Xu等[7]对高Nb TiAl基合金同种摩擦焊接机理进行研究发现,新的再结晶晶粒、摩擦形变孪晶相交和片层相互交织生长共同作用促使层状界面变得弯曲和模糊。Dong等[8]发现TiAl合金与40Cr钢摩擦焊接过程中,大量C原子扩散进入界面层,形成C富集区,导致大量的脆性TiC相生成。Park等[9]发现TiAl/Cu摩擦焊接界面上生成了CuTiAl和Cu2TiAl 2种金属间化合物(IMC),TiAl/Ni的摩擦焊接界面上生成了约100 μm宽的Al3NiTi2和AlNi2Ti混合相层。Cai等[10]采用Ti/V/Cu钎料激光焊接异种γ-TiAl合金制备镍基高温合金,获得了良好的接头。焊接区由AlNi2Ti、CuNiTi、(V, Cr)SS (SS指固溶体)和(Cu, Ni)SS组成。γ-TiAl界面区由AlCuTi和AlCu2Ti组成。详细讨论了焊接区和γ-TiAl界面区的组织演变和形成机制。对接头的力学测试表明,平均抗拉强度为170 MPa,断裂接头通过焊接区和γ-TiAl界面区。Du等[11,12]确定了TiAl合金与GH3039合金摩擦-扩散双重焊接界面的典型组织结构:TiAl/Ti3Al + Al3NiTi2/Al3NiTi2/AlNi2Ti/Ni3(Al, Ti) + (Ni, Cr)SS/(Ni, Cr)SS/GH3039。文献[12]指出,在GH3039侧附近的焊接区,形成了大量具有α-Cr的bcc结构的富Cr晶粒,富Ni和富Cr晶粒的分布是互补的。Ti和Al易溶于富Ni晶粒中,Mn易溶于富含Cr晶粒中。但并未深入分析界面结构的形成机制。Du等[13]还获得了TiAl合金与GH3039合金摩擦焊接界面Al3NiTi2和AlNi2Ti 2种脆性相的断裂韧性。但并未就这2种相的脆性机制进行分析。

通过断口表面成分和相分析及裂纹扩展路径分析,已知TiAl基合金与GH3039合金摩擦焊接头的断裂性能与焊接界面Al3NiTi2和AlNi2Ti等脆性相密切相关,当焊接接头中Al3NiTi2相较多时,该异种材料摩擦焊接头的性能变差[11~13]。为提高TiAl基合金与GH3039合金摩擦焊接头性能,需在焊接过程中控制接头中脆性相的含量及分布,理论上首先应揭示摩擦-扩散双重焊接界面的微观组织演变规律及形成机制。为此,本工作测试表征了TiAl基合金与GH3039合金在摩擦焊接过程中不同摩擦时刻,摩擦焊后热处理以及摩擦-扩散双重焊接头界面的微观组织,利用透射电子显微镜(TEM)研究焊接过程中过渡相的压缩变形和裂纹扩展形态,分析焊接界面Al3NiTi2和AlNi2Ti 2种合金相的脆性机制。旨在为改进IMC与金属焊接工艺、提高焊接接头性能提供理论指导,促进TiAl合金在发动机废气涡轮增压器上的应用。

1 实验方法

实验所用TiAl基合金为真空感应悬浮炼制的铸造合金,热处理方式为:热等静压+真空退火。GH3039高温合金为单相奥氏体固溶强化合金。试样均为直径25 mm、长60 mm的圆棒,摩擦焊前用丙酮清洗焊接表面,材料化学成分见表1。

表1 实验材料化学成分 (atomic fraction / %)

Table 1

| Alloy | Ti | Al | Ni | Cr | V | Fe | Mo | Nb | Si | Mn | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TiAl | 49.0 | 47.5 | - | 1.0 | 2.5 | - | - | - | - | - | - |

| GH3039 | 0.6 | 1.1 | 70.2 | 22.6 | - | 2.9 | 1.2 | 0.7 | 0.45 | 0.23 | 0.02 |

摩擦焊设备为C500型连续驱动摩擦焊机,并配备有工业计算机闭环控制系统。扩散焊设备为FJK-2型辐射加热真空扩散焊机。首先对TiAl基合金与GH3039合金进行摩擦焊接及焊后热处理,得到摩擦焊接头。为稳定焊接界面结构,调整焊接界面中间过渡相的相结构及厚度,再对摩擦焊接头进行一次加压扩散焊接,得到摩擦-扩散双重焊接头。摩擦焊接及焊后热处理工艺参数为:摩擦压力500 MPa,顶锻压力560 MPa,一级摩擦时间2 s,二级摩擦时间10 s,焊后回火温度560℃,保温45 min,空冷。扩散焊接参数为:温度950℃,压力40 MPa,保温60 min。

在摩擦阶段不同时刻,使主轴转速强制减为零而不施加顶锻压力,从而得到不同二级摩擦时间的焊接接头。所研究的焊接不同阶段接头试样主要对应以下7种时刻(阶段):(a) 摩擦3 s;(b) 摩擦5 s;(c) 摩擦8 s;(d) 摩擦10 s;(e) 摩擦12 s +顶锻(摩擦焊接结束);(f) 摩擦焊接头经焊后热处理;(g) 经焊后热处理摩擦焊接头+扩散焊接(双重焊接全过程)。

利用Verios G4型扫描电子显微镜(SEM)对接头微观组织进行观察。采用Helios G4 CX型聚焦离子/电子双束电镜(FIB)制备接合面处TEM样品,利用Talos F200X场发射TEM的扫描透射(STEM)和高分辨(HRTEM)功能测试表征过渡相的晶体结构和微观形貌,利用JXA-8100 (4CH)型电子探针显微分析仪(EPMA)测定界面层元素成分。采用Themis Z型双球差校正TEM配备的Hysitron PI95原位纳米力学测试系统对TEM样品上焊接界面Al-Ni-Ti三元脆性相的压缩性能进行表征,分析其在压缩作用下的变形、位错和裂纹扩展。

2 结果与讨论

2.1 焊接界面形成机制分析

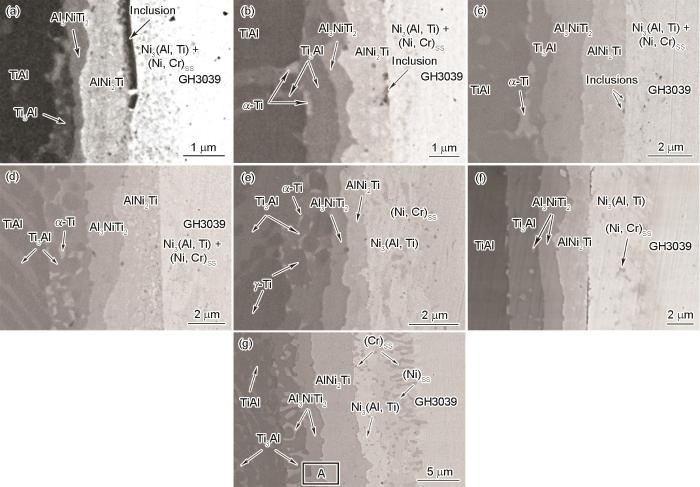

图1

图1

TiAl基合金与GH3039合金双重焊接不同阶段焊合区微观组织

Fig.1

Microstructures of the weld zone in different stages of the double welding of TiAl-based alloy and GH3039 alloy (SS—solid solution)

(a) friction time 3 s (b) friction time 5 s (c) friction time 8 s (d) friction time 10 s

(e) friction time 12 s + upset (friction welding) (f) friction welding + post weld heat treatment

(g) friction welding + post weld heat treatment + diffusion welding (full process of the double welding)

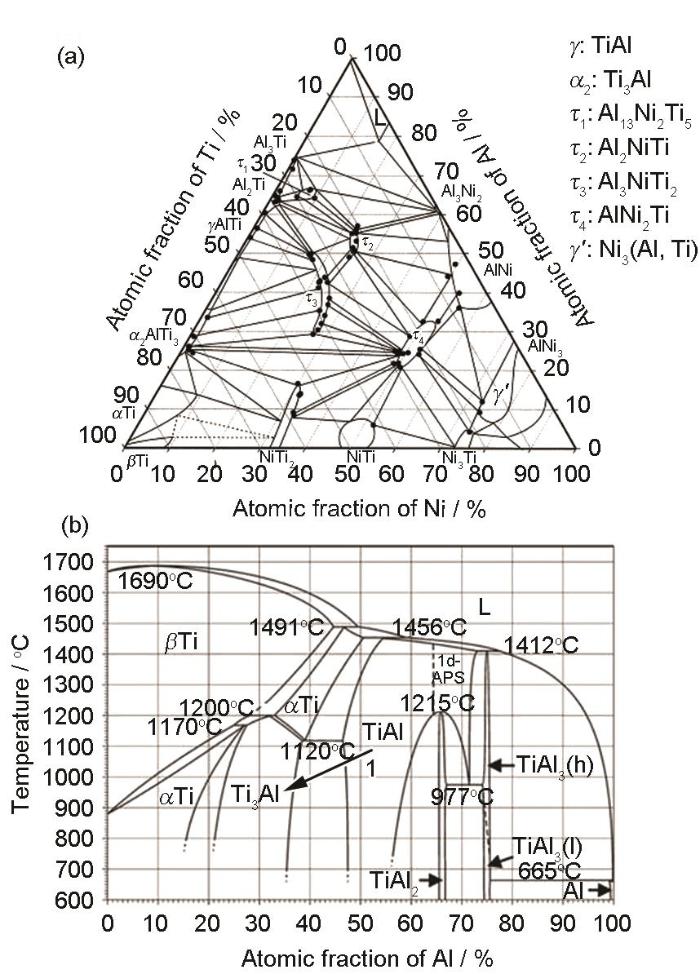

图2

图2

Ti、Al、Ni合金元素相关相图:Al-Ni-Ti三元相图700℃等温截面图[14]及Ti-Al二元相图[15]

Fig.2

Phase diagrams of Ti, Al, and Ni alloy elements

(a) isothermal section of the ternary system Al-Ni-Ti at 700oC[14]

(b) Ti-Al binary phase diagram[15] (1d-APS: (Ti5Al11, Ti2Al5) four sided superstructure; TiAl3(h): D022 structure; TiAl3(l): Ti8Al24 structure)

(1) 原始焊接面上夹杂物的聚集与消失。摩擦开始时,凹凸不平的焊接表面在摩擦压力作用下通过干摩擦产生机械挖掘和塑性变形。此时焊接界面温度较低,没有达到发生相变的温度,过渡相尚未形成,焊接界面上的元素还处于物理混合状态。随着摩擦焊接过程的进行,焊件的原始表面被旋转摩擦破坏而变得平整,内部纯净金属开始接触,焊接界面温度升高,由干摩擦转变为黏塑性摩擦。在摩擦焊接初期,界面上的高温金属暴露在空气中容易形成氧化物等夹杂物(图1a)。通过摩擦焊接界面的自清理,初始焊接面上的夹杂物和高温黏塑性金属不断被挤压变形,相互焊合后又被旋转运动反复撕裂,形成一个剪切区并不断由内向外运动形成飞边。随着摩擦时间的延长,飞边逐渐变大,焊接界面趋于封闭,夹杂物含量明显减少(图1b),逐渐变得分散(图1c),直至完全消失,形成笔直的原始焊接面,即AlNi2Ti-Ni3(Al, Ti)相界(图1d)。

(2) Ni3(Al, Ti)和(Ni, Cr)SS相的形成与稳定。物理界面消失后,形成了冶金界面(焊合区)。在焊接高温及两侧化学势梯度驱动下,Ti、Al元素由TiAl侧向GH3039侧扩散,Ni、Cr元素由GH3039侧向TiAl侧扩散。TiAl母材中的Al比Ti在Ni中的固溶度高,会优先向GH3039侧扩散。焊接界面上形成的IMC过渡相的组元和比例会按照原子扩散通量比优先生成。Ti、Al元素与Ni反应会优先生成Ni3X (X为Ti或Al)[16],因而,GH3039侧首先形成Ni3(Al, Ti)过渡相(图2a[14]中γ′区)。GH3039合金中还包含着23% (原子分数)的Cr原子,以固溶的形式存在于GH3039合金内。Ni元素与Ti、Al形成Ni3(Al, Ti)后,GH3039合金内的Ni含量相对减少。由于Cr原子在Ni3(Al, Ti)中的溶解度仅有11.4% (摩尔分数)[17,18],新生成的Ni3(Al, Ti)相无法完全将其溶解,所以,在Ni3(Al, Ti)相的周围Cr含量相对增加。根据Ni-Cr二元相图[19],Ni基中Cr含量超过一定值后,会通过调幅分解逐渐生成Cr含量相对于GH3039母材较高的富Cr固溶体相。摩擦焊接中前期,Ni3(Al, Ti)相形核并稍微长大后,同时就会有富Cr固溶体相形核并生长,从而Ni3(Al, Ti)与富Cr固溶体相处于一种混合交织的状态(图1a~d)。在摩擦焊接后期及热处理阶段,随着元素的扩散和第二相的长大,Ni3(Al, Ti)和(Ni, Cr)SS从混合状态中分离并开始分层(图1e和f)。由于Ni含量远高于Cr,且摩擦焊接时间极短,富Ni固溶体相的含量远高于富Cr固溶体相(图1e和f)。在扩散焊的高温高压作用下,调幅分解现象继续发生。过饱和固溶体中的Ni、Cr原子通过上坡扩散分别聚集。Ni、Cr富集区中的原子将进一步富化,贫区中的原子则逐渐贫化,从而形成了稳定的且同时包含富Ni和富Cr的固溶体相(图1g)。在Ni3(Al, Ti)与(Ni, Cr)SS的双相区,Ni含量虽然仍远高于Cr,但大部分的Ni与Al、Ti形成了Ni3(Al, Ti),少部分的Ni与Cr形成了(Ni, Cr)SS。从而在扩散焊接的调幅分解过程中,会在Ni3(Al, Ti)与(Ni, Cr)SS的双相区形成Cr的偏聚。从热力学角度,扩散的根本驱动力来自于化学势梯度而非浓度梯度。Cr原子从富Ni固溶体相的高化学位区域向富Cr固溶体相的低化学位区域迁移,会使焊接界面体系的自由能降低,因而,在Ni3(Al, Ti)相层内生成的是富Cr固溶体而不是富Ni固溶体(图1g)。富Cr固溶体中Cr原子分数为44%[11],根据Ni-Cr二元合金相图[19],在1000℃时,镍基固溶体中的Cr含量达到44%仍未发生相变。但当温度低于1000℃时(扩散焊接温度为950℃),Cr元素就会过饱和分解析出,形成bcc结构的富Cr固溶体。因此,双重焊阶段所形成的富Ni固溶体和富Cr固溶体是分别具有fcc和bcc结构的2种固溶体相。

(3) AlNi2Ti和Al3NiTi2相的形成与长大。在摩擦焊接中前期,从GH3039合金中扩散过来的Ni原子在原始焊接界面GH3039侧生成Ni3(Al, Ti)相后继续向TiAl侧扩散,但浓度减小。TiAl基合金在与含有Ni、Cu或Au的材料发生反应时,会生成AlM2Ti (M为Ni、Cu或Au)型金属间化合物[20]。依据过渡相化学式的原子比,AlNi2Ti中的Ni含量比Al3NiTi2高。沿着Ni元素浓度梯度降低方向,AlNi2Ti与Al3NiTi2相会分别在GH3039侧和TiAl侧生成(图1a和图2a[14]中τ3、τ4相区)。AlNi2Ti形成后,在浓度梯度作用下,两侧的原子继续发生相互扩散,GH3039侧热力影响区发生动态再结晶。在顶锻冷却的亚动态再结晶阶段以及焊后热处理和高温扩散焊接的静态再结晶阶段,AlNi2Ti相继续长大,晶粒逐渐变得粗大。

(4) Ti3Al和Al3NiTi2双相区的形成。全片层TiAl基合金基体为γ-TiAl + α2-Ti3Al的片层团。Al原子扩散速率比Ti要快,容易与Ni结合,与反应界面接触的TiAl母材中的Al原子浓度会逐渐减少,Ti原子浓度相对逐渐增加,当Al原子分数减少至38%时,发生TiAl→Ti3Al的相变(图2b[15]箭头1),Ti3Al会优先从TiAl母材的α2相上孪生生长(图1b)。AlNi2Ti与TiAl反应生成的Al3NiTi2相在长大过程中,Ti3Al随即开始形核并生长,Al3NiTi2晶粒周围形成Ti3Al相层(图1d)。在扩散焊阶段,Ti3Al继续从TiAl母材的α2相上沿着轴向压力方向生长,形成垂直于焊合面的柱状组织。摩擦焊时形成的Ti3Al相与Al3NiTi2相继续交互生长,使得双重焊后在TiAl母材相邻区域形成了以交融嵌合方式分布的Ti3Al和Al3NiTi2双相区(图1g)。

2.2 焊接界面过渡相晶体结构分析

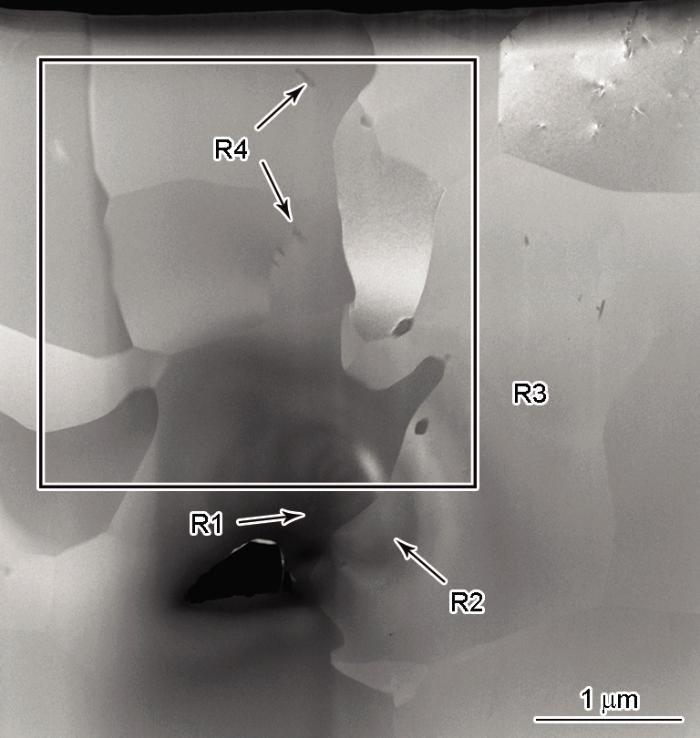

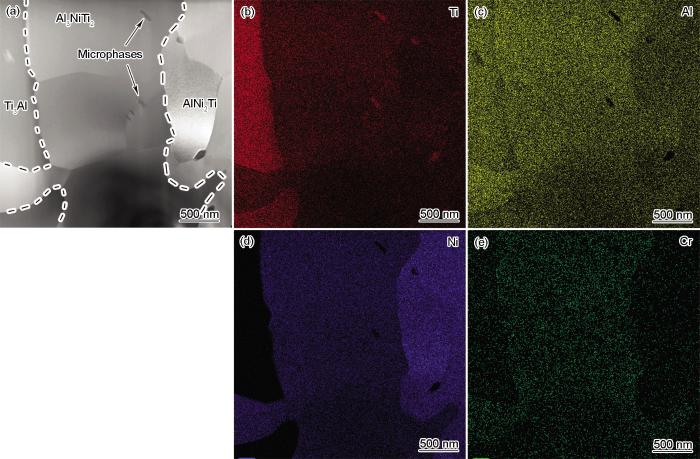

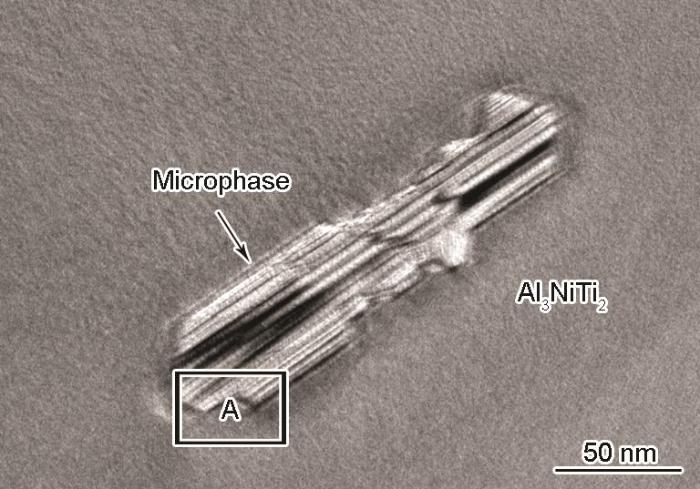

前期研究[13]发现,摩擦-扩散双重焊接头焊合区内韧性最差、最容易开裂的过渡相层是Al3NiTi2和AlNi2Ti,因此,采用TEM重点分析了该焊合区(图1g区域A)相的微观组织,如图3所示。TEM下该区域分为衬度不同的3个区域,分别对应3个相层。能够清晰地分辨出不同过渡相的晶界及晶粒分布。对图3中框线内区域进行EDS元素面扫描,结果如图4所示。可以看出,在每个过渡相层内各个合金元素含量基本均匀分布,元素差异较大的分界线就是相界。结合FIB制取TEM试样的位置和图1过渡相的分布,可以确定图4a中的3个过渡相分别为Ti3Al、Al3NiTi2和AlNi2Ti。除3种主要过渡相外,从Ti、Al、Ni、Cr元素面分布图上观察到在Al3NiTi2和AlNi2Ti相内弥散分布着Ti含量高,但Al、Ni、Cr含量很低的(即成分完全不同于Al3NiTi2和AlNi2Ti相)、宽度仅有50~100 nm的微小合金相(R4)。下面将围绕图3中的Al3NiTi2相(R1区域)、AlNi2Ti相(R2、R3区域)位错(墙)和微小合金相(R4区域)的晶体结构、晶粒类型和取向关系进行深入分析。

图3

图3

摩擦-扩散双重焊焊合区微观组织的TEM像(图1g中区域A)

Fig.3

TEM image of microstructure of the friction- diffusion double welding zone (Region A in Fig.1g)

图4

图4

摩擦-扩散双重焊焊合区的TEM像和EDS面扫描

Fig.4

TEM image (a) and EDS mappings of Ti (b), Al (c), Ni (d), and Cr (e) elements of friction-diffusion double welding zone

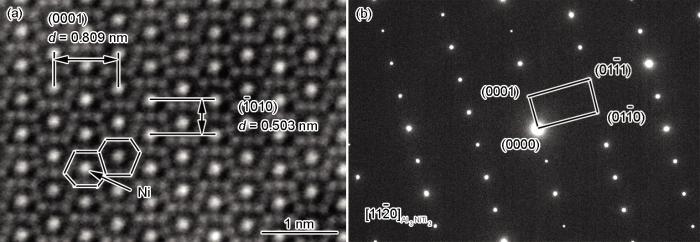

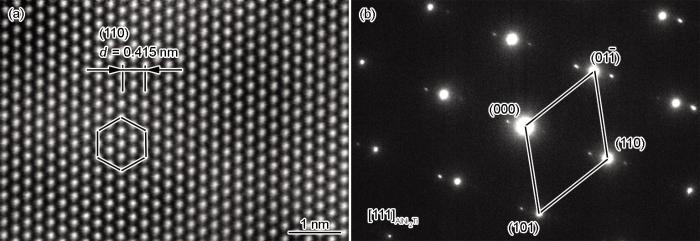

对图3中R1区域的Al3NiTi2相进行TEM微结构表征,结果如图5所示。在STEM模式下清晰地看到了规则排列的原子投影。相对原子质量越大的元素在原子像投影图中显示得越大,因而,六边形中间的原子为Ni (图5a)。Al3NiTi2相内的原子排列非常规整,晶面没有发生断裂和弯曲,无位错产生,说明Al3NiTi2相很难发生塑性变形。通过对Al3NiTi2原子像和选区电子衍射(SAED)花样标定(图5b),可以确定Al3NiTi2相为MgZn2型Laves相。R2区域的AlNi2Ti相TEM表征结果如图6所示。由于投影图中看到的原子下面均存在Al、Ni、Ti 3种原子的堆垛,因而,原子像投影图中的原子均表现为相对原子质量最大的Ni原子投影形状大小(图6a)。AlNi2Ti相内的原子排列规则,晶面没有发生断裂和弯曲,无位错产生,说明AlNi2Ti相同样很难发生塑性变形。通过对AlNi2Ti原子像和SAED花样标定(图6b),可以确定AlNi2Ti相属于bcc结构。

图5

图5

Fig.5

Atomic projection STEM image (a) and selected area electron diffraction (SAED) pattern (b) of Al3NiTi2 phase in region R1 in Fig.3 (d—spacing)

图6

图6

Fig.6

Atomic projection STEM image (a) and SAED pattern (b) of AlNi2Ti phase in region R2 in Fig.3

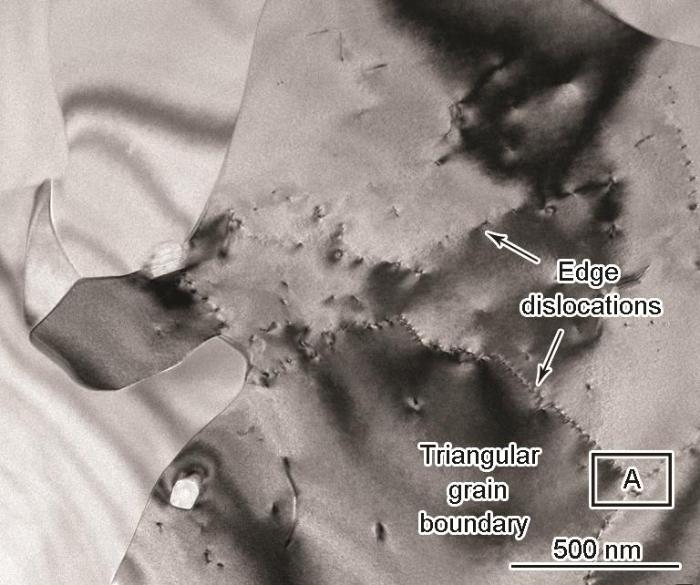

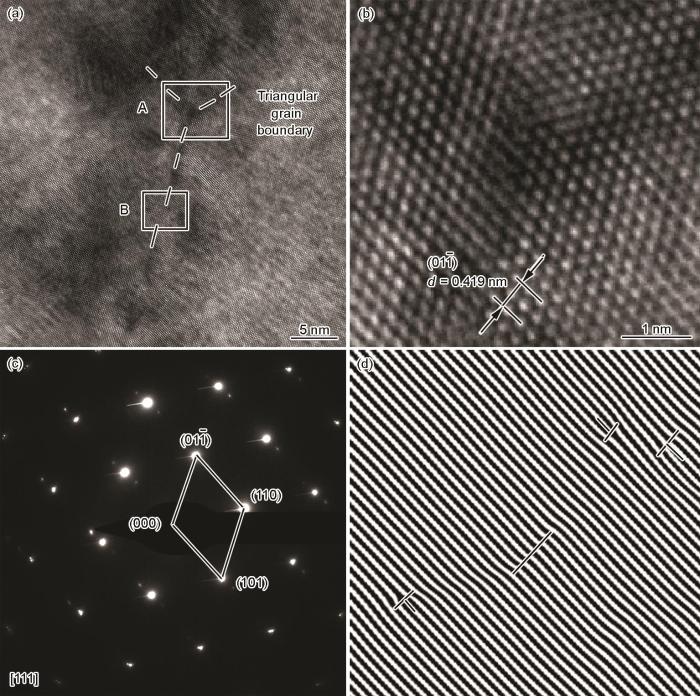

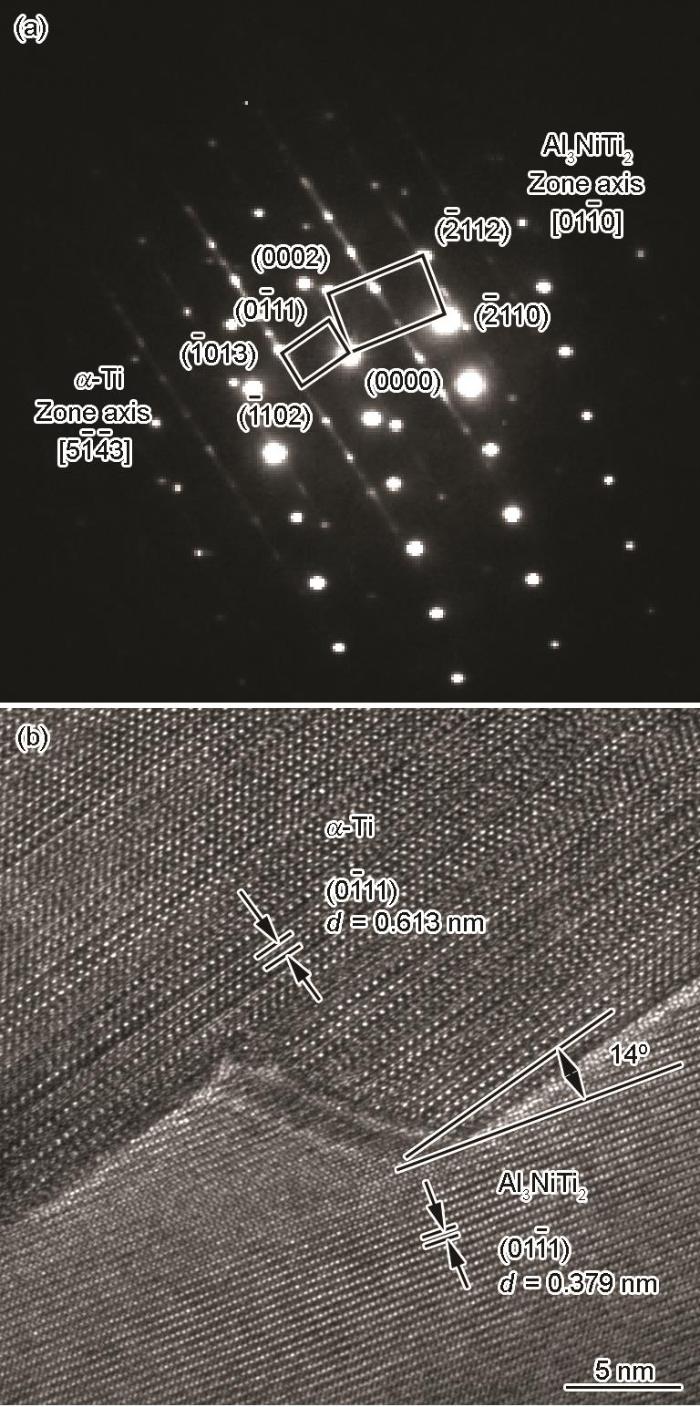

图7为图3中R3区域TEM明场像。可见,在AlNi2Ti相的晶界和亚晶界处形成了大量的位错(墙)。一般在滑移面上,越靠近晶界,位错密度越大。但该区域AlNi2Ti相的晶界和亚晶界处的位错比较均匀,属于典型的小角度晶界上的刃型位错。对图7三角晶界处(A处)进行HRTEM分析,结果如图8所示。图8b为图8a中A处的放大图。可以看出,虽然晶界上晶体点阵发生畸变,但相邻2个晶粒的(01

图7

图8

图8

Fig.8

TEM microstructure characteristics of the triangular grain boundary AlNi2Ti phase at position A in Fig.7

(a) HRTEM image (b) HRTEM image at triangular grain boundary (c) SAED pattern at triangular grain boundary

(d) Moire stripe on (01

图9

图10

图10

Fig.10

SAED pattern (a) and HRTEM image (b) at phase boundary of pure Ti and Al3NiTi2 at position A in Fig.9

2.3 焊接界面过渡相原位力学性能分析

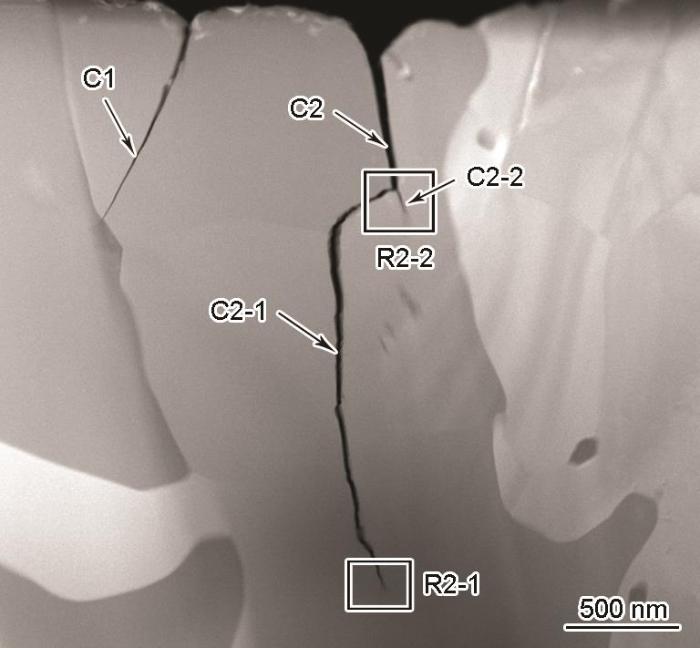

图11

图11

原位压缩裂纹扩展形貌的TEM像

Fig.11

TEM image of the crack growth by the in situ compression (C2-1 and C2-2 show the branches of cracks C1 and C2, respectively; R2-1 and R2-2 show the tip areas of cracks C2-1 and C2-2, respectively)

裂纹C2首先沿着最大压应力方向传播,在Al3NiTi2晶界处裂纹扩展方向发生改变,主裂纹C2-1沿着晶界扩展,传播一段距离后,穿过晶界的薄弱(缺陷)区,继续沿着最大压应力方向扩展。在主裂纹沿着晶界向前扩展的同时,在晶界另一侧诱发出次裂纹C2-2,沿着裂纹初始方向继续扩展。当主裂纹C2-1穿过晶界继续沿着最大压应力方向扩展时,断裂功主要消耗在主裂纹的扩展上。同时,由于次裂纹穿越晶界消耗过多的断裂功,作用在次裂纹上的剩余断裂功不足以使次裂纹继续扩大,次裂纹C2-2的扩展只能被迫终止,从而形成细小的次生微裂纹。

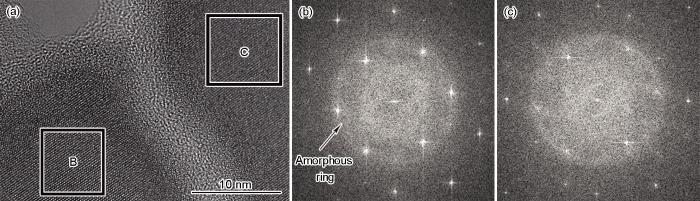

裂纹形核与扩展过程中,未在裂纹附近观察到位错,Al3NiTi2相没有任何的塑性变形痕迹。为进一步分析无位错形成的裂纹在Al3NiTi2相上形成机理,对主裂纹C2-1尖端附近的R2-1区域和次裂纹C2-2附近的R2-2区域进行HRTEM分析,结果分别如图12和13所示。可以观察到裂纹尖端大多数金属原子排列呈现无周期、无规则状态,周期性长程有序结构特征基本消失(图12a和13a)。弹性变形使得主裂纹尖端附近晶格产生畸变,晶面发生弯曲,弯曲角度约为15° (图13a)。对裂纹附近的HRTEM像进行快速Fourier变换(FFT),发现FFT图上存在拉长的衍射斑点、较大的漫散中心斑和规则的亮环(即非晶环)。研究结果表明,晶格畸变使裂纹左侧、右侧和尖端附近晶体均开始非晶化,但有序结构并没有完全消失,尚未完全形成无序的非晶体,即裂纹附近表现为部分有序结构变为无序结构,有序和无序并存的晶体结构的非晶化状态。

图12

图12

Fig.12

HRTEM image of crack tip in R2-1 area in Fig.11 (a), and the fast Fourier transforms (FFT) of zone B (b) and zone C (c) near the crack tip

图13

图13

Fig.13

HRTEM image of crack tip in R2-2 area in Fig.11 (a), and FFT of zone B (b) and zone C (c) near the crack tip

综上所述,Al3NiTi2相压缩开裂时,有序排列的原子在应力作用下产生畸变,在各种形变能和晶界能的作用下,从弹性变形极限直接过渡到裂纹形核,没有经历塑性变形和位错运动阶段。但晶格面发生了微区变形,原子排列从有序结构转变为无序结构。

3 结论

(1) TiAl基合金与GH3039合金摩擦-扩散双重焊接过程中,界面上陆续发生相变形核并初步长大形成新的过渡相:Ni3(Al, Ti)、(Ni, Cr)SS、Al3NiTi2、AlNi2Ti、Ti3Al。扩散焊的压力和高温促进Ti3Al与Al3NiTi2形成稳定的双相区,促使(Ni, Cr)SS区调幅分解形成相互交错呈柱状分布的fcc结构(Ni)SS和bcc结构(Cr)SS。

(2) Al3NiTi2和AlNi2Ti 2种过渡相分别属于六方和bcc结构。AlNi2Ti相内存在位错组成的小角度晶界。Al3NiTi2相内弥散分布着极少的α-Ti相,α-Ti与Al3NiTi2相处于非共格状态。

(3) 在TEM原位压缩实验中,Al3NiTi2相出现裂纹形核和迅速扩展前,未发现明显的塑性变形和位错运动。裂纹尖端附近晶格面发生微区变形,原子排列从有序结构转变为无序结构,晶体逐渐非晶化。但裂纹尖端附近有序结构并未完全消失,尚未完全形成无序的非晶体,表现为有序和无序并存的晶体结构。

参考文献

Microstructure and mechanical properties of vacuum diffusion bonding joints for γ-TiAl based alloy

[J].

A novel continuous and controllable method for fabrication of as-cast TiAl alloy

[J].

Microstructure and joining properties of high Nb-containing TiAl alloy brazed joints

[J].

The transient liquid phase bonding process of a γ-TiAl alloy with brazing solders containing Fe or Ni

[J].The high Nb-containing gamma-TiAl alloy Ti-45Al-5Nb-0.2B-0.2C (in at. %) was successfully brazed by transient liquid phase (TLP) bonding using two brazing solders with different melting point depressing elements (MPD): Ti-24Ni and Ti-29Fe (in at. %). The brazing process was executed for 24 h at 1110 degrees C. An additional annealing was performed for 168 hat 1000 degrees C for a better homogenization. The joints were characterized with high-energy X-ray diffraction (HEXRD) and scanning electron microscopy (SEM) using energy dispersive X-ray spectroscopy (EDX). Depending on the MPD and if the specimens were annealed two to three symmetrically arranged transition zones developed between the substrate and the middle of the joint with different microstructures, phase compositions, and chemical compositions. Beside alpha(2) and gamma which have been present in the substrate additional phases as beta, beta(o), omega(o),tau(3), and tau(2) were identified in the joints. We discuss the different solidification paths and the following solid-state transformations. The Fe-containing joint solidified via a single beta(o) phase field leading to large beta(o) grains. In contrast, the Ni-containing joint solidified via a two-phase field resulting in a finer grained microstructure.

Microstructure and mechanical properties of Al2O3/TiAl joints brazed with B powders reinforced Ag-Cu-Ti based composite fillers

[J].

Microstructure characteristics and mechanical properties of laser-welded joint of γ-TiAl alloy with pure Ti filler metal

[J].

Friction weldability of a high Nb containing TiAl alloy

[J].

Microstructure and mechanical properties of friction welds between TiAl alloy and 40Cr steel rods

[J].

Effects of insert metal type on interfacial microstructure during dissimilar joining of TiAl alloy to SCM440 by friction welding

[J].

Microstructure evolution and formation mechanism of γ-TiAl/Ni-based superalloy laser-welded joint with Ti/V/Cu filler metals

[J].

A novel method of friction-diffusion welding between TiAl alloy and GH3039 high temperature alloy

[J].

Intermediate phases of TiAl/GH3039 friction welding joint

[J].

Characterizing micromechanical properties of friction welding interface between TiAl alloy and GH3039 superalloy

[J].

The ternary system Al-Ni-Ti Part I: Isothermal section at 900oC; Experimental investigation and thermodynamic calculation

[J].

Reassessment of the binary aluminum-titanium phase diagram

[J].

Forming mechanism of interface intermetallic compounds for difusion bonding

[J].

扩散连接接头金属间化合物新相的形成机理

[J].

Isothermal section at 927oC of Cr-Ni-Ti system

[J].

Constitution of the ternary system Cr-Ni-Ti

[J].

The Cr-Ni-Ti (chromium-nickel-titanium) system-update

[J].

Effects of brazing filler on properties of brazed joints between TiAl and metallic materials

[J].

First-principles study of coherent interfaces of Laves-phase MgZn2 and stability of thin MgZn2 layers in Mg-Zn alloys

[J].

Hardness and friction coefficient of fused silica under scratching considering elastic recovery

[J].

Brazing TiAl intermetallics using TiNi-V eutectic brazing alloy

[J].

Brazing high Nb containing TiAl alloy using TiNi-Nb eutectic braze alloy

[J].

Diffusion bonding of AlCoCrFeNi2.1 eutectic high entropy alloy to TiAl alloy

[J].