TiAl合金具有较低的密度、优良的抗氧化性、良好的高温比强度和抗蠕变等性能,其板材可用于航空飞行器的热防护蒙皮、喷嘴和翼舵系统等[1~3]。然而,由于TiAl合金的本征脆性及较差的高温变形能力,其板材制备难度很大[4]。尤其是制备薄板材料,其在热加工过程中强烈的热散失和极高的显微组织应变敏感性进一步增加了大规格板材的加工难度。目前,除了不断优化包套锻造、挤压和轧制等技术手段和工艺参数[5~7],还采用优化合金成分的策略来提升TiAl合金的高温变形能力。Kim[8]提出了β型γ-TiAl合金成分范围为Ti-(40~45)Al-(2~8)Nb-(1~8)(Cr, Mn, V, Mo)-(0~0.5)(B, C) (原子分数,%,下同),由于Al含量的降低及大量β相稳定元素的添加,该合金具有晶粒尺寸细小均匀、流变应力低、高温变形能力优异等特点,其高温变形能力明显优于常规TiAl合金[9],是具有发展前景的新一代高温轻质结构材料,在航天领域具有重大应用潜力。

对于β型γ-TiAl合金来说,β相稳定元素的添加可以明显降低TiAl合金在包套轧制时的流变应力,但大量合金元素(如Nb、Mo、V、Cr等)的添加使TiAl合金的凝固路径发生变化,相组成也变得复杂[10~13],如引入大量β/B2相、ω相等。多相组织的加工硬化、不均匀的流变软化和相变等相互作用,会加剧热变形过程中显微组织的不均匀变形,甚至形成绝热剪切带[14~16]。国内外针对β型γ-TiAl合金的高温热变形及组织调控开展了大量研究工作。Niu等[17]和Zhao等[18]采用铸锭冶金法成功制备出Ti-44Al-6V-3Nb-0.3Y合金板材,组织由完全动态再结晶的γ和B2相组成,不存在明显的各向异性。张俊红等[19]采用名义成分为Ti-48Al-2Cr-0.5Mo的合金,通过包套轧制工艺成功制备了具有均匀、细小显微组织的TiAl合金薄板,其平均晶粒尺寸仅约为3 μm。然而,由于合金元素的添加,β型γ-TiAl合金的显微组织对于热变形的敏感性会发生改变[20~22],不同变形条件下合金显微组织的演变行为多样化,从而增加了不同成分TiAl合金组织调控的难度[23]。在上述变形过程中,合金元素的添加对合金相变行为、位错、孪晶等变形微结构变化有较大影响,从而影响难变形片层的变形、分解机制和多相组织的协调变形机制。关于合金元素对β型γ-TiAl合金显微组织演变及热变形机制的影响仍然缺乏系统研究。综上所述,在不同变形条件下,研究合金元素的添加对β型γ-TiAl合金的组织演化规律及变形机制的影响,可为该类合金在实际热机械加工过程中工艺设计和显微组织调控提供理论指导,从而促进β型γ-TiAl合金板材的工程化应用。

本工作研究了Ti-44Al-5Nb-1Mo和Ti-44Al-5Nb-1Mo-2V-0.2B合金在不同温度和应变速率变形后的组织特征及软化行为。通过对比分析2种β型γ-TiAl合金在不同变形条件下的显微组织演化,阐明了添加V和B对合金显微组织的影响。此外,通过研究位错、孪晶等缺陷在2种合金片层结构中的分解过程,阐明了合金元素对2种合金变形机制的影响。以期为β型γ-TiAl合金的后续热加工工艺制定及组织调控提供指导。

1 实验方法

采用真空自耗电弧炉经过3次重熔得到名义成分为Ti-44Al-5Nb-1Mo和Ti-44Al-5Nb-1Mo-2V-0.2B的铸锭,尺寸分别为110 mm (直径) × 360 mm (长)和110 mm (直径) × 490 mm (长)。对铸锭进行1260℃、4 h的均匀化处理,然后随炉冷却至室温。采用电火花线切割技术在铸锭心部切取尺寸为8 mm (直径) × 12 mm (长)的圆柱形试样,试样的高度方向沿铸锭的轴向。试样表面车光亮后,使用Gleeble-3500热模拟试验机对其进行单道次热压缩实验。在高纯Ar气氛保护下进行压缩实验,样品以10℃/s的速率升温至1050~1250℃,保温300 s后开始实验,工程应变为60%,应变速率为0.001~1 s-1,变形后再以10℃/s的速率冷至室温。

沿垂直于热压缩方向观察显微组织。利用ULTRA55扫描电子显微镜(SEM)的背散射电子像(BSE)、JEOL JXA-8530F场发射电子探针(EPMA)及Tecnai G2 F20透射电子显微镜(TEM)进行微观组织观察和选区电子衍射(SAED)分析。用于SEM-BSE观察的样品制备方法如下:金相试样经过机械研磨后,使用配比(体积比)为HClO4∶C4H10O∶CH4O = 1∶7∶12的溶液进行电解抛光,温度约为-25℃,电压为25~30 V。用于EPMA面扫描成分分析的样品制备方法如下:金相试样经过机械研磨并抛光后,使用配比(体积比)为HF∶HNO3∶H2O = 1∶1∶18的溶液进行深腐蚀。用于TEM观察的样品制备方法如下:将尺寸合适的样品经过机械研磨至厚度为30~50 μm,使用冲孔器获得直径3 mm的圆片后,使用配比(体积比)为HClO4∶C4H10O∶CH4O = 1∶7∶12的溶液进行电解双喷减薄,双喷温度低于-20℃,电压为25 V。

2 实验结果与讨论

2.1 均匀化处理显微组织对比

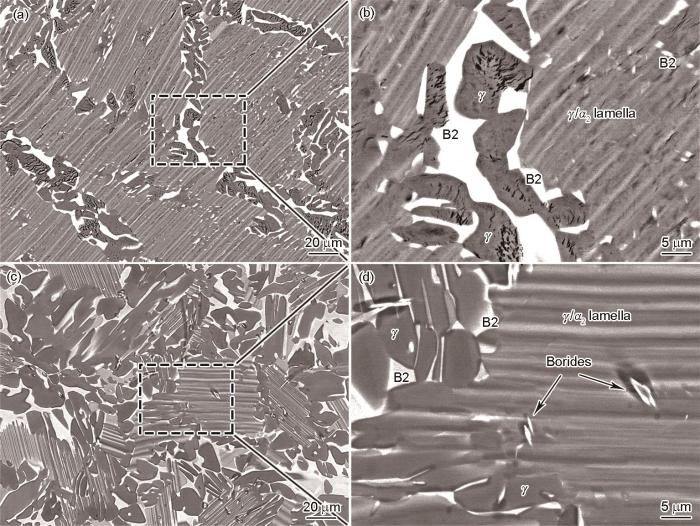

图1

图1

Ti-44Al-5Nb-1Mo和Ti-44Al-5Nb-1Mo-2V-0.2B合金均匀化后的SEM像

Fig.1

Low (a, c) and high (b, d) magnified SEM images of as-homogenized Ti-44Al-5Nb-1Mo (a, b) and Ti-44Al-5Nb-1Mo-2V-0.2B (c, d) alloys

V和B的添加改变了Ti-44Al-5Nb-1Mo合金的凝固路径,导致其形成了不同于Ti-44Al-5Nb-1Mo合金的组织特征[24]。该合金在高温区间的凝固路径可以表示为L→L + βprimary→(β + TiB)eutectic + βprimary (其中,L表示液相,βprimary表示初生β相,(β + TiB)eutectic表示由共析反应生成的β相和硼化物)。凝固过程中,大量的TiBeutectic为βeutectic提供形核质点,因此而形成不同取向的β相。在随后的冷却过程中,发生β→α相变,此相变涉及α相从β相中析出的12种方式,即发生晶体学分割,可进一步促进α相晶粒及后续片层团的细化[25]。另外,V作为β相稳定元素,可以提升β相在凝固过程中的稳定性,因此Ti-44Al-5Nb-1Mo-2V-0.2B合金中大量高温β相得以保留至室温。为了进一步观察硼化物的形态及成分,对该合金进行了深腐蚀[26]。图2a和b是硼化物在EPMA面扫描选区的二次电子(SE)及BSE像。可见,该区域由多个片层团晶粒和片层团之间的多相组织组成。Nb、Mo和V作为强β相稳定元素,存在于B2相中,如图2c~e的右上部分所示。2个B2相晶粒之间存在着明显的贫Nb、Mo和V区域,根据该区域的形貌和元素分布特征,可判定为α2相。另外,B元素的分布图(图2f)显示了硼化物在片层团附近的存在形态及分布。短棒状硼化物长度低于5 μm,存在于片层团周围和片层团内部的片层界面处,除了棒状硼化物,图2还显示了尺寸范围为0.5~2.0 μm的颗粒状硼化物,其分布特征与短棒状硼化物相近。

图2

图2

均匀化处理后Ti-44Al-5Nb-1Mo-2V-0.2B合金的EPMA面扫描分析

Fig.2

EPMA element mapping analyses of as-homogenized Ti-44Al-5Nb-1Mo-2V-0.2B alloy

(a) secondary electron (SE) image (b) backscattered electron (BSE) image

(c-f) element distribution maps for Nb (c), Mo (d), V (e), and B (f)

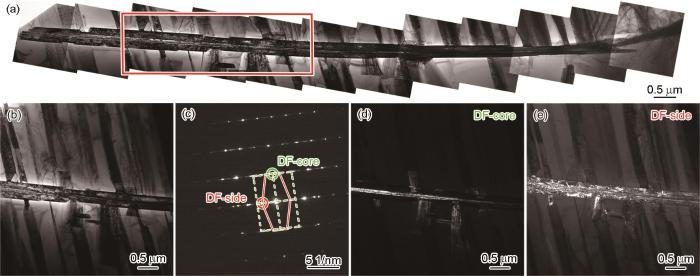

图3

图3

均匀化处理后Ti-44Al-5Nb-1Mo-2V-0.2B合金中硼化物的TEM像及SAED花样

Fig.3

TEM images and SAED pattern of the borides in as-homogenized Ti-44Al-5Nb-1Mo-2V-0.2B alloy

(a) morphology of a boride (b) local bright field (BF) image of the boride in Fig.3a

(c) SAED pattern of the boride (d, e) dark field (DF) images of the boride

2.2 变形温度对显微组织的影响

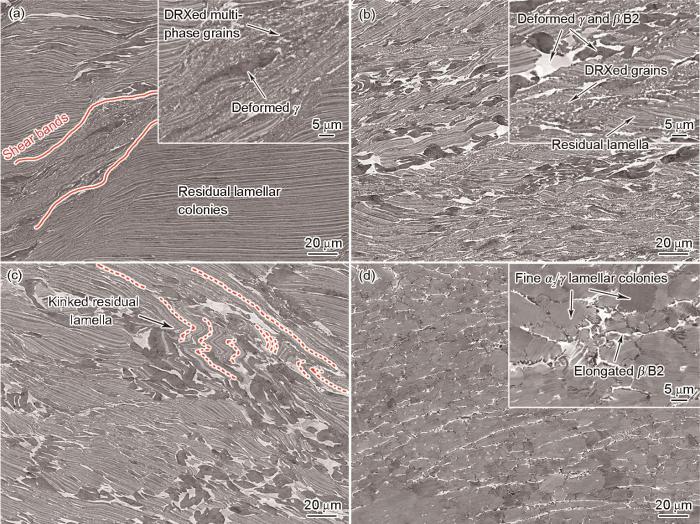

图4为Ti-44Al-5Nb-1Mo合金在不同温度下、应变速率为1 s-1时变形后的显微组织。变形温度为1050℃时,该合金的组织仍以粗大的片层团为主(尺寸为90~200 μm),且片层团内存在宽度为20~50 μm的变形剪切带。变形剪切带的形貌如图4a插图所示,该带状组织由细小的多相混合晶粒(尺寸低于1 μm的亚微米级晶粒)、少量条状γ和β/B2相晶粒及残余片层(尺寸为10~30 μm)组成,这说明此工艺极易引起Ti-44Al-5Nb-1Mo合金的不均匀变形。当变形温度为1100℃时,残余片层团尺寸明显减小,且不存在上述变形剪切带,如图4b所示。多相混合组织的变形均匀性大幅提高,但此时合金的变形仍主要集中在片层团之间的区域。由图4b插图可见,残余片层附近存在大量细小的多相再结晶晶粒。随着变形温度升高至1200℃,如图4c所示,残余片层团中的α2片层有所宽化,细小的β/B2相晶粒打断了α2/γ片层的连续性,片层团之间的γ和β/B2相晶粒尺寸明显增加。当温度升高至1250℃时,如图4d所示,组织主要由尺寸为10~20 μm的等轴α2/γ片层团组成,其片层间距很小,在SEM下难以分辨,片层团之间分布着细长的γ相(宽度约为0.5 μm)和β/B2相(宽度为1~2 μm),如图4d插图所示。

图4

图4

Ti-44Al-5Nb-1Mo合金在不同温度下、应变速率为1 s-1时变形后显微组织的SEM像

Fig.4

SEM images of the microstructure for Ti-44Al-5Nb-1Mo alloy deformed at 1 s-1 under different deformation temperatures (Insets show the corresponding high magnified SEM images, DRX—dynamic recrystallized )

(a) 1050oC (b) 1100oC (c) 1200oC (d) 1250oC

由此可知,在温度低于1100℃时,Ti-44Al-5Nb-1Mo合金的显微组织对变形温度不敏感,极易出现由局域流变而形成的变形带;在温度不低于1200℃时,该合金对温度的敏感性明显提高。1250℃处于该合金的(α + β)双相区,在温度和应力的作用下,Ti-44Al-5Nb-1Mo合金发生了非平衡相变,α、γ和β/B2相完全相变为α和β/B2相,即α + γ + β/B2→α + β/B2。随着变形的进行,相变产生的α与β/B2晶粒沿垂直于压缩方向拉长变形,α相发生了动态再结晶或球化。在快速冷却的条件下,形成了如图4d所示的形貌。

图5

图5

Ti-44Al-5Nb-1Mo-2V-0.2B合金在不同温度下、应变速率为1 s-1时变形后显微组织的SEM像

Fig.5

SEM images of the microstructure for Ti-44Al-5Nb-1Mo-2V-0.2B alloy deformed at 1 s-1 under different deformation temperatures (Insets show the corresponding high magnified SEM images)

(a) 1050oC (b) 1100oC (c) 1200oC (d) 1250oC

随变形温度升高至1200℃,如图5c所示,组织由片层团及其附近的γ和β/B2相组成,片层团以α2相片层为主,而γ相片层宽度较窄,片层团特征与低温变形后的残余片层明显不同。对于Ti-44Al-5Nb-1Mo-2V-0.2B合金,此时的变形温度已处于(α + β)双相区或接近α单相区。α/γ片层、片层团之间的β/B2和γ相易发生α + γ + β/B2→α + β/B2转变。相变产生的大量α相晶粒在高温热变形的作用下再次变形,随后在冷却过程中析出γ相片层。在图5c所示的部分片层团中,γ相片层从α2相的心部开始析出并逐渐向晶界扩展。此外,一些高温α相会以α2单相的形式保留至室温,如图5c中箭头所示。当变形温度升高至1250℃时,α + γ + β/B2→α + β/B2相变发生得更加充分,在片层团附近无较大的块状γ相存在,如图5d所示。片层团均匀、细小,尺寸为10~15 μm,且片层间距极细,如图5d插图所示。此外,显微组织中β/B2相的含量较其他变形条件明显减少。这表明在1250℃保温及变形的过程中,β/B2相会向α相转变,即发生α + β/B2→α转变。β相稳定元素的重新分配降低了β/B2相的稳定性,并在一定程度上提高了α/α2相的稳定性,若延长保温/变形时间,β/B2相可被完全消除。

除了上述特征,当变形温度高于1100℃时,Ti-44Al-5Nb-1Mo-2V-0.2B合金中片层团附近的γ和β/B2相形态出现较大变化。在低温 (1050~1100℃)变形时,残余片层团附近有大量的γ和β/B2相。β/B2相的内部存在大量亚晶界,其变形机制以动态回复为主。随着变形温度升高,片层团周围γ相的含量明显减少,γ相晶粒主要从β/B2相内部以针状或块状形态析出。随着变形温度的升高,γ相会逐渐向β/B2相转变,即发生γ→β/B2。但由于变形温度相对较低,相变并不能完全发生,因此还有一些尺寸较大的块状γ相保留下来。另外,γ→β/B2转变会造成β/B2相中溶质元素(Al和Nb等)的过饱和固溶。这些溶质元素在快速冷却的条件下析出,促进针状γ相的形成。

综上所述,对于Ti-44Al-5Nb-1Mo合金,当变形温度低于1100℃时,主要的变形机制有3种,分别是片层团的偏转,片层团内部和晶界的γ、β/B2相的变形,及变形剪切带的产生。随着温度升高至1100~1200℃,片层团的相变分解逐渐成为主要的变形机制。温度在1200~1250℃范围内时,合金组织表现出极高的温度敏感性,由间距极细的等轴片层团和少量β/B2相组成。对于Ti-44Al-5Nb-1Mo-2V-0.2B合金,随着变形温度的升高,除了可以促进复杂的变形诱导相变的发生,还会促进α和β/B2相的动态再结晶/球化,从而提高此合金的组织均匀性。Ti-44Al-5Nb-1Mo-2V-0.2B合金表现出更低的L(α/γ)→α + γ + β/B2、α + γ + β/B2→α + β/B2和γ→β/B2相变温度。

2.3 应变速率对显微组织的影响

合适的应变速率可以在很大程度上提升TiAl合金在不同温度的变形能力[27],本工作选取Ti-44Al-5Nb-1Mo和Ti-44Al-5Nb-1Mo-2V-0.2B合金在温度为1050和1200℃、应变速率为0.001~1 s-1变形后的典型组织进行对比观察。

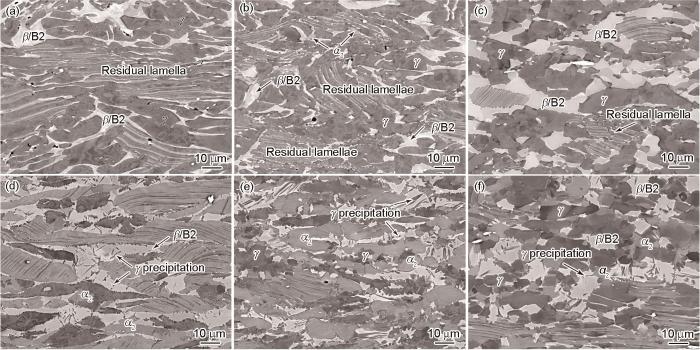

图6为Ti-44Al-5Nb-1Mo合金在不同工艺下变形后的显微组织。变形温度为1050℃时,组织以残余片层为主,较快的应变速率(1和0.1 s-1)使热变形局域化,组织流线型特征明显,如图6a和b中的虚线所示。当应变速率降至0.01 s-1,组织均匀性有所提高,但仍有变形带的存在,由片层团分解产生的多相晶粒的尺寸明显增加,残余片层含量减少,如图6c所示。随着应变速率降至0.001 s-1,残余片层充分宽化、连续性低,表现出即将完全破碎的趋势。在实际的TiAl合金热加工过程中,过低的应变速率导致热加工时间较长,导致坯料温度的降低,难以获得完全再结晶组织。残余片层附近多相晶粒的尺寸在5~8 μm之间,如图6d所示。由此可知,应变速率的降低可以大幅提高Ti-44Al-5Nb-1Mo合金在低温变形时的组织均匀性。当变形温度为1200℃、应变速率为0.1 s-1时,虽然此变形温度超过了共析转变温度并接近α + β双相区,但片层团中的L(α/γ)→α + γ + β/B2转变程度仍然很低,组织以弯折、宽化的α2片层为主,如图6e所示。随着应变速率降至0.01 s-1,片层分解程度有所提高,然而组织均匀性仍然较差,如图6f所示。

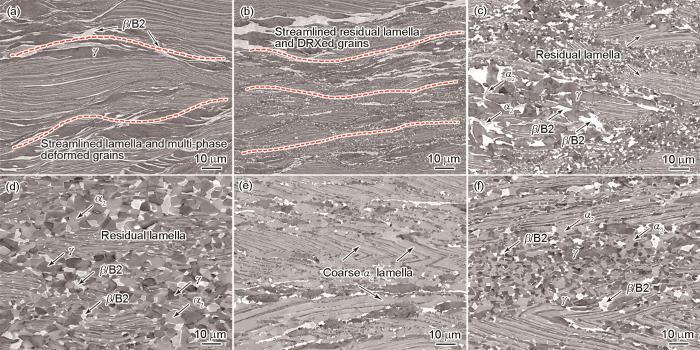

图6

图6

Ti-44Al-5Nb-1Mo合金在不同热变形工艺下进行高温热变形后显微组织的SEM像

Fig.6

SEM images of the microstructure for Ti-44Al-5Nb-1Mo alloy deformed at different deformation conditions

(a) 1050oC, 1 s-1 (b) 1050oC, 0.1 s-1 (c) 1050oC, 0.01 s-1

(d) 1050oC, 0.001 s-1 (e) 1200oC, 0.1 s-1 (f) 1200oC, 0.01 s-1

图7为Ti-44Al-5Nb-1Mo-2V-0.2B合金在不同条件下变形后的显微组织。变形温度为1050℃、应变速率为1 s-1时,合金的显微组织由残余片层和其周围的γ和β/B2相晶粒组成,如图7a所示。片层团分解产生大量γ和β/B2相晶粒,残余片层团中的γ相片层宽化明显,与周围γ相晶粒之间不存在明显的界面。应变速率为0.01 s-1时,片层团进一步分解,如图7b所示。而当应变速率降为0.001 s-1时,如图7c所示,组织以γ和β/B2相为主,一些由相变产生的α2/γ片层开始出现,并且仅有少量残余片层。另外,部分β/B2相中析出了块状γ相。这表明,较低的应变速率可以促进Ti-44Al-5Nb-1Mo-2V-0.2B合金在低温 (1050℃)时的L(α/γ)→α + γ + β/B2和γ→β/B2转变。

图7

图7

Ti-44Al-5Nb-1Mo-2V-0.2B合金在不同热变形工艺下进行高温热变形后显微组织的SEM像

Fig.7

SEM images of the microstructure for Ti-44Al-5Nb-1Mo-2V-0.2B alloy deformed at different deformation conditions

(a) 1050oC, 1 s-1 (b) 1050oC, 0.01 s-1 (c) 1050oC, 0.001 s-1

(d) 1200oC, 1 s-1 (e) 1200oC, 0.01 s-1 (f) 1200oC, 0.001 s-1

如图7d~f所示,在1200℃变形时,组织中α2相含量较高,β/B2相中有针状γ相析出。可以断定,此时合金的变形以发生α + γ + β/B2→α + β/B2和γ→β/B2转变为主。随着应变速率的降低,组织中残余片层含量大幅降低,γ相含量有所增加,而β/B2相含量几乎不变。此变形温度处于该合金的α + β + γ三相区,应变速率的降低使变形组织逐渐接近平衡态,γ和β/B2相晶粒的形态都由拉长的条状转变为等轴状,如图7f所示,多相组织发生了完全动态再结晶。通常认为β/B2相具有较高的层错能,高温热变形时以动态回复为主要变形机制,而应变速率的降低可以促进β/B2相在1200℃发生动态再结晶并长大。

Ti-44Al-5Nb-1Mo合金中有较高的Nb含量,经过均匀化处理后合金中仍有超过70%的粗大片层团组织,导致其高温热变形能力较差。添加V和B元素后,大量硼化物被引入,同时β相稳定性显著提高,这有利于合金中片层团的尺寸细化、片层界面的取向多样化,从而降低难变形片层的变形难度。Ti-44Al-5Nb-1Mo-2V-0.2B合金的变形组织明显比Ti-44Al-5Nb-1Mo合金更加均匀。综上所述,对于Ti-44Al-5Nb-1Mo合金,当变形条件为温度1200℃、应变速率低于0.01 s-1时,可以得到晶粒尺寸均匀、细小的三相混合组织;当变形条件为温度1250℃、应变速率约为1 s-1时,可获得近全片层组织(在等轴片层团晶界存在着一些β/B2相)。对于Ti-44Al-5Nb-1Mo-2V-0.2B合金,在1200℃、应变速率0.01~0.001 s-1变形后,可以得到近双态组织(在片层团和γ相晶界存在着一些β/B2相);当选取变形温度1250℃、应变速率约1 s-1,可获得晶粒尺寸均匀的近全片层组织以及大量尺寸均匀且片层间距很细的片层团。

2.4 流变软化机制

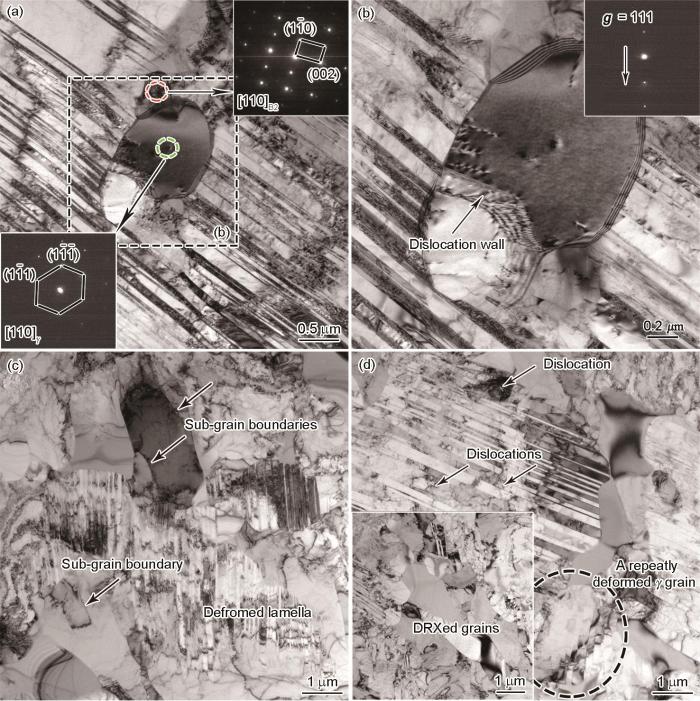

由以上显微组织分析可知,Ti-44Al-5Nb-1Mo合金中粗大的残余片层难以完全消除,其高温热变形以片层组织的变形为主,图8给出了片层组织在高温热变形过程中的演变行为。变形温度为1050℃、应变速率为1 s-1时,如图8a所示,片层发生了轻微的弯曲,部分片层的边界不平整,其内部存在大量的位错。图8a中右上方的插图为B2相在[110]晶带轴的SAED花样,左下方的插图为γ相在[110]晶带轴的SAED花样。可见,片层的连续性被尺寸约为0.3 μm的B2相和1.5 μm的γ相打断。选取黑色虚线框区域进一步观察,如图8b所示。在双束条件(插图)下,可在倒易矢量 g = 111时观察到γ相晶粒中的位错明场像,位错在该晶粒中塞积并逐渐形成位错墙,如箭头所示。γ相晶粒内部存在不同的衬度,这表明随着变形的进行位错墙会发展为小角度晶界,进一步可形成γ相亚晶粒或动态再结晶晶粒。随着应变速率的降低,片层分解产物的尺寸会随着变形的进行而增加,如图8c所示,此时片层结构中的位错密度仍较高。片层分解产生的晶粒在后续变形过程中继续发生变形,其内部存在大量位错,部分位错缠结形成了亚晶界,如图中箭头所示。如图8d所示,随着应变速率降低至0.001 s-1,片层中的缺陷密度有所降低,一部分γ相晶粒内形成了形变孪晶,如图8d中右下方区域所示,还有一部分片层分解的产物在变形过程中发生了再结晶,如图8d插图所示,其内部无位错存在。

图8

图8

Ti-44Al-5Nb-1Mo合金中片层组织演化的TEM分析

Fig.8

TEM analyses of the lamellar evolution for Ti-44Al-5Nb-1Mo alloy

(a) 1050oC, 1 s-1 (Insets show the SAED patterns of B2 and γ phase)

(b) high magnified image of square area in Fig.8a (Inset shows the SAED pattern of two-beam image)

(c) 1050oC, 0.01 s-1 (d) 1050oC, 0.001 s-1 (Inset shows the DRX grains)

图9为Ti-44Al-5Nb-1Mo-2V-0.2B合金中的片层组织在高温热变形过程中的变形行为。可以发现,变形温度为1050℃、应变速率为1 s-1时,合金中的片层明显宽于Ti-44Al-5Nb-1Mo合金。片层界面在应力作用下变得不平整,如图9a中的红色虚线所示。一些再结晶晶粒出现在剧烈变形的片层之间,如黑色虚线区域所示。片层内部存在大量位错,位错塞积形成位错墙,部分位错墙转化为小角度晶界,如图中的黑色箭头所示,所形成的亚晶粒尺寸约为0.3 μm,片层仍保持着较好的连续性。随着应变速率降低至0.01 s-1,如图9b所示,片层开始宽化,其中的位错密度有所降低。片层破碎程度明显提高,其分解产物中仍存在较高密度的位错,如黑色箭头所示。部分晶粒发生了再结晶,内部无位错存在。该合金在温度为1050℃的变形以位错诱导的片层破碎、再结晶为主。在变形温度较高时,合金中片层的破碎还与形变孪晶密切相关。变形温度为1200℃、应变速率为1 s-1时,合金的显微组织中存在大量的形变孪晶,如图9c和d所示。图9c显示了与片层界面平行的孪晶界,如蓝色虚线所示,插图分别显示了该孪晶的SAED花样及中心暗场像。这些孪晶界的宽度低于40 nm,其周围存在大量位错。除了这类孪晶,合金变形的片层中还存在大量与片层界面成固定夹角的孪晶[28],如图9d所示,右侧的插图显示了这种孪晶的SAED花样。这些孪晶与位错相互缠绕,如图9d右上方的插图所示。随着变形的进行,这些形变孪晶及其附近的位错可以在片层组织变形过程中起协调作用,还可以为片层的破碎分解提供大量形核点。

图9

图9

Ti-44Al-5Nb-1Mo-2V-0.2B合金显微组织的TEM分析

Fig.9

TEM analyses of the microstructure of Ti-44Al-5Nb-1Mo-2V-0.2B alloy

(a) 1050oC, 1 s-1 (b) 1050oC, 0.01 s-1

(c) 1200oC, 1 s-1, shows the twin boundaries paralleling to the lamellae (Insets show the SAED pattern and corresponding dark field image. T—twinning, γT—twinning of γ phase)

(d) 1200oC, 1 s-1, shows the secondary twins (Insets show the high magnified image of the square area and SAED pattern)

综上所述,V和B元素的添加使Ti-44Al-5Nb-1Mo合金具有更好的变形能力,片层组织在高温热变形过程中更易发生宽化,大量的位错和孪晶在这些宽化的片层中更易启动,为此类合金组织中难变形片层团的破碎和分解提供了有利条件。变形不再集中于易变形的片层团晶界,从而减缓了合金在热变形过程中的应力集中,大幅提高了显微组织的均匀性。

3 结论

(1) Ti-44Al-5Nb-1Mo-2V-0.2B合金中存在大量长链状、棒状及颗粒状的硼化物,这些硼化物在合金凝固过程中,通过改变凝固路径,使2种TiAl合金表现出较大的显微组织和对热变形敏感性的差异。相对于Ti-44Al-5Nb-1Mo合金,Ti-44Al-5Nb-1Mo-2V-0.2B合金具有更好的高温变形能力。

(2) 对于Ti-44Al-5Nb-1Mo合金,低温热变形的主要机制为难变形片层团的偏转,片层团附近γ和β/B2相的变形,及变形带的产生。随着温度升高,片层团的相变分解逐渐成为主要的变形机制。温度达到1250℃时,变形组织会表现出极高的温度敏感性。对于Ti-44Al-5Nb-1Mo-2V-0.2B合金,随着变形温度的升高,其主要变形机制为变形诱导的相变(引起片层分解),α和β/B2相的动态再结晶及球化,合金的组织均匀性较高。应变速率的降低与变形温度的升高对变形组织带来的影响相似。

(3) 对于Ti-44Al-5Nb-1Mo合金,当变形温度约为1200℃、应变速率低于0.01 s-1时,可得到晶粒尺寸均匀、细小的三相混合组织;当变形温度约为1250℃、应变速率为1 s-1,可得到晶粒尺寸均匀的近全片层组织。对于Ti-44Al-5Nb-1Mo-2V-0.2B合金,在1200℃、应变速率0.01~0.001 s-1条件下变形,可得到近双态组织;在温度1250℃、应变速率约1 s-1的条件下变形,可得到晶粒尺寸均匀的近全片层组织。

参考文献

Present status for rolling TiAl alloy sheet

[J].TiAl alloy sheets are important strategic structural materials in aerospace and automotive industry because of their high strength-to-weight ratio and high service temperature. However, the preparation of TiAl alloy sheets is difficult, especially the rolling of large-size high-performance TiAl alloy sheets. The preparation process, size, microstructure, and mechanical properties of hot-rolling TiAl alloy sheets using ingot metallurgy, powder metallurgy, direct rolling, and roll bonding approaches in recent years were reviewed. The features and existing problems of the above processing routes were discussed. Meanwhile, some suggestions on rolling large-size TiAl alloy sheets and its future development were proposed.

TiAl合金板材轧制研究现状

[J].在航空航天和汽车工业领域,轻质高强耐高温的TiAl合金板材是重要的战略结构材料。然而,TiAl合金板材成形难度大,尤其是大尺寸高性能TiAl合金轧板的制备更是困难。本文从TiAl合金轧板制备方法研究现状出发,综述了近年来铸锭冶金轧制、粉末冶金轧制、铸锭直接热轧和叠轧法制备TiAl合金板材的工艺、尺寸、组织和力学性能,论述了上述制备方法的特点及存在的不足,提出了关于制备大尺寸高性能TiAl合金轧板的建议以及未来发展方向。

Advances and challenges of TiAl base alloys

[J].The history of research and development of γ-TiAl intermetallic alloys was outlined and divided into 4 stages: starting (1974~1985), revolutionary (1986~1995), emerging (1996~2005) and specialty materials (2006~). Major events and landmarks at the different stages were recounted to provide a framework for understanding scientific and technological progress. Key advances in the following 6 areas were reviewed: alloying, microstructure type, primary processing (melting), secondary processing (hot working), properties (including creep, fracture and fatigue, and oxidation), and tertiary processing (forming, covering both investment casting and near-net shape powder metallurgy). Future challenges were identified as follows: improvement of centrifugal casting technology, low-cost wrought process, development of third-generation alloys that meet design specifications, new applications based on new technologies, and viability of new forming routes such as additive manufacturing。

钛铝金属间化合物的进展与挑战

[J].

Recent development of new high-temperature titanium alloys for high thrust-weight ratio aero-engines

[J].

高推重比航空发动机用新型高温钛合金研究进展

[J].

Development of β-solidifying γ-TiAl alloys sheet

[J].

Microstructure characteristics of Ti-43Al alloy during twin-roll strip casting and heat treatment

[J].

Effects of hot-pack rolling process on microstructure, high-temperature tensile properties, and deformation mechanisms in hot-pack rolled thin Ti-44Al-5Nb-(Mo, V, B) sheets

[J].

Research progress on preparation technology of titanium aluminum alloy and its intermetallic compounds

[J].

钛铝合金及其金属间化合物制备工艺研究进展

[J].

Microstructural evolution and mechanical properties of a forged gamma titanium aluminide alloy

[J].

Hot deformation behavior of β phase containing γ-TiAl alloy

[J].

Effects of lamellar spacing on microstructural stability and creep properties in β-solidifying γ-TiAl alloy by directional solidification

[J].

Prior particle boundaries and microstructural homogenization of a β-solidifying γ-TiAl alloy fabricated from prealloyed powder

[J].

Microstructure evolution and tensile properties of conventional cast TiAl-based alloy with trace Ni addition

[J].

Precipitation behavior of ωo phase and texture evolution of a forged Ti-45Al-8.5Nb-(W, B, Y) alloy during creep

[J].

Effect of multipass deformation at elevated temperatures on the flow behavior and microstructural evolution in Ti-6Al-4V

[J].

Work hardening and recovery in fully lamellar TiAl: Relative activity of deformation systems

[J].The relative activity of deformation systems during work hardening and thermal recovery has been investigated in fully lamellar TiAl. This has been done by a combination of a series of deformation/static recovery experiments and numerical simulations based on a defect density-based crystal plasticity model. Firstly, active deformation systems in differently oriented polysynthetically twinned crystals/single lamellar colonies have been studied. Subsequently, numerical experiments on a polycolony microstructure have been used to investigate the inhomogeneous microplasticity (i.e. the typical microyield) in fully lamellar TiAl. From this, it has been possible to analyse how changes in the lamella thickness, domain size and colony size influence the onset of macroscopic yield. Based on static recovery experiments with differently oriented polysynthetically twinned crystals, numerical studies have revealed trends in the recovery of work hardening in both polysynthetically twinned crystals and polycolony microstructures.

A β-solidifying TiAl alloy reinforced with ultra-fine Y-rich precipitates

[J].

Effect of pack rolling on microstructures and tensile properties of as-forged Ti-44Al-6V-3Nb-0.3Y alloy

[J].

Microstructural control and mechanical properties of a β-solidified γ-TiAl alloy Ti-46Al-2Nb-1.5V-1Mo-Y

[J].

Pack rolling of TiAl based alloy

[J].

包套轧制制备TiAl基合金板材

[J].

Effect of co-alloying elements on the structural stability, elastic, ductility and thermodynamic properties of TiAl intermetallic compound

[J].

Mechanical behaviour of Ti-Nb-Hf alloys

[J].

Effect of Y2O3 particles on the fracture toughness of directionally solidified TiAl-based alloys

[J].

Rapid decomposition of lamellar microstructure and enhanced hot workability of an as-cast triphase Ti-45Al-6Nb-1Mo alloy via one-step alpha-extrusion & annealing

[J].

High temperature deformation behaviour and microstructure of cast in-situ TiAl matrix composite reinforced with carbide particles

[J].

Microstructure refinement of cast TiAl alloys by β solidification

[J].

Fracture behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles

[J].

Hot deformation behavior and deformation mechanism of two TiAl-Mo alloys during hot compression

[J].

Evidence for deformation twinning of the D019-α2 phase in a high Nb containing TiAl alloy

[J].It is commonly agreed that the alpha(2) phase in gamma(TiAl)-based alloys is quite difficult to deform plastically especially by order twinning. In the present study, for the first time we report deformation twinning in the alpha(2) phase in a nearly-lamellar two-phase gamma-TiAl alloy investigated by electron microscopy. Diffraction pattern and high-resolution images indicate that the twinning plane is (20 (2) over bar1) and the twinning direction is [10 (14) over bar], which is essentially analogous to what has been observed in disordered hexagonal structures. The twinning and anti-twinning mechanisms are interpreted. The twinning is a combined result of superpartial dislocation glide activated by the dissociation of < 2c + a > type superdislocation, accompanied by atomic shuffling and short-range diffusion which is facilitated by the anti-structural bridges diffusion mechanism during high-temperature compression. The appearance of deformation twinning in the a2 phase can play an important role for the excellent mechanical properties of high Nb containing TiAl alloys, which is of great importance for the further development of gamma-TiAl alloys.