不论相变的条件如何,低碳低合金钢的相变产物与原奥氏体晶粒保持特定的位向关系,所以合金钢的相变产物又被称为协变相变产物[12]。协变相变产物具有复杂的结构,其结构决定了高强度低合金钢的力学性能。提高强韧性和淬透性的实质即是通过对相变热力学和动力学因素的控制,进而对协变相变组织进行调控,既要避免形成M/A组织,也要促使大角晶界的生成[8]。提高大角晶界密度可以起到细化有效晶粒尺寸的作用,大角晶界来源于相邻不同取向变体之间的界面,因而提高强韧性和淬透性的本质是对协变相变组织的控制。吴彬彬等[8,13]的研究表明,以密排面分组(CP分组)为主导的相变,具有更高的大角晶界密度、板条束(block)边界密度、变体1/变体2 (V1/V2)变体对含量,韧性更高;且对于贝氏体而言,硬度随着大角晶界密度的增加而增加,而马氏体的硬度高于贝氏体但是其大角晶界密度却低于贝氏体。M/A岛作为裂纹的起裂因素极易诱发裂纹形成并使其扩展,从而严重损害韧性,并显著提高韧脆转变温度;其含量越少、分布越细小弥散,对韧性越好。因此,提高协变相变组织的性能不能单纯地靠细化、减少M/A岛或改善大角晶界状况,而是必须同时优化M/A岛和大角晶界。

本工作系统研究了不同含量Ni在高强度低合金钢中的作用。通过末端淬火实验研究Ni含量对淬透性的影响;通过连续冷却转变实验研究Ni含量对相变温度的影响,并利用扫描电镜(SEM)和电子背散射衍射(EBSD)研究在低冷速下Ni含量对协变相变产物显微组织和晶体学特征的影响,揭示组织转变过程与晶体学特征的联系;同时结合相变热力学和动力学过程分析在低冷速下Ni含量对组织转变过程及产物的影响,揭示Ni对贝氏体完全转变和M/A岛的影响。

1 实验方法

本实验设计了2种C、Si、Mn、Cr、Mo、V、Ti、B等元素含量接近但Ni含量不同的低碳低合金钢,其化学成分如表1所示。首先通过末端淬火实验得到淬透性曲线,端淬实验过程如下:对试样进行900℃保温30 min正火处理,随后加热到850℃保温30 min,试样出炉后立即在端淬实验装置上进行喷水冷却,喷水时间为15 min,接下来沿平行于试样轴线的方向上磨出2个相互平行的平面,磨削深度为0.5 mm,使用HRS-150洛氏硬度仪在2个相互平行的平面上进行平均硬度测试,绘制成淬透性曲线。随后将实验材料加工成直径3 mm、长10 mm的圆柱试样,利用Linseis-L78-RITA热模拟试验机,通过静态连续冷却实验来测定0.92Ni钢和2.94Ni钢的连续冷却转变(CCT)曲线。测定方法为:将试样以50℃/s的速率加热到1000℃,保温15 min,分别以0.5、1、3、5、10、30以及50℃/s的速率冷却到室温,记录冷却过程中的热膨胀曲线。将连续冷却后的试样在热电偶位置垂直轴向剖开,利用HVIS-1000ZDT显微硬度计进行Vickers显微硬度测试,加载1 kg持续15 s,每隔5 μm做5个压痕,测试试样的平均硬度。将试样研磨抛光并经3% (质量分数)硝酸酒精溶液侵蚀后利用Mira3场发射SEM观察显微组织。随后将侵蚀过的试样使用10%HCLO4 + 5%C3H8O3 + 85%C2H5OH (质量分数)的电解液进行电解抛光,用于EBSD检测。EBSD分析采用MIRA 3 LMH FE-SEM,并配备Oxford Symmetry EBSD探测器,加速电压为20 kV,工作距离为16 mm,倾角为70°,步长为0.15 µm。

表1 2种高强度低合金钢的化学成分

Table 1

| Steel | C | Si + Mn | Ni | Cr + Mo | V + Ti | B | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.92Ni | 0.16 | 1.40 | 0.92 | 1.22 | 0.107 | 0.0015 | 0.0081 | 0.0170 | Bal. |

| 2.94Ni | 0.16 | 1.41 | 2.94 | 1.19 | 0.105 | 0.0014 | 0.0082 | 0.0171 | Bal. |

2 实验结果

2.1 淬透性曲线

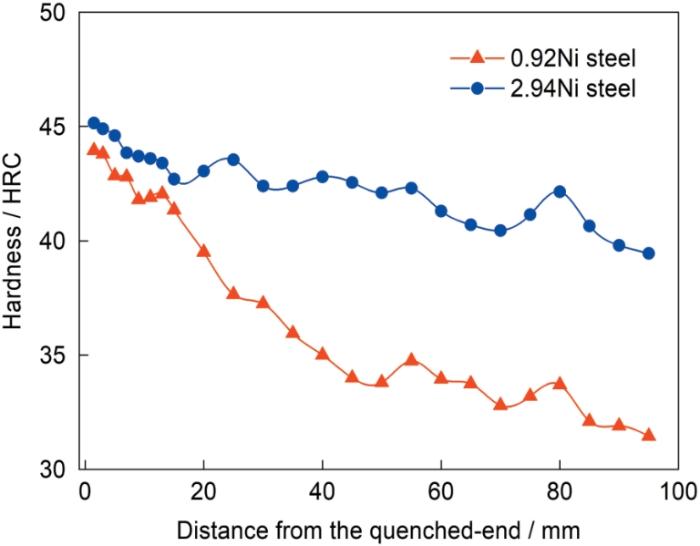

图1为0.92Ni钢和2.94Ni钢的淬透性曲线。可以看出,2.94Ni钢的淬透性曲线位于0.92Ni钢的上方。在距离端淬表面较近的位置,0.92Ni钢和2.94Ni钢的硬度差别不大。但是随着距端淬表面的距离的增加,0.92Ni钢的硬度急剧下降,距端淬表面50 mm时硬度下降趋于平缓,在距端淬表面90 mm处硬度只有31 HRC。与0.92Ni钢相比,2.94Ni钢的硬度变化很小,整条曲线都较为平缓,没有急剧的硬度降低,在距端淬表面90 mm处硬度仍有39 HRC。可见,2.94Ni钢的淬透性明显高于0.92Ni钢。众所周知,随着距端淬表面距离的增加,端淬试样的冷却速率逐渐减小。因此,有必要进行连续冷却实验来测定0.92Ni钢和2.94Ni钢的CCT曲线。

图1

图1

0.92Ni钢和2.94Ni钢的淬透性曲线

Fig.1

Hardenability curves of 0.92Ni steel and 2.94Ni steel

2.2 CCT曲线及硬度

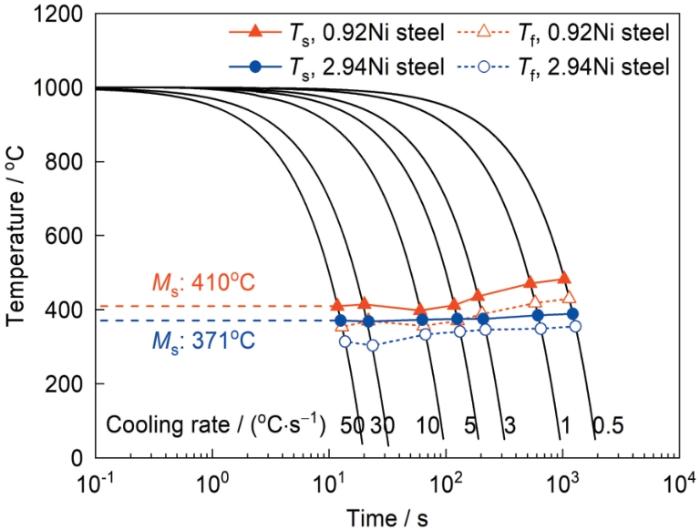

0.92Ni钢和2.94Ni钢在1000℃保温后的CCT曲线如图2所示。可以看出,在不同冷却速率下,2种钢的相变温度差异明显,冷却速率降低时差异更为显著。对于2.94Ni钢,当冷却速率从50℃/s降低到0.5℃/s时,相变起始温度由371℃略微升高到389℃,相变结束温度由314℃升高到355℃,相变温度范围缩小。0.92Ni钢的相变起始温度和相变结束温度均高于2.94Ni钢,其相变温度范围明显较大。当冷却速率从50℃/s降低到0.5℃/s时,相变起始温度明显升高,由410℃升高到483℃,相变结束温度也由354℃升高到430℃。0.92Ni钢和2.94Ni钢在冷却速率分别大于5和3℃/s时主要以马氏体相变为主,马氏体转变开始温度(Ms)分别为410和371℃。可见Ni含量增加可以显著降低相变起始温度。

图2

图2

0.92Ni钢和2.94Ni钢的连续冷却转变(CCT)曲线

Fig.2

Continuous cooling transition (CCT) curves of 0.92Ni steel and 2.94Ni steel (Ms—starting temperature of martensitic transformation, Ts—starting temperature of phase transformation at each cooling rate, Tf—finishing temperature of phase transformation at each cooling rate)

图1中0.92Ni钢和2.94Ni钢的淬透性曲线表现出明显差别,这是因为2者在低冷速下的相变温度有所不同。当冷却速率降低到3℃/s甚至更低时,2.94Ni钢的相变开始温度没有明显的变化。因此,也可以通过相变开始温度的变化来分析淬透性。当冷却速率从50℃/s降低到5℃/s以下时,淬透性低的0.92Ni钢的相变开始温度显著升高,而2.94Ni钢的相变开始温度即使在冷却速率降低到0.5℃/s时也没有变化。

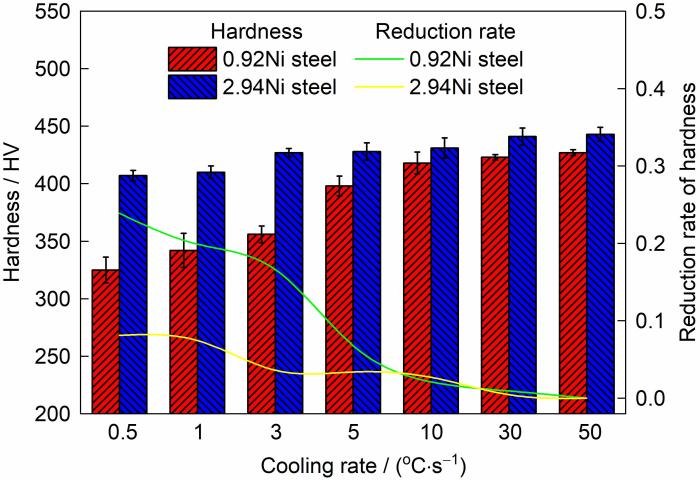

样品在不同冷速下的Vickers硬度和相对于冷却速率为50℃/s时的硬度下降率如图3所示。可以看出,在各冷速下2.94Ni钢的硬度都要高于0.92Ni钢,且随着冷却速率的降低,2种钢的硬度差异越来越大,这与图1中淬透性曲线表现出来的差异一致。当冷却速率小于10℃/s时,0.92Ni钢的硬度下降率曲线开始急剧上升,而2.94Ni钢的硬度变化较小。对于0.92Ni钢,当冷却速率从50℃/s降到0.5℃/s时,硬度降低了24%,也就是说冷却速率为0.5℃/s时的硬度仅有冷却速率为50℃/s时的76%。相比之下,2.94Ni钢在低冷速下的硬度是高冷速下的92%,比0.92Ni钢在低冷速下的硬度高了82 HV。在低冷速下2种钢之间的硬度差异与Ni含量有关,Ni含量会显著影响低冷速下2种样品的相变温度,从而影响相变产物。

图3

图3

0.92Ni钢和2.94Ni钢在不同冷速下的Vickers硬度与硬度下降率

Fig.3

Vickers hardnesses and hardness decrease rates of 0.92Ni steel and 2.94Ni steel at different cooling rates

2.3 显微组织晶体学特征

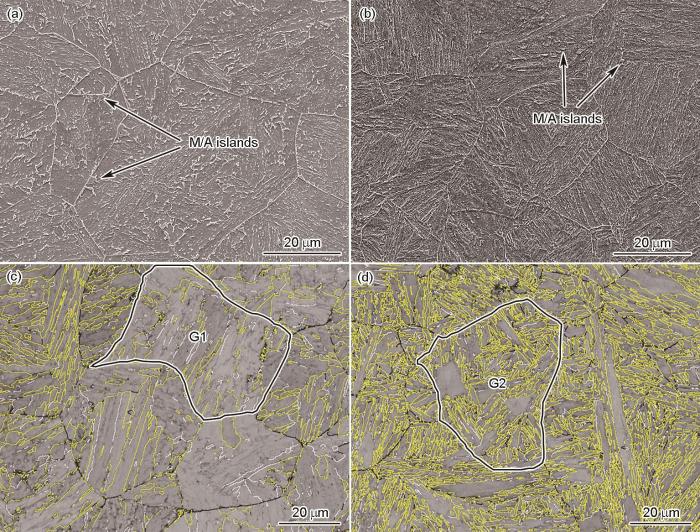

0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的SEM像和EBSD像如图4所示。由图4a和b可知,2种钢的组织差异明显,0.92Ni钢的显微组织主要以粒状贝氏体为主,而2.94Ni钢则呈现出典型的板条贝氏体组织。此外,在0.92Ni钢中可清晰见到粗大的块状M/A岛,2.94Ni钢中的M/A岛明显细化且呈薄膜状弥散分布。显微组织的差异也很好地说明了2.94Ni钢的淬透性高于0.92Ni钢。图4c和d给出了带有晶界的Kikuchi带质量图(BC图),小角晶界和大角晶界分别用白线(5° < θ < 15°,θ为晶界角度)、黑线(15° ≤ θ ≤ 45°)和黄线(θ > 45°)表示。可以看出,0.92Ni钢的大角晶界很少,且无序、不规则的分布;而2.94Ni钢的大角晶界以平行排列为主,其中夹杂少量的小角晶界,而且大角晶界密度明显高于0.92Ni钢。表2给出了精确的晶界密度统计。0.92Ni钢和2.94Ni钢的大角晶界密度分别为0.48和1.38 μm-1,小角晶界密度分别为0.19和0.22 μm-1。结果表明,2者的差别主要在大角晶界密度。因此,大角晶界对于提高贝氏体组织的硬度具有重要贡献。

图4

图4

0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的SEM像和带有晶界的BC图

Fig.4

SEM images (a, b) and band contrast (BC) (c, d) images with grain boundaries of 0.92Ni steel (a, c) and 2.94Ni steel (b, d) at a cooling rate of 0.5℃/s (M/A—martensite/austenite; G1 and G2: representative grains of two steels; white lines indicate low angle grain boundaries (LAGBs): 5° < θ < 15° (θ—misorientation angle), black lines (15° ≤ θ ≤ 45°) and yellow lines (θ > 45°) indicate high angle grain boundaries (HAGBs))

表2 0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的晶界密度

Table 2

| Steel | 5° < θ < 15° | 15° ≤ θ ≤ 45° | θ > 45° |

|---|---|---|---|

| 0.92Ni | 0.19 | 0.05 | 0.48 |

| 2.94Ni | 0.22 | 0.09 | 1.38 |

3 分析讨论

3.1 变体分析:组织可视化与数字化

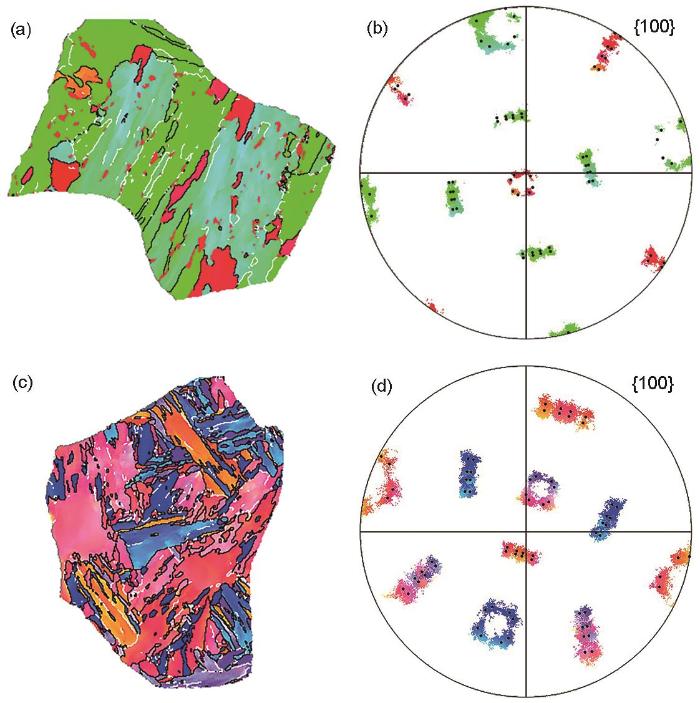

为了揭示2种钢中大角晶界的来源,对组织进行可视化与数字化分析。将图4c和d中用黑色线标出来的G1、G2晶粒作为0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的代表性晶粒,图5和6描绘了代表性晶粒的内部结构,图5中不同的颜色代表了不同的取向。通过计算得到G1晶粒的位向关系为119.9°、7.9°和196.1°,G2晶粒的位向关系为122.6°、9.4°和193.7°。从而进一步得出V1变体在理论K-S关系下的取向与实际位向关系下的取向间的取向差角,G1和G2分别为3.6°和2.8°。使用此位向关系绘制了基于K-S关系的理论极图,并与G1和G2晶粒的实验极图相比较,如图5b和d所示。由图可知2者高度一致,表明G1和G2晶粒的变体与原奥氏体晶粒之间保持K-S关系[18,19]。

图5

图5

在冷速为0.5℃/s时0.92Ni钢和2.94Ni钢的代表晶粒G1和G2的反极图和极图

Fig.5

Inverse pole figures (a, c) and pole figures (b, d) of the representative grain G1 of 0.92Ni steel (a, b) and representative grain G2 of 2.94Ni steel (c, d) at a cooling rate of 0.5oC/s (Black dots: theoretical pole figure based on K-S relationship; color plots: experimental pole figure)

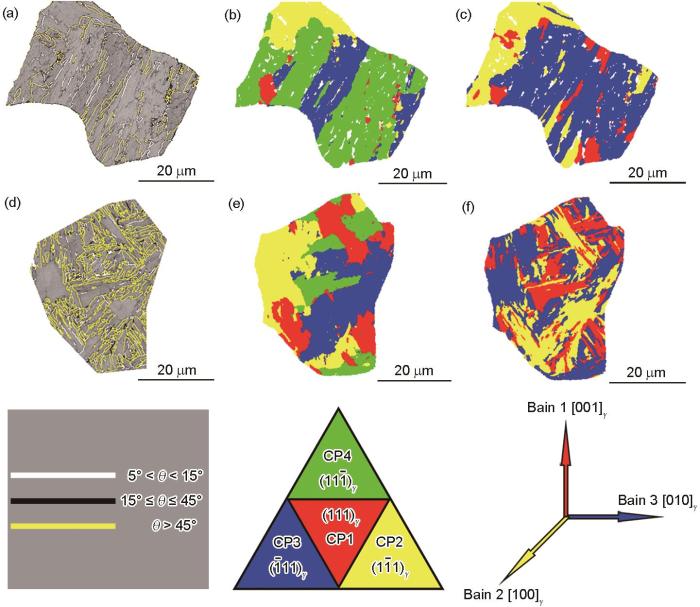

图6

图6

0.92Ni钢和2.94Ni钢的代表性晶粒G1和G2通过晶界(GB)图、密排面(CP)分组、Bain分组描绘的微观结构

Fig.6

Microstructures of representative grain G1 of 0.92Ni steel (a-c) and representative grain G2 of 2.94Ni steel (d-f) depicted by grain boundary (GB) (a, d), closed-packed plane (CP) group (b, e), and Bain group (c, f)

从图6a和d中的晶界(GB)图可以看出,G2晶粒比G1晶粒表现出更高的大角晶界(θ > 45°)密度并且组织更为精细,这与表2中的晶界密度统计结果所一致。一般来说,由单一奥氏体晶粒转变而来的低碳钢有24种变体,可分为4个CP分组和3个Bain分组[20]。先前的研究[14,21,22]表明,当一个Bain分组包含多个CP分组时为Bain分组主导的相变,这种情况下无法形成高密度的大角晶界;而一个CP分组包含多个Bain分组时为CP分组主导的相变,意味着可形成的大角晶界密度比较高。为了更好地揭示相变模式,对G1和G2晶粒进行CP分组和Bain分组的可视化处理,结果如图6b和e及6c和f所示。CP分组图中的红色、黄色、蓝色和绿色分别代表CP1、CP2、CP3和CP4,Bain分组图中的红色、黄色和蓝色分别代表Bain 1、Bain 2和Bain 3。结合GB图和Bain分组图可以发现,属于同一Bain分组的变体之间存在小角晶界,属于不同Bain分组的变体之间存在大角晶界。原奥氏体晶粒G1除了红色的CP1分组变体较少之外,大部分为CP2、CP3和CP4;原奥氏体晶粒G2的4个CP分组比例和分布相对均匀很多。由此可见,G1和G2都由大块的CP分组组成,这种大块的CP分组模式有利于产生由CP分组主导的相变,但是2者的Bain分组截然不同。G1表现出近乎单一Bain分组(Bain 3),它占据了原奥氏体晶粒G1接近3/4的区域, Bain 3分组中包含CP3和CP4分组,占据了G1 1/4区域的Bain 2也包含了CP2和CP4这2个分组,所以G1是Bain分组主导的相变。而G2表现出均匀细小的Bain分组并行排列,在G2被大块CP分组均匀占据的条件下形成了同一CP分组包含多个Bain分组的现象,CP1分组包含Bain 1和Bain 2,CP2分组包含Bain 1和Bain 3,CP3分组包含Bain 1、Bain 2和Bain 3,CP4分组包含Bain 1、Bain 2和Bain 3,所以G2是CP分组主导的相变。因此,与G1相比,G2以CP分组主导的相变形成了更多的大角晶界。2种钢的组织差异与变体选择有关,以Bain分组主导的相变具有更强的变体选择,更难形成不同的变体[23]。显然,0.92Ni钢的变体选择强于2.94Ni钢,难以形成不同的变体。

在奥氏体向马氏体或贝氏体转变的过程中,一般会形成24个变体以保持与原奥氏体近似的K-S关系,变体的选择会影响相变产物的取向、形貌和力学性能[21~26]。因此,有必要对变体进行数字化定量分析,以便阐明在低冷速下Ni含量对变体选择的影响。单一奥氏体的变体选择差异较大,因而需要对整个区域的变体对含量进行计算。选取0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的EBSD表征区域中的6个奥氏体晶粒进行位向关系计算,在此基础上取位向关系平均值,得到0.92Ni钢的平均位向关系为120.4°、8.6°和195.7°,2.94Ni钢的平均位向关系为121.7°、9.3°和194.6°。基于此结果,也能求出V1变体与其他23个变体的角轴对关系和取向差,并且以此计算出整个区域的变体对边界密度,结果分别如表3和图7所示。实际的位向关系与标准K-S位向关系有些偏差,这是因为在马氏体或贝氏体转变过程中存在相变应力的调节[20]。在属于Bain 1分组(V1/V4、V8、V11、V13、V16、V21和V24)的变体对中,它们的位向关系与标准K-S位向关系的偏差更大一些。

表3 基于标准K-S和实际位向关系下V1和其他23个变体的取向差及边界类型

Table 3

Variant | Plane parallel | Direction parallel | Rotation angle/axis from V1 | CP group | Bain group | Boundary type | ||

|---|---|---|---|---|---|---|---|---|

| Exact K-S OR | 0.92Ni steel | 2.94Ni steel | ||||||

| V1 | (111) γ //(011) α | [ | - | - | CP1 | Bain1 | - | |

| V2 | [ | 60.0°/[11 | 60.3 | 60.2 | Bain 2 | Block | ||

| V3 | [01 | 60.0°/[011] | 59.9 | 60.0 | Bain 3 | Block | ||

| V4 | [01 | 10.5°/[0 | 5.0 | 5.2 | Bain 1 | Sub-block | ||

| V5 | [1 | 60.0°/[0 | 59.9 | 60.0 | Bain 2 | Block | ||

| V6 | [1 | 49.5°/[011] | 55.2 | 54.9 | Bain 3 | Block | ||

| V7 | (1 | [10 | 49.5°/[ | 52.3 | 51.2 | CP2 | Bain 2 | Packet |

| V8 | [10 | 10.5°/[11 | 8.8 | 9.9 | Bain 1 | Packet | ||

| V9 | [ | 50.5°/[10313] | 53.1 | 52.4 | Bain 3 | Packet | ||

| V10 | [ | 50.5°/[ | 52.0 | 51.0 | Bain 2 | Packet | ||

| V11 | [011] γ //[ | 14.9°/[13 5 1] | 12.1 | 13.1 | Bain 1 | Packet | ||

| V12 | [011] γ //[ | 57.2°/[ | 57.9 | 57.5 | Bain 3 | Packet | ||

| V13 | ( | [0 | 14.9°/[513 1] | 12.1 | 13.1 | CP3 | Bain 1 | Packet |

| V14 | [0 | 50.5°/[ | 52.0 | 51.0 | Bain 3 | Packet | ||

| V15 | [ | 57.2°/[ | 57.0 | 56.3 | Bain 2 | Packet | ||

| V16 | [ | 20.6°/[1111 6] | 15.0 | 16.2 | Bain 1 | Packet | ||

| V17 | [110] γ //[ | 51.7°/[11611] | 51.8 | 51.0 | Bain 3 | Packet | ||

| V18 | [110] γ //[ | 47.1°/[24 1021] | 52.4 | 51.4 | Bain 2 | Packet | ||

| V19 | (11 | [ | 50.5°/[ | 53.1 | 52.4 | CP4 | Bain 3 | Packet |

| V20 | [ | 57.2°/[36 | 57.9 | 57.5 | Bain 2 | Packet | ||

| V21 | [0 | 20.6°/[30 | 16.7 | 18.2 | Bain 1 | Packet | ||

| V22 | [0 | 47.1°/[102124] | 52.4 | 51.4 | Bain 3 | Packet | ||

| V23 | [101] γ //[ | 57.2°/[ | 57.0 | 56.3 | Bain 2 | Packet | ||

| V24 | [101] γ //[ | 21.1°/[9 | 17.1 | 18.6 | Bain 1 | Packet | ||

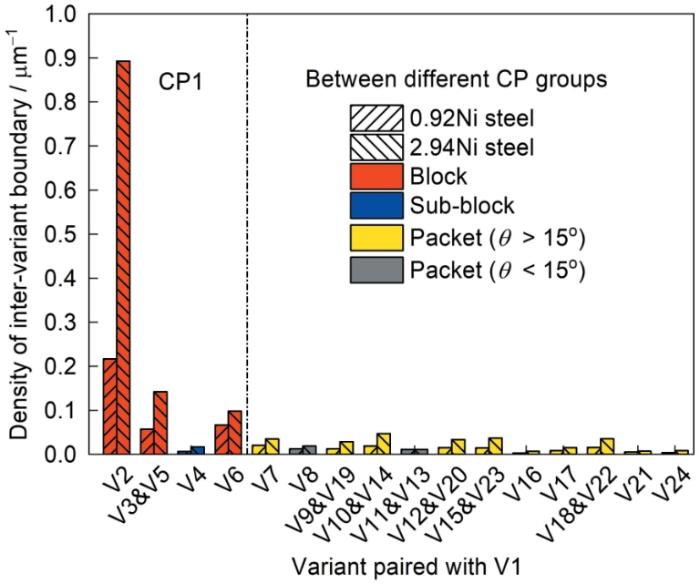

图7

图7

0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的变体对边界密度

Fig.7

Densities of inter-variant boundaries in 0.92Ni steel and 2.94Ni steel cooled at 0.5oC/s

变体边界进一步分为板条束(block)、亚板条束(sub-block)和块(packet)边界[20],这3种边界密度和硬度结果如表4所示。可以明显看出,2.94Ni钢的block边界密度远高于0.92Ni钢,而其他边界密度差别不大。因此,贝氏体的硬度与block边界密度有关,block边界密度越高则硬度越高,这与前人研究结果[22,23]一致。而block边界属于大角晶界,这也说明2种钢的硬度差异是由大角晶界决定的,即贝氏体的大角晶界密度越高则硬度越高。根据Hall-Petch关系[12,27]可知,硬度与有效晶粒尺寸有关,不仅与原始奥氏体晶粒尺寸有关,还与其复杂的内部组织(packet、block和条(lath))尺寸有关,有效晶粒尺寸越细则硬度越高。由此可推断,具有高密度大角晶界的相变产物有利于硬度的提高。由表3可知,除了V1/V4变体对的边界属于sub-block边界以外,属于同一CP1分组的V1/V2~V6变体对边界都是block边界;而剩余19个变体对边界都是packet边界。从图7可以看出,属于同一CP1分组的V1/V2、V1/V3(&V5)和V1/V6变体对边界密度明显高于其他变体对,尤其是V1/V2变体对,且这些变体对的边界都是block边界。2.94Ni钢的block边界密度明显高于0.92Ni钢,其中以V1/V2变体对贡献最大:2.94Ni钢的V1/V2变体对边界密度远高于0.92Ni钢。此外,2.94Ni钢的V1/V3 (&V5)和V1/V6变体对边界密度也略高于0.92Ni钢。显然,2种钢的block边界密度差异主要归因于V1/V2变体对边界。以往的研究[13,14,20,22]表明,贝氏体转变温度越低,形成的V1/V2变体对越多,以及相变起始温度在Ms附近的连续冷却转变都可以形成更多的V1/V2变体对,这主要与发生相变时的相变驱动力有关,即相变驱动力越大则V1/V2变体对含量越多。

表4 0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的板条束、亚板条束、块边界密度和Vickers硬度

Table 4

| Steel | Boundary density / μm-1 | Vickers | |||

|---|---|---|---|---|---|

| Block | Sub-block | Packet(θ < 15°) | Packet (θ > 15°) | hardness HV | |

| 0.92Ni | 0.34 | 0.01 | 0.02 | 0.12 | 325 ± 11 |

| 2.94Ni | 1.13 | 0.02 | 0.03 | 0.25 | 407 ± 5 |

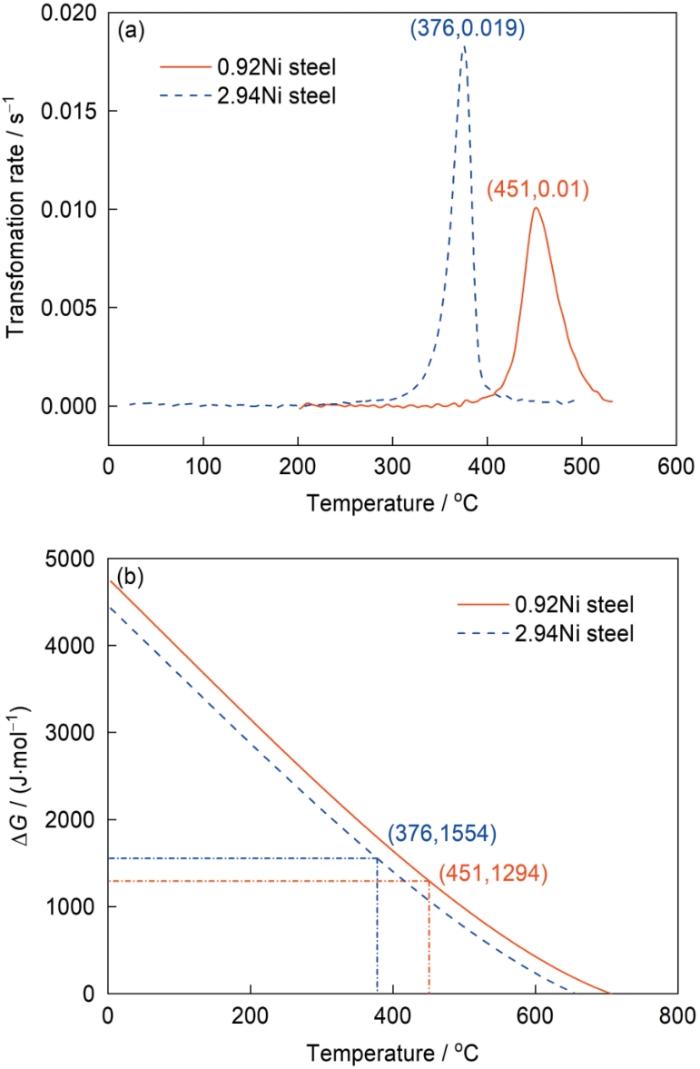

3.2 相变热力学与动力学分析

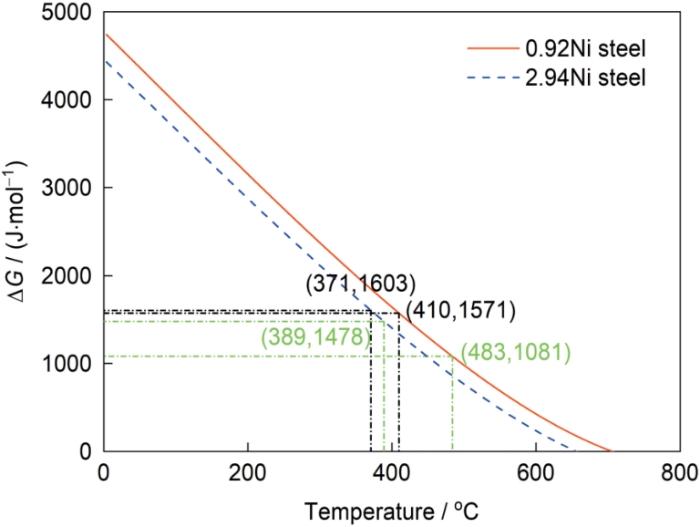

当冷却温度、冷速条件一致时,Ni含量影响了其相变温度,从而影响了奥氏体转变过程及转变产物,因此有必要研究2种钢在低冷速下的相变热力学和动力学。Ni含量对相变的影响直接表现在降低了相同冷速下的相变温度,因而相变的热力学条件是不同的。通过Thermal-Calc热力学计算软件对相变驱动力进行计算,得到相变驱动力与温度之间的关系,如图8所示。图中黑色线为Ms所对应的相变驱动力,绿色线为冷速为0.5℃/s时的相变开始温度所对应的相变驱动力,括号内为交点坐标。可以看出,Ni含量的增加使相变驱动力随温度变化曲线向下移动,也就是说使任意温度下的相变驱动力降低;但是Ni含量的增加又会降低相变温度,使得相同冷速下开始发生相变时的相变驱动力增加。当冷速为0.5℃/s时,2.94Ni钢开始相变时的相变驱动力为1478 J/mol,而0.92Ni钢为1081 J/mol,此时相变温度对相变驱动力的影响占主导地位。0.92Ni钢和2.94Ni钢的最小马氏体相变驱动力分别为1571和1603 J/mol,因此,马氏体相变的最小相变驱动力与Ni含量大小无关。

图8

图8

0.92Ni钢和2.94Ni钢的相变驱动力(ΔG)与温度的关系

Fig.8

Curves of phase transition driving force (ΔG) versus temperature for 0.92Ni steel and 2.94Ni steel (Black line: phase transition driving force value corresponding to Ms; green line: phase transition driving force value corresponding to the phase transition start temperature when the cooling rate is 0.5oC/s)

相变驱动力越大,形成的V1/V2变体对越多,如果相变驱动力非常大,奥氏体晶粒会在极短的时间内转变为具有大量位错的马氏体组织;如果贝氏体的相变驱动力不那么大,会首先形成先相变的贝氏体,在此基础上再形成新的组织[28]。当冷速为0.5℃/s时,2.94Ni钢的相变起始于Ms附近,相变驱动力远远高于0.92Ni钢,但是又未达到马氏体的最小相变驱动力,因此具有更高V1/V2变体对密度。

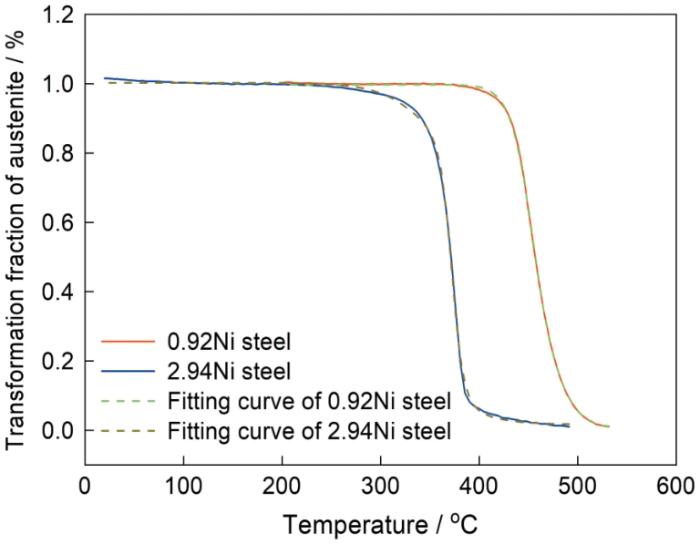

利用杠杆定律[29]通过热膨胀曲线可求得转变动力学曲线(转变分数-温度曲线),转变分数(f)可由下式表示:

式中,DT为发生相变时样品的实际膨胀量;Dγ 为fcc结构相的膨胀量;Dα 为bcc结构相的膨胀量;Q为最大转变分数,Q = 1 - fAr,fAr为残余奥氏体的体积分数,在图4c和d结果中并未观察到明显的残余奥氏体,因此Q近似为1。通过计算得到0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的奥氏体转变动力学曲线如图9所示,2者的曲线均呈典型的S型。在奥氏体转变过程中,随着温度降低,由于过冷度增大,相变驱动力变大(如图8所示),转变速率增加;同时,由于转变速率与C的扩散速率呈正相关,而随着温度的降低,C扩散速率下降,使转变速率降低。奥氏体转变受上述2方面因素影响,动力学曲线呈现S型,转变速率最高点出现于某一中间温度[30]。

图9

图9

0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的奥氏体转变分数随温度的变化及使用BiDoseResp函数拟合的曲线

Fig.9

Curves of transformation fraction of austenite vs temperature for 0.92Ni steel and 2.94Ni steel cooled at 0.5oC/s and corresponding fitting curves obtained by BiDoseResp function

图10

图10

0.92Ni钢和2.94Ni钢在冷速为0.5℃/s时的奥氏体转变速率随温度的变化,最快转变速率温度所对应的ΔG

Fig.10

Curves of transformation rate of austenite vs temperature for 0.92Ni steel and 2.94Ni steel cooled at 0.5oC/s (a) and ΔG corresponding to the temperature of the fastest transition rate (b)

3.3 相变过程与组织的关系

在低冷速下,组织转变的时间也比较长,当冷速为0.5℃/s时,0.92Ni钢和2.94Ni钢的相变持续时间分别为106和68 s。因此,相变过程是贝氏体和奥氏体并存的情形,贝氏体与奥氏体的界面逐渐向未转变的奥氏体部分移动。在这个两相并存的相变过程中,C的扩散无疑也是很重要的。徐祖耀和李学敏[31,32]计算了低碳马氏体形成过程中C的扩散所需时间,当奥氏体C含量(质量分数,下同)从0.27%富集至1.04%所需的时间仅为10-4 s数量级(极端情况下为10-7 s)。这意味着即使是C含量为0.27%的马氏体转变,C原子的扩散也跟得上马氏体的形成。实际上,贝氏体在较高温度下形成时,C可以在几分之一秒内从片条内逃逸。在相变过程中,多余的C从贝氏体片条扩散到未转变的奥氏体,下一贝氏体片条就从富C的奥氏体中长出,直至最终不满足奥氏体转变的热力学条件,才停止转变。贝氏体作为不完全转变的相变,在这种情况下未转变的奥氏体愈加富C,在转变后期会形成一定量的残余奥氏体,残余奥氏体在冷却到室温以后又形成M/A岛,如图4a和b所示。M/A岛的形态及含量对性能有重要影响,相对于弥散、细小、薄膜状的M/A岛,块状、粗大的M/A岛对韧性的危害更大。而贝氏体相变的完全转变程度直接影响M/A岛的含量。此时,贝氏体相变过程中未转变奥氏体所能容纳的C含量至关重要,未转变奥氏体的最大C含量越高,则可形成的贝氏体分数越大,贝氏体相变越完全,M/A岛的含量越少。这些影响都可以由

式中,T为温度,括号内为函数的自变量。因此,通过将

表5 磁性和非磁性项的自由能近似函数表达式[33]

Table 5

| Function | Temperature range | ||

|---|---|---|---|

| -6660 | 7 | 900 K > T > 300 K | |

| 650 | -1 | 900 K > T > 620 K | |

| 0 | 0 | T < 620 K |

将表5中列出的函数表达式代入

多种合金元素的影响可以通过求和相加来得到:

为了计算

式中,xC为C的质量分数。

表6

合金元素引起的磁性项温度变化(

Table 6

| Alloying element | ||

|---|---|---|

| Si | -3 | 0 |

| Mn | -37.5 | -39.5 |

| Ni | -6 | -18 |

| Mo | -26 | -17 |

| Cr | -19 | -18 |

| V | -44 | -32 |

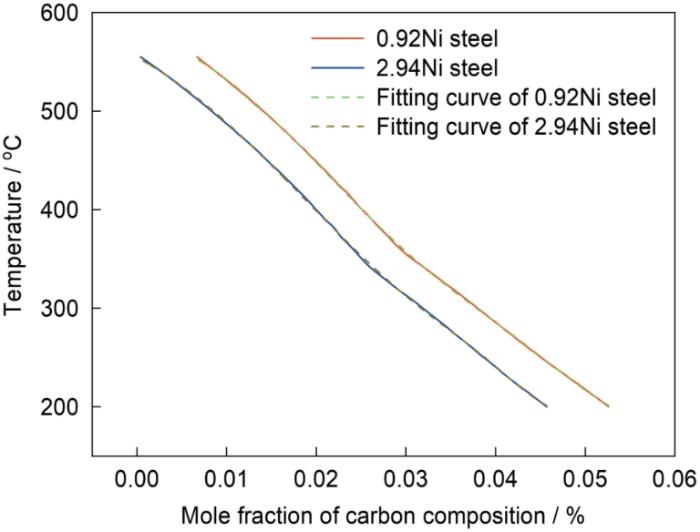

使用方程

可见,在任一C含量下,0.92Ni钢的

利用Bhadeshia[35]开发的钢铁材料固态相变热力学和动力学软件MUCG83计算0.92Ni钢和2.94Ni钢的

图11

图11

0.92Ni钢和2.94Ni钢的

Fig.11

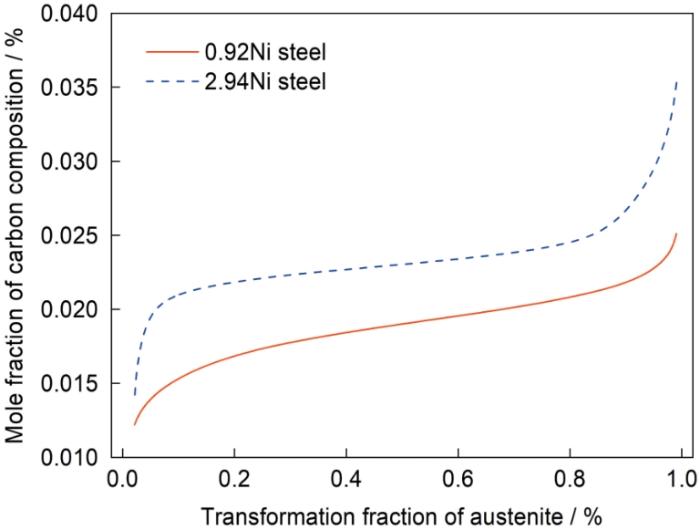

式中,

图12

图12

0.92Ni钢和2.94Ni钢未转变奥氏体的最大C含量随奥氏体转变分数的变化

Fig.12

Curves of maximum carbon composition of untransformed austenite vs austenite transformation fraction for 0.92Ni steel and 2.94Ni steel cooled at 0.5oC/s

4 结论

(1) Ni含量从0.92%提高到2.94%可以大幅提高高强度低合金钢的淬透性,使淬透性曲线保持平缓。降低了相同冷速下的相变开始温度和结束温度,使2.94Ni钢在0.5℃/s的低冷速下获得板条贝氏体组织和薄膜状M/A岛,从而使钢在低冷速下仍保持较高的硬度;而0.92Ni钢在0.5℃/s的低冷速下获得粒状贝氏体组织和块状M/A岛,具有较低的硬度。

(2) Ni含量的增加使得相变驱动力随温度变化曲线向下移动,使任意温度下的相变驱动力降低;但是Ni含量的增加又会降低相变温度,使相同冷速下开始相变时的相变驱动力增加。在0.5℃/s的低冷速下,2.94Ni钢的相变驱动力更大,此时相变温度对相变驱动力的影响占主导地位。2种钢的奥氏体转变动力学曲线呈现典型的S型,2.94Ni钢最快转变速率更大,最快转变速率对应温度更低、相变驱动力更大。

(3) 在0.5℃/s的低冷速下,2.94Ni钢相变驱动力更大但未达到马氏体的最小相变驱动力,形成以CP分组为主导的相变模式,变体选择更弱,因此具有更高的大角晶界密度、block边界密度和V1/V2变体对密度;而0.92Ni钢相变驱动力较小,形成以Bain分组为主导的相变模式,变体选择更强,具有较低的大角晶界密度、block边界密度和V1/V2变体对密度。

(4) Ni含量的增加使得

参考文献

Structure-property relationship in a 960 MPa grade ultrahigh strength low carbon niobium-vanadium microalloyed steel: The significance of high frequency induction tempering

[J].

Determining role of heterogeneous microstructure in lowering yield ratio and enhancing impact toughness in high-strength low-alloy steel

[J].

Advanced vanadium alloyed steel for heavy product applications

[J].

Incompleteness of bainite transformation in quenched and tempered steel under continuous cooling conditions

[J].

Effect of alloying element Al on hardenabilitity and mechanical properties of micro-B treated ultra-heavy plate steels

[J].Utilizing Jominy end quenching test, chemical phase analysis and thermo-dynamical calculation, study of the effect of alloying elements on hardenability and mechanical properties of a B-bearing ultra-heavy plate steel was carried out. The results showed that small amount of Ti addition could form TiN for its much higher bonding ability than B, fixing N element and thus making B free. Normal Al content failed to prevent BN from precipitating due to the weaker competition for N than B. However, when Al content was increased as high as 0.07%, the competition of Al for N was distinctly improved, making solid-solution B increased. For proper chemical combination of B and N-fixing element, hardenability was increased and accordingly both microstructure and mechanical properties were improved so that the quantity and size of martensite/austenite (M/A) islands and granular bainite were decreased markedly, and low-temperature impact toughness and tensile properties were improved by a large degree. The calculation was in a good accord with experimental results.

合金元素Al对微B处理特厚钢板淬透性及力学性能的影响

[J].

Microstructural characterization and mechanical properties across thickness of ultra-heavy steel plate

[J].

Particle-stimulated nucleation of ferrite in heavy steel sections

[J].

Study on crystallographic characteristics of high strength low alloy steel and its composition-process-performance relationship

[D].

高强度低合金钢晶体学特征及其成分-工艺-性能关系研究

[D].

Microstructure evolution and impact toughness variation for high strength steel multi-pass weld metals with various cooling rates

[J].

New insights into the mechanism of cooling rate on the impact toughness of coarse grained heat affected zone from the aspect of variant selection

[J].

Carbon microalloying effect of base material on variant selection in coarse grained heat affected zone of X80 pipeline steel

[J].The carbon is one of the basic alloying solutes in steels. In the present study, the newly carbon microalloyed X80 steel was designed for the next generation of pipeline and the carbon microalloying effect of base material on the crystallographic structure of coarse grained heat affected zone (CGHAZ) of X80 girth welded joints was systematically investigated using electron back-scattering diffraction (EBSD), considering the fact that crystallography is the most intrinsic aspect in evaluating the microstructure. The results indicated a remarkable variation in the density of high angle grain boundaries and their dispersion by increasing the carbon content of 0.03wt%. It was attributed to the differential shearing mechanism, which was primarily sheared by variant pairing of V1/V2 at 0.06 wt% carbon, whereas at lower 0.03wt% carbon, V1/V4 pairing mechanism dominated the transformation. The preferential variant pairing transformation mechanism at differential carbon content therefore generated dissimilarly selected variants. Thus, as the carbon content increased, the variant selection effect upon phase transformation was attenuated by generating more variants from different Bain groups. The variant pair V1/V2 belonging to different Bain groups neighboring in CGHAZ of high carbon steel increased the density of high angle boundary (Sigma 3 boundary). Moreover, the variation in CTOD (crack -tip opening displacement) property of HAZ suggested that it should be primarily correlated to the block size (or density of block boundaries) of CGHAZ.

On coherent transformations in steel

[J].

Relationship between high angle grain boundaries and hardness after γ→α transformation

[J].

Crystallographic insights into the role of nickel on hardenability of wear-resistant steels

[J].

Effects of small Ni addition on the microstructure and toughness of coarse-grained heat-affected zone of high-strength low-alloy steel

[J].

Morphology and crystallography analyses of HSLA steels with hardenability enhanced by tailored C-Ni collocation

[J].

The limits of strength and toughness in steel

[J].

Crystallographic analysis of proeutectoid ferrite/austenite interface and interphase precipitation of vanadium carbide in medium-carbon steel

[J].

Crystallography of ausformed upper bainite structure in Fe-9Ni-C alloys

[J].

Effects of transformation temperature on variant pairing of bainitic ferrite in low carbon steel

[J].

Tailoring variant pairing to enhance impact toughness in high-strength low-alloy steels via trace carbon addition

[J].

New insight into the hardenability of high strength low alloy steel from the perspective of crystallography

[J].

EBSD study on the significance of carbon content on hardenability

[J].Two high strength low alloy steels with different carbon content were studied to elucidate the effect of carbon content on hardenability in terms of crystallography. The hardness reduction from 2 to 50 mm distance from the surface in end-quenched steels of 0.09C and 0.12C was 8.0 and 3.2 HRC, respectively, which implied higher hardenability of 0.12C steel than 0.09C. At low cooling rate, the microstructure of 0.09C and 0.12C steel was granular and lath bainite, respectively, and the density of high angle grain boundaries (HAGBs) of 0.12C steel was significantly greater than 0.09C. Carbon improved the hardenability by optimizing the variant selection to increase the density of high angle grain boundary (HAGB). (C) 2019 Elsevier B.V.

Crystallography and interphase boundary of martensite and bainite in steels

[J].

Variant selection of lath martensite and bainite transformation in low carbon steel by ausforming

[J].

Comparison of variant selection between lenticular and lath martensite transformed from deformed austenite

[J].

The nature and consequences of coherent transformations in steel

[J].

Thermodynamic basis of twin-related variant pair in high strength low alloy steel

[J].

A model of isothermal and non isothermal transformation kinetics of bainite in 0.5%C steels

[J].

Influence of austenitizing temperature on the microstructure and impact toughness of a high strength low alloy HSLA100 steel

[J].<p>The effect of austenitizing temperature on the microstructures and -20 ℃ impact toughness of HSLA100 steel was investigated by Gleeble-3500 thermal simulator. Its microstructures were observed by SEM and EBSD, and the relevant transformation kinetics was also analyzed by means of dilatometer. The results show that the microstructure of HSLA100 steel changes gradually from granular to lath bainite with increasing austenitizing temperature. The highest impact toughness of samples was achieved at austenitizing temperature of 1000 ℃, in which martensite-austenite (M/A) islands are finer and dispersed and the density of high angle boundaries is maximum. M/A islands, however, become coarser and this density lowers below 1000 ℃, beyond 1000 ℃, these islands are refined, being accompanied by a dramatic decrease of this density of high angle boundaries. Kinetics analysis indicates that with increasing austenitizing temperature, the transformation start temperature decreases but the transformation rate increases. Both lower start temperature and faster rate would facilitate M/A islands refining. All the transformation occurring in samples might be divided into two stages: bainite and martensite stages. The highest transformed fraction of bainite is achieved in the bainite stage at about 1000 ℃, resulting in the best impact toughness of HSLA100 steel. The crystallographic analysis of the well refined M/A islands at 1000 ℃ and 1300 ℃ shows that major high angle boundaries occur prior at the boundaries between different Bain groups belong to the same crystallographic group set to at austenite boundaries when covariance transformation occurring. When over-increasing austenitizing temperature, the covariance transformation products in coarser austenite grains are dominated by only one Bain group belong to the crystallographic group set, leading to the density of high angle boundaries and thus the impact toughness of HSLA100 steel decreasing.</p>

奥氏体化温度对HSLA100高强度低合金钢组织及冲击韧性的影响

[J].

Diffusion of carbon during the formation of low-carbon martensite

[J].

低碳马氏体形成时碳的扩散

[J].

Diffusion of carbon during formation of low-carbon martensite (Continued)

[J].

低碳马氏体形成时碳的扩散(续)

[J].

Thermodynamics of the austenite-proeutectoid ferrite transformation: Fe-C alloys

[J].

Thermodynamic analysis of isothermal transformation diagrams

[J].