镍基高温合金在600℃以上具有较高的强度、良好的抗氧化和抗燃气腐蚀能力,广泛应用于航空航天、能源等领域热端部件的制造[1~3]。实际服役时,镍基高温合金部件通常受复杂温度和应力场共同作用,可能使力学性能降低甚至发生断裂失效现象。因此,研究镍基高温合金在近服役条件下的力学性能与内在变形机理具有重要意义。针对单轴加载下温度对镍基高温合金力学行为和变形机理影响的研究[4~6]发现,基体与沉淀相之间的应力分配、滑移剪切应力以及沉淀相-位错相互作用均随温度变化而明显改变,从而导致合金力学行为存在差异。而针对多轴加载作用下高温合金变形的问题,近几年国内外仅开展了一些探索性工作,且主要集中在加载方式对疲劳寿命影响等方面[7~9],而多轴加载对材料强度、塑性及变形机理影响等方面的研究相对较少。已有研究[10,11]表明,多轴加载可能改变孪生或位错运动进而影响镍基高温合金蠕变或疲劳性能。但多轴或复合加载方式对高温合金力学性能的影响未见报道,对于其内在微观变形机制亦尚无清晰认识。根据其他金属材料的多轴加载变形行为可知,材料的强度、塑性及其变形机理均与加载方式密切相关。针对不同复合加载方式下铝合金等材料断裂行为的研究[12~15]发现,剪切力占比越大,则韧窝畸变越明显,断面倾斜度越大。Nicholson等[16]对比分析了NiTi合金在扭转、拉伸、压缩变形前后的组织变化,发现在不同加载方式下会形成不同R相变体。Yang等[17]发现在经过不同程度预压缩变形的镁合金中产生了织构,织构随预压缩应变增大而增强,最终导致扭转屈服强度增大。Polatidis等[18]发现奥氏体钢在单轴和多轴加载时分别产生了<111>和<101>织构,前者有利于孪晶产生,而后者有利于马氏体相变。研究[19~22]表明,对低碳钢等材料施加一定程度的预扭转变形时,材料内部会产生大量位错并形成一种与位错有关的梯度结构,且该梯度结构会明显提升材料力学性能。而Pan等[23]对高熵合金施加循环预扭转变形时发现,形成的梯度结构除了位错外还含有一定数量的孪晶和层错,使材料强度提升的同时还保持拉伸塑性不损失。同时,Ding等[24]观察到TiAl合金在预扭转变形后产生的梯度结构中存在大量孪晶,且孪晶含量随预扭转角度增加而增多,最终导致延伸率增大。Gravell和Ryu[25]通过模拟研究发现,单晶Cu预变形产生的位错会与拉扭复合加载变形产生的位错发生相互作用。

可见,加载方式对金属材料力学性能和内在变形机理均有重要影响。为了研究多轴加载对高温合金力学性能的影响,本工作采用单轴拉伸、预扭转拉伸、单轴扭转和预拉伸扭转等4种加载方式,并结合微观组织表征和中子衍射实验,研究了单一、复合加载条件下多晶镍基高温合金GH4169的力学性能变化规律,以及不同加载方式下微观变形机制的差异。

1 实验方法

1.1 力学性能分析

实验材料采用GH4169镍基高温合金,主要化学成分(质量分数,%)为[7]:Ni 53.44,Cr 18.53,Mo 3.06,Nb 5.30, Co 0.13,C 0.02,Mn 0.05,Si 0.06,Cu 0.04,Al 0.56,Ti 0.99,Fe 17.71。将原始铸锭加工成直径6 mm、长度100 mm的狗骨头状圆柱形试样,如图1所示。实验采用的MAMT-100拉压扭力学试验系统具有拉伸、扭转、压缩和力-热耦合等多种功能,专门设计用于结合中子科学装置开展原位力学实验。基于该设备,在室温下分别进行预扭转拉伸和预拉伸扭转的多轴加载实验。拉伸实验时采用变形控制,变形量通过2D视频引伸计监测得到;扭转实验时采用扭角控制,扭转角度直接通过传感器读取。预扭转拉伸实验时,首先将未变形样品(标记为undeformed)分别扭转0°、90°、360°和720°等角度后保持恒定,随后以3.3 × 10-4 s-1的应变速率拉伸样品直至断裂。将相应的拉伸样品依次标记为PRTOR-0、PRTOR-90、PRTOR-360和PRTOR-720,下文中将这些样品统称为PRTOR样品。预拉伸扭转实验时,首先将4组样品分别拉伸至0、5%、20%和40%后保持应变不变,随后以30°/min的速率扭转样品直至断裂。将相应的扭转样品依次标记为PRTEN-0、PRTEN-5、PRTEN-20和PRTEN-40,下文中将这些样品统称为PRTEN样品。

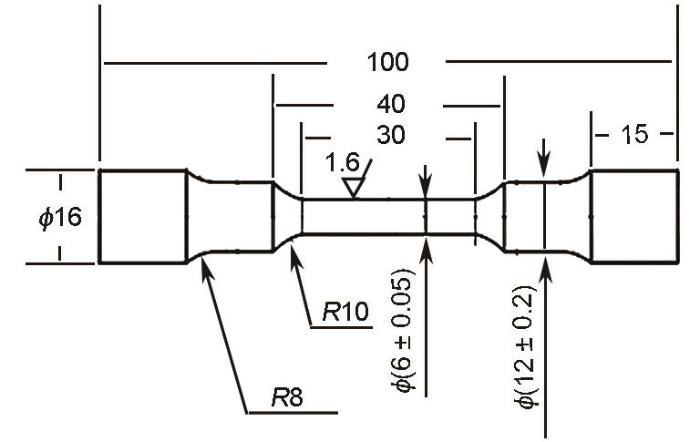

图1

图1

力学性能测试样品示意图

Fig.1

Schematic of the samples for mechanical property measurements (unit: mm)

对于拉伸实验,通过视频引伸计可直接得到真实应变(εtrue)。基于拉伸变形过程材料总体积不变的假设,可得真实应力(σtrue)[26]:

式中,σmeasured为拉伸机直接测得的拉应力。

对于扭转实验,通过上述拉压扭力学试验系统可直接获取扭矩(T)和扭角(φ)曲线。尽管测试过程未使用扭转应变片获取真实扭转应变,但通过样品表面标记线变化分析可知,测得的最大扭转角度与实际值之间的误差在1%以内,因此可近似认为测得的扭角等同于真实扭角。将T和φ转换成相应的剪切应力(τ)和剪切应变(γ),如下式所示[26]:

式中,d为样品直径,L为样品标距。

比较材料拉伸与扭转变形行为时,需将各自的应力和应变转换成等效应力(σe)和等效应变(εe),如下式所示[26]:

拉伸时:

扭转时:

1.2 微观结构表征

采用Gemini 300场发射扫描电镜(SEM)观察样品的断口形貌,低倍和高倍数下的工作电压分别采用5和10 kV。采用Nordlys Max3电子背散射衍射仪(EBSD)表征PRTOR-360样品晶界和取向差分布,工作加速电压为20 kV。表征前对试样依次进行机械抛光和化学腐蚀处理,化学腐蚀液为40 mL H2SO4和100 mL CH3OH混合溶液。采用Tecnai G2 F20透射电镜(TEM)观测PRTOR-0和PRTOR-360样品位错形态,通过MTP-1A电解双喷减薄仪制备TEM样品,电解液为5%HClO4和95%CH3OH (体积分数)混合溶液,温度为-30℃,电流为60 mA,同时通过离子研磨去除样品表面污染。

利用高压中子衍射谱仪(HPND)[27]对未变形样品和PRTOR-0、PRTOR-360、PRTEN-0、PRTEN-20变形断裂样品进行中子衍射实验。将样品竖直放置于样品台中心,样品轴向方向垂直于中子入射-衍射平面(即与散射矢量相互垂直)。该谱仪的单色器由13片弧形排列的Ge(511)单晶片组成,选取的实验波长(λ)为0.15925 nm;中子注量率约为2.8 × 106 n/(cm2·s),最佳分辨率为0.35%;探测角度(2θ)范围为20°~140°,针对每个样品的实验采谱时间为8 h。采用GSAS-II[28]软件对中子衍射全谱数据进行Rietveld精修处理,峰形拟合函数为Pseudo-Voigt函数。采用残余应力中子分析谱仪(RSND)[29]原位观测预拉伸扭转过程中样品衍射峰的动态变化,选取的实验波长为0.15863 nm。实验时,将拉压扭力学试验系统安装在谱仪样品台上;二维位置灵敏探测器(灵敏区300 mm × 300 mm)布置于衍射角52.3°位置;入射束与衍射束方向形成夹角的角平分线平行于试样轴向(即拉伸加载方向)。

采用Ungár和Borbély[30]修正的Williamson-Hall方法估算位错密度。根据该方法,衍射峰展宽为:

式中,K为倒格矢长度(K = 2sinθ / λ);ΔK为衍射峰展宽(ΔK = 2cosθ·Δθ / λ);M为取决于位错的有效外截止半径的无量纲常数;ρ为位错密度;r为相干散射区域的平均尺寸,通常情况下(0.9 / r)2很小,可忽略不计;b为Burgers矢量模;C为平均衬度因子,其值反映了由位错造成的Bragg衍射峰展宽的各向异性。C可以表示为[31]:

式中,h、k和l为衍射晶面的Miller指数;常数Ch00和q与晶格弹性常数C11、C12和C44有关。依照

2 实验结果与讨论

2.1 力学性能

图2为拉伸和扭转样品的等效应力-应变曲线和力学性能测试结果。由图2a和b可见,随预扭转角度增加,拉伸样品屈服强度(取εe = 0.2%时对应的应力)和极限强度均增大,延伸率则减小。其中,单轴拉伸试样的屈服强度和极限强度分别为357.4和877.4 MPa,延伸率为49.8%;随着预扭转角度增加至720°,拉伸屈服强度和极限强度分别增大至886.2和991.5 MPa (较单轴拉伸样品增幅分别约为150%和13%),延伸率减小至13.1% (较单轴拉伸样品降幅约为74%)。由图2b可见,适当的预扭转使材料同时兼具较高的强度和塑性。譬如,预扭转角度为360°时,试样的屈服强度、极限强度和延伸率分别为769.9 MPa、903.3 MPa和30.5%。由图2c和d可见,单轴扭转试样的屈服强度和极限强度分别为409.5和1113.0 MPa,延伸率为201.3% (需说明的是,扭转样品径向为非均匀变形,这里的延伸率是基于最大扭转角分析的结果[21~23]);当预拉应变小于20%时,随预拉应变增加,扭转样品屈服强度和延伸率有所增大,极限强度则逐渐减小;随着预拉应变增加至20%,扭转屈服强度增大至537.6 MPa (较单轴扭转样品增幅约为31%),而扭转极限强度减小至839.7 MPa (较单轴扭转样品降幅约为25%),延伸率则增大至234.2% (较单轴扭转样品增幅约为16%);当预拉应变为40%时,样品屈服强度和极限强度分别减小至342.1和512.7 MPa,延伸率则骤减到9.7%。相较于预拉应变20%的情形,屈服强度、极限强度和延伸率均明显减小。这可能是因为40%的预拉应变已接近拉伸变形极限(见图2a中PRTOR-0样品),此时样品内部可能出现了微孔洞或微裂纹等缺陷。

图2

图2

拉伸和扭转样品的等效应力-应变曲线和力学性能

Fig.2

Equivalent stress-strain curves (a, c) and mechanical properties (b, d) for PRTOR (a, b) and PRTEN (c, d) specimens (PRTOR and PRTEN are the shortened name for pre-torsion and pre-tension, respectively)

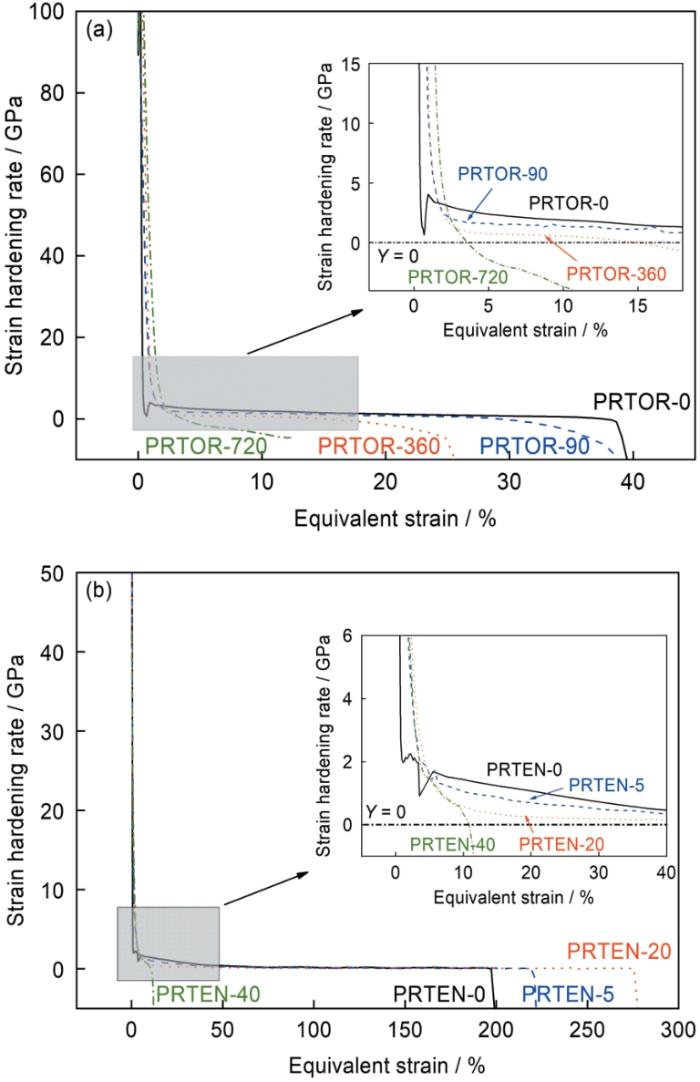

将等效应力对等效应变作微分处理,得到拉伸和扭转样品的加工硬化率曲线,如图3所示。由图3a可见,单轴拉伸时,加工硬化率先快速降低、后升高,然后缓速减小直至颈缩发生;而预扭转拉伸时,加工硬化率先快速降低、后缓速减小,并不出现单轴拉伸时的加工硬化率上升阶段。由图3a插图可见,拉伸样品加工硬化率总体上随预扭转角度增大而减小。例如,当等效应变为10%时,PRTOR-0、PRTOR-90、PRTOR-360和PRTOR-720样品的加工硬化率分别为1.93、1.36、0.56和-3.63 GPa。由图3b可见,单轴扭转样品加工硬化率随等效应变的变化趋势与单轴拉伸样品基本一致。预拉伸扭转样品加工硬化率的变化趋势与预扭转拉伸样品也大致相似。由图3b插图可见,扭转样品加工硬化率随预拉应变增大而减小。例如,当等效应变为10%时,PRTEN-0、PRTEN-5、PRTEN-20和PRTEN-40样品的加工硬化率分别为1.44、1.07、0.58和0.34 GPa。

图3

图3

拉伸和扭转样品的加工硬化率曲线

Fig.3

Strain hardening rate curves of PRTOR (a) and PRTEN (b) specimens (Insets show the corres-ponding enlargement for the range of relatively low strains as marked by the squares)

2.2 断口形貌与受力分析

图4为拉伸和扭转断裂样品的实物照片,图中给出了断裂面与横截面夹角(ψ )测量值。由图4a可见,PRTOR样品的ψ 随预扭转角度增加而逐渐增大。PRTOR-0、PRTOR-90、PRTOR-360和PRTOR-720样品的ψ 依次为0°、24°、30°和49°。由图4b可见,对于预拉伸扭转样品,当预拉应变达到一定程度时断裂平面才出现明显倾斜。PRTEN-0、PRTEN-5和PRTEN-20样品断裂面与横截面基本平行,即ψ 接近0°,而PRTEN-40样品的ψ 则为14°。需指出的是,尽管PRTEN-5和PRTEN-20样品断裂面与横截面基本平行,但与PRTEN-0样品相比,其断面存在明显凹凸不平的区域(详见后文),说明它们在变形过程中受到拉应力作用。

图4

图4

拉伸和扭转系列断裂样品实物图

Fig.4

Photographs of PRTOR (a) and PRTEN (b) specimens after fracture (Insets show the measured angle ψ between the fracture plane and transverse cross section)

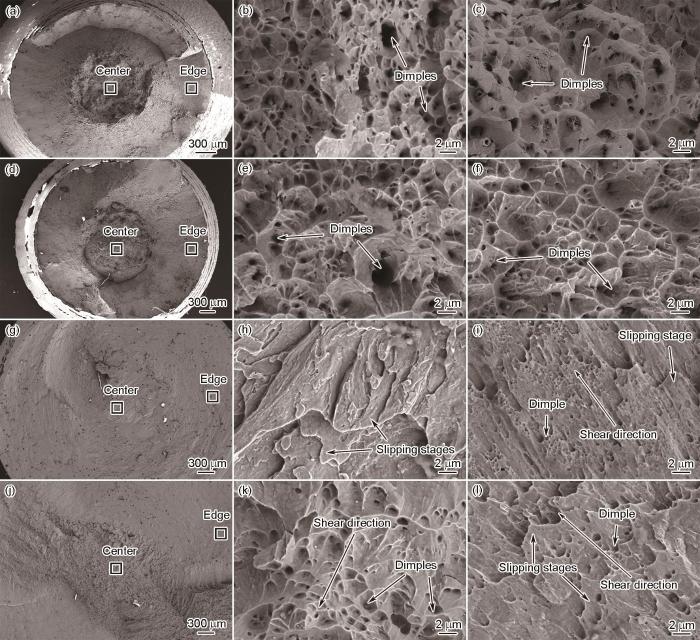

图5为拉伸和扭转断裂样品断口形貌的SEM像。由图5a可见,PRTOR-0样品的宏观断口呈杯锥状,主要由中心纤维区和边缘剪切唇区构成;中心和边缘区存在大量深浅不一的等轴韧窝(图5b和c),韧窝尺寸为0.5~5 μm。这表明,单轴拉伸样品在拉应力作用下发生典型的韧窝穿晶断裂[32]。由图5d可见,尽管PRTOR-360样品宏观断口依然呈杯锥状,但其边缘剪切唇区出现由剪切变形导致的凹凸不平特征;尽管纤维区和剪切唇区均存在大量韧窝,但剪切唇区的韧窝相较纤维区发生轻微变形、且明显变浅(图5e和f),这可能是剪切应力参与了剪切唇区变形的结果[33]。由图5g可见,PRTEN-0样品的宏观断口为光滑平面,且存在明显剪切痕迹;中心区存在大量与滑移面分离相关的台阶[34](图5h);而边缘区不仅有滑移台阶,还存在大量亚微米级的拉长韧窝(图5i)。这说明,单轴扭转样品中心区的断裂机理为滑移分离,而边缘区的断裂则由滑移分离和韧窝穿晶2种机理共同主导。由图5j可见,尽管PRTEN-20样品的宏观断口呈一个平面,但存在大面积粗糙区域,这说明材料变形并非由单纯剪切应力导致;中心区存在大量韧窝,且韧窝凸起方向与剪切应力方向一致(图5k);而边缘区存在明显的滑移台阶和大量亚微米级的拉长韧窝(图5l)。综上表明,预扭转拉伸样品主要为韧窝穿晶断裂,而预拉伸扭转样品存在滑移分离和韧窝穿晶2种断裂机理。由此可见,在不同加载方式下镍基高温合金的断裂机理明显不同,且样品不同区域的主导断裂机理也有差异。

图5

图5

拉伸和扭转断裂样品断口形貌的SEM像

Fig.5

Low magnification SEM images (a, d, g, j) for specimens after fracture, and the corresponding high magnification images for the center (b, e, h, k) and edge (c, f, i, l) areas that are marked by open squares in low magnification images for PRTOR-0 (a-c), PRTOR-360 (d-f), PRTEN-0 (g-i), and PRTEN-20 (j-l) specimens

断口形貌分析结果表明,拉伸-扭转复合加载下样品变形需同时考虑拉应力和剪切应力的作用。因此,分析了多轴加载下圆柱状样品受力状态,并绘制了断裂示意图,如图6所示。根据Dowling[26]提出的理论,预扭转拉伸加载下材料断裂时,ψ与τ、拉应力(σ)的关系为tan2ψ = 2τ / σ。因此,τ随预扭转角度增加而增大,夹角ψ亦随之逐渐增大,与实验规律相符(图4a)。预拉伸扭转加载下材料断裂时,上述关系变为tan2ψ = |-σ / 2τ|。因此,σ随预拉伸应变增加而增大,ψ亦逐渐增大,与实测结果基本相符(图4b)。需指出的是,由于实际微观结构和受力情况的复杂性,Dowling理论仅适用于定性判断上述ψ 的变化趋势,而无法作定量预测分析。譬如,预加载产生的应力可能在随后变形过程中逐渐松弛[35]。镍基高温合金预拉伸扭转变形时,由于较大的扭转塑性,预拉伸产生的应力可能在材料扭断之前就已完全释放。因此,PRTEN-0、PRTEN-5和PRTEN-20样品的断裂面与剪切面夹角接近0° (见图4b)。

图6

图6

多轴加载下样品断裂与样品侧表面某点受力分析示意图

Fig.6

Schematic of the fracture of specimens under tension-torsion loading (a) and the force analysis at one point in the lateral surface (σ and τ represent the tensile and shear stresses on the fracture plane, respectively; σy and σz denote the normal stresses perpendicular to XZ and XY planes, respectively; τzy and τyz represent the shear stresses within XY and XZ planes, respectively) (b)

2.3 中子衍射结果与位错密度分析

图7给出了变形前后拉伸和扭转样品的中子衍射实测全谱。由图7a可见,未变形和断裂样品均主要由γ相组成。与未变形样品相比,不同加载方式下变形断裂样品的衍射峰出现了较明显的位移和宽化现象(图7b),说明加载变形导致了晶格畸变和微观结构变化。Rietveld精修分析结果(表1)显示,未变形样品、PRTOR-0、PRTOR-360、PRTEN-0和PRTEN-20样品的晶格常数依次为0.35977、0.35972、0.35984、0.35987和0.35995 nm (误差均约为0.00001 nm)。需注意的是,由于中子衍射实验时散射矢量平行于样品径向,图7a所示衍射全谱数据来自于径向取向晶粒簇的贡献。比较可见,单轴拉伸使径向晶格常数减小,单轴扭转则使其增大。前者是因为拉伸过程中试样沿轴向伸长、沿径向收缩;后者则是因为扭转过程中晶格沿剪切应力方向被拉长。此外,对于PRTOR-360样品,预扭转产生剪切应变的同时还导致拉伸塑性降低,因此其径向晶格常数比PRTOR-0样品大;而对于PRTEN-20样品,扭转导致的剪切应变增量大于预拉应变,所以其晶格常数大于PRTEN-0。

图7

图7

变形前后拉伸和扭转样品的中子衍射全谱

Fig.7

Neutron diffraction patterns (a) as well as the partial enlargement of square area in Fig.7a (b) for the undeformed specimen and those deformed PRTOR and PRTEN specimens under different loading modes

表1 变形前后拉伸和扭转样品的晶格常数和位错密度

Table 1

| Specimen | Lattice parameter / nm | Dislocation density / (1014 m-2) |

|---|---|---|

| Undeformed | 0.35977 | 0.5 ± 0.2 |

| PRTOR-0 | 0.35972 | 5.9 ± 0.9 |

| PRTOR-360 | 0.35984 | 4.6 ± 0.4 |

| PRTEN-0 | 0.35987 | 10.8 ± 0.7 |

| PRTEN-20 | 0.35995 | 8.2 ± 0.8 |

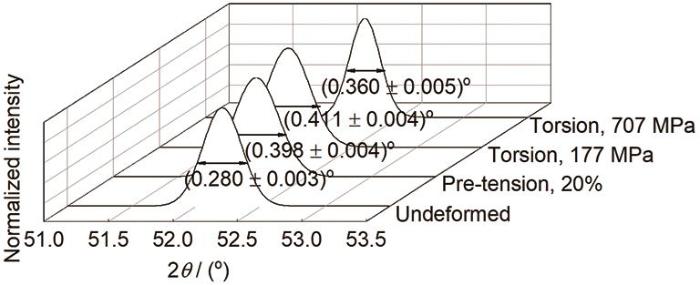

图8为不同衍射峰对应(ΔK)2与K2C数据的线性拟合结果。可见,数据点相较于拟合直线出现了一定偏移,这可能与实际情况下应变分布各向异性相关[36],这里分析不予考虑。拟合结果显示,初始未变形样品、PRTOR-0、PRTOR-360、PRTEN-0和PRTEN-20变形断裂样品的斜率分别约为2.1 × 10-5、2.4 × 10-4、1.8 × 10-4、4.4 × 10-4和3.3 × 10-4。根据Prasad等[37]计算得到的q = 1.5015和Ch00= 0.1945,进一步计算出不同加载方式下变形前后拉伸和扭转样品的位错密度,结果也列于表1中。可见,初始样品、PRTOR-0、PRTOR-360、PRTEN-0和PRTEN-20变形断裂样品的位错密度依次约为0.5 × 1014、5.9 × 1014、4.6 × 1014、10.8 × 1014和8.2 × 1014 m-2。相比于未变形样品,变形断裂后材料内部的位错密度均明显增大;多轴加载下样品的位错密度相比于单轴加载情形略有变小。图9给出了预拉伸扭转过程中试样(200)晶面衍射峰的原位观测结果。由图可见,未变形、预拉应变20%、扭转应力177 MPa (弹性阶段,见图2c)和707 MPa (塑性阶段,见图2c)下的(200)峰宽分别为0.280°、0.398°、0.411°和0.360°。这说明,预拉伸扭转过程中(200)衍射峰依次出现宽化和变窄现象,即加载后试样的衍射峰宽均大于未变形试样,而扭转至塑性时衍射峰宽则小于预加载状态。

图8

图8

变形前后拉伸和扭转样品的不同衍射峰对应(ΔK)2与K2C数据的线性拟合结果

Fig.8

Linear fitting curves of (ΔK)2 and K2C for undeformed (a), PRTOR-0 (b), PRTOR-360 (c), PRTEN-0 (d), and PRTEN-20 (e) specimens (K, ΔK, and C denote the length of reciprocal lattice vector, peak broadening, and average contrast factor, respectively)

Yang等[17]和Polatidis等[18]的研究表明,预变形将在材料内部产生大量位错。而Zhao等[38]和Wang等[39]发现,当预变形样品在其他方向上发生塑性变形时,新增变形将产生“新位错”;同时,由于“新位错”中存在与“旧位错”符号相反的位错,2者相遇时预变形产生的“旧位错”将发生湮灭。本工作中,复合加载下预变形阶段使样品内部产生一定的初始位错或“旧位错”;在随后的加载变形过程中,这些“旧位错”将被塑性变形增殖产生的“新位错”所湮灭。上述(200)峰原位实验规律(图9)一定程度上反映了位错增殖和湮灭过程。当 “旧位错”的湮灭速率大于“新位错”的产生速率时,最终的总位错密度减小。图10给出了单轴和预扭转拉伸样品位错形态的TEM像。可见,单轴拉伸样品内部大量位错相互缠结形成位错胞结构;与之相比,预扭转拉伸样品的位错较少。TEM表征结果再次印证了位错湮灭效应。

图9

图9

预拉伸扭转过程中试样(200)晶面衍射峰的动态变化

Fig.9

Development of the reflection (200) during torsion process at the pre-tension loading

图10

图10

单轴和预扭转拉伸样品的TEM像

Fig.10

TEM images for PRTOR-0 (a) and PRTOR-360 (b) specimens

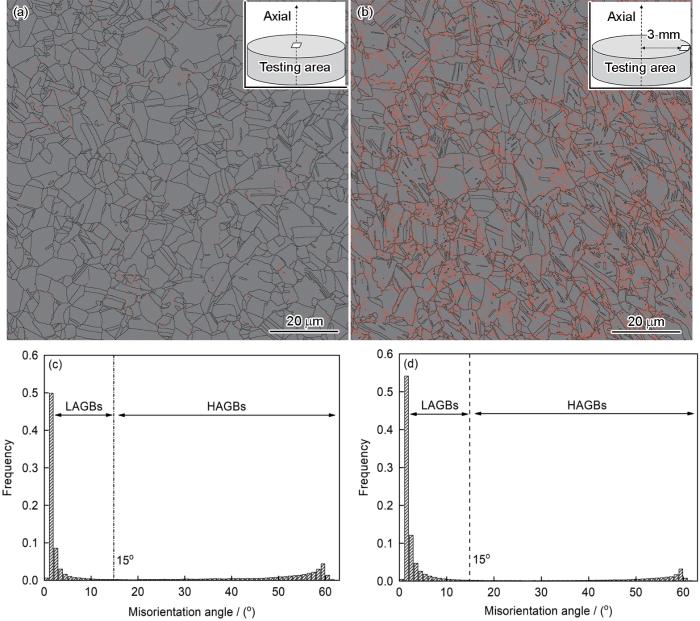

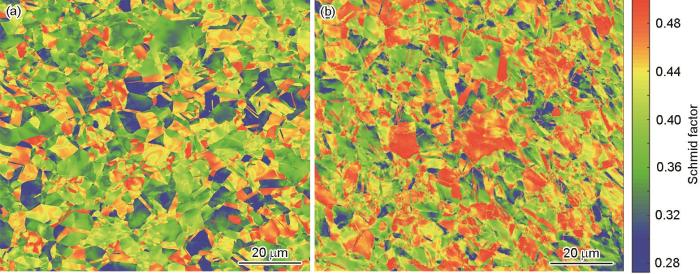

根据位错理论[40~42],材料强度将随位错密度增大而增强。位错密度对强度产生的增量为∆σ = αGbρ1/2(其中,α为增强系数,G为剪切模量)。样品在屈服阶段前的初始位错密度随预变形量增加而增大,因此PRTEN-20样品的屈服强度高于PRTEN-0样品。上述结果显示,由于位错湮灭效应,变形断裂样品PRTEN-20的最终位错密度小于PRTEN-0样品,所以其极限强度小于PRTEN-0样品。然而,对于拉伸变形断裂样品,尽管PRTOR-360样品的总位错密度小于PRTOR-0样品,但前者的极限强度却大于后者,基于上述位错理论无法解释。为进一步理解该现象,利用EBSD表征分析了PRTOR-360样品中心和边缘不同区域的晶界分布情况,结果如图11所示。图11a和b中的黑色和红色线分别表示高角度(> 15°)和低角度(< 15°)晶界。可见,PRTOR-360样品边缘区域晶界分布明显不同于中心区域,即前者低角度晶界更多。取向差分布图定量地反映了这一规律,即边缘区域的低角度晶界明显多于中心区域。譬如,在样品中心区域取向差角度约2°的晶界比例略低于0.5 (图11c),而样品边缘区域这类晶界比例明显高于0.5 (图11d)。考虑到低角度晶界基本由位错组成[26,40],可知PRTOR-360样品边缘区域存在大量位错,而中心区域的位错较少。图12为 PRTOR-360样品中心和边缘区域的Schmid因子分布图。计算时基于切向力模型,结果取所有滑移系Schmid因子最大值。可见,边缘区域Schmid因子总体上大于中心区。这表明,在扭转过程剪切应力作用下边缘区位错容易形成和开动。由于多晶粒协调变形,这些位错可能在晶界附近或应力集中区域聚集[43~45],进而造成边缘区位错密度较大。

图11

图11

PRTOR-360样品不同区域的晶界和取向差分布图

Fig.11

Grain boundary maps (a, b) and misorientation distribution profiles (c, d) of center (a, c) and edge (b, d) areas for PRTOR-360 specimens (Insets in Figs.11a and b show schematically the positions of sampling point or testing area. The red and black lines represent the low angle (< 15°) grain boundaries (LAGBs) and high angle (> 15°) grain boundaries (HAGBs), respectively)

图12

图12

预扭转拉伸样品的Schmid因子分布图

Fig.12

Schmid factor maps of center (a) and edge (b) areas for PRTOR-360 specimen

综上分析,预扭转样品形成了一种位错差异化分布的梯度结构。研究[23,24]表明,在此类梯度结构中,由于位错与层错或孪晶之间的相互作用、以及预变形导致的背应力,将导致材料强度明显提升。当梯度结构对材料强度的强化作用大于总位错密度减小(即位错湮灭)对强度的弱化效应时,材料的极限强度将依然增加。因此,预扭转形成的梯度结构可能是PRTOR-360样品的屈服强度和极限强度高于PRTOR-0样品的主要原因。需要说明的是,上述基于位错密度的强度增量公式通常仅适用于单轴加载情形[46,47]。由于拉伸-扭转复合加载下涉及位错和梯度结构2种强化作用,而后者对于强度的影响比较复杂,目前尚未确立定量关系[23,24]。此外,关于位错类型,考虑到试样为晶粒尺寸约10 μm (图11a和b)的多晶材料,在拉伸作用下,由于大量晶界存在导致的塑性应变梯度,变形早期主要为几何必需位错(GND);统计储存位错 (SSD)则随应变而逐渐增长,在变形后期SSD将和GND共同起主导作用[48]。在扭转作用下,由于径向应变非均匀性,试样中心以GND强化为主,边缘区则同时包含GND和SSD强化[49]。考虑到GND的Burgers矢量不为零、具有方向性,复合加载下发生湮灭的可能主要为GND。分析可见,拉伸-扭转复合加载下2类位错对材料性能可能均有重要作用。上述位错、梯度结构与材料力学性能之间的定量联系将是后续工作值得深入研究的关注点。

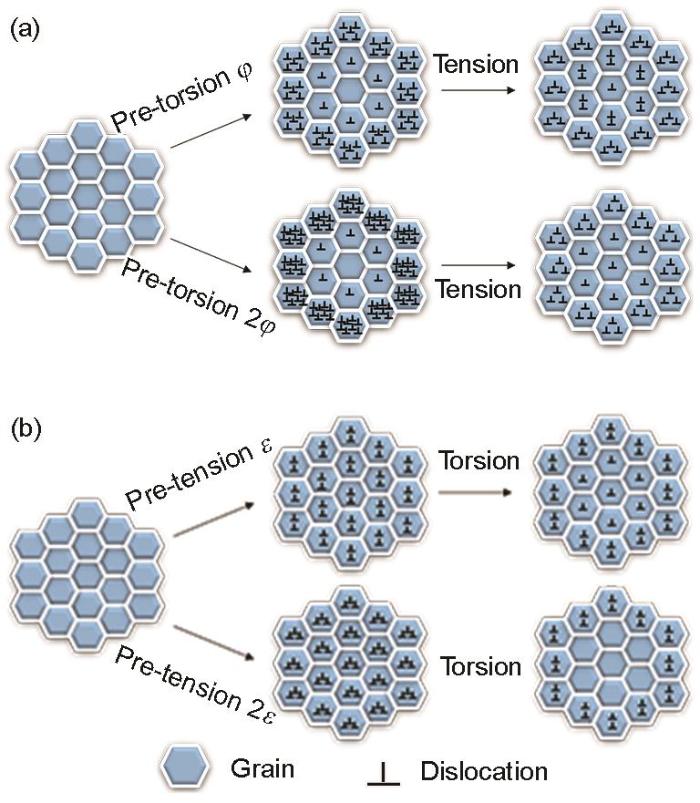

2.4 多轴加载变形机理

综上结果分析,绘制了不同预加载方式下样品微观变形机理示意图,如图13所示。当初始样品进行预扭转加载(扭转角为φ)时,在剪切应力作用下材料发生扭转变形,样品边缘处将产生大量位错,而中心区产生较少位错,从而形成了位错梯度结构。随着扭转角度增加,此类梯度结构将更为明显[21~23]。在随后的拉伸加载变形过程中,由于位错湮灭效应,样品中的总位错密度降低;且预扭转角度越大(如扭转角为2φ),位错密度的降低程度也越大,如图13a所示。在预扭转拉伸加载下,由于预变形产生的初始位错的强化效应使屈服强度得以提升;预扭转形成梯度结构的强化作用一定程度上抵消了位错湮灭效应对材料强度的削弱影响,因此极限强度随预扭转变形程度增加而增强。

图13

图13

不同预加载方式下样品微观变形机理示意图

Fig.13

Schematics of microscopic deformation mecha-nism under pre-torsion (φ—torsion angle) (a) and pre-tension (ε—strain) (b) modes

如图13b所示,当初始样品进行预拉伸加载(预拉应变为ε)时,将在样品内部产生比较均匀的位错,且位错密度随着预拉应变增加(如预拉应变为2ε)而增大;在随后的扭转加载变形过程中,样品中的总位错密度降低,且位错密度降低程度随预拉应变增加而增大。在这种预拉伸扭转加载方式下,初始位错的强化效应使屈服强度得以提升,而随后复合加载下的位错湮灭效应使样品极限强度有所降低。

综上可见,预拉伸扭转样品的强度主要受位错密度影响,而预扭转拉伸样品的强度还与形成的梯度结构密切相关。上述研究结果不仅可丰富多轴复杂应力加载条件下高温合金变形机理的理解,还可增加高强高韧性合金设计与开发思路。譬如,通过设计匹配拉伸、扭转等不同复合或多轴加载方式,可对高温合金内部初始微观结构以及变形机理进行调控,基于梯度或分级结构实现材料强度和韧性的综合强化。

3 结论

(1) 多晶镍基高温合金GH4169的力学性能明显依赖于拉伸-扭转复合加载方式。随预扭转角度增加,拉伸样品屈服强度和极限强度均增大(增幅分别约150%和13%),延伸率和加工硬化率则逐渐减小;在20%预拉应变下,扭转样品屈服强度和延伸率均有所增大(增幅分别约31%和16%),极限强度和加工硬化率则逐渐减小。拉伸样品主要呈韧窝穿晶断裂,而扭转样品则主要为滑移分离和韧窝穿晶断裂;且随着预变形程度增加,断裂面与横截面间的夹角逐渐增大。

(2) 加载方式对晶格畸变和位错密度演化均产生重要影响。由于拉应力和剪切应力的作用,拉伸和扭转分别导致径向晶格间距减小与增大。相比于未变形样品,拉伸和扭转变形后样品内部位错密度明显增大;同时复合加载下样品的位错密度相对于单轴加载情形略小,表明存在一定程度的位错湮灭,即预加载形成的初始位错被塑性变形产生的位错抵消。

(3) 预拉伸扭转样品的强度主要受位错密度影响,而预扭转拉伸样品的强度还与形成的梯度结构有关。预加载产生初始位错的强化效应使屈服强度得以提升,而随后复合加载下的位错湮灭效应使预拉伸扭转样品的极限强度有所降低。而对于预扭转拉伸样品,预扭转形成的梯度结构的强化作用一定程度上抵消了位错湮灭效应的影响。

参考文献

Portevin-Le Châtelier effect in wrought Ni-based superalloys: Experiments and mechanisms

[J].The Portevin-Le Chatelier (PLC) effect is a plastic instability in alloys at certain strain rates and deformation temperatures. This plastic instability exhibits serrated yielding in the temporal domain and strain localization in the spatial domain. Wrought Ni-based superalloys often exhibit the PLC effect. To guarantee the safe and stable operation of equipment, it is important to study the PLC effect in wrought Ni-based superalloys. This paper provides a review of various experimental phenomena and micromechanisms related to the PLC effect in wrought Ni-based superalloys, which have been reported in various publications in recent years and include work from our own group. The influences of stacking fault energy and γ′ precipitates on the PLC effect in wrought Ni-based superalloys are also discussed in detail. Additionally, several suggestions for the future study of the PLC effect in wrought Ni-based superalloys are provided.

Research and development in materials and processes of superalloy fabricated by laser additive manufacturing

[J].The research and development progress of laser additive manufacturing technology in superalloys are summarized in this paper. The technical characteristics and application of additive manufacturing in superalloys, formation mechanism, and the types of microstructure and metallurgical defects are introduced in detail. Moreover, the defect control methods of additive manufacturing of superalloys are summarized from the aspects of laser parameters and composition design, and the direction of laser process parameter optimization and composition optimization is clarified. Finally, the future development trend and research direction of laser additive manufacturing in superalloys are summarized and prospected from the aspects of process optimization and material design.

激光增材制造高温合金材料与工艺研究进展

[J].概述了激光增材制造技术在高温合金中的进展。介绍了增材制造高温合金的技术特点和应用、微观组织及冶金缺陷的形成机制与种类,并从激光参数以及成分设计2个方面综述了增材制造高温合金的缺陷控制方法,明确了激光工艺参数优化与成分优化的方向。最后,从工艺和材料2个方面对激光增材制造在高温合金中的未来发展趋势与研究方向进行了展望。

Comparison of intergranular strain formation of conventional and newly developed nickel based superalloys

[J].

CRSS of γ /γ ′ phases from in situ neutron diffraction of a directionally solidified superalloy tension tested at 900℃

[J].

Evidence of variation in slip mode in a polycrystalline nickel-base superalloy with change in temperature from neutron diffraction strain measurements

[J].

On the γ ′ precipitates of the normal and inverse Portevin-Le Châtelier effect in a wrought Ni-base superalloy

[J].

Life assessment of multiaxial thermomechanical fatigue of a nickel-based superalloy Inconel 718

[J].

Planar-biaxial low-cycle fatigue behavior of the nickel-base alloy Inconel 718 at elevated temperatures under selected loading conditions

[J].

A generalized fatigue damage parameter for multiaxial fatigue life prediction under proportional and non-proportional loadings

[J].

Mechanical twinning in Ni-based single crystal superalloys during multiaxial creep at 1050℃

[J].

A crystal plasticity investigation of slip system interaction, GND density and stored energy in non-proportional fatigue in nickel-based superalloy

[J].

The effects of stress triaxiality, temperature and strain rate on the fracture characteristics of a nickel-base superalloy

[J].

Mixed mode I/II crack growth investigation for bi-metal FSW aluminum alloy AA7075-T6/pure copper joints

[J].

On the roles of stress-triaxiality and strain-rate on the deformation behavior of AZ31 magnesium alloys

[J].

The multi-axial deformation behavior of bulk metallic glasses at high homologous temperatures

[J].

Mapping of texture and phase fractions in heterogeneous stress states during multiaxial loading of biomedical superelastic NiTi

[J].

The effect of pre-twinning on the mechanical behavior of free-end torsion for an extruded AZ31 magnesium alloy

[J].

The interplay between deformation mechanisms in austenitic 304 steel during uniaxial and equibiaxial loading

[J].

An outstanding synergy of high strength and ductility in gradient structured low-carbon steel

[J].

Enhancing the mechanical properties of low-carbon steel by a graded dislocation microstructure

[J].

Effect of torsion deformation on microstructure and mechanical properties of twin induced plasticity (TWIP) steel in Fe-Mn-Al-Si system

[D].

扭转变形对Fe-Mn-Al-Si系TWIP钢微观组织及力学性能的影响

[D].

Gradient hierarchical grain structures of Al0.1CoCrFeNi high-entropy alloys through dynamic torsion

[J].Al0.1CoCrFeNi high-entropy alloys are firstly processed by cyclic dynamic torsion (DT) using Split- Hopkinson Torsional Bar. Gradient hierarchical microstructures produced by DT are investigated using electron backscattered diffraction, transmission electron microscopy, and nanoindentation tests. Based on the gradient torsional strain, significant grain refinement, remarkable work hardening, and hierarchical deformation substructures are introduced into the current DT-HEAs. (C) 2018 Elsevier B.V.

Gradient cell-structured high-entropy alloy with exceptional strength and ductility

[J].\n For most alloys, conventional or high entropy, increasing strength comes at the cost of poor ductility. Although there are many strategies to break this inverse relationship, Pan\n et al\n. now show that cyclic torsion on a high-entropy alloy enhances strength without degrading ductility (see the Perspective by Yeh). Cyclic torsion creates a gradient of dislocations and low-angle grain boundaries from the surface to the interior that organize into tiny stacking faults and twin when straining begins. These structures allow for the good ductility while simultaneously helping to work harden the alloy. —BG\n

Enhanced high-temperature tensile property by gradient twin structure of duplex high-Nb-containing TiAl alloy

[J].

Latent hardening/softening behavior in tension and torsion combined loadings of single crystal FCC micropillars

[J].

Fenghuang: High-intensity multi-section neutron powder diffractometer at CMRR

[J].

GSAS-II: The genesis of a modern open-source all purpose crystallography software package

[J].The newly developedGSAS-IIsoftware is a general purpose package for data reduction, structure solution and structure refinement that can be used with both single-crystal and powder diffraction data from both neutron and X-ray sources, including laboratory and synchrotron sources, collected on both two- and one-dimensional detectors. It is intended thatGSAS-IIwill eventually replace both theGSASand theEXPGUIpackages, as well as many other utilities.GSAS-IIis open source and is written largely in object-oriented Python but offers speeds comparable to compiled code because of its reliance on the Python NumPy and SciPy packages for computation. It runs on all common computer platforms and offers highly integrated graphics, both for a user interface and for interpretation of parameters. The package can be applied to all stages of crystallographic analysis for constant-wavelength X-ray and neutron data. Plans for considerable additional development are discussed.

Neutron diffractometer RSND for residual stress analysis at CAEP

[J].

The effect of dislocation contrast on X-ray line broadening: A new approach to line profile analysis

[J].The x-ray line profiles of an ultrafine grained copper crystal, produced by equal-channel angular pressing, were measured by a special high resolution diffractometer with negligible instrumental line broadening. The analysis of the line breadths and the Fourier coefficients have shown that taking into account the contrast caused by dislocations on line profiles gives new scaling factors in the Williamson–Hall plot and in the Warren–Averbach analysis, respectively. When strain is caused by dislocations the new procedure proposed here enables a straightforward determination of particle size and strain, the latter in terms of the dislocation density.

The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice

[J].It has been shown recently that in many cases strain anisotropy in powder diffraction can be well accounted for by the dislocation model of the mean square strain. The practical application assumes knowledge of the individual contrast factorsCof dislocations related to particular Burgers, line and diffraction vectors or to the average contrast factorsC¯. A simple procedure for the experimental determination ofC¯has been worked out, enabling the determination of the character of the dislocations in terms of a simple parameterq. The values of the individualCfactors were determined numerically for a wide range of elastic constants for cubic crystals. TheC¯factors andqparameters were parametrized by simple analytical functions, which can be used in a straightforward manner in numerical analyses, ase.g.in Rietveld structure refinement procedures.

Effect of combined torsion and tension on the microstructure and fracture behavior of 316L austenitic stainless steel

[J].

Effect of microstructure on torsion properties of Ti-5Al-5Mo-5V-3Cr-1Zr alloy

[J].

Postcritical deformation of steels in plane stress state

[J].

A method to calculate the dislocation density of a TWIP steel based on neutron diffraction and synchrotron X-ray diffraction

[J].

基于中子衍射和同步辐射X射线衍射的TWIP钢位错密度计算方法

[J].

Synchrotron diffraction characterization of dislocation density in additively manufactured in 718 superalloy

[J].

The dislocation-based fatigue deformation mechanism of a RAFM steel under multi-axial loadings

[J].

The effect of reverse strain on microstructure and strengthening of copper fabricated by severe plastic deformation of torsion process

[J].

Strengthening and toughening mechanisms of precipitation-hardened Fe53Mn15Ni15Cr10Al4Ti2C1 high-entropy alloy

[J].

析出强化Fe53Mn15Ni15Cr10Al4Ti2C1高熵合金强韧化机制

[J].以fcc结构高熵合金为基础合金,通过添加Al、Ti和C元素,设计了新型析出强化Fe<sub>53</sub>Mn<sub>15</sub>Ni<sub>15</sub>Cr<sub>10</sub>Al<sub>4</sub>Ti<sub>2</sub>C<sub>1</sub>高熵合金。经过轧制后该合金含有纳米结构轧制条带(含有变形孪晶)和高密度位错结构。中温长时间热处理后该合金具有纳米结构非均匀组织,包括轧制条带、位错和大量的纳米析出相,表现出优异的强度-塑性匹配关系。该合金优异的力学性能是由于组织中与基体共格的L1<sub>2</sub>型析出相起到了显著的析出强化作用,使该合金强度明显提高;另一方面,高密度位错得到有效回复,改善了合金的应变硬化能力。采用中温长时间热处理可获得强度-塑性匹配优异的非均匀组织析出强化高熵合金。

Strain rate dependency of dislocation plasticity

[J].Dislocation glide is a general deformation mode, governing the strength of metals. Via discrete dislocation dynamics and molecular dynamics simulations, we investigate the strain rate and dislocation density dependence of the strength of bulk copper and aluminum single crystals. An analytical relationship between material strength, dislocation density, strain rate and dislocation mobility is proposed, which agrees well with current simulations and published experiments. Results show that material strength displays a decreasing regime (strain rate hardening) and then increasing regime (classical forest hardening) as the dislocation density increases. Accordingly, the strength displays universally, as the strain rate increases, a strain rate-independent regime followed by a strain rate hardening regime. All results are captured by a single scaling function, which relates the scaled strength to a coupling parameter between dislocation density and strain rate. Such coupling parameter also controls the localization of plasticity, fluctuations of dislocation flow and distribution of dislocation velocity.

The dislocation behaviour and GND development in a nickel based superalloy during creep

[J].

Evolution of dislocation density distributions in copper during tensile deformation

[J].

Relationship between dislocation structure characteristics at triple junction and grain orientation in high pure copper

[J].

Nonadditive strengthening functions for cold-worked cubic metals: Experiments and constitutive modeling

[J].

Dependence of dynamic yield stress of binary alloys on the dislocation density under high-energy impacts

[J].

Dislocation-type evolution in quasi-statically compressed polycrystalline nickel

[J].