基于上述原因,Kou和Le[22]提出了利用热源振荡优化焊缝凝固组织的方法。目前为止,焊接热源振荡已成为细化凝固组织、减少焊缝内部冶金缺陷的有效方法[8,23]。由于热源的快速局部移动不仅可以促进液态金属的流动,而且可以实现热源的更均匀加载,因此利用焊接热源振荡来细化晶粒、抑制缺陷是十分可行的[24]。Yuan等[23]通过电弧摆动促进了枝晶破碎和成分过冷的增加,明显细化了晶粒。而施加脉冲电流也可以有效振荡热源和熔池,且由于其优异的性能,早在1960s就已经被应用在焊接当中[25]。与恒电流焊接相比,脉冲电流焊接具有许多独特的优势,例如更高的电弧稳定性、更高的焊缝深宽比、更窄的热影响区范围、更低的热裂纹敏感性、细晶粒度、更低的孔隙率和改善力学性能等[26,27]。此外,脉冲电流焊接提供了更高的生产效率和优异的液滴转移控制能力[28,29]。

尽管脉冲电流焊接有许多优点,但由于脉冲电流频率值具有唯一可调性,使得其对熔池的搅拌作用十分有限[29]。传统的脉冲电流逐渐不能完全满足工业需求。因此人们提出了高频脉冲电流变极性焊接、复合(双)脉冲电流焊接等。高频脉冲电流变极性焊接具有焊接过程稳定和阴极清洁效果的优点[30],但由于其具有低能量密度的自由发散电弧,焊接生产效率相对较低[31,32]。而复合脉冲电流焊接具有高效、降低孔隙率、降低裂纹敏感性、精确的电流调节等优点,逐渐被人们关注[33~35]。Liu等[29]探究了复合脉冲电流对铝合金焊缝轮廓、几何形状的影响,Yao等[36]探究了不同工艺参数对复合脉冲电流的熔化极气体保护焊(GMAW)焊缝成形的影响。Wang等[37]对AA6061和ER4043合金的复合脉冲电流GMAW进行了研究,发现复合脉冲电流对材料组织性能的优化要大于单脉冲电流。Wang等[38]对双脉冲电流的电弧形态以及焊缝的宏观成形进行了研究,发现焊缝晶粒有细化效果,但是并未针对具体的晶粒细化效果、参数影响规律、晶粒细化机制等展开探讨;Wang等[39]重点分析了双脉冲电流作用下的热循环规律及其对气孔溢出和裂纹敏感性的影响规律等,但是并未对脉冲电流对晶粒尺度的影响规律进行研究。

综上所述,现阶段的研究主要集中在脉冲电流对焊缝的形貌以及性能的影响,而关于脉冲电流对焊缝晶粒细化的形核机制以及复合脉冲电流焊接频率对晶粒细化的影响鲜有报道。本工作通过分析无脉冲电流、传统脉冲电流和复合脉冲电流情况下以及不同脉冲电流频率对铝合金等离子弧焊的微观组织的影响,探究铝合金复合脉冲电流等离子弧焊的晶粒细化机制。

1 实验方法

采用5 mm厚5A06铝合金轧制板材作为研究对象,其化学成分(质量分数,%)为:Mg 6.8,Si 0.04,Fe 0.4,Cu 0.1,Mn 0.5,Zn 0.02,Ti 0.02,Al余量。如图1所示,本实验采用Dynasy700焊机,其电流输出范围为5~700 A,直流脉冲电流频率范围为0.1~5 kHz,传统脉冲电流可通过焊机的自有功能获得。同时在基本脉冲电流信号(小脉冲电流)的基础上,利用复合脉冲电流信号控制系统作用一组频率相对较低的附加脉冲电流信号(大脉冲电流),2者共同作用产生双脉冲电流焊接电流信号。复合脉冲电流信号控制程序基于6251采集卡,用LabView编写而成,同时利用单片机来输出频率和占空比都可调的PWM波形,对Dynasy700焊机电流实施控制,并制作相应的电流采集板实时监控焊接电流,实现闭环回路控制。图1b和c所示为本工作设计的脉冲电流波形。其中,图1b为传统脉冲电流波形,周期内包含峰值和基值2个阶段,通过占空比调节峰值与基值所占脉冲电流周期的比例;图1c为复合脉冲电流波形,其脉冲电流波形由大脉冲电流与小脉冲电流复合而成。图1d和e所示分别为本工作实时采集到的传统脉冲电流波形和复合脉冲电流波形,与本工作对脉冲电流波形的设计相符,说明控制是有效的。

图1

图1

实验焊接设备及常规脉冲电流和复合脉冲电流的电流波形

Fig.1

Welding equipment (a), current waveforms of conventional pulse (b) and composite pulse (c), current acquisition waveforms of conventional pulse (d) and composite pulse (e), and sampling positions (f) (PAW—plasm arc welding)

表1 等离子传统脉冲电流方法的晶粒细化效果探究实验设计

Table 1

Sample No. | Base current / A | Peak current / A | First pulse frequency / Hz | First peak time percent / % | Plasma gas flux / (L·min-1) | Shielding gas flux / (L·min-1) |

|---|---|---|---|---|---|---|

| C0 | 180 | - - | 10 | 10 | ||

| S1 | 90 | 210 | 20 | 75 | 10 | 10 |

| S2 | 90 | 210 | 40 | 75 | 10 | 10 |

| S3 | 90 | 210 | 60 | 75 | 10 | 10 |

| S4 | 90 | 210 | 80 | 75 | 10 | 10 |

| S5 | 90 | 210 | 100 | 75 | 10 | 10 |

表2 等离子复合脉冲电流方法的晶粒细化效果探究实验设计

Table 2

Sample No. | Base current / A | Peak current / A | First pulse frequency / Hz | Second pulse frequency / Hz | First peak time percent / % | Second peak time percent / % |

|---|---|---|---|---|---|---|

| C0 | 180 | - | - | - | - | |

| D1 | 90 | 210 | 50 | 2 | 75 | 50 |

| D2 | 90 | 210 | 50 | 4 | 75 | 50 |

| D3 | 90 | 210 | 50 | 6 | 75 | 50 |

| D4 | 90 | 210 | 50 | 8 | 75 | 50 |

| D5 | 90 | 210 | 50 | 10 | 75 | 50 |

焊接完成后,对焊缝进行切割、打磨和抛光制备金相试样,切割位置如图1f矩形框所示,不同参数所得焊缝的取样位置相同。观察面为焊缝的上表面和横截面。为了方便分析晶粒尺寸,焊接试样利用含氟硼酸(HFB4)与蒸馏水的腐蚀液进行电解抛光。利用BX51-P偏光显微镜观察焊缝的宏观形貌、微观组织,统计气孔数量。由于不同晶粒在偏光显微镜中显示为不同的颜色,由此可以更清晰地辨别晶粒的尺寸,本工作根据ASTM E112—2013标准线性截距法在焊缝截面上取至少5个点计算其平均晶粒度。利用EVO10扫描电子显微镜(SEM)观察焊缝微观组织形貌并对成分进行能谱(EDS)分析,判断形核方式;采用JSM-7900F电子背散射衍射(EBSD)对焊缝晶粒取向、晶界角和织构特征进行分析。

2 实验结果

2.1 传统脉冲电流对铝合金焊缝晶粒结构的影响

不同脉冲电流频率时铝合金等离子弧焊缝上表面的微观组织如图2所示。焊缝晶粒尺寸与脉冲电流频率变化关系如图3所示。如图2a所示,常规无脉冲电流等离子弧焊缝上表面的微观组织晶粒粗大,晶粒尺寸约为78.2 μm,焊缝中心存在大量非常明显的柱状晶(如白色椭圆框所示),同时有气孔的存在,数量较多。图2b为频率20 Hz时焊缝的微观组织,晶粒平均尺寸为65.0 μm,与无脉冲电流焊缝相比,晶粒尺寸明显减小,但是在焊缝中心部位仍然有大量的柱状晶,同时焊缝中仍然有较大量的气孔。当脉冲电流频率增加到40 Hz时,晶粒尺寸约为58.2 μm,焊缝中心部位柱状晶的数量明显减少,同时焊缝中气孔的数量和尺寸也明显减小,如图2c所示。当脉冲电流频率继续升高到60和80 Hz时,如图2d和e所示,焊缝中心部位的柱状晶完全被抑制,整个焊缝都由等轴晶组成,晶粒尺寸约为55.6和52.0 μm。同时焊缝中的气孔已经非常稀少。当脉冲电流频率增加到100 Hz时,焊缝的微观组织和晶粒结构得到了非常有效的改变,整个焊缝由细小致密的等轴晶组成,晶粒尺寸约为50.6 μm,而且焊缝中无任何肉眼可见的气孔。

图2

图2

传统脉冲电流等离子弧焊焊缝上表面偏光图

Fig.2

Polarization micrographs of upper surface of conventional pulse current PAW

(a) C0 (b) S1 (c) S2 (d) S3 (e) S4 (f) S5

图3

图3

传统脉冲电流下焊缝晶粒尺寸变化

Fig.3

Change of grain size under conventional pulse current PAW

同时,由铝合金等离子弧焊缝横截面在不同脉冲电流频率时的微观组织(图4)可知,其晶粒尺寸变化规律与焊缝上表面晶粒尺寸变化相似,皆是随着脉冲电流频率的增加,晶粒尺寸减小,并且柱状晶逐渐被抑制,显微组织由致密的等轴晶组成,几乎观察不到气孔,因此证明施加脉冲电流使得铝合金焊缝的横截面和纵截面晶粒都得到细化。综上所述,脉冲电流可以有效细化等离子弧焊缝的晶粒尺寸,而且随着脉冲电流频率的升高,晶粒细化效果逐渐增强,同时气孔也得到有效抑制。

图4

图4

传统脉冲电流等离子弧焊焊缝横截面偏光图

Fig.4

Polarization micrographs of cross-section of conventional pulse current PAW

(a) C0 (b) S1 (c) S2 (d) S3 (e) S4 (f) S5

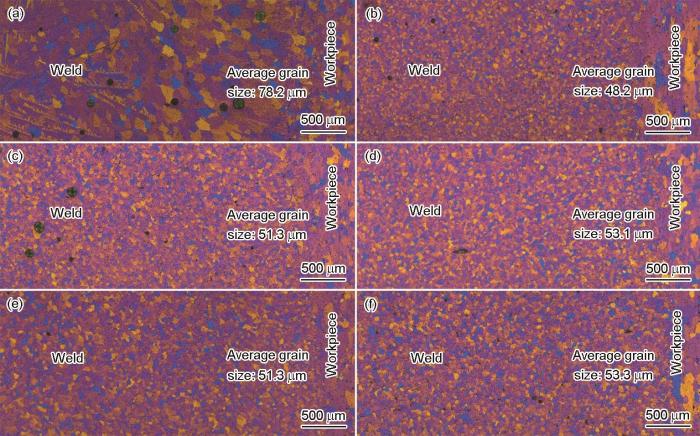

2.2 复合脉冲电流对铝合金焊缝微观组织的影响

图5

图5

复合脉冲电流等离子弧焊焊缝上表面偏光图

Fig.5

Polarization micrographs of upper surface under composite pulse current PAW

(a) C0 (b) D1 (c) D2 (d) D3 (e) D4 (f) D5

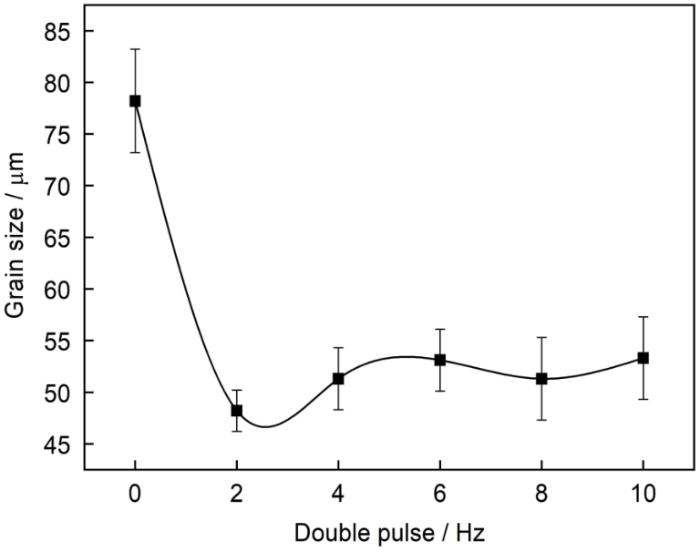

图6

综上所述,在高频脉冲电流频率不变的情况下,低频脉冲电流频率的升高对晶粒尺寸并未造成明显影响,但是复合脉冲电流焊缝的晶粒细化效果要优于传统脉冲电流。

2.3 不同脉冲电流铝合金焊缝EBSD分析结果

由前文可以看出,传统脉冲电流和复合脉冲电流对焊缝晶粒都有着明显的细化作用,则有必要对焊缝晶粒取向、晶界角以及织构特征进行深入分析。选取晶粒尺寸相近的S4和D4试样以及空白对照组C0试样进行EBSD分析,结果如图7所示。对比3张图的晶粒取向可以看出,未加脉冲电流时,蓝色晶粒占比较大,也就是说晶粒取向主要为<111>方向,当施加脉冲电流之后,晶粒颜色变得更加平均,晶粒取向变得更加随机。对比3组实验参数下的晶粒尺寸分布可以看出,C0组试样的晶粒尺寸主要集中在70~90 μm,而S4和D4组试样的晶粒尺寸主要集中在40~60 μm。经过计算,C0组平均晶粒度为76.7 μm,小于70 μm的晶粒仅占比40.1%;S4组平均晶粒度为55.2 μm,比C0组试样晶粒尺寸减小了28%,小于70 μm的晶粒占比81.8%;D4组平均晶粒度为53.2 μm,比C0组试样晶粒尺寸减小了30%,小于70 μm的晶粒占比90.4%。对比3组试样晶界角的变化(将> 15°的晶界角统称为大角度晶界),C0、S4和D4试样大角度晶界占比分别为79.8%、92.9%和89.0%。图8更有力说明了脉冲电流的加入对焊缝晶粒尺寸和大角度晶界的影响,即脉冲电流的加入对晶粒细化有促进作用,且有利于低能量的小角度晶界转变为高能量的大角度晶界,而大角度晶界对晶粒的生长有着阻碍作用,又进一步促进了晶粒细化。图9为C0、S4和D4 3组试样的极图。可以看出,未加脉冲电流时构件在<001>、<110>、<111> 3个方向存在着明显的织构特征,最大取向密度为2.6;施加脉冲电流后,不论是传统脉冲电流还是复合脉冲电流,都使构件在3个方向上的织构强度有一定减弱,最大取向密度分别减小到了1.487和1.404。这说明脉冲电流的加入阻碍了晶粒沿低指数晶面上的定向生长,促使柱状晶向等轴晶转变,对晶粒细化有促进作用。

图7

图7

晶粒取向、晶粒尺寸分布及晶界角分布图

Fig.7

Grain orientations (a1-c1), grain size distributions (a2-c2), and grain boundary angle distributions (a3-c3) of C0 (a1-a3), S4 (b1-b3), and D4 (c1-c3) samples

图8

图8

不同类型脉冲电流对焊缝晶粒尺寸和大角度晶界占比的影响

Fig.8

Influence of different types of pulse current on grain size and the proportion of large-angle grain boundaries (LAGBs)

图9

图9

C0、S4和D4样品的极图

Fig.9

Pole figures of C0 (a), S4 (b), and D4 (c) samples (TD—transverse direction, RD—rolling direction)

3 分析讨论

3.1 脉冲电流对焊缝熔池热力状态的影响

温度梯度(G)、生长速率(R)及其组合形式GR是重要的凝固参数。凝固的组织形貌是由固/液界面的稳定性来确定的[23]:

这是熔池凝固界面生长准则的稳态形式。式中,

图10

图10

温度梯度和生长速率对凝固组织形貌的影响

Fig.10

Influence of temperature gradient and growth rate on the morphology of solidification structure

Wang等[37]探究了单脉冲电流(SP)与双脉冲(DP)电流电弧焊的温度变化行为,发现DP-GMAW过程中热输入和熔深随时间呈周期性变化。DP-GMAW过程中随时间变化的热输入的另一个重要结果是熔池的周期性收缩和膨胀。在DP-GMAW过程中,熔池几何形状和冷却速率的变化导致了独特的凝固条件和微观结构,与SP-GMAW获得的凝固条件和微观结构显著不同。他们还发现DP-GMAW焊缝的凝固生长速率R的平均值大于SP-GMAW的常数R。且DP-GMAW的冷却速率大于SP-GMAW的冷却速率,因此双脉冲电流对组织的细化效果要大于传统脉冲电流的细化效果。此结论与本实验结果相符。另一方面,有研究[40]指出,由于金属液本身在凝固过程中存在着温度变化和固/液转变现象,这会导致熔池的振荡作用。当通过其他物理场引入新的振动时,若其振动频率与未凝固组织本身固有频率相吻合时,则将促进熔池的晶粒细化;反之晶粒细化效果减弱。对比图3和6可以看出,当采用复合脉冲电流时,晶粒的细化效果会随着脉冲电流频率的增加而减弱,复合脉冲电流的频率与熔池本身的固有频率差距逐渐变大,导致晶粒细化效果逐渐减弱。

3.2 脉冲电流对焊缝熔池形核机制的影响

枝晶破碎、晶粒脱落和异质形核是常见的3种晶粒细化机制[23]。焊接过程中熔池周围的材料会被加热到液相线温度(TL)与共晶温度(TE)之间,这将会导致晶粒无法被完全融化。随着焊接的进行,熔池对流可能造成部分熔化的晶粒从围绕着熔池的固液混合物中脱离出来,若这些部分熔化的晶粒在熔池中留存下来,则可以在熔池中长大为等轴晶粒并促进晶粒细化,此即晶粒分离细化机制。由于这些部分熔化晶粒在焊接过程中会不断产生,因此晶粒脱落造成的晶粒细化也在不断发生。此外,随着脉冲电流频率增加,熔池温度起伏加剧,瞬时的高温会使被带入熔池的大量部分熔化晶粒完全熔化,且Wang等[41]的实验研究发现,随着脉冲电流频率的增加焊缝部分熔化区的范围会减小,也就是说晶粒分离发生几率减小,即晶粒脱落细化效果会随着电路脉冲电流频率增加而减弱,这与本实验结果相违背,说明晶粒脱落不是复合脉冲电流晶粒细化的主要机制。

图11

图11

焊缝EDS分析结果

Fig.11

EDS analysis results of C0 (a), S4 (b), and D4 (c) samples

4 结论

(1) 施加传统脉冲电流与复合脉冲电流对5A06铝合金晶粒细化效果显著。施加传统脉冲电流时,随着脉冲电流频率的增加晶粒细化效果逐渐增强,在脉冲电流频率增加到100 Hz时,晶粒尺寸从78.2 μm降到了50.6 μm;施加复合脉冲电流时,随着低频脉冲电流频率的升高,晶粒尺寸变化不明显,晶粒尺寸从未加电流的78.2 μm降到48.2 μm。

(2) 复合脉冲电流的晶粒细化效果要优于单脉冲电流。单脉冲电流最大细化效果为30%,而复合脉冲电流最大细化效果可达到40%,晶粒取向分布更加随机,大角度晶界角占比增加。

(3) 脉冲电流细化晶粒主要是通过对熔池的振荡作用,促进糊状区枝晶的破碎与枝晶尖端的重熔,增加形核点,阻碍柱状晶生长,从而细化了焊缝晶粒。

参考文献

Consolidation phenomena in laser and powder-bed based layered manufacturing

[J].

Machining of aluminum alloys: A review

[J].

Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting

[J].

Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting

[J].

Phase relations and precipitation in Al-Mg-Si alloys with Cu additions

[J].

Effects of ultrasonic assisted friction stir welding on flow behavior, microstructure and mechanical properties of 7N01-T4 aluminum alloy joints

[J].Conventional friction stir welding (FSW) and ultrasonic assisted friction stir welding (UAFSW) were employed to weld 6-mm thick 7N01-T4 aluminum alloy plates. Weld forming characteristics and material flow behavior in these two different welding processes were studied and compared. Ultrasonic vibration was applied directly on the weld in axial direction through the welding tool. Metal flow behavior, microstructure characteristics in the nugget zone (NZ) and evolution of the mechanical properties of naturally aged joints were studied. Results show that the ultrasonic vibration can significantly increase the welding speed of defect-free welded joint. At the rotation speed of 1200 rpm, the UAFSW can produce defect-free welded joints at a welding speed that is 50% higher than that of the conventional FSW. Ultrasonic vibrations can also improve surface quality of the joints and reduce axial force by 9%. Moreover, ultrasonic vibrations significantly increase the volume of the pin-driven zone (PDZ) and decrease the thickness of the transition zone (TZ). The number of subgrains and deformed grains resulting from the UAFSW is higher than that from the FSW. By increase the strain level and strain gradient in the NZ, the ultrasonic vibrations can refine the grains. Ultrasonic energy is the most at the top of the NZ, and gradually reduces along the thickness of the plate. The difference in strengths between the FSW and the UAFSW joints after post-weld natural aging (PWNA) is small. However, the elongation of the UAFSW is 8.8% higher than that of the FSW (PWNA for 4320 h). Fracture surface observation demonstrates that all the specimens fail by ductile fracture, and the fracture position of the UAFSW joint changes from HAZ (PWNA for 120 h) to NZ (PWNA for 720 and 4320 h).

Effects of high-intensity ultrasonic-wave emission on the weldability of aluminum alloy 7075-T6

[J].

Grain refinement through arc manipulation techniques in Al-Cu alloy GTA welds

[J].

Microstructural characterization and grain refinement of AA6082 gas tungsten arc welds by scandium modified fillers

[J].

A synchrotron X-ray radiography study of dendrite fragmentation induced by a pulsed electromagnetic field in an Al-15Cu alloy

[J].

Grain refining by ultrasonic stirring of the weld pool

[J].

The role of ultrasonic treatment in refining the as-cast grain structure during the solidification of an Al-2Cu alloy

[J].

A solidification model for the columnar to equiaxed transition in welding of a Cr-Mo ferritic stainless steel with Ti as inoculant

[J].

The mechanism of grain refinement of titanium by silicon

[J].

Effect of rare earth elements on microstructure and oxidation behaviour in TIG weldments of AISI 316L stainless steel

[J].

Grain refinement of hypoeutectic Al-Si alloys with B

[J].

Microstructure and tensile behavior of hybrid nano-micro SiC reinforced iron matrix composites produced by selective laser melting

[J].

Selective laser melting of TiB2/H13 steel nanocomposites: influence of hot isostatic pressing post-treatment

[J].

Grain refinement in laser manufactured Al-based composites with TiB2 ceramic

[J].

Grain refinement limit and mechanical properties of 6063 alloy inoculated by Al-Ti-C (B) master alloys

[J].

Grain refinement of Mg-Al(-Mn) alloys by SiC additions

[J].

Grain structure and solidification cracking in oscillated arc welds of 5052 aluminum alloy

[J].

Grain refining of magnesium welds by arc oscillation

[J].

Grain refinement and laser energy distribution during laser oscillating welding of Invar alloy

[J].

The effect of pulsed GTA welding on the residual stress of a stainless steel weldment

[J].

Effect of pulsed current and post weld aging treatment on tensile properties of argon arc welded high strength aluminium alloy

[J].

Influences of pulsed current welding and post weld aging treatment on fatigue crack growth behaviour of AA7075 aluminium alloy joints

[J].

Selection of parameters of pulsed current gas metal arc welding

[J].

Study on welding process and prosperities of AA5754 Al-alloy welded by double pulsed gas metal arc welding

[J].

Investigation of molten pool behavior and weld bead formation in VP-GTAW by numerical modelling

[J].

Keyhole welding of AA2219 aluminum alloy with double-pulsed variable polarity gas tungsten arc welding

[J].

Process characteristics and properties of AA2219 aluminum alloy welded by double pulsed VPTIG welding

[J].

Influence of GMAW droplet size on fume formation rate

[J].

The influence of double pulse on porosity formation in aluminum GMAW

[J].

Weld pool profile characteristics of Al alloy in double-pulsed GMAW

[J].

Effects of operational parameters on the characteristics of ripples in double-pulsed GMAW process

[J].This study focuses on the characteristics of the ripples of the weld bead formed during the double-pulsed gas metal arc welding (DP-GMAW) process. As a special output of the process, ripples include many useful information and can reflect the quality of the welding process. The work analyzed the operational characteristics of the DP-GMAW process based on robot operation which used the latest twinpulse XT DP control process, and then selected five key operational parameters, such as average current, welding speed, twin pulse frequency, twin pulse relation, and twin pulse current change in percent, to explore their effects on the formation and characteristics of ripples. A reliable method of measuring the distance of the ripples was used to provide convincing data. According to a series of experimental observations and analyses, the distance of ripples and appearance under different conditions were obtained. Also, curve fitting equations between each operational parameter and corresponding distances of ripples was obtained. To testify the effectiveness of the curve fitting equations, corresponding verifying experiments were conducted, and the results showed that all the errors were below 10%. In addition, the different levels of the operational parameters on the formation and characteristics of ripples were provided. This work can be a reference for the process and quality control improvement for the DP-GMAW process.

A pathway to microstructural refinement through double pulsed gas metal arc welding

[J].

Influence of low-pulsed frequency on arc profile and weld formation characteristics in double-pulsed VPTIG welding of aluminium alloys

[J].

Perspective on double pulsed gas metal arc welding

[J].

A review on the effect of laser pulse shaping on the microstructure and hot cracking behavior in the welding of alloys

[J].

HF pulse effect on microstructure and properties of AC TIG butt-welded joint of 6061Al alloy

[J].