformation mechanisms available in CrCoNi, which together underpin the unusually large ductility at low temperatures.

Metalloid substitution elevates simultaneously the strength and ductility of face-centered-cubic high-entropy alloys

[J].

Deformation mechanisms of Mo alloyed FeCoCrNi high entropy alloy: In situ neutron diffraction

[J].

Stacking fault energy analyses of additively manufactured stainless steel 316L and CrCoNi medium entropy alloy using in situ neutron diffraction

[J].Stacking fault energies (SFE) were determined in additively manufactured (AM) stainless steel (SS 316 L) and equiatomic CrCoNi medium-entropy alloys. AM specimens were fabricated via directed energy deposition and tensile loaded at room temperature. In situ neutron diffraction was performed to obtain a number of faulting-embedded diffraction peaks simultaneously from a set of (hkl) grains during deformation. The peak profiles diffracted from imperfect crystal structures were analyzed to correlate stacking fault probabilities and mean-square lattice strains to the SFE. The result shows that averaged SFEs are 32.8 mJ/m for the AM SS 316 L and 15.1 mJ/m for the AM CrCoNi alloys. Meanwhile, during deformation, the SFE varies from 46 to 21 mJ/m (AM SS 316 L) and 24 to 11 mJ/m (AM CrCoNi) from initial to stabilized stages, respectively. The transient SFEs are attributed to the deformation activity changes from dislocation slip to twinning as straining. The twinning deformation substructure and atomic stacking faults were confirmed by electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). The significant variance of the SFE suggests the critical twinning stress as 830 ± 25 MPa for the AM SS 316 L and 790 ± 40 MPa for AM CrCoNi, respectively.

High-density nanoprecipitates and phase reversion via maraging enable ultrastrong yet strain-hardenable medium-entropy alloy

[J].

Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures

[J].High-entropy alloys are an intriguing new class of metallic materials that derive their properties from being multi-element systems that can crystallize as a single phase, despite containing high concentrations of five or more elements with different crystal structures. Here we examine an equiatomic medium-entropy alloy containing only three elements, CrCoNi, as a single-phase face-centred cubic solid solution, which displays strength-toughness properties that exceed those of all high-entropy alloys and most multi-phase alloys. At room temperature, the alloy shows tensile strengths of almost 1 GPa, failure strains of similar to 70% and K-JIc fracture-toughness values above 200 MPa m(1/2); at cryogenic temperatures strength, ductility and toughness of the CrCoNi alloy improve to strength levels above 1.3 GPa, failure strains up to 90% and K-JIc values of 275 MPa m(1/2). Such properties appear to result from continuous steady strain hardening, which acts to suppress plastic instability, resulting from pronounced dislocation activity and deformation-induced nano-twinning.

In situ neutron diffraction study of a new type of stress-induced confined martensitic transformation in Fe22Co20Ni19Cr20Mn12Al7 high-entropy alloy

[J].

Cooperative deformation in high-entropy alloys at ultralow temperatures

[J].

Work hardening behavior of dual phase copper-iron alloy at low temperature

[J].

In situ neutron diffraction study on the deformation behavior of the plastic inorganic semiconductor Ag2S

[J].

Time-of-flight neutron Bragg-edge transmission imaging of microstructures in bent steel plates

[J].

Time-of-flight neutron transmission imaging of martensite transformation in bent plates of a Fe-25Ni-0.4C alloy

[J].

Strain imaging by Bragg edge neutron transmission

[J].

Non‐destructive examination of loads in regular and self-locking Spiralock® threads through energy-resolved neutron imaging

[J].

Residual stress relaxation by bending fatigue in induction-hardened gear studied by neutron Bragg edge transmission imaging and X-ray diffraction

[J].

Bragg-edge elastic strain tomography for in situ systems from energy-resolved neutron transmission imaging

[J].

Characterization and application of Bragg-edge transmission imaging for strain measurement and crystallographic analysis on the IMAT beamline

[J].This paper presents a series of experiments to characterize the performance of the new IMAT beamline at the ISIS pulsed neutron source and provides examples to showcase the potential applications of Bragg-edge transmission imaging on the instrument. The characterization includes determination of the IMAT spectral and spatial resolutions through calibration measurements, and also determination of the precision and the accuracy of Bragg-edge analysis for lattice parameters of ceramics, metals and textured engineering alloys through high-temperature measurements. A novel Bragg-edge analysis method based on the cross-correlation of different Bragg edges has been developed to provide an estimate of the change in lattice parameter, which is especially useful for measurements of textured samples. Three different applications of the Bragg-edge transmission imaging technique are presented, including strain mapping, texture mapping and obtaining crystallographic information, i. e. the dependence on temperature of the Debye-Waller factor. The experimental results demonstrate the ability of the IMAT beamline to provide accurate strain measurements with uncertainties as low as 90 mu epsilon with reasonable measurement time, while characteristic materials parameters can be mapped across the sample with a spatial resolution of 300-600 mu m for a strain map and down to similar to 90 mu m for a texture map.

Influence of carbon concentration and magnetic transition on the austenite lattice parameter of 30Mn-C steel

[J].

Neutron Bragg-edge transmission imaging for microstructure and residual strain in induction hardened gears

[J].A time-of-flight Bragg-edge neutron transmission imaging was used to investigate the microstructure and strain distributions in a gear hardened by a newly developed two-step induction-heating method: precursor (Sample 1) and final product (Sample 2). The edge-position and edge-broadening were determined and mapped with high spatial resolution, which enabled us to confirm the two-dimensional distributions of the microstructure and residual strain. A deep hardened layer was made for Sample 1 in which martensite was formed on the entire teeth and the outer peripheral portion of the gear body. Sample 2 was subjected to double induction-hardening, where a tempered martensite was formed as the thermal refined microstructure between a fine-grained martensite at the tooth surface and a ferrite-pearlite microstructure at the core. The relationship between edge-broadening and the Vickers hardness described by a linear equation was employed to derive the elastic residual strain. The residual strain map for Sample 2 revealed that a steep compressive strain was introduced into the fine-grained martensite at the tooth surface by the super rapid induction-heating and quenching process. The reversal of tension was speculated to occur below 2 mm from the tooth tip, and the strain was almost zero in the core region.

Microstructure and texture analysis of 304 austenitic stainless steel using Bragg edge transmission imaging

[J].

Nondestructive characterization of laser powder bed fusion parts with neutron Bragg edge imaging

[J].

Mechanical surface treatment studies by Bragg edge neutron imaging

[J].

Spatial distribution and preferred orientation of crystalline microstructure of lead-bismuth eutectic

[J].

Pulsed neutron imaging based crystallographic structure study of a Japanese sword made by sukemasa in the muromachi period

[J].

Origin of the enhanced hardness of a tempered high-nitrogen martensitic steel

[J].

A new method for the quantitative analysis of the scale and composition of nanosized oxide in 9Cr-ODS steel

[J].

Evolution of the precipitate composition during annealing of vanadium micro-alloyed steels by in-situ SANS

[J].

Differentiation of γ'- and γ''- precipitates in Inconel 718 by a complementary study with small-angle neutron scattering and analytical microscopy

[J].We present an experimental method to distinguish and quantify the two strengthening phases gamma' and gamma '' in the nickel-based superalloy Inconel 718. So far, this was only achieved by techniques that evaluated sample volumes in the nano-to micrometer range. In this study, reliable volume fractions of the precipitates were obtained and calculated from ex-situ small-angle neutron scattering (SANS) on differently heat treated specimens. For interpretation of the SANS curves, a structural model was set up, using complementary information from measurements by transmission electron microscopy (TEM) and atom probe tomography (APT). Phase identification, as well as size distributions, morphologies and crystal-lographic information of the precipitates were obtained by TEM. APT provided compositional information, which is necessary to calculate the scattering contrast of each phase. As a benefit of using bulk neutron diffraction for quantification, volumes of a few tens of cubic millimeters are analyzed and thus, significantly better statistics are obtained. The measured gamma '' volume fractions are remarkably lower than stated in previous works, but now well fulfill the chemical mass balance. (C) 2018 Acta Materialia Inc. Published by Elsevier Ltd.

Quantitative analysis of cementite spheroidization in pearlite by small-angle neutron scattering

[J].

Effects of nanosized precipitates on the Portevin-Le Chatelier behavior: Model prediction and experimental verification

[J].

Quantitative assessment of the influence of the Portevin-Le Chatelier effect on the flow stress in precipitation hardening AlMgScZr alloys

[J].

Multi-physics instrument: Total scattering neutron time-of-flight diffractometer at China Spallation Neutron Source

[J].

PDFfit2 and PDFgui: Computer programs for studying nanostructure in crystals

[J].

Structure of metallic glasses: Experiments and models

[J].

A medium-range structure motif linking amorphous and crystalline states

[J].Amorphous materials have no long-range order, but there are ordered structures at short range (2-5 Å), medium range (5-20 Å) and even longer length scales. While regular and semiregular polyhedra are often found as short-range ordering in amorphous materials, the nature of medium-range order has remained elusive. Consequently, it is difficult to determine whether there exists any structural link at medium range or longer length scales between the amorphous material and its crystalline counterparts. Moreover, an amorphous material often crystallizes into a phase of different composition, with very different underlying structural building blocks, further compounding the issue. Here, we capture an intermediate crystalline cubic phase in a Pd-Ni-P amorphous alloy and reveal the structure of the medium-range order, a six-membered tricapped trigonal prism cluster (6M-TTP) with a length scale of 12.5 Å. We find that the 6M-TTP can pack periodically to several tens of nanometres to form the cube phase. Our experimental observations provide evidence of a structural link between the amorphous and crystalline phases in a Pd-Ni-P alloy at the medium-range length scale and suggest that it is the connectivity of the 6M-TTP clusters that distinguishes the crystalline and amorphous phases. These findings will shed light on the structure of amorphous materials at extended length scales beyond that of short-range order.

Local atomic structure of a high-entropy alloy: An X-ray and neutron scattering study

[J].

Local order in high-entropy alloys and associated deuterides—A total scattering and Reverse Monte Carlo study

[J].

An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy

[J].

Liquid-like thermal conduction in intercalated layered crystalline solids

[J].As a generic property, all substances transfer heat through microscopic collisions of constituent particles1. A solid conducts heat through both transverse and longitudinal acoustic phonons, but a liquid employs only longitudinal vibrations2,3. As a result, a solid is usually thermally more conductive than a liquid. In canonical viewpoints, such a difference also serves as the dynamic signature distinguishing a solid from a liquid. Here, we report liquid-like thermal conduction observed in the crystalline AgCrSe2. The transverse acoustic phonons are completely suppressed by the ultrafast dynamic disorder while the longitudinal acoustic phonons are strongly scattered but survive, and are thus responsible for the intrinsically ultralow thermal conductivity. This scenario is applicable to a wide variety of layered compounds with heavy intercalants in the van der Waals gaps, manifesting a broad implication on suppressing thermal conduction. These microscopic insights might reshape the fundamental understanding on thermal transport properties of matter and open up a general opportunity to optimize performances of thermoelectrics.

Local atomic structures and lattice dynamics of inverse colossal barocaloric ammonium thiocyanate

[J].

Mictomagnetism and suppressed thermal conduction of the prototype high-entropy alloy CrMnFeCoNi

[J].High-entropy alloys are characteristic of extensive atomic occupational disorder on high-symmetric lattices, differing from traditional alloys. Here, we investigate the magnetic and thermal transport properties of the prototype face-centered-cubic high-entropy alloy CrMnFeCoNi by combining physical properties measurements and neutron scattering. Direct-current and alternating-current magnetizations measurements indicate a mictomagnetic behavior with coexisting antiferromagnetic and ferromagnetic interactions below room temperature and three anomalies are found at about 80, 40, and 20 K, which are related to the paramagnetic to antiferromagnetic transition, the antiferromagnetic to ferromagnetic transition, and the spin freezing, respectively. The electrical and thermal conductivities are significantly reduced compared to Ni, and the temperature dependence of lattice thermal conductivity exhibits a glass-like plateau. Inelastic neutron scattering measurements suggest weak anharmonicity so that the thermal transport is expected to be dominated by the defect scattering.

Hydrogen diffusion in bulk and nanocrystalline palladium: A quasielastic neutron scattering study

[J].

Direct measurement of hydrogen diffusivity and solubility limits in Zircaloy 2 (formula unit of ZrH0.0155) using incoherent quasi-elastic neutron scattering

[J].The diffusivity of hydrogen is an important property of light water nuclear reactor (LWR) fuel cladding. LWR cladding absorbs hydrogen during normal operation, a contributing factor to embrittlement that decreases the lifetime of the fuel. Mass transport of hydrogen is dictated by an Arrhenius behavior typical of solid state diffusion and the associated activation energy is therefore a property relevant to LWR fuel performance. We have used incoherent quasi-elastic neutron scattering (QENS) to directly measure the diffusivity of hydrogen in recrystallized Zircaloy 2 with a hydrogen concentration of 170 mu g/g. We rely upon the low-Q expansion for long-range diffusion to determine diffusivity as a function of temperature between 572 and 780 K. We find the diffusivity is given by D(T) = 0.0067 exp (-0.461 eV/kT) [cm(2)/s] below 670 K and by D(T) = 0.0012 exp (-0.36 eV/kT) [cm(2)/s] above 670 K. Our activation energy below 670 K agrees with the value typically used to assess hydrogen diffusivity in LWR cladding [Kearns, Journal of Nuclear Materials 43 (1972) 330], but is approximately 20% lower above 670 K. The two different activation barriers are attributed to impurity trapping of hydrogen solutes at lower temperature that ceases to influence diffusivity at higher temperature. The application of the Oriani model for diffusion with impurity trapping to our system demonstrates the plausibility of this hypothesis. We believe this mechanism may be responsible for historical discrepancies of measured hydrogen diffusivity in Zr-based alloys. The elastic intensity versus temperature in fixed window scans exhibit inflection points that are in good agreement with the published terminal solid solution solubility limits for hydrogen in Zircaloy 2. (C) 2019 Elsevier B.V.

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Long-range ordered porous carbons produced from C60

[J].