冷轧热处理中锰钢整体力学性能优异,但是塑性失稳严重,塑性失稳主要包括Lüders应变和Portevin-Le Chatelier (PLC)效应,塑性失稳有损成形性能。研究[11]表明,冷轧热处理中锰钢的塑性失稳与残余奥氏体的稳定性密切相关:冷轧热处理中锰钢的残余奥氏体稳定性高且差异小,马氏体相变集中发生在变形量较大的区域,因此不能在形变前期提供加工硬化来弱化Lüders应变,而且容易导致严重的PLC效应。因此,合理调控残余奥氏体稳定性,使其在更大应变范围内发生马氏体相变,是优化和改善中锰钢力学性能的关键。影响残余奥氏体稳定性的因素有很多,包括残余奥氏体的化学成分、晶粒尺寸、形貌、晶体取向以及相邻相等[12],其中化学成分、晶粒尺寸以及形貌对稳定性影响更为显著。研究[13]表明,当退火前组织中存在珠光体时,在退火过程中珠光体中的渗碳体和附近的铁素体转变为奥氏体,此时还有少量铁素体未转变,因此冷却后得到间隔分布的铁素体和残余奥氏体,并且这种残余奥氏体的Mn含量很高。Zhang等[14]使用热轧Fe-0.42C-3.71Mn-1.45Si (质量分数,%)钢,通过调控热处理工艺,得到含珠光体的原始组织,进行淬火-配分工艺后得到了薄膜状和块状的残余奥氏体,这2种残余奥氏体在拉伸变形过程中表现出了不同的稳定性,在保证整体力学性能的前提下,优化了材料局部力学性能。

冷轧中锰钢存在塑性失稳现象可以通过设计不同稳定性的残余奥氏体来改善。鉴于此,本工作通过预处理获得珠光体+马氏体+铁素体的三相组织,在临界退火后的最终组织中获得了具有不同化学成分和形貌的2种残余奥氏体,研究了2种残余奥氏体的特点,分析了残余奥氏体稳定性对力学性能的影响,探讨不同稳定性残余奥氏体在不同变形阶段的作用机理。

1 实验方法

实验所用中锰钢的化学成分(质量分数,%)为:C 0.18,Mn 5.45,Al 1.62,Si 0.50,Fe余量。在50 kg中频感应熔炼炉冶炼,浇铸冷却后开坯锻造成60 mm厚的钢坯。钢坯在箱式加热炉中随炉加热至1200℃保温1.5 h,经5道次热轧后冷却至600℃保温1.5 h,然后空冷至室温。热轧板为3 mm厚的钢板,热轧后酸洗,最终经多道冷轧成1.4 mm厚的钢板。

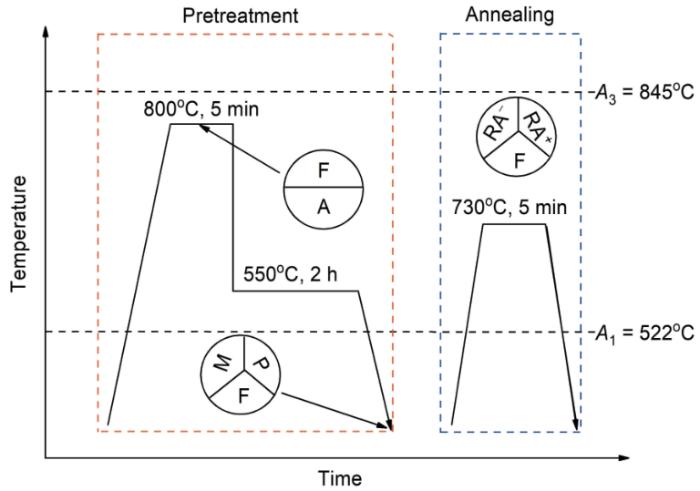

冷轧钢板按照图1所示的工艺进行热处理,所得试样命名为PA730-5。具体热处理过程如下:首先,将钢板在800℃保温5 min,得到奥氏体(austenite,A)和铁素体(ferrite,F)的双相组织,随即在550℃下保温2 h后水淬,得到珠光体(pearlite,P) +马氏体(martensite,M) +铁素体的多相组织,此过程称为预处理(pretreatment);经过预处理的试样在730℃退火5 min,其微观组织为铁素体+残余奥氏体(retained austenite,RA),其中残余奥氏体有2种,分别为由珠光体转变而成的富Mn薄膜状残余奥氏体(RA+)和马氏体转变而成的贫Mn块状残余奥氏体(RA-)。为了对比,引入不经预处理的钢板直接在730℃退火3 min,对应的试样命名为A730-3。

图 1

图 1

热处理工艺示意图

Fig.1

Schematic of heat treatment process (A1—start temperature of pearlite transformed to austenite, A3—temperature of all ferrite transformed to austenite, A—austenite, F—ferrite, P—pearlite, M—martensite, RA—retained austenite, RA+—Mn-rich RA, RA-—Mn-poor RA)

PA730-5试样进行机械研磨抛光,使用体积分数为4%的硝酸酒精溶液腐蚀后,分别在Axio Vret A1型金相显微镜(OM)和Sigma300型扫描电镜(SEM)下进行微观组织观察,并依据GB/T15749—2008定量金相测量方法,使用OM自带软件对珠光体含量(体积分数)进行统计。A730-3和PA730-5试样进行研磨抛光,用体积分数为15%的高氯酸酒精溶液电解腐蚀,在SEM下对试样进行组织观察。PA730-5试样经机械研磨至厚度50 μm后双喷减薄,随后利用带有能谱仪(EDS)的JEM-F200型透射电镜(TEM)测量残余奥氏体中的元素含量。

A730-3和PA730-5试样研磨抛光后,用体积分数为20%的高氯酸酒精溶液电解抛光去除应力,利用D8 Advance型X射线衍射仪(XRD)对试样中的残余奥氏体进行定量分析,用

式中,Iγ 为奥氏体(200)、(220)、(311)衍射峰积分强度,Iα 为铁素体(200)、(211)衍射峰积分强度。

利用

式中,XC、XMn和XAl分别为残余奥氏体中C、Mn和Al的质量分数,a为残余奥氏体的晶格常数,由

式中,λ为X射线波长,θ为衍射角,h、k、l为晶面指数。使用XRD峰半高宽数据,采用

式中,β为铁素体XRD峰的半高宽(FWHM);b为Burgers矢量模,取值为 2.48 × 10-10 m。

根据GB/T228—2002,将A730-3和PA730-5试样制成标距为25 mm的非比例拉伸试样,在CMT-30型电子试验机下进行拉伸实验,加载速率2 mm/min。根据

式中,

2 实验结果

2.1 微观组织构成与残余奥氏体特性

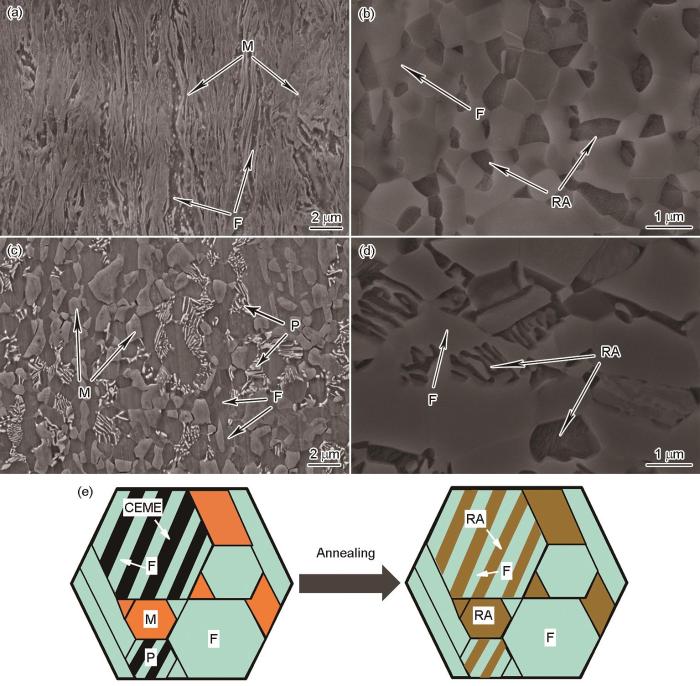

图2为A730-3和PA730-5试样退火前后微观组织的SEM像及PA730-5试样奥氏体转变示意图。如图2a所示,原始冷轧板的微观组织为马氏体和铁素体。经过预处理后微观组织由珠光体、铁素体和马氏体组成(图2c),其中珠光体体积分数约占22%。A730-3和PA730-5试样退火后最终组织如图2b和d所示,均由铁素体和残余奥氏体组成,A730-3试样的铁素体晶粒更为细小。A730-3试样最终组织中残余奥氏体主要为块状残余奥氏体。而PA730-5试样中的残余奥氏体呈块状和薄膜状,块状残余奥氏体源自于马氏体,薄膜状残余奥氏体源自于珠光体[12],与其相邻的薄膜状铁素体交替呈层状分布,很大程度遗传了珠光体的形貌[14,18]。PA730-5试样2种形貌残余奥氏体获得的原理如图2e所示。

图2

图2

A730-3和PA730-5试样退火前后的SEM像和奥氏体转变示意图

Fig.2

SEM images of A730-3 (a, b) and PA730-5 (c, d) samples before (a, c) and after (b, d) annealing, and schematics of austenite transformation of PA730-5 sample (CEME—cementite) (e)

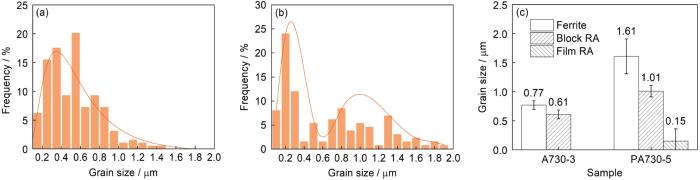

图3为A730-3和PA730-5试样残余奥氏体及铁素体晶粒尺寸分布。如图3a所示,A730-3中残余奥氏体晶粒尺寸多分布于0.2~0.9 μm之间,约占晶粒总数的65.06%,这表明A730-3试样残余奥氏体晶粒尺寸相对集中,均匀且细小。从图3b可以看出,因为PA730-5中存在2种不同形貌的残余奥氏体,其残余奥氏体晶粒尺寸分布出现2个峰值:薄膜状残余奥氏体平均晶粒尺寸在0.15 μm左右,在0.1~0.3 μm形成一个峰值;块状残余奥氏体平均晶粒尺寸在1 μm左右,在0.8~1.2 μm又形成一个峰值。从图3c中可见,PA730-5中块状残余奥氏体和铁素体平均晶粒尺寸要大于A730-3块状残余奥氏体和铁素体平均晶粒尺寸。

图3

图3

A730-3和PA730-5试样的残余奥氏体晶粒尺寸分布图和平均晶粒尺寸

Fig.3

RA grain size distributions of A730-3 (a) and PA730-5 (b) samples, and average grain sizes of each phase in the microstructure (c)

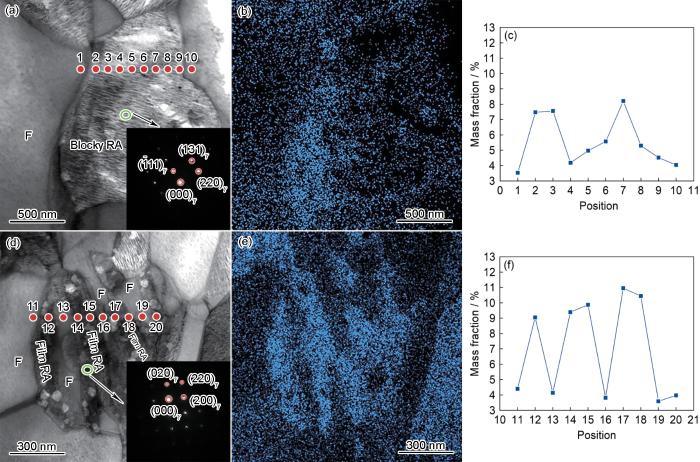

图4为PA730-5试样退火后块状和薄膜状残余奥氏体的TEM像、选区电子衍射(SAED)花样及EDS分析。根据图4a和d中插图的SAED花样可确定所选区域为残余奥氏体。由图可见,块状残余奥氏体晶粒尺寸约为1 μm (图4a)。薄膜状残余奥氏体与铁素体呈片层状分布,奥氏体薄膜厚度约100 nm;薄膜状残余奥氏体周围铁素体中并无明显的位错,这是因为PA730-5经过多次热处理,晶粒发生回复再结晶导致位错密度有所降低(图4d)。从Mn元素的EDS面扫描结果可知,薄膜状残余奥氏体中Mn元素富集程度明显高于块状残余奥氏体(图4b和e),这是因为Mn元素在珠光体中的富集程度远高于马氏体,在短时间的临界退火过程中,Mn元素没有得到充分扩散,因此在薄膜状残余奥氏体中得到富集。为了直观地体现2种残余奥氏体中Mn含量的差异,采用EDS点扫描的方式测量图4a和d中点1~20的Mn元素含量,所得结果如图4c和f所示。可见,块状残余奥氏体中Mn含量较低,且分布不均,其平均Mn元素含量约为6.18% (质量分数,下同),而薄膜状残余奥氏体中平均Mn元素含量相对较高,约为9.94%。Mn元素对于残余奥氏体的稳定性尤为重要,其稳定性可以通过马氏体相变的驱动力(ΔGch)来描述[17]:

图4

图4

PA730-5试样退火后块状和薄膜状残余奥氏体的TEM像、SAED花样及EDS分析

Fig.4

TEM images and SAED patterns (insets) (a, d), and corresponding EDS element mappings (b, e) and EDS point concentrations (c, f) of Mn element of blocky (a-c) and film (d-f) RA in PA730-5 sample after annealing (Red dots in Figs.4a and d show EDS scanning points)

式中,MC、MMn为残余奥氏体中C和Mn的摩尔分数,经过换算得块状和膜状残余奥氏体中C和Mn的摩尔分数分别为3.16%、5.99%和3.17%、9.69%;T为热力学温度(298 K)。通过

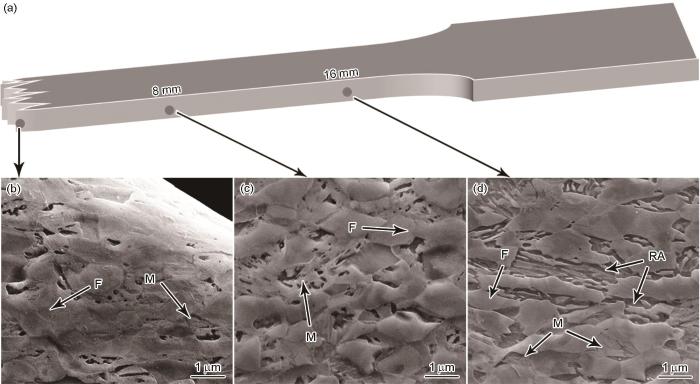

图5

图5

PA730-5试样拉伸断裂后距离断口不同位置的取样位置示意图及SEM像

Fig.5

Schematic of sample location (a) and corresponding SEM images (b-d) away from fracture successively in PA730-5 sample

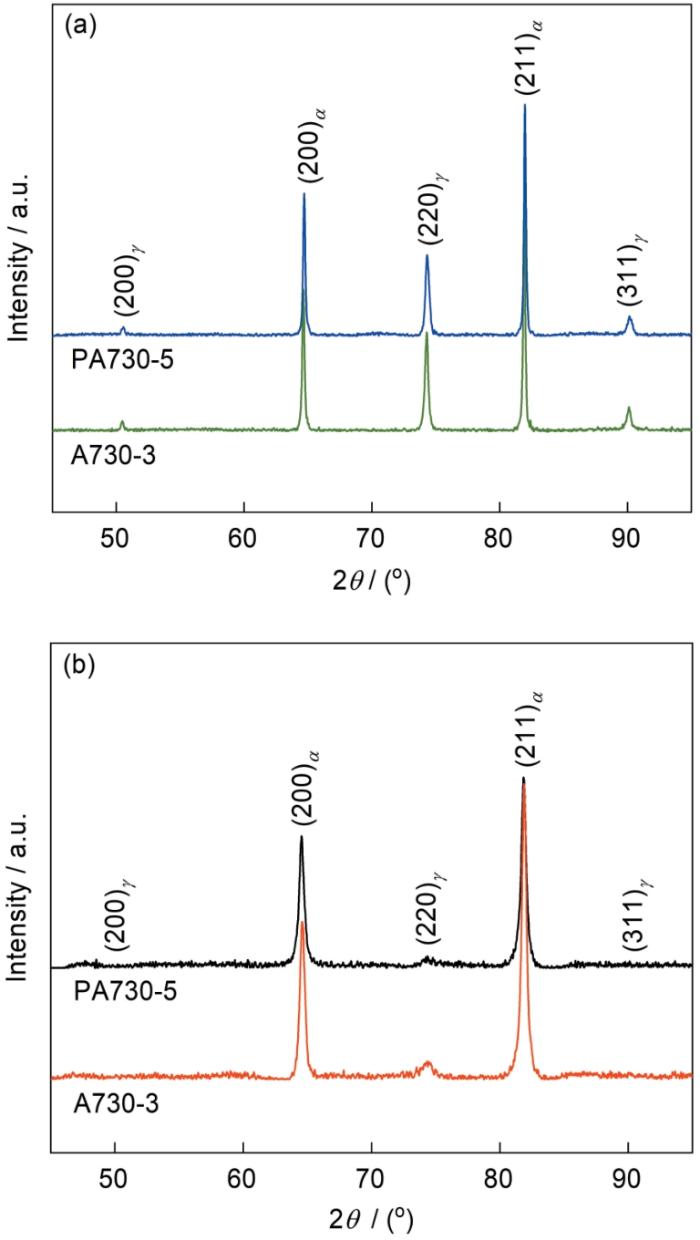

图6为A730-3和PA730-5试样拉伸前和拉伸断裂后断口处的XRD谱。由图可见,A730-3和PA730-5试样在拉伸前存在很高的残余奥氏体衍射峰(图6a),这表明试样中存在大量的残余奥氏体,而拉伸断裂后残余奥氏体的衍射峰不明显(图6b)。经计算,拉伸前A730-3和PA730-5试样残余奥氏体体积分数分别为29.18%和28.11%;拉伸断裂后,A730-3和PA730-5试样在断口处的残余奥氏体体积分数分别为7.91%、3.74%。研究[17]表明,细小颗粒状残余奥氏体的稳定性高于薄膜状残余奥氏体,而薄膜状残余奥氏体的稳定性又高于块状残余奥氏体。如图2b所示,A730-3试样中存在细小颗粒状的残余奥氏体,因其稳定性高,在拉伸的过程中难以发生马氏体相变,从而导致断后A730-3中的残余奥氏体含量相对较高。

图6

图6

A730-3和PA730-5试样拉伸前和拉伸断裂后断口处的XRD谱

Fig.6

XRD spectra of A730-3 and PA730-5 samples before (a) and after (b) tensile fracture

利用

式中,VRA0为初始残余奥氏体含量;VRA为应变为δ时的残余奥氏体含量;k反映残余奥氏体的机械稳定性,其值越大,残余奥氏体的机械稳定性越低。经过计算,A730-3和PA730-5试样断口处的k分别为3.04和5.93,显然A730-3试样残余奥氏体的机械稳定性比PA730-5试样高,这就意味着在变形量相同的条件下,PA730-5中残余奥氏体先发生相变。

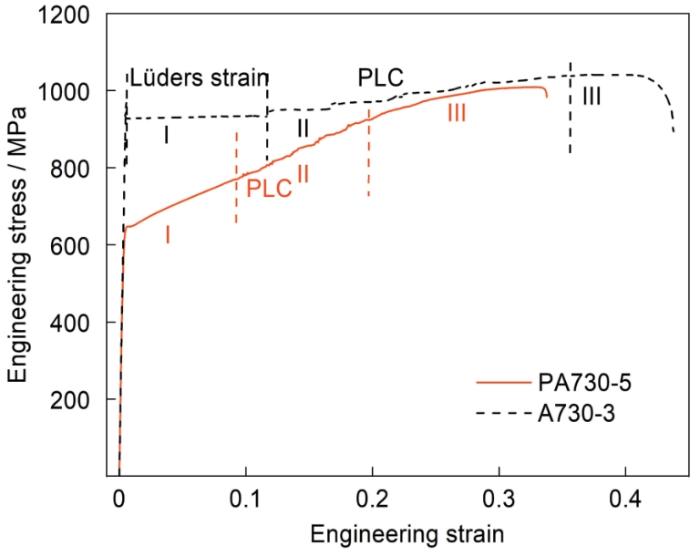

2.2 力学性能

图7为A730-3和PA730-5试样的工程应力-应变曲线。由图可知,A730-3试样的工程应力-应变曲线表现为较长的屈服平台(Ⅰ)和剧烈的曲线抖动(Ⅱ),表明该试样出现了严重塑性失稳,体现为明显的Lüders应变和PLC效应;PA730-5试样为连续屈服,没有Lüders应变,虽然工程应力-应变曲线在第Ⅱ阶段也出现了很微弱的抖动,但其PLC效应相较A730-3已经显著弱化。

图7

图7

A730-3和PA730-5试样的工程应力-应变曲线

Fig.7

Engineering stress-strain curves of A730-3 and PA730-5 samples (PLC—Portevin-Le Chatelier)

A730-3和PA730-5试样退火后的力学性能如表1所示。可见,2个试样均拥有良好的力学性能,其抗拉强度均超过1000 MPa,断后延伸率在30%以上,强塑积在30 GPa·%以上。值得注意的是,PA730-5试样的力学性能呈现出更合理的强屈比。

表1 A730-3和PA730-5试样退火后的力学性能

Table 1

| Sample | YS MPa | UTS MPa | TE % | UTS / YS | UTS × TE GPa·% |

|---|---|---|---|---|---|

| A730-3 | 922 | 1041 | 43 | 1.12 | 44.76 |

| PA730-5 | 652 | 1025 | 34 | 1.57 | 34.85 |

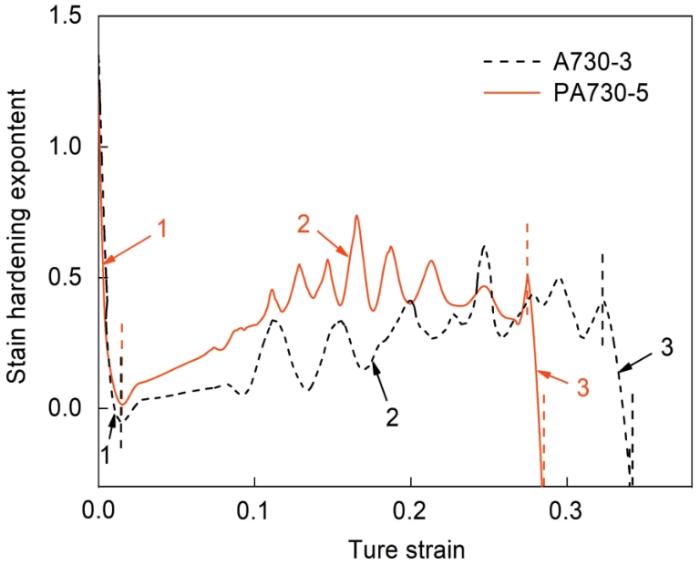

图8为A730-3和PA730-5试样的加工硬化指数曲线。根据变形机制和曲线特征,加工硬化指数曲线分为3个阶段[20,21]:第1阶段,曲线迅速下降,这与铁素体形变有关;第2阶段,曲线开始上升,这是因为发生了TRIP效应的强化作用;进入到第3阶段后,残余奥氏体含量逐渐减少,TRIP效应逐渐减弱,加工硬化速率逐渐降低,直至结束。由图8可知,加工硬化指数曲线进入第2阶段的初始阶段,PA730-5试样的加工硬化指数要高于A730-3试样,这表明PA730-5试样的TRIP效应更积极。第2阶段的中后段,2个试样的硬化指数剧烈波动,此时PA730-5试样中相对稳定的薄膜状残余奥氏体开始转变,表现出了良好的硬化能力,A730-3试样中残余奥氏体也开始大量发生相变,TRIP效应的强化效果明显。随着曲线进入第3阶段,2个试样中仅剩余少量过于稳定的残余奥氏体,此时加工硬化指数急剧下降。

图8

图8

A730-3和PA730-5试样的加工硬化指数曲线

Fig.8

Work hardening index curves of A730-3 and PA730-5 samples

3 分析讨论

3.1 残余奥氏体稳定性对Lüders应变与PLC效应的影响

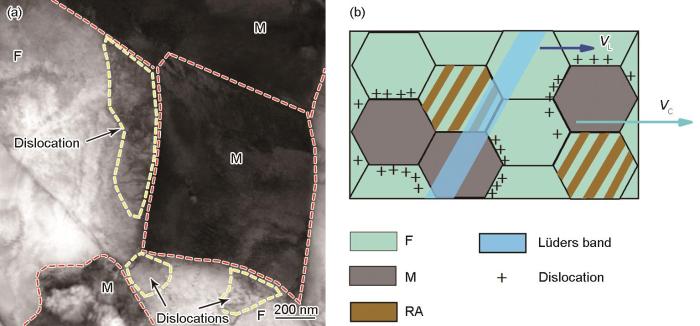

PA730-5试样中不同稳定性的残余奥氏体组织在保证了中锰钢力学性能优势的前提下,实现了连续屈服,消除了Lüders应变,弱化了PLC效应。由图7可知,A730-3试样拉伸曲线呈现明显的Lüders应变(很长的屈服平台);而PA730-5试样的拉伸曲线则没有屈服平台,为连续屈服。屈服平台会导致拉伸试样表面出现Lüders带,从而影响试样表面质量,应尽量避免。研究[30~32]表明,冷轧中锰钢出现Lüders应变是一种普遍现象,而导致Lüders应变出现的主要原因是变形开始阶段组织中可动位错少[33]。对于中锰钢,如果有一定量残余奥氏体在变形的开始阶段发生马氏体相变,则有助于弱化甚至完全消除Lüders应变[34]。根据图3c可知,PA730-5试样组织中存在晶粒尺寸较大、稳定性较差的块状残余奥氏体。这部分残余奥氏体能在塑性变形初期发生马氏体相变,引起周围铁素体中出现可移动位错,进而增加组织中的可移动位错,从而弱化甚至消除Lüders应变。如图9a所示,在PA730-5试样断后的组织中,马氏体周围的铁素体晶界处出现高密度位错(dislocation),这表明在拉伸前期,块状残余奥氏体相变提供了可动位错。

图9

图9

PA730-5试样断后的TEM像和Lüders带运动示意图

Fig.9

TEM image of PA730-5 sample after fracture (a) and schematic of motion of Lüders band (b) (VL—Lüders band moving rate, VC—tensile rate)

根据

式中,VC为拉伸仪器的夹头速率,VL为Lüders带移动速率。其中,VC为定值(2 mm/min),所以l与VL成反比,即Lüders带运动越快,Lüders应变越小。如图9b的示意图所示,块状的马氏体提供了位错,使得VL增大,因此钢在拉伸前期没有Lüders应变。

3.2 高强屈比

式中,ky为比例常数,对于低碳钢取值为17.4 MPa·mm1/2;d0为铁素体晶粒尺寸。经计算,可得到A730-3和PA730-5试样的σg分别为644和488 MPa。

式中,

PA730-5试样中存在2种稳定性不同的残余奥氏体,稳定性较差的块状残余奥氏体在第1阶段(图7)发生相变,避免了屈服点延伸,强度得到提升;在第2、3阶段,稳定性高的薄膜状残余奥氏体发生相变,使得强度和塑性得到提升;同时,PA730-5试样中发生相变的残余奥氏体含量更高,TRIP效应表现优异,因此在位错和晶粒细化对强度贡献更小的情况下,使得PA730-5试样仍然获得了与A730-3试样相同水平的抗拉强度,这也是PA730-5试样具有高强屈比的原因。

4 结论

(1) 以珠光体+马氏体+铁素体的多相组织为初始组织进行临界退火后,能够获得2种不同稳定性的残余奥氏体:Mn元素富集(9.94%)的薄膜状残余奥氏体,源自于珠光体;适当Mn含量(6.18%)的块状残余奥氏体,主要源自于马氏体。

(2) PA730-5试样中的2种残余奥氏体的稳定性差异较大,在整个变形过程中都有TRIP效应:稳定性较差的块状残余奥氏体,在塑性变形初始阶段发生相变,有助于消除Lüders应变;稳定性较高的薄膜状残余奥氏体,在变形中后期发生相变,有助于获得高强塑性。

(3) PA730-5试样不仅保持了高抗拉强度(> 1000 MPa)和高断裂延伸率(> 30%),而且还具有连续屈服和高强屈比的特点。

参考文献

Mechanism of dynamic strain-induced ferrite transformation in a 3Mn-0.2C medium Mn steel

[J].Medium Mn steels (MMSs) have Mn contents of 3%-12% (mass fraction), and have been energetically investigated as the most promising candidates of the third-generation advanced high-strength steel. Their phase transformations and microstructures during various heat treatments and thermomechanical processes have received wide attention with the purpose to achieve an optimal balance of cost-efficient alloying compositions and mechanical properties. The aim of this work is to investigate the microstructural behavior of deformation-induced ferrite transformation (DIFT), starting from austenite, which occurs in MMS. Then, improved understandings of the formation of ultrafine ferrite via the DIFT and conservation of this microstructure during the post-deformation period can be obtained. For this purpose, a 3Mn-0.2C MMS with lower contents of alloying elements was selected. Microstructures and alloying element distributions of the thermomechanically processed samples were analyzed via EBSD and EPMA. The results showed that the DIFT occurred in the thermomechanically processed 3Mn-0.2C MMS in the α + γ region. Characteristic multiphase microstructures consisting isolated martensite and fine-grained equiaxed ferrite concomitant with fine islands of retained austenite dispersed between ferrite grains can be obtained. During the DIFT, the enhanced nucleation of ferrite at α/γ interfaces can not only increase the ferrite nucleation density but also facilitate extensive impingement among the neighboring grains. Formation of ultrafine ferrite via the DIFT in MMS can be interpreted in terms of unsaturated nucleation and limited growth. In addition, partitioning of Mn between the ultrafine ferrite and austenite is accelerated during the DIFT such that a large number of Mn-enriched fine islands of austenite are left untransformed at the α/α grain boundaries or at triple junctions. These islands of austenite are considered to play critical roles not only for obtaining retained austenite at room temperature but also for conserving the ultrafine microstructure of the DIFT during the post-deformation processing.

3Mn-0.2C中锰钢形变诱导铁素体动态相变机理

[J].

Influence of silicon addition on intercritical annealing process and tensile properties of medium Mn steel

[J].

Effect of intercritical annealing process on microstructure and mechanical properties of cold-rolled medium manganese steel

[J].

临界退火工艺对冷轧中锰钢微观组织和力学性能的影响

[J].采用扫描电镜、透射电镜和拉伸试验等研究了临界退火工艺对Fe-10.2Mn-0.48C-2.2Al-0.7Si-0.75V的冷轧中锰钢微观组织和力学性能的影响。通过热力学计算确定最佳的退火温度,以便获得最佳的力学性能。结果表明:临界退火后实验钢获得了板条状和等轴状奥氏体晶粒,同时铁素体中存在高密度位错。奥氏体的体积分数受退火温度的影响较大。实验钢的力学性能是由TRIP效应、TWIP效应和位错强化共同决定的。实验钢抗拉强度和伸长率随退火温度升高呈现出先增加后降低的趋势,在650℃退火后,实验钢的抗拉强度为1409 MPa,伸长率为16.4%,强塑积为23.1 GPa·%。

Enhanced hydrogen embrittlement resistance of medium Mn steel by tailoring retained austenite morphology

[J].

Effects of intercritical annealing temperature on the tensile behavior of cold rolled 7Mn steel and the constitutive modeling

[J].Medium Mn steel is composed of sub-micron grained ferrite and austenite, the unstable austenite may transform to martensite during plastic straining. Although the mechanical properties of medium Mn steel could be easily tested by tensile test, it is quite difficult to directly measure the influences of different constituent phases on the tensile and work hardening behavior. Thus, at the present work, EBSD, TEM, XRD and a constitutive model based on dislocation density have been used to study the effects of intercritical annealing (IA) temperature on the tensile properties and work hardening behavior of a newly designed medium Mn steel, Fe-7%Mn-0.3%C-2%Al (mass fraction). Experimental results showed that with the increase of IA temperature, the mechanic stability of reverted austenite decreased gradually and the kinetics of strain induced martensite rose rapidly. The stability of the reverted austenite was moderate when intercritically annealed at 700 ℃, this led to the best plasticity and the optimal mechanical properties. Simulated results exhibited that the mechanic stability of austenite has a decisive influence on the tensile behavior of the material. The austenite stability will be too high if the IA temperature is lower, and this will lead to the lower work hardening rate and uniform elongation; when the IA temperature is moderate, the stability of austenite will be optimum, consequently strain-induced martensite would be progressively produced during straining and result in the higher work hardening rate and prolonged uniform elongation; the stability of austenite will be too lower if the IA temperature is higher, thus larger volume fraction of strain-induced martensite would be formed in a short period, and this would result in the higher tensile strength but the inferior uniform elongation.

退火温度对冷轧7Mn钢拉伸行为的影响及模拟研究

[J].

Mechanical property and retained austenite of low-Si TRIP steel

[J].The mechanical properties and work-hardening characteristics of A low-Si TRIP steel were researched by the tensile test.The change of structure before and after tensile test,especially the change of retained austenite,were studied with scanning electron microscope(SEM),X-ray diffraction(XRD),electron back-scattered diffraction(EBSD) and transmission electron microscope(TEM).The results show that the low-Si TRIP steel has good mechanical properties,no yield point and possess of low yield ratio,meantime it has better extensibility and homogeneous strain than DP steel.Retained austenite distribution also affects the stability of the low-Si TRIP steel,retained austenite in ferrite grain still exists after the tensile test.

低硅TRIP钢的力学性能及残余奥氏体稳定性研究

[J].

Application of quenching and partitioning processing to medium Mn steel

[J].

Effect of intercritical tempering temperature on microstructure evolution and mechanical properties of high strength and toughness medium manganese steel

[J].The effect of intercritical tempering temperature (TT) on the microstructure evolution and mechanical properties of 3.6Mn medium manganese steel, which contained martensite and austenite, was investigated by X-ray diffraction, electron backscattering diffraction and transmission electron microscopy, as well as Thermo-Calc calculation. The results showed that the volume fraction of reversed austenite (RA) increased firstly and then decreased with the increasing TT in the range of 550~650 °C. When the TT was below 620 °C, lath-like RA with good stability was mainly displayed between martensite laths and its size is about 100 nm. When the TT was higher than 650 °C, larger-size and block RA was formed in the martensite block boundaries, and part of the RA transformed into fresh martensite during cooling. The yield strength and tensile strength of the experimental steels decreased gradually as the TT increased, but the tensile strength increased gradually with the formation of block RA and fresh martensite. Lath-like RA could significantly improve the toughness and plasticity with slight loss of yield strength, but block RA decreased slightly them.

Effect of cold deformation extent and ART annealing duration on the microstructure and mechanical properties of a medium manganese steel

[J].

Influence of intercritical annealing temperature on microstructure and mechanical properties of a cold-rolled medium-Mn steel

[J].

Recent progress and future research prospects on the plastic instability of medium-Mn steels: A review

[J]

中锰钢塑性失稳现象的研究进展及未来研究展望

[J].

Effect of Mn heterogeneous distribution on microstructures and mechanical properties of quenching and partitioning steels

[J].The ever increasing demand for safe and lightweight steel has promoted the development of advanced high-strength steel (AHSS). Recently, many AHSSs have been developed through chemical heterogeneity, resulting in microstructure refinement and mechanical property optimization. Although many efforts emphasize the construction of Mn-heterogeneous high-temperature austenite (γ-Fe), the influence of Mn-heterogeneous distribution remains unclear. In this work, different austenitization times and temperatures are applied to Mn-partitioned pearlite, followed by the same quenching and partitioning process. The effect of Mn distribution in high-temperature austenite on the microstructural evolution and mechanical properties is systematically investigated. Results show that the Mn-heterogeneous high-temperature austenite can tailor the austenite-to-martensite transformation during quenching. The Mn-depleted austenite is then readily transformed into lath martensite, and the Mn-enriched austenite is mainly retained as film roughness (RA), both of which assemble the ghost pearlite. With an increase in austenitization time and temperature, the Mn atom diffusion from the Mn-enriched austenite (originated from cementite lamellae) to the Mn-depleted one (originated from ferrite lamellae) increases, leading to the decreased chemical heterogeneity in high-temperature austenite. Thus, the fraction of ghost pearlite decreases while the fraction and size of blocky RA and coarse lath martensite increase. A wider lath martensite lowers the strength of the yield or the elastic limit of steel. The increased fraction and size of blocky RA ensure an increased uniform elongation by transformation-induced plasticity effect, whereas the transformation product (i.e., fresh martensite) is detrimental to the post-uniform elongation. Meanwhile, because the fractions of RA and martensite hardly change with austenitization condition, the ultimate tensile strength (about 1700 MPa) and total elongation (about 20%) are relatively constant. Therefore, tuning the Mn distribution in high-temperature austenite provides an effective strategy to tailor yield strength and uniform elongation while maintaining large ultimate tensile strength and total elongation.

非均质Mn分布对淬火-配分钢微观组织和力学性能的影响

[J].

The role of retained austenite on the stress-strain behaviour of chemically patterned steels

[J].

Heterogeneous quenching and partitioning from manganese-partitioned pearlite: Retained austenite modification and formability improvement

[J].

Effects of hot deformation and subsequent austempering on the mechanical properties of Si-Mn TRIP steels

[J].

Microstructure and mechanical properties of a novel cold rolled medium-Mn steel with superior strength and ductility

[J].Recently, energy conservation, environmental protection and security are the main factors considered by the automotive manufacturers. Medium-Mn steel with excellent combination of specific strength and ductility have been regarded as the potential candidates for automotive applications. The excellent combination of specific strength and ductility depends on the microstructure under different heat treatment processes of the steels. Therefore, the relationship of the combination of specific strength and ductility and microstructure should be studied in detail. A new alloy system of aluminum-containing medium-Mn steel was developed in this study. The addition of aluminum stabilizes α-ferrite, and facilitates the presence of δ-ferrite during solidification. The addition of Mn and C compensates the effect of aluminum on phase stability and ensures austenite formation. In this investigation, the effects of intercritical annealing temperature on the microstructure and tensile properties of a newly designed cold-rolled aluminum-containing medium-Mn steel (0.2C-5Mn-0.6Si-3Al, mass fraction, %) were investigated by SEM, XRD and uniaxial tensile tests. The tensile results show that an excellent combination of ultimate tensile strength (σb) of 1062 MPa, total elongation (δ) of 58.2% and σb×δ of 61.8 GPa% could be obtained after annealing at 730 ℃. The inverted austenite of the cold-rolled steel coarsenes and gradually changes its morphology from mainly lamellar to mainly equiaxed with increasing intercritical annealing temperature, and a duplex microstructure consisting of multi-scale retained austenite could be obtained at 730 ℃, which possesses suitable mechanical stability and thus presents prolonged transformation-induced plasticity (TRIP) effect during tensile deformation. This kind of sustainable TRIP effect and the cooperative deformation of ferrite are responsible for the superior mechanical properties. The investigation of tensile fracture behavior shows that the nucleation and growth of voids occurred mainly at the interfaces between soft ferrite and hard martensite induced by deformation.

一种新型高强度高塑性冷轧中锰钢的组织和力学性能

[J].研究了两相区退火温度对一种新型冷轧中锰钢(0.2C-5Mn-0.6Si-3Al,质量分数,%)显微组织及拉伸性能的影响。结果表明,在退火温度为730 ℃时,冷轧中锰钢可获得优异的强度与塑性配合,即抗拉强度为1062 MPa,总伸长率为58.2%,强塑积为61.8 GPa%。随着退火温度升高,逆转变奥氏体逐渐粗化,且由片层状组织形态逐渐向等轴状组织形态转变,在一定退火温度下可获得奥氏体晶粒尺寸分布较为宽泛的多尺度的组织形态。这种多尺度组织形态的残余奥氏体具有适当的机械稳定性,能够产生连续不断的相变诱发塑性(TRIP)效应。连续不断的TRIP效应与铁素体在变形过程中的良好配合,是冷轧中锰钢获得高强度、高塑性的主要原因。冷轧中锰钢拉伸断裂的裂纹主要萌生于软相的铁素体(δ-铁素体)及超细晶铁素体与形变诱导马氏体(残余奥氏体)的界面处。

Advanced high strength steel (AHSS) development through chemical patterning of austenite

[J].

Control of core-shell type second phase formed via interrupted quenching and intercritical annealing in a medium manganese steel

[J].

Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite

[J].

The microstructure evolution and tensile properties of medium-Mn steel heat-treated by a two-step annealing process

[J].The martensitic hot-rolled 0.3C-6Mn-1.5Si (wt%) steel was annealed at 630 °C for 24 h to improve its cold rollability, followed by cold rolling and annealing at 670 °C for 10 min. The annealing process was designed based on the capacities of industrial batch annealing and continuous annealing lines. A duplex submicron austenite and ferrite microstructure and excellent tensile properties were obtained finally, proved the above process is feasible. “Austenite memory” was found in the hot-rolled and annealed sample which restricted recrystallization of lath martensite, leading to lath-shaped morphology of austenite and ferrite grains. “Austenite memory” disappeared in the cold-rolled and annealed sample due to austenite random nucleation and ferrite recrystallization, resulting in globular microstructure and refinement of both austenite and ferrite grains. The austenite to martensite transformation contributed most of strain hardening during deformation and improved the uniform elongation, but the dislocation strengthening played a decisive role on the yielding behavior. The tensile curves change from continuous to discontinuous yielding as the increase of cold-rolled reduction due to the weakening dislocation strengthening of austenite and ferrite grains related to the morphology change and grain refinement. A method by controlling the cold-rolled reduction is proposed to avoid the Lüders strain.

Hydrogen embrittlement of intercritically annealed cold-rolled 0.1C-5Mn steel

[J].

两相区退火处理冷轧0.1C-5Mn中锰钢的氢脆敏感性

[J].对0.1C-5Mn中锰钢冷轧后在650 ℃进行不同保温时间的两相区逆相变退火处理,利用电化学充氢和慢应变速率拉伸(SSRT)实验研究了其氢脆敏感性。结果表明,冷轧后中锰钢在退火过程中发生奥氏体逆转变,在退火10 min时可获得优异的强度和塑性配合。随着退火时间延长,可扩散H含量及氢脆敏感性增加,特别是氢脆敏感性的增加幅度十分显著。充氢断口起裂区呈现典型的空心韧窝及包含奥氏体(变形后转变为马氏体)晶粒的实心韧窝的混合断裂模式,这种实心韧窝本质上是在应力作用下氢致裂纹沿奥氏体与铁素体的界面萌生与扩展而形成的一种脆性沿晶断裂。氢脆断裂行为主要与退火过程中逆转变奥氏体的含量及其机械稳定性等因素有关。

Influence of intercritical annealing temperature on microstructure and mechanical properties of medium Mn TRIP steel

[J].

临界退火温度对中锰TRIP钢组织和性能的影响

[J].

A novel cold-rolled medium Mn steel with an ultra-high product of tensile strength and elongation

[J].

Effect of a two-step annealing process on deformation-induced transformation mechanisms in cold-rolled medium manganese steel

[J].

Microstructure and mechanical properties of hot-rolled and cold-rolled medium-Mn TRIP steels

[J].This study investigated the microstructure and mechanical properties of hot-rolled and cold-rolled medium-Mn transformation-induced plasticity (TRIP) steel. The experimental steel, processed by quenching and tempering (Q & T) heat treatment, exhibited excellent mechanical properties for hot-rolled and Q & T steels (strength of 1050–1130 MPa and ductility of 16–34%), as well as for cold-rolled and Q & T steels (strength of 878–1373 MPa and ductility of 18–40%). The mechanical properties obtained after isothermal holding at 775 °C for one hour for cold-rolled/Q & T steel were superior to that of hot-rolled/Q & T steel. Excellent mechanical properties were attributed to the large amount of retained austenite, which produced a discontinuous TRIP effect. Additionally, the differences in mechanical properties correlated with the morphology, stability and content of retained austenite. The cold-rolled sample, quenched from 650 °C (CR 650°C) had extensive TRIP effects in the middle and late stages of the deformation, leading to better mechanical properties. The fracture modes of the hot-rolled sample, quenched from 650 °C, and the cold-rolled sample quenched from 650 °C, were ductile fractures, resulting in excellent ductility.

Microstructure and mechanical properties of a novel heterogeneous cold-rolled medium Mn steel with high product of strength and ductility

[J].The mechanical properties of a novel heterogeneous cold-rolled medium Mn steel were investigated by means of mechanical testers, in situ EBSD (electron back-scattered diffraction) and SDTEM (spherical differential transmission electron microscope). The results show that the sample annealed at 680°C consists of multiple microstructure of austenites (granular shape, blocky shape, and lath-like shape) and fine ferrite grains. The heterogeneous steel has ultimate tensile strength of 1.27 GPa, total elongation of 54.5% and product of strength and elongation of 69.3 GPa·%. During tensile deformation the granular-shape austenite with a low C/Mn content preferentially transforms into martensite ahead of the blocky-shape and lath-like austenite with high C/Mn content, and the multi-type microstructure of austenite with various stability lead to a continuous TRIP effect in a large strain region, which is responsible for the excellent properties of the heterogeneous medium Mn steel. In addition, austenite grain boundaries or austenite/ferrite interfaces are the preferred nucleation zone of martensite during deformation. The effect of Mn/C content on austenite stability readily overrides those of grain size.

一种新型高强塑积异质冷轧中锰钢的力学性能

[J].使用原位电子背散射衍射(EBSD)和球差透射电镜(ACTEM)等手段,研究了新型异质结构中锰TRIP钢在拉伸过程中微观组织的演变机制和力学性能。结果表明,在680℃退火后的实验钢中生成了多形貌、多尺度的异质奥氏体结构(颗粒状、块状、片层状奥氏体)和铁素体组织,其抗拉强度为1272 MPa,总延伸率为54.5%,强塑积高达69.3 GPa·%。在拉伸过程中C/Mn含量较低的颗粒状奥氏体先发生相变,而C/Mn含量较高的块状和片层状奥氏体在较大的应变范围内逐渐发生相变,从而导致高强度与高塑性的良好匹配。结果还表明,马氏体相变优先在奥氏体晶界/相界附近的区域形核。与晶粒尺寸相比,C/Mn元素对奥氏体稳定性的作用更重要。

Effect of carbide evolution on Lüders behavior of cold rolled ART 0.1C-7Mn steel

[J].

碳化物演变对冷轧ART0.1C-7Mn钢Lüders行为影响

[J].

Kinematic and thermal characteristics of Lüders and Portevin-Le Châtelier bands in a medium Mn transformation-induced plasticity steel

[J].

High strength and ductility combination in nano-/ultrafine-grained medium-Mn steel by tuning the stability of reverted austenite involving intercritical annealing

[J].

The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe-9Mn-0.05C steel

[J].

Correlation between Lüder strain and retained austenite in TRIP-assisted cold rolled steel sheets

[J].

Austenite stability and heterogeneous deformation in fine-grained transformation-induced plasticity-assisted steel

[J].

Effect of grain refinement on thermal stability of metastable austenitic steel

[J].

Effect of grain size on thermal and mechanical stability of austenite in metastable austenitic stainless steel

[J].

Microstructural characteristics and tensile behavior of medium manganese steels with different manganese additions

[J].