作为过饱和固溶体,多主元合金被认为具有4种核心特性:高构型熵、缓慢扩散、剧烈晶格畸变、鸡尾酒效应[3]。基于对多主元合金具备高构型熵的认知,含有3种主元的合金常被称为中熵合金,主元超过3种的合金常被称作高熵合金。值得注意的是,由于多主元合金的高构型熵建立在假设各主元的原子半径相同且合金为理想固溶体的基础上,因此材料领域对于高构型熵是否为多主元合金的共性仍存在争议[5]。此外,由于其缓慢扩散的特性,多主元合金被认为在抗辐照[6]以及高温下的结构稳定性[7]方面具有良好的应用前景。与单主元合金不同,多主元合金内的各主元素浓度都很高,合金内单个原子通常被其他种类的元素围绕,邻近原子间的原子尺寸及电负性差异造成剧烈晶格畸变,进而带来显著的置换固溶强化效应。此外,多主元合金内元素间的焓相互作用使得合金内存在局域有序畴[8],即某些元素与相邻元素间存在聚集或相互排斥的倾向。局域有序畴与位错交互作用,使得多主元合金表现出与简单固溶体不同的位错动力学行为[9]。鸡尾酒效应是指通过往多主元合金中添加特定的元素以获得相应的性能,例如控制Cr或Al的含量以提高合金的耐腐蚀性能[10]。由于多种元素的添加,多主元合金表现出元素本征特性和元素间相互作用的复合效应。例如通过添加与其他主元的原子半径和电负性显著不同的元素,可以进一步增大多主元合金的晶格畸变,实现超高强度。例如CoNiV[11]、NbTaTiVZr[12]、CoCrNiFePd[13]合金就是巧妙地结合了多主元合金的剧烈晶格畸变与鸡尾酒效应,从而实现了超高强度。

此前多主元合金研究领域大多认为多主元合金中的元素随机分布,但近期研究人员借助原子分辨率的扫描透射电镜(STEM)分析发现,多主元合金的元素存在结构短程有序与化学短程有序。并且,多主元合金在原子尺度的局域成分波动为其带来了特殊的位错动力学行为。例如,在fcc结构FeCoCrNiPd合金[13]与bcc结构TiZrNbHf合金[14]中,原子尺度的局域成分偏聚阻碍位错运动,导致位错交滑移,并带来优异的塑性。bcc难熔多主元合金具备优异的中/高温力学性能,其在超过1200℃高温区间的力学性能超过了目前广泛使用的镍基高温合金(高于1200℃强度大幅下降),并且在中温区间(600~1000℃)出现强度-温度平台,而不是强度随温度升高而下降[15]。Wang等[16]发现bcc结构MoNbTi合金中,刃位错(而不是螺位错)在合金塑性变形过程中起到主导地位,这与传统bcc结构合金在室温下变形时螺位错运动占主导地位不同。bcc结构多主元合金中非螺位错起到的作用,从一定程度上解释了难熔多主元合金具有优异中/高温力学性能的原因。

由于多主元合金具备特殊的结构与优异的力学性能,研究人员在近10年研发出了大量新型多主元合金。除了调控多主元合金的成分,还通过调控合金的结构以进一步提升其力学性能,例如:双相合金[17,18]、孪生诱发塑性/相变诱发塑性(TWIP/TRIP)合金[19,20]、共晶合金[21,22]等。调控合金的结构还可以通过细化多主元合金晶粒从而引入高密度的缺陷(如晶界)以阻挡位错运动,大幅提升多主元合金的强度。当晶粒尺寸细化到100 nm以下时,即纳米结构多主元合金,合金通常具备超高强度。然而,高密度的晶界阻挡位错运动的同时,位错容易在晶界处塞积,应力集中导致裂纹生成,使得合金塑性降低,即:强度-塑性相互掣肘[23]。

本文从纳米结构多主元合金的强塑化研究存在的挑战出发,综述了剧烈塑性变形(severe plastic deformation,SPD)、物理气相沉积(physical vapor deposition,PVD)、机械合金化(mechanical alloying,MA)等纳米结构制备方法对多主元合金力学性能的影响。阐述了相关合金的跨尺度变形机制及塑性变形起源,并对未来纳米结构多主元合金的研发及机制分析进行了展望。

1 纳米结构多主元合金的制备与调控方法

1.1 剧烈塑性变形

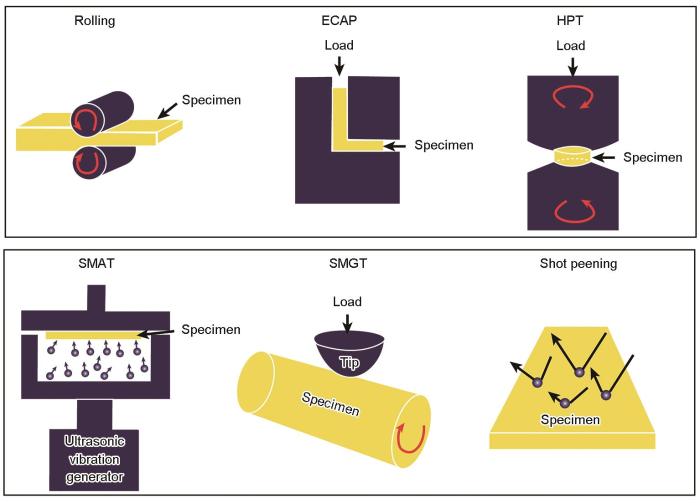

剧烈塑性变形常被用于制备纳米结构金属,通过对金属施加应力,使其发生塑性变形,变形过程中金属内产生大量位错,位错不断增殖并形成亚晶界。随着应变的增大,晶粒之间的取向差增大,小角晶界变为大角晶界,金属的晶粒被细化为超细晶或纳米晶[24]。剧烈塑性变形的特点之一是需要外界对金属施加较大的应力,促使其发生剧烈塑性变形从而获得高密度缺陷(位错、晶界)。常见的剧烈塑性变形方法示意图如图1所示。等径角挤压(equal-channel angular pressing,ECAP)是一类常用的剧烈塑性变形方法,通过在样品上施加压力,使样品通过特制模具发生大塑性变形,以达到晶粒细化的效果。Shahmir等[25]应用角度为110°的ECAP模具反复4次处理CoCrFeNiMn多主元合金,将合金晶粒尺寸由100 μm减小至100 nm。通过控制后续热处理的温度与时间,将合金结构由初始单相fcc结构调控为σ相分布在fcc基体中的双相结构[25]或fcc/hcp双相结构[26],其室温屈服强度可达1 GPa。

图1

图1

常见的剧烈塑性变形方法示意图

Fig.1

Schematics of severe plastic deformation (SPD) approaches for fabricating nanostructured multi-principal-element alloys (ECAP—equal-channel angular pressing, HPT—high pressure torsion, SMAT—surface mechanical attrition treatment, SMGT—surface mechanical grinding treatment)

使用反复扭转(cyclic torsion,CT)处理Al0.1-CoCrFeNi (原子分数,%)多主元合金[27],可以获得晶粒尺寸随着距离表面深度增大而增大的梯度结构,合金表面会形成纳米尺度的位错胞以及高密度的层错与孪晶。在塑性变形过程中,合金内的层错、孪晶与位错协同运动,可以为合金提供高塑性。因此,反复扭转处理后Al0.1CoCrFeNi合金的屈服强度由138 MPa提升至539 MPa,同时保持高均匀延伸率(43%)[27]。通过高压扭转(high pressure torsion,HPT)处理等原子比HfNbTaTiZr合金[28],当等效应变为50时,合金保持单相bcc结构,晶粒尺寸由铸造态的200 μm减小到80 nm;合金屈服强度由铸造态的1030 MPa提升至1480 MPa,延伸率略有降低,由铸造态的15%降低到了10%。值得注意的是,纳米晶HfNbTaTiZr合金在200℃仅退火20 min就出现了硬度提升,而粗晶HfNbTaTiZr合金在200℃退火300 min后硬度并未改变。这意味着纳米晶HfNbTaTiZr合金的热稳定性显著低于对应的粗晶合金,原因在于合金内部存在大量的晶界与位错作为扩散途径与形核点,促进了元素的重组以及合金的相分离。通过HPT处理得到的等原子比CoCrFeMnNi纳米晶合金(晶粒尺寸50 nm)也出现了类似的结构不稳定现象,在450℃退火5 min后发生了相分离,由初始的单相fcc结构变为了多相结构[29]。因此,热稳定性是纳米晶合金应用需要考虑的问题。

通过有意识地设计纳米晶多主元合金在加热过程中的结构演变,可以得到优异的力学性能。Nguyen等[30]使用HPT处理Al9(CoCrFeMnNi)91 (原子分数,%)合金,获得了纳米尺寸的fcc基体包含bcc有序相(B2)的结构,该合金具有2000%的超高延伸率,变形机制主要有:(1) 合金中生成了σ相,B2相与σ相的钉扎作用阻止了可能发生的晶粒长大,使得合金在1073 K下拉伸时发生晶粒细化;(2) 合金的fcc基体与B2晶粒内高密度位错的运动协调应变,容纳了较高的塑性变形。HPT处理过程中的温度可影响合金在塑性变形后的结构。在一定温度范围内,随着温度提高,位错活动增强,促进合金的晶粒细化。此外,随着HPT应变率的增大,合金的组织结构也会更加均匀。

应用表面处理方法,如表面机械研磨处理(surface mechanical attrition treatment,SMAT)、表面机械滚压(surface mechanical grinding treatment,SMGT)、喷丸(shot peening)、硬切削(hard turning)等,可以在复杂形状的样品上获得梯度纳米晶结构,即合金表面为纳米晶,晶粒尺寸随深度增加而增大。处理强度、处理时间等因素会影响处理后的合金结构。以喷丸为例,在一定范围内,提高喷丸强度和延长处理时间可有效提高纳米晶粒的分布深度。梯度纳米晶合金在塑性变形过程中,位于不同深度的晶粒由于尺寸不同会导致应变梯度的形成,可以促进几何必需位错(geometry necessary dislocation,GND)的生成与运动,从而使合金拥有良好的应变硬化能力以及拉伸塑性。并且,熔点相对较低的金属(例如Cu[31]和Mg[32])在塑性变形过程中,合金表层的纳米晶发生晶界迁移与晶粒长大,长大后的晶粒内的位错运动再加上芯部粗晶的位错运动协同作用可带来高强度与高拉伸塑性。此外,通过结合梯度纳米晶结构与异质多相结构,可以进一步提升多主元合金的强度与塑性。例如,在SMAT处理Al0.5Cr0.9FeNi2.5V0.2 (原子分数,%)合金后,将其进行热处理以促进生成L12与B2纳米析出相,可将合金的屈服强度由340 MPa提升至960 MPa,同时保持优异的延伸率(16%)[33];液氮温度(77 K)下对CoCrNi合金进行表面纳米晶化处理时,合金发生fcc-hcp相变,其强塑性优于在室温下进行纳米晶化处理但不发生fcc-hcp相变的CoCrNi合金[34]。

1.2 纳米结构多主元合金膜制备方法

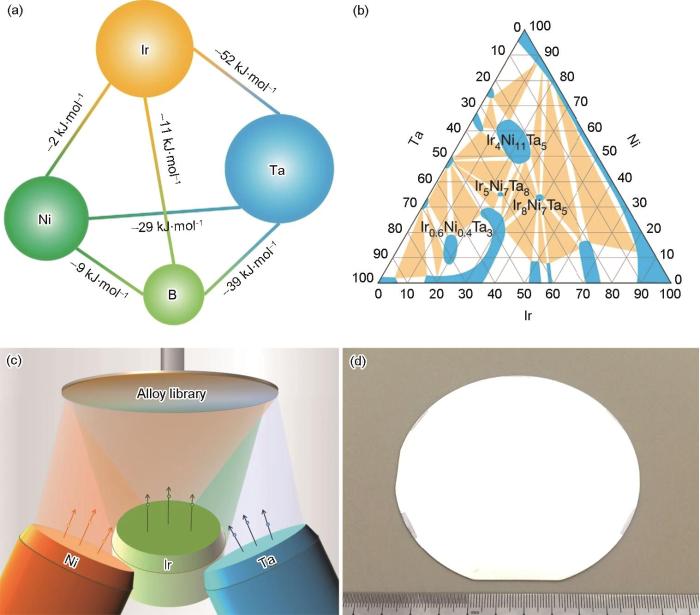

常用的多主元合金膜制备方法包括:磁控溅射、激光熔覆、热喷涂、电化学沉积等[35]。由于磁控溅射的冷却速率大于108 K/s,此方法制备出的晶态金属材料通常具备纳米级的晶粒尺寸[36],因此本章节以磁控溅射为例介绍纳米结构多主元合金膜。通过控制溅射的功率和时间,可以在基底上获得纳米级或微米级厚度的金属膜。磁控溅射法可以使用单个靶材或多靶共溅射。对于多靶共溅射系统,可以通过设计样品台,调整其与不同靶位之间的距离,样品台上靠近某一个靶材的区域将获得较高含量的此种靶材的成分。这样,在单次溅射中就可获得具备成分梯度的试样,即:单次溅射即可获得成千上万种成分的样品,符合高通量合金设计和性能筛选的理念(如图2[38]所示)。因此,高通量磁控溅射方法被用来高效筛选具备优异非晶形成能力[37]和热稳定性[38]的金属材料。由于多主元合金的成分空间巨大,使用高通量磁控溅射方法有助于加速开发具备优异强塑性的多主元合金[39]。

图2

图2

基于磁控溅射的高通量材料制备方法[38]

Fig.2

High-throughput material fabrication method based on magnetron co-sputtering[38]

(a) heat of mixing between the selected elements is shown and their relative size difference is indicated by spheres

(b) isothermal projection of the Ir-Ni-Ta ternary phase diagram

(c) schematic of magnetron co-sputtering

(d) appearance of the combinatorial thin-film materials library deposited on a 100-mm-diameter silicon wafer

使用磁控溅射制备的纳米晶NbMoTaW多主元合金在微柱压缩实验中屈服强度可达6.5 GPa[40],并且在600℃下保持高屈服强度(5 GPa)[41]。此外,由于采用磁控溅射方法制备的薄膜与基底的性能存在差异,例如热膨胀系数不同,因此薄膜存在内应力,导致其结构可能与熔融冶炼法制备的样品不同。更为重要的是,磁控溅射是一种非平衡态沉积过程,其制备出的材料结构与其相应平衡态块体材料的结构差异较大,因此使用磁控溅射方法制备纳米结构多主元合金时需要注意这一点。例如,熔融冶炼法制备的粗晶CoCrNi多主元合金为单相fcc结构[42],而磁控溅射法制备的纳米晶CoCrNi合金为fcc与hcp双相结构[43]。

1.3 机械合金化

机械合金化是指将不同成分的金属或合金粉末放置在高能球磨机中,利用机械能使粉末反复发生塑性变形、冷焊、断裂与扩散的固态合金化方法。机械合金化过程中的工艺参数包括:球磨时间、球料比、球磨转速、磨球直径等。研究[44]表明,使用直径为20 mm的研磨球和300 r/min的转速研磨粉末50 h,AlCoCuNiZn粉末混合物尚未完全合金化。但当研磨速率提高到350 r/min并使用不同尺寸(10~20 mm)的混合研磨球时,则会获得单相fcc合金。由于机械合金化过程为非平衡态,并且纳米级尺寸的粉末可促进元素的扩散,因此机械合金化常被用于制备常规方法难以合成的材料,也常被用于制备过饱和固溶体[45]。Varalakshmi等[46]于2008年首次使用机械合金化方法制备了多主元合金,通过高能球磨机处理Al、Fe、Ti、Cr、Zn和Cu粉末,随后将合金粉末进行静压固化,获得了晶粒尺寸约为10 nm的等原子比AlFeTiCrZnCu合金。Fu等[47]使用球磨与放电等离子烧结(SPS)方法制备了Co0.5FeNiCrTi0.5 (摩尔分数,%)合金,此合金在压缩实验中屈服强度高达2.65 GPa。由于通过球磨可以制备大量的合金粉末,而机械合金化可用于制备大尺寸的样品,此种制备方法对于多主元合金的工业应用具有重要意义。

2 纳米结构多主元合金的强塑化机制

2.1 细晶强化

金属材料的强度通常随晶粒尺寸的降低而增大,符合Hall-Petch关系[48,49]:H = H0 + kHPd-1/2 (其中,H为合金的硬度,H0为合金的本征硬度,kHP为Hall-Petch系数,d为晶粒尺寸)。Liu等[50]观察到FeCoNiCrMn多主元合金的Hall-Petch系数高于传统fcc结构合金,原因可能在于多主元合金的晶格畸变以及局域成分不均匀性导致位错滑移方式变为波浪滑移。随着纳米晶的尺寸进一步降低至特定区间,晶界运动在塑性变形中占据主导地位,合金可能发生晶界滑移或晶粒长大导致软化,出现反Hall-Petch效应[51]。Čížek等[28]在HPT处理的HfNbTaTiZr合金中观察到了反Hall-Petch现象,当等效应变为50时,晶粒尺寸为80 nm,屈服强度由铸造态的1030 MPa提升至1480 MPa;然而当应变进一步增大至> 100时,晶粒尺寸不会进一步减小,然而屈服强度随着等效应变的增大而减小。

为了进一步提升纳米结构合金的强塑性,许多研究致力于克服反Hall-Petch效应。通过晶界工程降低晶界能(例如使晶界弛豫或使溶质元素在晶界偏聚)可以稳定晶界,克服反Hall-Petch效应。Hu等[52]制备了Ni-Mo合金,通过适度地热处理以促进元素在晶界偏聚,成功降低了晶界能,在10 nm的晶粒尺寸区间进一步提升了Ni-Mo合金的硬度。类似地,通过引入B使其偏聚在VNbMoTaW纳米结构多主元合金的晶界,合金获得了5.7 GPa的超高屈服强度[53]。此外,使用纳米尺寸非晶相替换合金的晶界,制备晶体-非晶纳米双相合金,也是克服反Hall-Petch效应的有效方法。Wu等[54]制备了Cr-Co-Ni (hcp晶体相)/Ti-Zr-Nb-Hf-Cr-Co-Ni (非晶相)纳米片层晶体-非晶多主元合金,该合金在室温微米柱压缩实验中显示出超高屈服强度(3.6 GPa)和优异的均匀塑性变形能力(15%应变)。此纳米片层合金的晶体相在室温拉伸实验中发生hcp-fcc相变,同时,非晶相出现塑性流变行为,晶体相与非晶相协同变形,使合金具有高塑性。

细晶强化效应是纳米晶材料中重要的强塑化机制,在一定晶粒尺寸范围内,晶粒越细小,强度越高,塑性越好,符合合金的Hall-Petch现象。超过这一范围,往往会存在反Hall-Petch现象,这种现象主要是由于纳米晶的尺寸进一步降低,晶界不稳定性被放大,晶界运动在塑性变形中取代位错运动占据了主导地位,此时合金可能发生晶界滑移或晶粒长大导致软化。为了提高纳米结构合金强塑性,克服反Hall-Petch现象,还需科研人员进一步研究。

2.2 固溶强塑化与有序畴强塑化

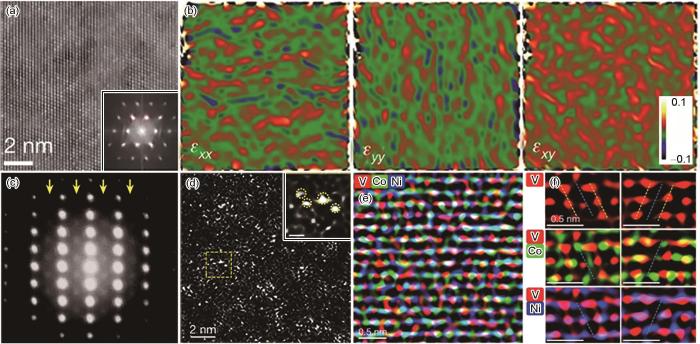

固溶强化是指通过往金属中引入原子半径和弹性模量与基体不同的元素,使材料的晶格发生畸变,从而增大晶格摩擦力,阻碍位错发射及运动,进而提升材料强度。固溶强化包括置换固溶强化与间隙固溶强化。传统的固溶强化规律多是针对稀固溶体,描述溶质与溶剂的交互作用及其带来的晶格应变。然而多主元合金为过饱和固溶体,没有溶质与溶剂的区别,因此,传统的固溶强化公式对于准确预测多主元合金强度存在局限性。目前效果显著的置换固溶强化方式是通过选择与其他组元差异较大的金属元素,以大幅提升多主元合金的固溶强化效应。例如,将CrMnFeCoNi合金中的Mn元素(Mullike电负性4.87)替换为Pd (Mullike电负性6.87),可将合金的屈服强度由410 MPa提升至604 MPa[13]。此合金内存在1~3 nm的局域成分波动(图3a和b[13]),增大了位错运动的阻力并促进位错发生交滑移,提升合金塑性变形能力。在NbTaTiV合金中添加相比于其他组元具有更大原子半径与更小电负性的Zr元素,增大原子半径差,导致晶格应变增大,可使合金的屈服强度由1.2 GPa提升至1.5 GPa[12]。

图3

图3

CrFeCoNiPd合金[13]和VCoNi合金[8]的原子尺度结构成分信息

Fig.3

Atomic-scale structural and chemical information of the CrFeCoNiPd[13] and VCoNi[8] alloys

(a) HAADF-STEM image of the CrFeCoNiPd alloy (Inset shows the corresponding selected area electron diffraction)[13]

(b) corresponding maps of horizontal normal strain (εxx ), vertical normal strain (εyy ), and shear strain (εxy ) of the CrFeCoNiPd alloy[13]

(c) nano-beam electron diffraction (NBED) pattern of the VCoNi alloy taken at [112] zone axis, the yellow arrows highlight the diffuse reflections at

(d) energy-filtered dark field TEM image of the VCoNi alloy taken using the diffuse reflections in Fig.3c (Inset is a magnified TEM image highlighting the coherently diffraction clusters corresponding to chemical short-range orders (CSROs))[8]

(e, f) EDS maps of the VCoNi alloy showing the elemental distributions of the alloy[8]

将CrCoNi合金中的Cr元素(原子半径0.1249 nm、Pauling电负性1.66)替换为V (原子半径0.1316 nm、Pauling电负性1.63),可以加剧多主元合金本身已经显著的晶格畸变,晶粒尺寸为6.5 μm的VCoNi合金[11]屈服强度高达近1 GPa,延伸率可达到38%。Chen等[8]通过纳米电子微区衍射(NBED)与原子分辨率的STEM及X射线能谱(EDS),分析了fcc结构VCoNi固溶体中的元素分布,直接观察到了固溶体中的化学短程序,并且解析了该化学短程序的尺寸、组分、三维构型。在[112]晶带轴使用NBED技术在

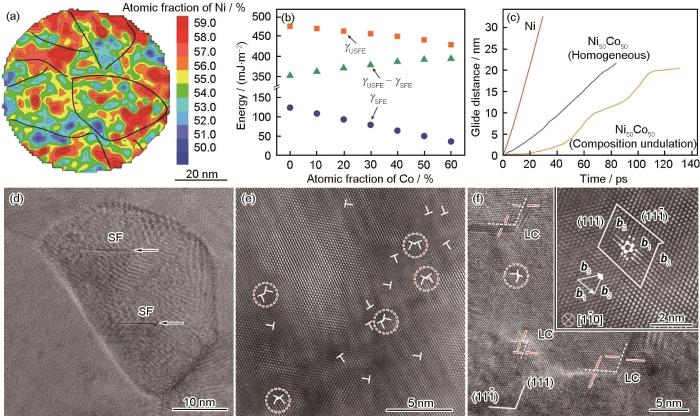

对于纳米结构金属,位错在晶界处形核后,极易穿过纳米尺寸晶粒,到达对面的晶界处后被晶界吸收。由于位错难以在纳米晶内部储存,晶粒内位错交互作用并增殖的概率大幅降低,限制了纳米结构金属的应变硬化能力[55]。多主元合金的剧烈晶格畸变与短程序,可阻碍位错运动,为合金提供较高的应变硬化能力。Li等[56]通过调控合金的不均匀性,设计制备了等原子比NiCo纳米晶合金,Ni与Co元素的原子尺寸与弹性模量接近,并且混合焓接近零,因此NiCo固溶体应处于接近化学无序的状态。Li等[56]使用电镀调控NiCo合金内的成分起伏(compositional undulation) (图4[56]),使得合金内不同区域具备不同的层错能,且层错能的差异较大,使位错运动受到阻碍。因此,即使此种NiCo合金的晶粒尺寸仅为26 nm,位错仍可在晶粒内存储与增殖。高密度的位错使得合金具备优异的应变硬化能力,因此,NiCo纳米晶合金具有超高强度(2.3 GPa)与良好的延伸率(16%)。

图4

图4

高强塑性NiCo纳米晶合金[56]

Fig.4

NiCo nanocrystalline alloy with ultrahigh strength and large ductility[56]

(a) atom probe tomography showing compositional undulation in the NiCo alloy

(b) stacking fault energy (γSFE), unstable stacking fault energy (γUSFE), and their difference as a function of Co content in the Ni-Co alloy

(c) glide distance as a function of time for a <110>/2 dissociated dislocation under a constant shear stress of

(d) HRTEM image of representative dissociated dislocations stored in the NiCo alloy after tension (SF—stacking fault)

(e) inverse fast Fourier-filtered image presenting Lomer locks (in red circles)

(f) HRTEM image showing Lomer locks (in red circles) and Lomer-Cottrell (LC) locks in the NiCo alloy after tension (Inset is the HAADF-STEM image showing the atomic structure of a representative Lomer lock. b1- b3 show the Burgers vectors)

原子半径小于0.1 nm的非金属元素,例如H、O、C、N、B,在合金中通常占据晶格的间隙位置。以bcc结构金属为例,间隙原子位于晶格的四面体间隙位置或八面体间隙位置。每个bcc晶胞中有6个八面体间隙位置,其尺寸为r0 = 0.155R (其中,r0为间隙位置的尺寸,R为金属原子的半径)[57]。每个bcc晶胞中有12个四面体间隙位置,其尺寸为r0 = 0.291R。间隙位置的尺寸通常小于间隙原子的半径,因此间隙原子导致晶格发生弹性应变,可以提升晶格摩擦力,从而提升金属强度[58]。Lei等[59]将2%O元素(原子分数)固溶在TiZrHfNb合金中,发现O原子倾向于占据Zr、Ti附近的间隙位置,生成尺寸1~3 nm的有序间隙化合物(ordered oxygen complexes)。此种有序间隙化合物钉扎位错,并通过促进位错交滑移以及生成Frank-Read位错源,造成高密度的位错运动。因此,仅2%O元素即可将TiZrNbHf合金的屈服强度提升48%,延伸率提升95%。此外,间隙原子的存在也会影响合金的层错能,例如Wang等[60]在Fe40.4Ni11.3Mn34.8Al7.5Cr6 (原子分数,%)合金中引入C原子,在提升晶格摩擦力的同时降低了层错能,导致位错运动的方式由波浪滑移转变为平面滑移,形成微带诱发塑性(microband induced plasticity,MBIP),使合金同时获得高强度与高塑性。

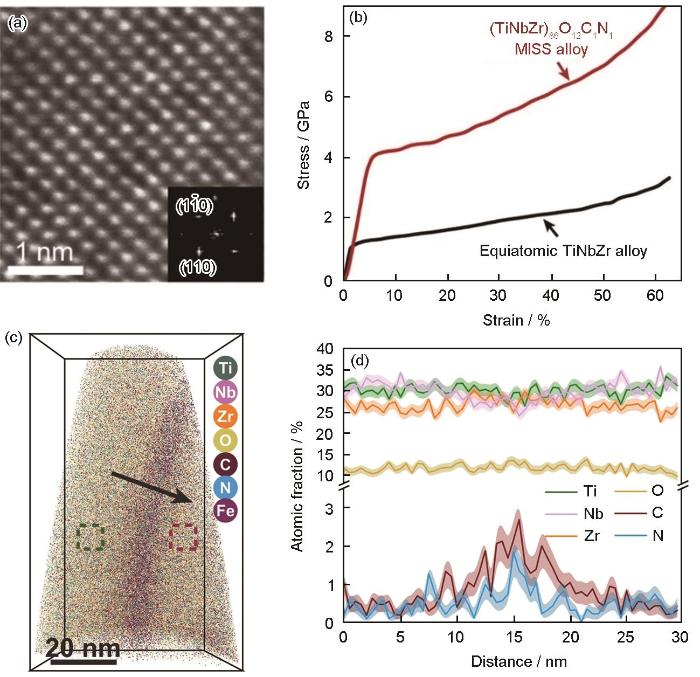

多主元合金为过饱和固溶体,其原子尺度的成分不均匀性导致局域晶格畸变,因此其间隙位置的尺寸并非理想情况,而是存在局域扩张与局域收缩。此外,临近间隙位置的组元不同造成的化学环境不同,也会影响间隙原子在晶格的占位。因此,多主元合金中间隙元素的固溶度以及间隙原子与位错的交互作用极有可能与稀固溶体不同。利用多主元合金这一特点,Liu等[61]将其作为基体固溶大量间隙元素,制备了大量间隙固溶合金。在TiNbZr合金中固溶12%O、1%C、1%N (原子分数),可将合金的屈服强度由1.3 GPa大幅提升至4.2 GPa (图5[61])。此合金的制备方法为磁控溅射,晶粒尺寸为40 nm,C、N偏聚于合金的晶界以降低晶界能,促进塑性变形过程中位错在晶内的增殖、存储与运动。因此,合金具备65%压缩均匀塑性。将置换固溶强化、间隙固溶强化与细晶强化结合,为开发具备超高强度与优异塑性的多主元合金提供了新思路。

图5

图5

(TiNbZr)86O12C1N1 合金的结构、成分和力学性能[61]

Fig.5

Structure, mechanical properties, and composition of the (TiNbZr)86O12C1N1 alloy

(a) HAADF-STEM image showing a bcc structure (Inset shows the corresponding selected area electron diffraction pattern)

(b) compressive engineering stress-strain curves of the alloys (MISS—massive interstitial solid solution)[61]

(c, d) atom probe tomography (APT) results[61]

多主元合金中剧烈的固溶强化效应可以大幅提高合金的强度,合金中的局部成分波动和有序结构也会阻碍位错运动,为合金提供较高的应变硬化能力,提高合金的强塑性。对多主元合金中的固溶元素和有序结构的调控,进而得到理想的力学性能和物理性能,成为目前多主元合金研究的热点。

2.3 第二相强塑化

在多主元合金中引入第二相是提升合金强塑性的常用方法之一。由于纳米结构合金中存在高密度的高能量界面,通过适度的热处理,此种合金内的高能量界面可作为形核点,促使生成高密度的纳米析出相[25]。将CoCrFeNiMn多主元合金先后在900及300℃下进行ECAP处理[26],合金结构由初始的单相fcc结构变为fcc/hcp双相结构。由于合金内高密度的相界与晶界有效地限制了位错的运动,该合金的室温屈服强度可达925 MPa。此外,将晶粒尺寸为50 nm的CoCrFeNiMn合金在450℃退火5 min,合金的成分分布出现不均匀,形成了新的富NiMn区和富Cr区。随着退火时间延长至15 h,合金发生晶粒长大,伴随着新的纳米尺寸富NiMn相、富Cr相与富FeCo相生成。此种纳米多相结构使合金硬度提高,由单相fcc纳米晶结构时的520 HV提升至630 HV[29]。此种纳米析出相虽然提升了CoCrFeNiMn纳米晶合金的强度,却降低了延伸率,导致合金塑性变形能力很差。CoCrFeNiMn纳米晶合金的断口内可观察到直径约500 nm的韧窝,而经过热处理获得纳米多相结构后,断口内韧窝直径大幅降低并伴随显著的沿晶断裂特征。对单相bcc结构的TiZrNbHfTa多主元合金进行HPT处理使其晶粒细化至约50 nm,合金具备超高强度(1.9 GPa)与高延伸率(7.9%)。将此纳米晶合金在500℃退火1 h[62],合金发生相分离,生成富NbTa的bcc相与富ZrHf的hcp相,强度下降至1.5 GPa,延伸率也下降至1.7%。

为了获得高强塑性的纳米结构多主元合金,需要调控第二相的成分与结构,使其既可以阻碍位错运动以提供应变硬化,同时又可以避免位错在界面处塞积导致的应力集中与裂纹生成。例如,经HPT处理的Al9(CoCrFeMnNi)91纳米晶合金,σ相在合金塑性变形过程中阻碍位错运动,提供应变硬化;同时合金内的纳米尺寸fcc晶粒与B2相内聚集了高密度的位错,通过晶内的位错运动为合金提供优异的塑性变形能力[30]。由此可见,在合金内引入至少2种不同强度的析出相,有望同时提升纳米结构多主元合金的强度与塑性。

2.4 TWIP、TRIP强塑化

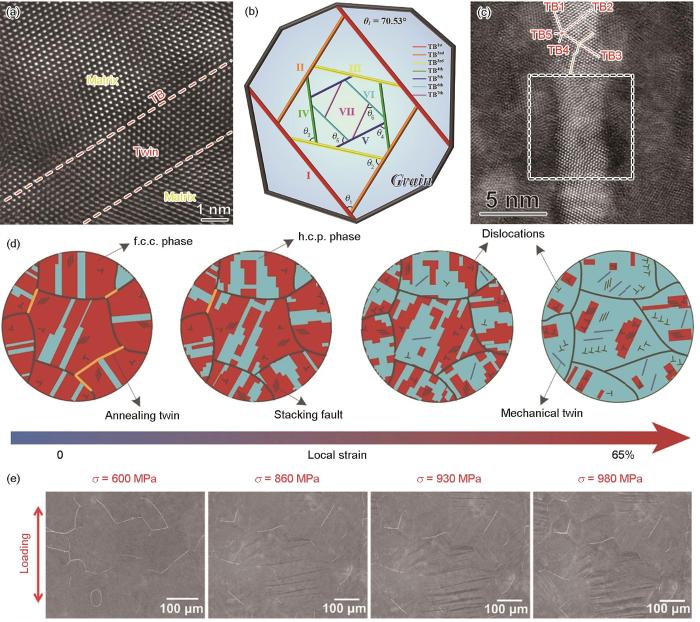

孪晶界一方面可以阻挡位错运动带来强化效应,另一方面,在合金发生屈服后,位错既可以在基体或孪晶中运动,也可以在孪晶界上攀移,因此TWIP效应为CoCrNi合金带来超高强度(1 GPa)与塑性(60%均匀延伸率)[42]。由于多主元合金的成分设计存在近无限的可能性,因此通过调控合金成分与热处理工艺,可以有效控制其析出相的成分、结构与体积分数,从而大幅提升合金在塑性变形过程中可承受的应力,在通常认为难以生成孪晶的高层错能合金中实现TWIP强塑化。例如,Wang等[63]研发了Fe-26Mn-16Al-5Ni-5C (原子分数,%)合金,其层错能约为79 mJ/m2,生成孪晶的临界应力为1.5~1.7 GPa。通过控制此合金内的B2相与κ碳化物相,使得合金在拉伸实验中可承受的应力达到1.9 GPa,从而在塑性变形过程中生成孪晶,实现TWIP强塑化(图6a[63])。

图6

图6

多主元合金中的孪生诱发塑性(TWIP)效应和相变诱发塑性(TRIP)效应[19,20,63,66,67]

Fig.6

Twinning induced plasticity (TWIP) and transformation induced plasticity (TRIP) behaviors for multi-principal-element alloys

(a) twining was observed in a high-stacking fault energy Fe-26Mn-16Al-5Ni-5C alloy[63] (TB—twin boundary)

(b) schematic of high-order twins[67] (Ⅰ-Ⅶ—the order of nanotwins, θi —the angle of different nanotwins)

(c) a nanostructured (CoCrNi)75Fe21Si2B2 alloy reveals five-order twins, which can serve as effect barriers against dislocation motion[66]

(d) schematics of the deformation mechanism for a TRIP dual-phase Fe50Mn30Co10Cr10 alloy[19]

(e) in situ SEM observations of the TRIP process in a Ta0.5HfZrTi alloy during continuous loading[20] (σ—tensile stress)

综上可知,将TWIP效应、TRIP效应与细晶强化、固溶强化结合,多种强化效应耦合作用对于获得超高强塑性的新型多主元合金具有巨大的潜力。

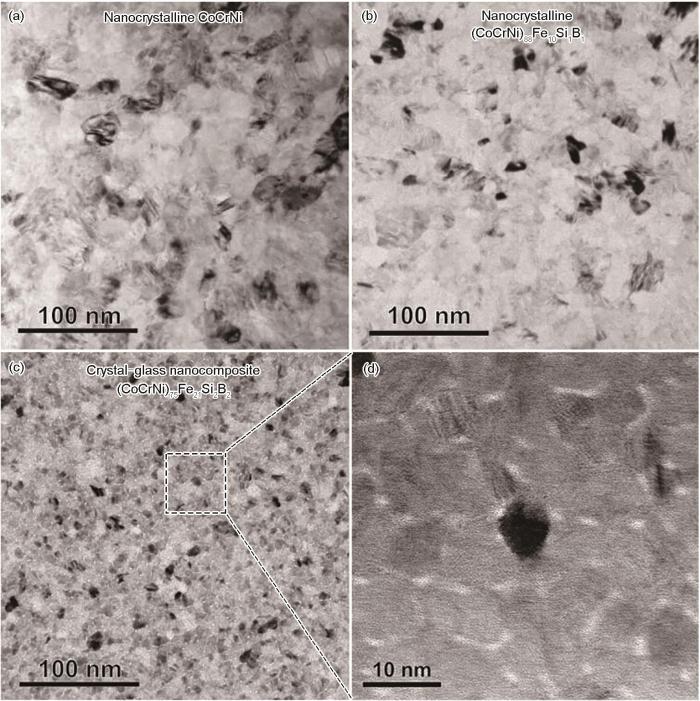

2.5 晶体-非晶纳米双相强塑化

非晶合金由于不具备长程有序的结构,因此通常有比对应晶态合金更高的屈服强度,然而非晶合金在塑性变形时极易发生脆性断裂,造成合金灾难性失效。非晶合金的力学性能存在明显的尺寸效应[68],当样品尺寸小于100 nm时,非晶合金的屈服强度可达到理论极限(约E / 10,E为弹性模量),并且塑性变形过程中会发生均匀流变[69,70]。因此,通过使用纳米尺寸的非晶相替代纳米结构合金的晶界,即制备晶体-非晶纳米双相合金,有助于避免纳米晶合金在变形过程中易出现的晶界运动(晶粒长大或晶界滑动)而导致的软化,从而获得超高强度[71]。另外,纳米尺寸非晶相的均匀塑性流变以及其与晶体相内位错运动的交互作用也有利于整体材料的均匀塑性变形。

设计晶体-非晶纳米双相结构多主元合金可以从控制组元之间的原子尺寸差异以及混合焓出发。当组元之间的原子尺寸差异较大且负混合焓较大时,合金易形成非晶结构[72]。通过在晶态多主元合金中引入非晶形成能力较高的元素,即与其他组元原子尺寸差异较大且负混合焓较高的元素,可以提升多主元合金的非晶形成能力[5]。例如在CoCrNiFe合金中加入Si、B,提高非晶形成能力。更为重要的是,Cr在界面处偏聚,增强了界面区域的负混合焓(Cr-Co、Cr-Fe、Cr-Ni混合焓为负),进一步提升了界面区域的非晶形成能力,导致部分晶界被非晶代替,因此随着Si、B含量增加,CoCrNi-Fe-Si-B合金由单相纳米晶结构变为晶体-非晶纳米双相结构(图7[66])。另一种获得晶体-非晶纳米双相多主元合金的方法是塑性变形,变形过程中位错大量累积直至破坏合金的晶格结构,导致合金结构出现局域非晶化,并带来额外的应变硬化效应[73]。

图7

图7

CoCrNi、(CoCrNi)88Fe10Si1B1和(CoCrNi)75Fe21Si2B2合金的TEM分析[66]

Fig.7

TEM images of the CoCrNi (a), (CoCrNi)88Fe10Si1B1 (b), and (CoCrNi)75Fe21Si2B2 (c) alloys[66] showing that the structure changes from nanocrystalline to crystal-glass dual-phase with increasing Si and B contents in the CoCrNi-Fe-Si-B alloys, and plane-view ABF-STEM image shows ≈ 1 nm-thick amorphous phase (brighter regions) appearing at triple points and along some grain boundaries (d)

当晶体-非晶纳米双相合金中的晶体相为固溶体时,位错在晶体相内或晶体-非晶界面处产生,穿过晶体相到达对面的晶体-非晶界面处,被晶体-非晶界面吸收;同时非晶相发生均匀塑性流变,促进晶体相与非晶相协同变形,从而实现超高强度与高塑性[74]。例如,Cr-Co-Ni (hcp晶体相)/Ti-Zr-Nb-Hf-Cr-Co-Ni (非晶相)纳米片层晶体-非晶多主元合金,其中两相的厚度约为10 nm,由于晶体相与非晶相的特征尺寸极小,以及存在高密度的异质界面,使得合金具备超高屈服强度(3.6 GPa)。该合金中的Cr-Co-Ni晶体相在室温拉伸下能发生hcp-fcc相变。同时,纳米尺寸非晶相在拉伸过程中可发生均匀塑性流变,因此,非晶相与晶体相协同变形为此双相合金带来优异的均匀塑性能力(室温微柱压缩实验15%应变)[54]。

通过使用纳米尺寸的非晶相替代纳米结构合金的晶界,制备晶体-非晶纳米双相合金,利用非晶结构固定晶界,从而避免纳米晶合金在变形过程中的晶界运动(晶粒长大或晶界滑动)而导致的软化,能够使合金获得超高强度。另一方面,纳米尺寸非晶相的均匀塑性流变及其与晶体相内位错运动的交互作用也有利于整体材料的均匀塑性变形,使合金获得良好的塑性。

3 纳米结构多主元合金的应用前景

随着材料基因工程的发展,如何高效地从海量样品中筛选出具备优异性能的新型材料成为材料领域的研究热点。通过设计调控磁控溅射靶材与基片之间的距离,在单次溅射中可获得具备成分梯度的样品(图2c[38]),因此使用高通量磁控溅射技术可以在短时间内制备成百上千种成分的样品[37,38]。基于磁控溅射方法的高通量材料设计、制备以及表征的关键难题在于如何选择靶材成分、设计靶位,以及针对海量样品的高效率表征。此外,磁控溅射过程中样品的冷却速率高达108 K/s[36],远高于制备块体合金的熔融冶炼方法。因此,将磁控溅射筛选出的合金成分用于制备块体样品时,应充分考虑到溅射与熔融冶炼方法在合金生长原理上的差异。Li等[37]应用热力学理论指导靶材设计,使用磁控溅射方法制备了大量样品,通过X射线衍射(XRD)方法快速筛选出非晶形成能力最高的合金成分后,将该成分用于块体合金制备。此种高通量材料设计、制备、表征方法对于研发纳米结构多主元合金具有借鉴和指导的意义。

4 结语及展望

(1) 多主元合金具备显著的置换固溶强化效应,通过在合金内引入高密度的界面,例如晶界、相界、孪晶界,制备纳米结构多主元合金,可以进一步提升合金的强度。显著的细晶强化和固溶强塑化、有序畴强塑化的耦合作用也成为纳米结构多主元合金的特性之一。

(2) 通过降低界面的自由能或者同时在合金内引入多种界面(即异质结构,例如晶体-非晶双相界面,第二相界面,孪晶界等),可以提升合金储存位错与促进位错增殖的能力,为合金带来优异的应变硬化能力以及塑性。虽然纳米结构合金具备优异的力学性能,然而合金内高密度的高能界面导致此种结构在加热或者受力时的稳定性较差。要实现纳米结构多主元合金的应用,需要提升此种合金的稳定性。

(3) 此外,多主元合金的过饱和固溶体特性使其得以作为基体固溶大量间隙元素,实现超高强度。多主元合金内的成分波动导致其表现出与单主元合金不同的位错动力学行为,此类具备剧烈晶格畸变的多主元合金,其内部溶质原子与位错的原子尺度交互作用尚有待阐明。

(4) 纳米多主元合金强度高,屈服强度一般都在吉帕级别,因此,塑性变形时的应力较大,可能带来不同的变形机制,例如在高层错能的纳米结构Al金属变形过程中出现了粗晶Al变形时不具备的变形孪晶现象[76]。因此,对纳米多主元合金的原子尺度表征、细晶强化和固溶强化的耦合效应对位错行为的影响机制,亟待科研工作者的进一步研究和发掘。纳米结构多主元合金的开发需要同时关注其热稳定性、强度和塑性。此外,由于多主元合金具备广阔的成分区间,亟需发展高通量材料设计、制备和表征方法,以高效地筛选出具备优异性能的合金。

参考文献

Microstructural development in equiatomic multicomponent alloys

[J].

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

High-entropy alloy: Challenges and prospects

[J].

More than entropy in high-entropy alloys: Forming solid solutions or amorphous phase

[J].

Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys

[J].A grand challenge in material science is to understand the correlation between intrinsic properties and defect dynamics. Radiation tolerant materials are in great demand for safe operation and advancement of nuclear and aerospace systems. Unlike traditional approaches that rely on microstructural and nanoscale features to mitigate radiation damage, this study demonstrates enhancement of radiation tolerance with the suppression of void formation by two orders magnitude at elevated temperatures in equiatomic single-phase concentrated solid solution alloys, and more importantly, reveals its controlling mechanism through a detailed analysis of the depth distribution of defect clusters and an atomistic computer simulation. The enhanced swelling resistance is attributed to the tailored interstitial defect cluster motion in the alloys from a long-range one-dimensional mode to a short-range three-dimensional mode, which leads to enhanced point defect recombination. The results suggest design criteria for next generation radiation tolerant structural alloys.

High temperature strength of refractory complex concentrated alloys

[J].Thermodynamic and mechanical properties of 15 single-phase and 11 multi-phase refractory complex concentrated alloys (RCCAs) are reported. Using the CALPHAD approach, phase diagrams for these alloys are calculated to identify the solidus (melting, T-m) temperatures and volume fractions of secondary phases. Correlations were identified between the strength drops at 1000 degrees C and 1200 degrees C and the alloy compositions, room temperature properties, melting temperatures and volume fractions of secondary phases. The influence of alloy density on the temperature dependence of specific yield strength was also explored. The conducted analysis suggests that the loss of high-temperature strength of single-phase BCC RCCAs is related to the activation of diffusion-controlled deformation mechanisms, which occurs at T >= 0.6 T-m, so that the alloys with higher T-m retain their strength to higher temperatures. On the other hand, a rapid decrease in strength of multi-phase RCCAs with increasing temperature above 1000 degrees C is probably due to dissolution of secondary phases. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Direct observation of chemical short-range order in a medium-entropy alloy

[J].

Short-range order and its impact on the CrCoNi medium-entropy alloy

[J].

Aqueous passivation of multi-principal element alloy Ni38Fe20Cr22Mn10Co10: Unexpected high Cr enrichment within the passive film

[J].

Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion

[J].

Lattice-distortion-enhanced yield strength in a refractory high-entropy alloy

[J].

Tuning element distribution, structure and properties by composition in high-entropy alloys

[J].

Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Multiplicity of dislocation pathways in a refractory multiprincipal element alloy

[J].Refractory multiprincipal element alloys (MPEAs) are promising materials to meet the demands of aggressive structural applications, yet require fundamentally different avenues for accommodating plastic deformation in the body-centered cubic (bcc) variants of these alloys. We show a desirable combination of homogeneous plastic deformability and strength in the bcc MPEA MoNbTi, enabled by the rugged atomic environment through which dislocations must navigate. Our observations of dislocation motion and atomistic calculations unveil the unexpected dominance of nonscrew character dislocations and numerous slip planes for dislocation glide. This behavior lends credence to theories that explain the exceptional high temperature strength of similar alloys. Our results advance a defect-aware perspective to alloy design strategies for materials capable of performance across the temperature spectrum.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys

[J].Precipitation-hardening high-entropy alloys (PH-HEAs) with good strength−ductility balances are a promising candidate for advanced structural applications. However, current HEAs emphasize near-equiatomic initial compositions, which limit the increase of intermetallic precipitates that are closely related to the alloy strength. Here we present a strategy to design ultrastrong HEAs with high-content nanoprecipitates by phase separation, which can generate a near-equiatomic matrix in situ while forming strengthening phases, producing a PH-HEA regardless of the initial atomic ratio. Accordingly, we develop a non-equiatomic alloy that utilizes spinodal decomposition to create a low-misfit coherent nanostructure combining a near-equiatomic disordered face-centered-cubic (FCC) matrix with high-content ductile Ni3Al-type ordered nanoprecipitates. We find that this spinodal order–disorder nanostructure contributes to a strength increase of ~1.5 GPa (>560%) relative to the HEA without precipitation, achieving one of the highest tensile strength (1.9 GPa) among all bulk HEAs reported previously while retaining good ductility (>9%).

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering

[J].

A promising new class of high-temperature alloys: Eutectic high-entropy alloys

[J].High-entropy alloys (HEAs) can have either high strength or high ductility, and a simultaneous achievement of both still constitutes a tough challenge. The inferior castability and compositional segregation of HEAs are also obstacles for their technological applications. To tackle these problems, here we proposed a novel strategy to design HEAs using the eutectic alloy concept, i.e. to achieve a microstructure composed of alternating soft fcc and hard bcc phases. As a manifestation of this concept, an AlCoCrFeNi2.1 (atomic portion) eutectic high-entropy alloy (EHEA) was designed. The as-cast EHEA possessed a fine lamellar fcc/B2 microstructure, and showed an unprecedented combination of high tensile ductility and high fracture strength at room temperature. The excellent mechanical properties could be kept up to 700 degrees C. This new alloy design strategy can be readily adapted to large-scale industrial production of HEAs with simultaneous high fracture strength and high ductility.

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals

[J].

Nanostructure formation mechanism of α-titanium using SMAT

[J].

Microstructure and properties of a CoCrFeNiMn high-entropy alloy processed by equal-channel angular pressing

[J].

Simultaneous deformation twinning and martensitic transformation in CoCrFeMnNi high entropy alloy at high temperatures

[J].

Gradient cell-structured high-entropy alloy with exceptional strength and ductility

[J].\n For most alloys, conventional or high entropy, increasing strength comes at the cost of poor ductility. Although there are many strategies to break this inverse relationship, Pan\n et al\n. now show that cyclic torsion on a high-entropy alloy enhances strength without degrading ductility (see the Perspective by Yeh). Cyclic torsion creates a gradient of dislocations and low-angle grain boundaries from the surface to the interior that organize into tiny stacking faults and twin when straining begins. These structures allow for the good ductility while simultaneously helping to work harden the alloy. —BG\n

Strength enhancement of high entropy alloy HfNbTaTiZr by severe plastic deformation

[J].

Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation

[J].

Ultrahigh high-strain-rate superplasticity in a nanostructured high-entropy alloy

[J].Superplasticity describes a material’s ability to sustain large plastic deformation in the form of a tensile elongation to over 400% of its original length, but is generally observed only at a low strain rate (~10−4 s−1), which results in long processing times that are economically undesirable for mass production. Superplasticity at high strain rates in excess of 10−2 s−1, required for viable industry-scale application, has usually only been achieved in low-strength aluminium and magnesium alloys. Here, we present a superplastic elongation to 2000% of the original length at a high strain rate of 5 × 10−2 s−1 in an Al9(CoCrFeMnNi)91 (at%) high-entropy alloy nanostructured using high-pressure torsion. The high-pressure torsion induced grain refinement in the multi-phase alloy combined with limited grain growth during hot plastic deformation enables high strain rate superplasticity through grain boundary sliding accommodated by dislocation activity.

Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper

[J].Nano-grained (NG) metals are believed to be strong but intrinsically brittle: Free-standing NG metals usually exhibit a tensile uniform elongation of a few percent. When a NG copper film is confined by a coarse-grained (CG) copper substrate with a gradient grain-size transition, tensile plasticity can be achieved in the NG film where strain localization is suppressed. The gradient NG film exhibits a 10 times higher yield strength and a tensile plasticity comparable to that of the CG substrate and can sustain a tensile true strain exceeding 100% without cracking. A mechanically driven grain boundary migration process with a substantial concomitant grain growth dominates plastic deformation of the gradient NG structure. The extraordinary intrinsic plasticity of gradient NG structures offers their potential for use as advanced coatings of bulk materials.

Nano-dual-phase metallic glass film enhances strength and ductility of a gradient nanograined magnesium alloy

[J].

Designing structures with combined gradients of grain size and precipitation in high entropy alloys for simultaneous improvement of strength and ductility

[J].

Shape-preserving machining produces gradient nanolaminate medium entropy alloys with high strain hardening capability

[J].

High entropy alloy coatings and technology

[J].Recently, the materials research community has seen a great increase in the development of multicomponent alloys, known as high entropy alloys (HEAs) with extraordinary properties and applications. In surface protection and engineering, diverse applications of HEAs are also being counted to benefit from their attractive performances in various environments. Thermally sprayed HEA coatings have outperformed conventional coating materials and have accelerated further advancement in this field. Therefore, this review article overviews the initial developments and outcomes in the field of HEA coatings. The authors have also categorized these HEA coatings in metallic, ceramic, and composite HEA coatings and discussed various developments in each of the categories in detail. Various fabrication strategies, properties, and important applications of these HEAs are highlighted. Further, various issues and future possibilities in this area for coatings development are recommended.

Nanostructured Zr-Pd metallic glass thin film for biochemical applications

[J].Zr-Pd metallic glassy thin films with a hierarchical nano-scale structure, produced by magnetron sputtering of the Zr and Pd powder mixture, demonstrate a unique combination of physical and biochemical properties. Thermal stability of the nano-structured glassy samples, their resistance to oxidation in dry air and phase transformation behavior are discussed in the present work. These binary alloy samples also show exceptionally high corrosion resistance and spontaneous passivation in a simulated body fluid. Experiments on the catalytic activity and biocompatibility of this nanostructured metallic glass indicate that this is a very suitable material for biochemical applications. Compared to the multicomponent alloys studied earlier this binary alloy has much simpler chemical composition, which makes preparation of the sample with defined stoichiometry easier, especially when the elements have different sputtering rates.

Data-driven discovery of a universal indicator for metallic glass forming ability

[J].

High-temperature bulk metallic glasses developed by combinatorial methods

[J].

High-entropy films and compositional gradient materials

[J].

高熵薄膜和成分梯度材料

[J].

Ultrastrong ductile and stable high-entropy alloys at small scales

[J].Zou, Yu; Ma, Huan; Spolenak, Ralph ETH, Dept Mat, Lab Nanomet, CH-8093 Zurich, Switzerland.

Nanocrystalline high-entropy alloys: A new paradigm in high-temperature strength and stability

[J].Metals with nanometer-scale grains or nanocrystalline metals exhibit high strengths at ambient conditions, yet their strengths substantially decrease with increasing temperature, rendering them unsuitable for usage at high temperatures. Here, we show that a nanocrystalline high-entropy alloy (HEA) retains an extraordinarily high yield strength over 5 GPa up to 600 °C, 1 order of magnitude higher than that of its coarse-grained form and 5 times higher than that of its single-crystalline equivalent. As a result, such nanostructured HEAs reveal strengthening figures of merit-normalized strength by the shear modulus above 1/50 and strength-to-density ratios above 0.4 MJ/kg, which are substantially higher than any previously reported values for nanocrystalline metals in the same homologous temperature range, as well as low strain-rate sensitivity of ∼0.005. Nanocrystalline HEAs with these properties represent a new class of nanomaterials for high-stress and high-temperature applications in aerospace, civilian infrastructure, and energy sectors.

Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy

[J].Combinations of high strength and ductility are hard to attain in metals. Exceptions include materials exhibiting twinning-induced plasticity. To understand how the strength-ductility trade-off can be defeated, we apply in situ, and aberration-corrected scanning, transmission electron microscopy to examine deformation mechanisms in the medium-entropy alloy CrCoNi that exhibits one of the highest combinations of strength, ductility and toughness on record. Ab initio modelling suggests that it has negative stacking-fault energy at 0K and high propensity for twinning. With deformation we find that a three-dimensional (3D) hierarchical twin network forms from the activation of three twinning systems. This serves a dual function: conventional twin-boundary (TB) strengthening from blockage of dislocations impinging on TBs, coupled with the 3D twin network which offers pathways for dislocation glide along, and cross-slip between, intersecting TB-matrix interfaces. The stable twin architecture is not disrupted by interfacial dislocation glide, serving as a continuous source of strength, ductility and toughness.

Unraveling dual phase transformations in a CrCoNi medium-entropy alloy

[J].

Synthesis and thermodynamic analysis of nanostructured CuNiCoZnAl high entropy alloy produced by mechanical alloying

[J].

High-entropy alloys by mechanical alloying: A review

[J].Mechanical alloying (MA) followed by sintering has been one of the most widely adopted routes to produce nanocrystalline high-entropy alloys (HEAs). Enhanced solid solubility, room temperature processing, and homogenous alloy formation are the key benefits provided by MA. Spark plasma sintering has largely been used to obtain high-density HEA pellets from milled powders. However, there are many challenges associated with the production of HEAs using MA, which include contamination during milling and high propensity of oxidation. The present review provides a comprehensive understanding of various HEAs produced by MA so far, with the aim to bring out the governing aspects of phase evolution, thermal stability, and properties achieved. The limitations and challenges of the process are also critically assessed with a possible way forward. The paper also compares the results obtained from high-pressure torsion, another severe plastic deformation technique.

Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying

[J].

Fabrication and properties of nanocrystalline Co0.5FeNiCrTi0.5 high entropy alloy by MA-SPS technique

[J].

The deformation and ageing of mild steel: III Discussion of results

[J].

Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy

[J].

Softening of nanocrystalline metals at very small grain sizes

[J].

Grain boundary stability governs hardening and softening in extremely fine nanograined metals

[J].Conventional metals become harder with decreasing grain sizes, following the classical Hall-Petch relationship. However, this relationship fails and softening occurs at some grain sizes in the nanometer regime for some alloys. In this study, we discovered that plastic deformation mechanism of extremely fine nanograined metals and their hardness are adjustable through tailoring grain boundary (GB) stability. The electrodeposited nanograined nickel-molybdenum (Ni-Mo) samples become softened for grain sizes below 10 nanometers because of GB-mediated processes. With GB stabilization through relaxation and Mo segregation, ultrahigh hardness is achieved in the nanograined samples with a plastic deformation mechanism dominated by generation of extended partial dislocations. Grain boundary stability provides an alternative dimension, in addition to grain size, for producing novel nanograined metals with extraordinary properties.Copyright © 2017, American Association for the Advancement of Science.

Bulk nanocrystalline boron-doped VNbMoTaW high entropy alloys with ultrahigh strength, hardness, and resistivity

[J].

Symbiotic crystal-glass alloys via dynamic chemical partitioning

[J].

Ductility and plasticity of nanostructured metals: Differences and issues

[J].

Uniting tensile ductility with ultrahigh strength via composition undulation

[J].

Interstitial equiatomic CoCrFeMnNi high-entropy alloys: Carbon content, microstructure, and compositional homogeneity effects on deformation behavior

[J].

Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes

[J].

The effect of interstitial carbon on the mechanical properties and dislocation substructure evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys

[J].

Massive interstitial solid solution alloys achieve near-theoretical strength

[J].Interstitials, e.g., C, N, and O, are attractive alloying elements as small atoms on interstitial sites create strong lattice distortions and hence substantially strengthen metals. However, brittle ceramics such as oxides and carbides usually form, instead of solid solutions, when the interstitial content exceeds a critical yet low value (e.g., 2 at.%). Here we introduce a class of massive interstitial solid solution (MISS) alloys by using a highly distorted substitutional host lattice, which enables solution of massive amounts of interstitials as an additional principal element class, without forming ceramic phases. For a TiNbZr-O-C-N MISS model system, the content of interstitial O reaches 12 at.%, with no oxides formed. The alloy reveals an ultrahigh compressive yield strength of 4.2 GPa, approaching the theoretical limit, and large deformability (65% strain) at ambient temperature, without localized shear deformation. The MISS concept thus offers a new avenue in the development of metallic materials with excellent mechanical properties.© 2022. The Author(s).

Thermodynamic instability of a nanocrystalline, single-phase TiZrNbHfTa alloy and its impact on the mechanical properties

[J].

High stress twinning in a compositionally complex steel of very high stacking fault energy

[J].Deformation twinning is rarely found in bulk face-centered cubic (FCC) alloys with very high stacking fault energy (SFE) under standard loading conditions. Here, based on results from bulk quasi-static tensile experiments, we report deformation twinning in a micrometer grain-sized compositionally complex steel (CCS) with a very high SFE of ~79 mJ/m, far above the SFE regime for twinning (<~50 mJ/m) reported for FCC steels. The dual-nanoprecipitation, enabled by the compositional degrees of freedom, contributes to an ultrahigh true tensile stress up to 1.9 GPa in our CCS. The strengthening effect enhances the flow stress to reach the high critical value for the onset of mechanical twinning. The formation of nanotwins in turn enables further strain hardening and toughening mechanisms that enhance the mechanical performance. The high stress twinning effect introduces a so far untapped strengthening and toughening mechanism, for enabling the design of high SFEs alloys with improved mechanical properties.© 2022. The Author(s).

High-strength and high-ductility nanostructured and amorphous metallic materials

[J].

High-order hierarchical nanotwins with superior strength and ductility

[J].

Crystal-glass high-entropy nanocomposites with near theoretical compressive strength and large deformability

[J].

Nanostructural metallic materials: Structures and mechanical properties

[J].

Approaching the ideal elastic limit of metallic glasses

[J].The ideal elastic limit is the upper bound to the stress and elastic strain a material can withstand. This intrinsic property has been widely studied for crystalline metals, both theoretically and experimentally. For metallic glasses, however, the ideal elastic limit remains poorly characterized and understood. Here we show that the elastic strain limit and the corresponding strength of submicron-sized metallic glass specimens are about twice as high as the already impressive elastic limit observed in bulk metallic glass samples, in line with model predictions of the ideal elastic limit of metallic glasses. We achieve this by employing an in situ transmission electron microscope tensile deformation technique. Furthermore, we propose an alternative mechanism for the apparent 'work hardening' behaviour observed in the tensile stress-strain curves.

Tensile ductility and necking of metallic glass

[J].Metallic glasses have a very high strength, hardness and elastic limit. However, they rarely show tensile ductility at room temperature and are considered quasi-brittle materials. Although these amorphous metals are capable of shear flow, severe plastic instability sets in at the onset of plastic deformation, which seems to be exclusively localized in extremely narrow shear bands approximately 10 nm in thickness. Using in situ tensile tests in a transmission electron microscope, we demonstrate radically different deformation behaviour for monolithic metallic-glass samples with dimensions of the order of 100 nm. Large tensile ductility in the range of 23-45% was observed, including significant uniform elongation and extensive necking or stable growth of the shear offset. This large plasticity in small-volume metallic-glass samples did not result from the branching/deflection of shear bands or nanocrystallization. These observations suggest that metallic glasses can plastically deform in a manner similar to their crystalline counterparts, via homogeneous and inhomogeneous flow without catastrophic failure. The sample-size effect discovered has implications for the application of metallic glasses in thin films and micro-devices, as well as for understanding the fundamental mechanical response of amorphous metals.

Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses

[J].Amorphous metallic alloys, or metallic glasses, are lucrative engineering materials owing to their superior mechanical properties such as high strength and large elastic strain. However, their main drawback is their propensity for highly catastrophic failure through rapid shear banding, significantly undercutting their structural applications. Here, we show that when reduced to 100 nm, Zr-based metallic glass nanopillars attain ceramic-like strengths (2.25 GPa) and metal-like ductility (25%) simultaneously. We report separate and distinct critical sizes for maximum strength and for the brittle-to-ductile transition, thereby demonstrating that strength and ability to carry plasticity are decoupled at the nanoscale. A phenomenological model for size dependence and brittle-to-homogeneous deformation is provided.

Dual-phase nanostructuring as a route to high-strength magnesium alloys

[J].

Calculations of amorphous-forming composition range for ternary alloy systems and analyses of stabilization of amorphous phase and amorphous-forming ability

[J].

Amorphization in extreme deformation of the CrMnFeCoNi high-entropy alloy

[J].Extreme deformation of high-entropy alloys increases toughness by converting crystalline structures to amorphous zones.

Hierarchical nanostructured aluminum alloy with ultrahigh strength and large plasticity

[J].High strength and high ductility are often mutually exclusive properties for structural metallic materials. This is particularly important for aluminum (Al)-based alloys which are widely commercially employed. Here, we introduce a hierarchical nanostructured Al alloy with a structure of Al nanograins surrounded by nano-sized metallic glass (MG) shells. It achieves an ultrahigh yield strength of 1.2 GPa in tension (1.7 GPa in compression) along with 15% plasticity in tension (over 70% in compression). The nano-sized MG phase facilitates such ultrahigh strength by impeding dislocation gliding from one nanograin to another, while continuous generation-movement-annihilation of dislocations in the Al nanograins and the flow behavior of the nano-sized MG phase result in increased plasticity. This plastic deformation mechanism is also an efficient way to decrease grain size to sub-10 nm size for low melting temperature metals like Al, making this structural design one solution to the strength-plasticity trade-off.

Reactive wear protection through strong and deformable oxide nanocomposite surfaces

[J].Wear-related energy and material loss cost over 2500 Billion Euro per year. Traditional wisdom suggests that high-strength materials reveal low wear rates, yet, their plastic deformation mechanisms also influence their wear performance. High strength and homogeneous deformation behavior, which allow accommodating plastic strain without cracking or localized brittle fracture, are crucial for developing wear-resistant metals. Here, we present an approach to achieve superior wear resistance via in-situ formation of a strong and deformable oxide nanocomposite surface during wear, by reaction of the metal surface with its oxidative environment, a principle that we refer to as 'reactive wear protection'. We design a TiNbZr-Ag alloy that forms an amorphous-crystalline oxidic nanocomposite surface layer upon dry sliding. The strong (2.4 GPa yield strength) and deformable (homogeneous deformation to 20% strain) nanocomposite surface reduces the wear rate of the TiNbZr-Ag alloy by an order of magnitude. The reactive wear protection strategy offers a pathway for designing ultra-wear resistant alloys, where otherwise brittle oxides are turned to be strong and deformable for improving wear resistance.© 2021. The Author(s).

Deformation twinning in nanocrystalline aluminum

[J].We report transmission electron microscope observations that provide evidence of deformation twinning in plastically deformed nanocrystalline aluminum. The presence of these twins is directly related to the nanocrystalline structure, because they are not observed in coarse-grained pure aluminum. We propose a dislocation-based model to explain the preference for deformation twins and stacking faults in nanocrystalline materials. These results underscore a transition from deformation mechanisms controlled by normal slip to those controlled by partial dislocation activity when grain size decreases to tens of nanometers, and they have implications for interpreting the unusual mechanical behavior of nanocrystalline materials.