非晶合金(metallic glass,MG)作为新兴的先进材料,由于其特殊的结构、良好的热塑性成形能力和优异的力学性能,近年来得到了广泛的关注[1~4]。在没有长程原子周期性和任何晶体缺陷的情况下,直接成型后的MG显示出独特的纳米级粗糙度类镜面表面,以及高强度、高断裂韧性和耐腐蚀性能,这使得它们在结构材料领域具有潜在的应用前景[5~7]。但在室温下,往复划动接触的灾难性破坏严重限制了它们的广泛应用[8]。具体来说,实际应用不可避免地会产生摩擦和磨损等循环变形。与单调力学行为相比,摩擦行为是一个更为复杂的过程,它涉及接触表面及亚表面的塑性变形、局部温度升高以及与环境发生化学反应等[9,10]。研究发现,MG在载荷、频率和环境等不同条件下表现出敏感的摩擦学性能[9],且与其亚稳特性密切相关[11,12]。如Yi等[13]发现,锆基非晶合金在摩擦过程中表面发生的脆性断裂使得其表现出差的耐磨性能。Rahaman等[12]发现,MG敏感的摩擦学特性与其在往复划动过程中表面及亚表面发生的热软化和结晶行为密切相关。事实上,在往复划动条件下,脆性断裂、热软化和结晶往往同时发生,这给MG摩擦行为的阐明和改善带来了极大的困难[11~13]。

近年来,含有多个等原子或近等原子比(5%~35%)主元的高熵合金(HEAs)因其具有的独特结构和性能而受到广泛关注[14,15]。得益于其高的构型熵(ΔSc > 1.5R,R为气体常数),HEAs即使在高温下也通常表现出稳定的单一无序固溶相结构[16,17]。研究[18]发现,当一些HEAs体系具有大的负混合焓(ΔHmix)、大的原子尺寸差(δ)以及高的ΔSc时,在快速冷却条件下可形成具有短程有序、长程无序的非晶结构,这类合金被命名为高熵非晶合金(high-entropy metallic glass,HE-MG)。多组元合金的设计理念使得HE-MG打破了性能受制于单一或者两组元主元素的现状,使其具有热力学上的高混合熵效应、动力学上的迟滞扩散效应以及性能上的鸡尾酒效应等特点[19,20],因此,其具有传统MG所不具备的优异性能和特点[19~24]。如,与传统MG相比,HE-MG加热时表现出更高的玻璃稳定性[22],以及接近极限的强度、优异的耐腐蚀性能等[23,24],这使得其成为未来制造业中新一代结构材料的备选材料之一。作为潜在的结构应用材料,HE-MG在实际应用中不可避免地会产生变形及摩擦磨损。因此,为了保证金属结构件的稳定服役,材料不仅需要具有优异的摩擦磨损性能,还应具有高强高韧的力学性能。然而,当前大部分研究[20~23]集中于HE-MG中高混合熵对其玻璃化形成的热力学和动力学过程的影响,对于高混合熵为其带来的特殊结构和高热稳定性与其摩擦性能间的内在联系报道甚少。因此,深入了解HE-MG的摩擦学行为具有重要的科学意义。

1 实验方法

选用非晶形成能力较好的TiZrHfCuBe HE-MG,使用WK-Ⅱ型非自耗真空电弧熔炼及负压吸铸系统制备出实验所需的HE-MG样品。铸锭样品的原始材料均为市售金属块材,纯度均大于99.95% (质量分数)。在Ar气环境下首先熔炼吸收Ti以降低环境中的O含量,进而进行合金熔炼,合金锭至少进行5次翻转以确保成分均匀。熔炼结束后,待完全冷却后取出母合金锭进行称量,烧损量需确保小于0.1% (质量分数)。通过水冷铜模吸铸法在WK-Ⅱ型非自耗真空电弧熔炼及负压吸铸系统中进行板状HE-MG样品的制备。其原理主要是利用熔炼腔体内的上、下压强差使熔融态合金吸铸到水冷铜模具中从而快速冷却凝固。所用铜模内径为60 mm (长) × 12 mm (宽) × 4 mm (高)。使用电火花线切割机将铸锭切割为10 mm × 10 mm × 4 mm尺寸的试样。由于纳米压痕测试基于样品表面是一个平行镜面的假设,所以对样品表面的平整度和粗糙度要求较高。因此,样品需要经机械抛光和振动抛光2次抛光处理以避免表面粗糙度对实验结果造成影响。最后,利用MFP3D原子力显微镜(atomic force microscope,AFM)对抛光表面的粗糙度进行测量,表面粗糙度小于10 nm的样品才考虑使用。

TiZrHfCuBe HE-MG样品的微观结构通过F200X高分辨透射电子显微镜(HRTEM)进行分析。热稳定性用DTA 449F3差示扫描量热仪(differential scanning calorimeter,DSC)进行分析,DSC实验在加热速率为10 K/min的流动Ar气环境下进行。样品的微力学响应首先通过纳米压痕进行分析。纳米压痕实验在Hysitron TI950高精度纳米压痕测试系统的位移控制测试模式下进行。每个样品上分别进行一组11 × 11压痕点的纳米压痕点阵实验,以获得具有统计学意义的数据。实验最大压入深度选择为2.5 μm,加载速率为0.01 μm/s,相邻压痕之间的间隔统一设置为50 μm,以避免相邻2个压痕之间变形区域的相互作用影响。纳米划痕实验在配备有扫描探针(scanning probe microscope,SPM)显微成像技术模块的NanoTest Vantage系统上进行,配备的压头为圆锥形金刚石压头(半径约 5 μm)。整个恒力控制下的纳米划痕测试分为如下3个过程:(1) 预划,以2 μN的载荷刮擦试样表面,以测量该区域表面粗糙度随位移的变化,为后续刻划数据的修正提供基准;(2) 刻划,采用恒定载荷为50 mN,速率分别为0.1、0.5和1.0 μm/s,划痕距离为30 μm的参数划进行刻划实验使其变形产生磨损,并记录划痕过程中的轴向力、切向力、深度等参数随划痕位移的变化;(3) 终划,仍然采用2 μN的载荷对划痕区域进行扫描,以确定划痕过后残余深度随划痕位移的变化。每次实验重复3次且相邻划痕间距大于200 μm,以保证实验的重复性和准确性。为了进一步研究TiZrHfCuBe HE-MG在纳米划痕下的微力学响应,同时设计了另一组变力控制下的纳米划痕实验:在预划及终划过程中同样采用2 μN的载荷对划痕区域进行扫描,在刻划过程中以0.5 μm/s的速率线性施加纳米划痕,将法向力分别以1和2 mN/s的速率从0增加到50 mN,总划痕距离同样为30 μm。纳米划痕实验结束后,利用SPM对划痕后留下的表面磨损痕迹进行成像和研究。

2 实验结果与讨论

2.1 TiZrHfCuBe HE-MG微观结构特征

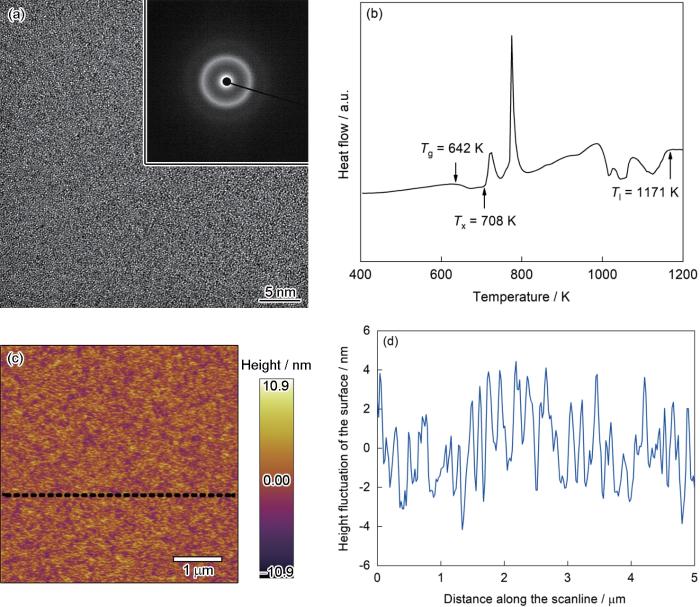

图1a为TiZrHfCuBe HE-MG的HRTEM像。可以清楚地看到,合金微观结构中的原子呈弥散分布且无明显的晶格条纹,其对应的选区电子衍射(selected area electron diffraction,SAED)花样呈漫散射环(图1a插图),表明合金的微观结构为非晶结构。图1b为合金在升温过程中的DSC曲线。可以看出,合金在升温过程中存在明显的玻璃转变和晶化过程,这与其他非晶合金的DSC实验结果类似[27,28]。TiZrHfCuBe HE-MG的热力学特征温度,即玻璃化转变温度(Tg)、晶化起始温度(Tx)及过冷液相区宽度(ΔT = Tx - Tg)分别为642、708和66 K。可以发现,与传统钛基非晶合金的过冷液相区宽度(以Ti45Zr16-Cu10Ni9Be20为例,其过冷液相区宽度仅为35 K)相比,TiZrHfCuBe HE-MG具有更宽的ΔT,这表明其在加热过程中具有更高的稳定性,可以抑制晶化的发生[27]。图1c为试样抛光表面的AFM高度像,沿抛光表面水平方向的剖面粗糙度分布曲线如图1d所示。结果显示,抛光处理后的样品表面较为平整,其最大粗糙度小于5 nm,这表明经过处理过后的样品表面符合纳米压痕及划痕测试标准,因此其可用于进一步的纳米压痕及划痕实验。

图1

图1

TiZrHfCuBe高熵非晶合金(HE-MG)的HRTEM像、升温过程的DSC曲线、抛光表面的原子力显微镜(AFM)高度像及沿水平方向剖面粗糙度分布曲线

Fig.1

HRTEM image and corresponding selected area electron diffraction (SAED) pattern (inset) (a) and heating differential scanning calorimeter (DSC) curve (b) of TiZrHfCuBe high-entropy metallic glass (HE-MG); atomic force microscope (AFM) height image of the polished surface (c); and profile roughness distribution curve along the horizontal direction of polished surface as shown by black dashed line in Fig.1c (d) (Tg—glass transition temperature, Tx—onset crystalli-zation temperature, Tl—liquidus temperature)

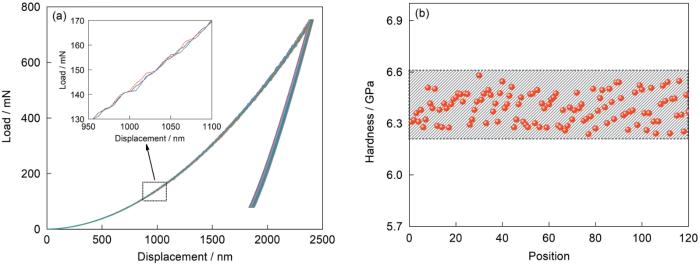

图2

图2

TiZrHfCuBe HE-MG纳米压痕载荷-位移曲线和硬度的统计分布

Fig.2

Different nanoindentation load-displacement curves of TiZrHfCuBe HE-MG obtained in the 11 × 11 nanoindentation lattice (Inset shows corresponding local enlarged load-displacement curves for better visualization) (a) and statistical distribution of hardness measured by nanoindentation (Shaded areas show the measured hardness values distribution interval, dotted lines show the lowest and highest measured hardness values, and red balls show the statistical distribution of hardness) (b)

式中,fi 和Mi 分别为合金中每种组元i所占的原子分数和Young's模量。经计算,TiZrHfCuBe HE-MG的理论硬度约为7.08 GPa。可以看出,测得的HE-MG最低硬度(6.24 GPa)也达到了理论硬度的88%,且90%以上的微观区域强度达到了理论硬度的90%以上,这一结果表明HE-MG的微观结构由自由体积较少的均匀刚性基体构成[25]。

2.2 TiZrHfCuBe HE-MG在不同划动速率下的纳米划痕行为

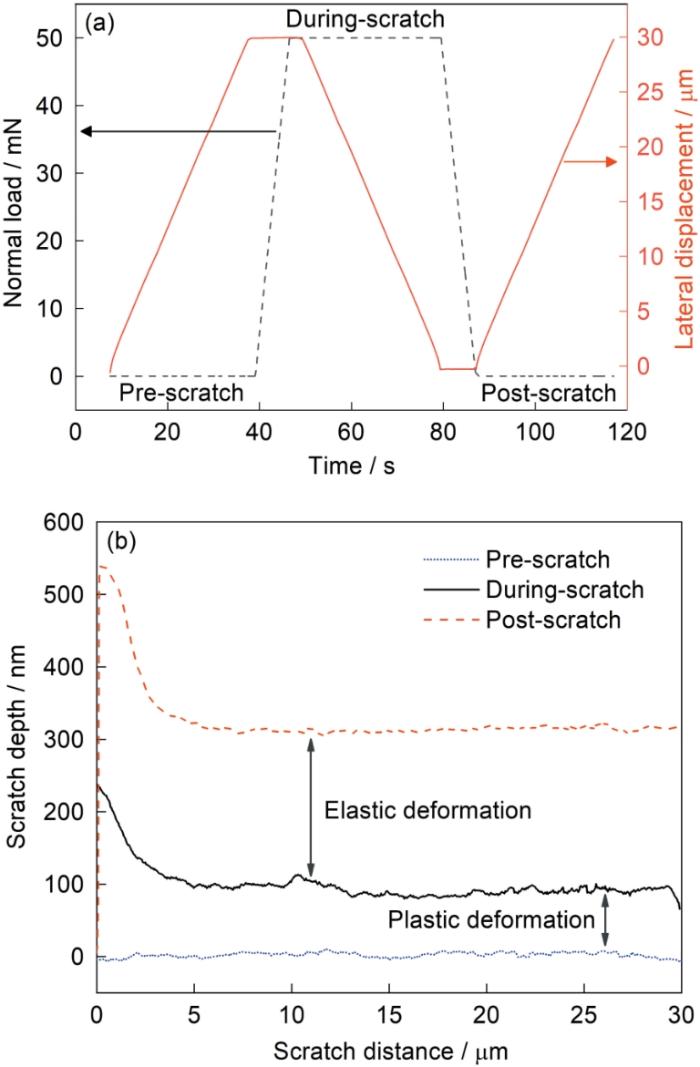

图3

图3

纳米划痕过程示意图和表面轮廓与纳米划痕过程中划痕距离的关系

Fig.3

Schematic of the nanoscratching process (a) and surface profiles as a function of scratch distance during the nanoscratching process (b)

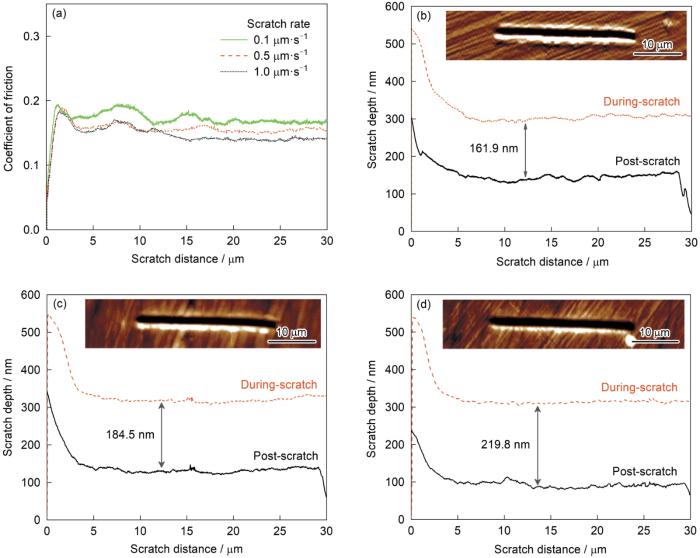

图4a为不同划动速率纳米划痕实验摩擦系数随划痕距离变化的曲线。可以清楚地看到,TiZrHfCuBe HE-MG摩擦系数呈现出2个不同的区域,即压头下压造成的初期不稳定阶段和随后整个划痕过程中的恒定阶段。在恒定阶段,不同划动速率条件下TiZrHfCuBe HE-MG的摩擦系数出现轻微降低,即从划动速率为0.1 μm/s的0.168减小到了划动速率为1.0 μm/s的0.141,且其随划痕距离的波动存在明显差异,即随着划动速率的增加,摩擦系数随划痕距离的波动越来越小。图4b~d给出了不同划动速率下获得的刻划和终划曲线。可以看出,随着划动速率的增大,刻划深度基本保持不变,但是残余划痕深度却逐渐减小,划动速率为1.0 μm/s的残余划痕深度达到最低(约98.6 nm),这说明随着划动速率的增加由磨损导致的材料破损去除越来越小。此外,残余划痕深度的减小也意味着划痕实验后HE-MG表面弹性回复的逐渐增大,如其从划动速率为0.1 μm/s的161.9 nm逐渐增大到了划动速率为1.0 μm/s的219.8 nm。图4b~d插图显示了样品在不同划动速率下的划痕形貌SPM像。可以看到,划动速率为0.1 μm/s的划痕形貌中磨损痕迹两侧有大量材料堆积,表明其塑性变形较为明显[32],对于划动速率为0.5和1.0 μm/s的划痕形貌,其磨损痕迹两侧的材料堆积较少。此外,磨损系数(K)可表示为[33]:

式中,V为划动实验时的磨损量,H为样品的硬度,Fn为法向力,x为划痕距离。

图4

图4

TiZrHfCuBe HE-MG在不同划动速率下的摩擦系数-划痕距离曲线及刻划深度和终划深度随划痕距离变化的曲线

Fig.4

Nanoscratch results of TiZrHfCuBe HE-MG at different scratch rates

(a) coefficient of friction as a function of the scratch distance

(b-d) scratch depth and penetration wear depth as a function of the scratch distance under scratch rates of 0.1 μm/s (b), 0.5 μm/s (c), and 1.0 μm/s (d) (Insets show the corresponding scanning probe microscope (SPM) images of the scratch surface after nanoscratch tests)

由

式中,τs为剪切强度;Ac为压头与试样表面的接触面积,Ac = πa2 (其中,a为接触面半径)。因此,黏附系数可推导为[38]:

式中,

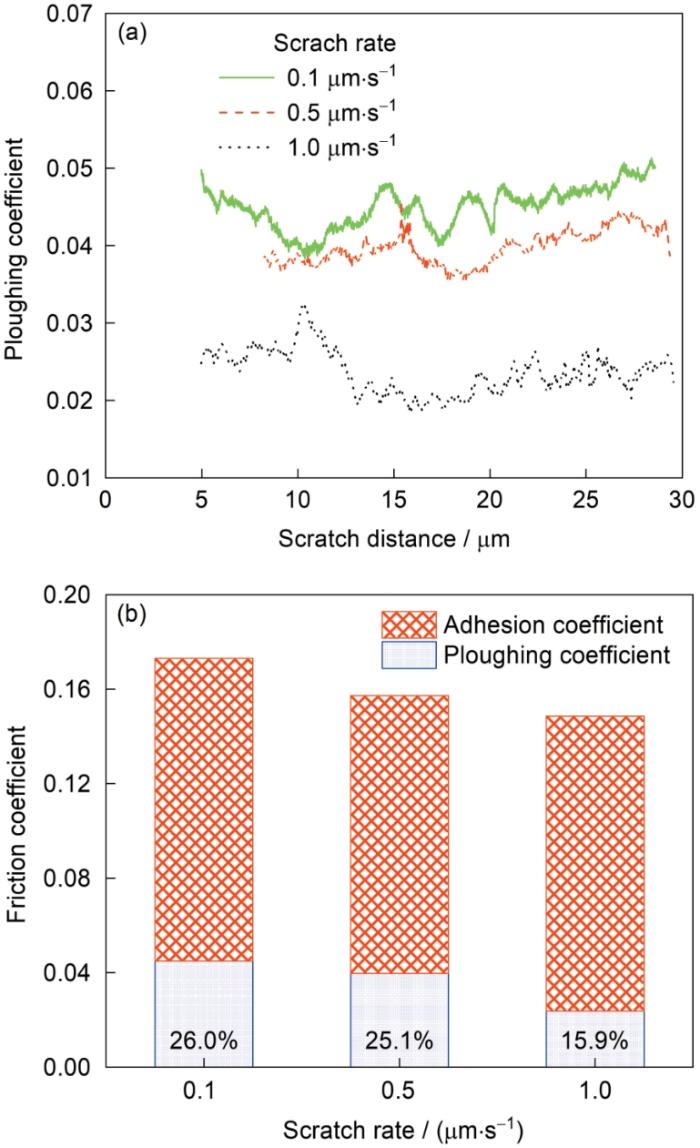

据此,样品在不同划动速率下的犁沟系数随划痕距离的变化曲线如图5a所示。可以看到,样品的犁沟系数与划动速率间表现出了明显的负相关性,即随着划动速率的增加,样品的塑性犁沟系数逐渐减小。众所周知,非晶合金的塑性变形与其变形单元——剪切转变区(shear transformation zone,STZ)的形成密切相关,而剪切力作用下剪切转变区的形成又强烈依赖于非晶合金微观结构区域的局部原子协同重排。自由体积所在的区域通常是发生原子协同重排的潜在位置[40]。对于自由体积较少的TiZrHfCuBe HE-MG微观结构,划痕下的局部塑性区相对较小。因此,在这些自由体积稀疏的区域中找到可以发生原子协同重排的潜在位置的概率较低[41,42]。此时,STZ的形成需要长程原子协同重排和相应较大的剪切转变区尺寸。在这种情况下,STZ需要沿最大剪切应力方向在特定位置进行剪切激活[43]。当划动速率较低时,单位时间内在压头下方的接触区域内原子发生剪切激活的概率较高,此时STZ的激活以及随后的剪切变形相对较为容易,这也可以由图4b中的结果得到证实。然而,随着划动速率的增加,在相同的时间内,压头下方的接触区域内原子发生剪切激活的概率越来越低。在这种情况下,STZ的激活以及随后的剪切变形变得越来越难,从而导致划痕过程中的犁沟系数逐渐减小(图5a),残余深度降低(图4c和d)。此外,划痕过程中的黏附系数可由μa = μf-μp来计算获得。图5b为样品在不同划动速率下的犁沟系数和黏附系数在摩擦系数中所占的比值。可以看出,随着划动速率的增加,犁沟系数在整个摩擦系数中所占的比值逐渐减小,这也进一步验证了样品的剪切变形越来越小。

图5

图5

不同划动速率下计算得到的塑性犁沟系数随划痕距离变化的曲线及犁沟系数和黏附系数在摩擦系数中所占的比值

Fig.5

Calculated ploughing coefficient as a function of the scratch distance under different scratch rates (a) and ratios of ploughing coefficient and adhesion coefficient in friction coefficient under different scratch rates (b)

2.3 TiZrHfCuBe HE-MG在不同加载速率下的纳米划痕行为

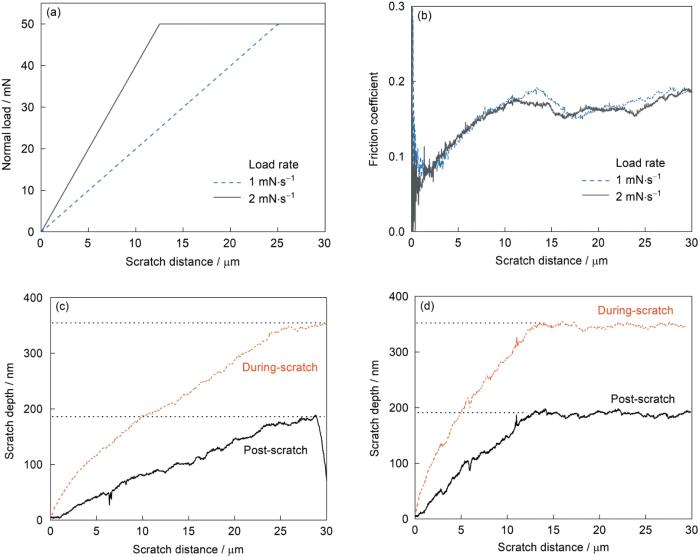

为了进一步研究TiZrHfCuBe HE-MG微观结构对其纳米划痕行为的影响,设计了另一组不同加载速率下的纳米划痕实验,其示意图如图6a所示。图6b~d为不同加载速率的纳米划痕实验结果。可见,不同加载速率下获得的摩擦系数表现出了相似的趋势,即摩擦系数随着划痕距离的增加先逐渐升高,后保持震荡波动(图6b)。图6c和d给出了不同加载速率下获得的刻划和终划曲线。可以看出,刻划深度和终划深度均随着加载力的增大而增大,最后加载力达到恒定后保持不变,而图6c曲线末端出现下降的原因可能由实验误差所致。与此同时,不同加载速率下获得的最终的刻划深度(约352.2 nm)和终划深度(约190.6 nm)基本相同,这说明加载速率的变化不会导致材料最终磨损残余深度的变化。

图6

图6

TiZrHfCuBe HE-MG不同加载速率下的纳米划痕实验示意图、摩擦系数-划痕距离曲线及1和2 mN/s加载速率下刻划深度和终划深度随划痕距离变化的曲线

Fig.6

Schematic of TiZrHfCuBe HE-MG nanoscratch process under different loading rates (a), friction coefficient as a function of the scratch distance (b), and scratch depth and penetration wear depth as a function of the scratch distance under loading rates of 1 mN/s (c) and 2 mN/s (d)

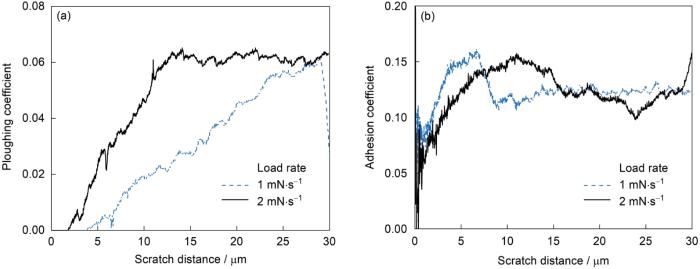

同样地,可以通过式(

图7

图7

不同加载速率下计算得到的塑性犁沟系数及黏附系数随划痕距离变化的曲线

Fig.7

Calculated ploughing (a) and adhesion (b) coefficients as function of the scratch distance under different load rates

3 结论

(1) DSC实验结果显示,与传统钛基非晶合金的过冷液相区宽度相比,TiZrHfCuBe高熵非晶合金具有更宽的过冷液相区宽度,表明其具有更高的热稳定性。纳米压痕结果显示,TiZrHfCuBe高熵非晶合金不同区域的纳米压痕硬度均接近其理论值90%以上,表明其微观结构由缺陷较少的均匀刚性基体构成。

(2) 在纳米划痕实验中,随着划动速率的增大,TiZrHfCuBe高熵非晶合金的刻划深度基本保持不变,但是残余划痕深度却逐渐减小。这归因于划动速率增加迟滞了TiZrHfCuBe高熵非晶合金微观结构中剪切转变区激活以及随后的剪切变形,从而导致划痕过程中的犁沟系数逐渐减小,残余深度降低。

(3) 在变加载速率的纳米划痕实验中,随着加载力的增加,用于剪切变形过程中剪切带形核的剪切转变区激活以及随后的剪切变形迟滞效应逐渐减小,导致塑性犁沟系数和划痕深度的逐渐增大。

参考文献

Ultrastable metallic glass by room temperature aging

[J].

Effect of nano-crystallization on dynamic compressive property of Zr-based amorphous alloy

[J].Zr-based amorphous alloys are characterized by high glass forming ability, high thermal stability and excellent mechanical properties. The amorphous alloys in thermodynamic metastable state have the tendency to change to metastable state with lower energy or even crystal structure in equilibrium state under certain temperature or pressure conditions. At present, few researches have been conducted on the mechanical behavior of partially crystallized Zr-Cu-Ni-Al-Nb amorphous alloys, especially the fracture behavior under dynamic loading. In this work, as-cast Zr-Cu-Ni-Al-Nb amorphous alloy was annealed to accomplish different levels of nano-crystallization by controlling holding time. DSC, XRD, HRTEM, SEM, quasi-static and dynamic compression tests were utilized to research the effect of nano-crystallization on compressive strength and fracture mechanism of Zr-based amorphous alloy under different strain rates. The results indicated that the volume fraction and size of nanoscale crystalline phase inside Zr-based amorphous alloy increased with the increasing of annealing holding time. The compressive strength of annealed Zr-based amorphous alloy increased first and then decreased with the increase of holding time. The variation of strain rates also affected the compressive strength, which decreased when the strain rate increased from 1×10-3 s-1 to 1×103 s-1, and increased when the strain rate continually increased to 3×103 s-1. Different degrees of nano-crystallization had an impact on the fracture characteristics of Zr-based amorphous alloy. As the degree of crystallization increased, the fracture morphology of compression samples changed from vein-like patterns to quasi-cleavage features and then to river patterns.

纳米晶化对锆基非晶合金动态压缩性能的影响

[J].以铸态Zr-Cu-Ni-Al-Nb非晶合金为材料,通过控制退火保温时间获得部分纳米晶化非晶合金,并采用DSC、XRD、HRTEM、SEM、准静态及动态压缩等手段,研究了纳米晶化对非晶合金在不同应变率下的抗压强度以及断裂机制的影响。结果表明,随着退火保温时间的增加,锆基非晶合金内部纳米级晶化相的体积分数及尺寸均增加。退火态非晶合金的抗压强度随着保温时间增加先增大后减小;应变率变化也会影响其抗压强度,从1×10<sup>-3</sup> s<sup>-1</sup>增加到1×10<sup>3</sup> s<sup>-1</sup>时强度降低,继续增加到3×10<sup>3</sup> s<sup>-1</sup>时强度有所升高。不同程度的纳米晶化对非晶合金的断裂特征产生影响,随着晶化程度的增大,压缩试样的断口形貌从脉状花样向类准解理特征再向河流状花样转变。

Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes

[J].

Structural characteristic and crystallization behavior of the (Fe0.33Co0.33Ni0.33)84 - x Cr8Mn8B x high-entropy-amorphous alloy ribbons

[J].

(Fe0.33Co0.33Ni0.33)84 - x Cr8Mn8B x 高熵非晶合金薄带的结构特征及其晶化行为

[J].基于前期的研究结果,降低Mn和Cr元素的含量,将2者的原子分数均固定在8%,设计出(Fe<sub>0.33</sub>Co<sub>0.33</sub>Ni<sub>0.33</sub>)<sub>84 - </sub><sub>x</sub>Cr<sub>8</sub>Mn<sub>8</sub>B<sub>x</sub> (x = 10、11、13、15和18)合金(简称10B、11B、13B、15B和18B),采用真空熔融甩带法制备出该系列合金的薄带。将合金薄带在不同温度下进行退火处理,通过XRD、DSC、TEM、SEM、万能拉伸试验机、OM、Vickers硬度计等研究了合金薄带的结构特征、晶化行为和力学性能。结果表明:11B合金薄带已完全形成非晶相(am),11B~18B合金薄带加热时都有2个结晶转变放热峰,B元素的添加提高了该系列合金的非晶形成能力(GFA)和热稳定性。11B~18B合金薄带在不同温度退火,bcc相、fcc相和硼化物(M<sub>23</sub>B<sub>6</sub>)等1种或多种混合物析出,其结晶行为分别为:11B和13B,[am]→[am′ + bcc]→[am″ + bcc + fcc]→[bcc + fcc + M<sub>23</sub>B<sub>6</sub>]→[fcc + M<sub>23</sub>B<sub>6</sub>];15B,[am]→[am′ + fcc + bcc]→[am″ + bcc + fcc + M<sub>23</sub>B<sub>6</sub>]→[bcc + fcc + M<sub>23</sub>B<sub>6</sub>]→[fcc + M<sub>23</sub>B<sub>6</sub>];18B,[am]→[am′ + fcc]→[am″ + fcc + M<sub>23</sub>B<sub>6</sub>]→[fcc + M<sub>23</sub>B<sub>6</sub>] (其中,am′和am″分别为第1次和第2次结晶残余非晶相)。

Imparities of shear avalanches dynamic evolution in a metallic glass

[J].

Effect of alloying elements on the microstructure and corrosion behavior of TiZr-based bulk metallic glasses

[J].

Mechanical and tribological properties of Zr-Cu-Ni-Al bulk metallic glasses with dual-phase structure

[J].

Environment-dependent tribological properties of bulk metallic glasses

[J].

Abrasive wear of Cu60Zr30Ti10 bulk metallic glass

[J].

Temperature rise at shear bands in metallic glasses

[J].

On the diversity of accommodation mechanisms in the tribology of bulk metallic glasses

[J].

Understanding the friction and wear mechanisms of bulk metallic glass under contact sliding

[J].

Guiding and deflecting cracks in bulk metallic glasses to increase damage tolerance

[J].

High-entropy alloys

[J].Alloying has long been used to confer desirable properties to materials. Typically, it involves the addition of relatively small amounts of secondary elements to a primary element. For the past decade and a half, however, a new alloying strategy that involves the combination of multiple principal elements in high concentrations to create new materials called high-entropy alloys has been in vogue. The multi-dimensional compositional space that can be tackled with this approach is practically limitless, and only tiny regions have been investigated so far. Nevertheless, a few high-entropy alloys have already been shown to possess exceptional properties, exceeding those of conventional alloys, and other outstanding high-entropy alloys are likely to be discovered in the future. Here, we review recent progress in understanding the salient features of high-entropy alloys. Model alloys whose behaviour has been carefully investigated are highlighted and their fundamental properties and underlying elementary mechanisms discussed. We also address the vast compositional space that remains to be explored and outline fruitful ways to identify regions within this space where high-entropy alloys with potentially interesting properties may be lurking.

Atomistic insights into the deformation mechanism of a CoCrNi medium entropy alloy under nanoindentation

[J].

Microstructure-dependent phase stability and precipitation kinetics in equiatomic CrMnFeCoNi high-entropy alloy: Role of grain boundaries

[J].

Mechanical and tribological performance of CoCrNiHf x eutectic medium-entropy alloys

[J].

High-entropy alloys with high saturation magnetization, electrical resistivity and malleability

[J].Soft magnetic materials (SMMs) find important applications in a number of areas. The diverse requirements for these applications are often demanding and challenging for the design and fabrication of SMMs. Here we report a new class of FeCoNi(AlSi)(x) (0 <= x <= 0.8 in molar ratio) SMMsbased on high-entropy alloys (HEAs). It is found that with the compositional and structural changes, the optimal balance of magnetic, electrical, and mechanical properties is achieved at x = 0.2, for which the combination of saturation magnetization (1.15 T), coercivity (1,400 A/m), electrical resistivity (69.5 mu Omega.cm), yield strength (342 MPa), and strain without fracture (50%) makes the alloy an excellent SMM. Ab initio calculations are used to explain the high magnetic saturation of the present HEAs and the effects of compositional structures on magnetic characteristics. The HEA-based SMMs point to new directions in both the application of HEAs and the search for novel SMMs.

Pseudo-quinary Ti20Zr20Hf20Be20-(Cu20 - x Ni x ) high entropy bulk metallic glasses with large glass forming ability

[J].

Intrinsic correlation between the fraction of liquidlike zones and the β relaxation in high-entropy metallic glasses

[J].

Identifying the origin of strain rate sensitivity in a high entropy bulk metallic glass

[J].

Utilization of high entropy alloy characteristics in Er-Gd-Y-Al-Co high entropy bulk metallic glass

[J].

Sluggish dynamics of homogeneous flow in high-entropy metallic glasses

[J].

Interface-related deformation phenomena in metallic glass/high entropy nanolaminates

[J].

Rejuvenation of metallic glasses by non-affine thermal strain

[J].

Bulk metallic glass composites containing B2 phase

[J].

Effect of Al on glass forming ability and thermal stability of Mg-Cu-Y alloys

[J].

Al对Mg-Cu-Y合金非晶形成能力及热稳定性的影响

[J].

Strength statistics of single crystals and metallic glasses under small stressed volumes

[J].

General relationship between strength and hardness

[J].

Tribological behavior of thermomechanically treated Al-Mg-Si alloy by nanoscratch measurements

[J].

Tribological behavior of an amorphous Zr20Ti20Cu20Ni20Be20 high-entropy alloy studied using a nanoscratch technique

[J].

A study of abrasive wear under three-body conditions

[J].

Evaluating abrasive wear of amorphous alloys using nanoscratch technique

[J].

Wear resistance of amorphous alloys and related materials

[J].

The ploughing friction: Analytical model with elastic recovery for a conical tip with a blunted spherical extremity

[J].

A theory of friction and wear during the abrasion of metals

[J].

Shear bands in metallic glasses

[J].

Intermediate temperature brittleness in metallic glasses

[J].

Yielding and shear banding of metallic glasses

[J].

Serrated flow behaviors of a Zr-based bulk metallic glass by nanoindentation

[J].