一般情况下,通过SPD法制备超细晶钢所需要的等效应变应大于4[14]。为了突破成型载荷限制,林鹏程等[15]最近提出3D-SPD轧制法,可以实现对块体材料施加6.5等效应变的SPD,从而成功制备晶粒尺寸为1 µm的块体棒材。Ueji等[16]利用马氏体作为冷轧退火的起始组织,仅用了等效应变为0.8的轧制变形在550℃保温退火30 min,即获得了尺寸为180 nm的等轴状铁素体晶粒。他们认为这种相对较小的应变得到超细晶的关键因素在于起始组织主要是板条马氏体。板条马氏体内有三级结构存在,这意味着马氏体本身可以看作是一种有很多大角度晶界存在的细晶组织,实验所得马氏体等效晶粒尺寸为3.2 µm。尽管马氏体相变可以细化奥氏体晶粒,但它并不能直接得到超细晶组织,轧制变形是得到超细晶的重要机制。马氏体轧制变形会在原始组织内诱导晶界形成,在马氏体细结构的基础上进一步细化组织,若加上退火工艺则可以减少晶粒内位错,将不清晰的晶界转变为更明显、可分辨的晶界,而马氏体内过饱和的C原子也有利于轧制过程中位错的塞积以及阻止退火过程中晶粒的长大。因此,以马氏体作为起始组织轧制退火是一种有效的制备超细晶的方法[17]。然而,马氏体塑性差,变形抗力高,且C含量越高,马氏体越脆,在变形时容易产生裂纹,难以作为SPD的起始组织。因此,利用马氏体起始组织通过大塑性变形来制备超细晶粒钢的研究主要集中在低碳钢[18,19]或无间隙原子(IF)钢[20]上。

为了将冷轧马氏体组织退火制备超细晶钢由低碳钢进一步扩充到中碳钢范围,本工作选用不含贵重合金元素的中碳钢作为实验材料,通过脱碳工艺制备出由表面至芯部C含量逐步增加的C梯度马氏体组织,通过在中碳钢表面引入低碳层,降低表面组织强度,成功通过大压下轧制出中碳马氏体钢,为下一步冷轧+退火工艺制备中碳超细晶钢奠定基础。同时,对比分析了轧制后梯度组织马氏体和均质马氏体的组织与力学性能,研究了C含量梯度分布对冷轧马氏体强塑性的影响,以期为其他合金钢成分梯度组织的研究和制备提供一种新的思路。

1 实验方法

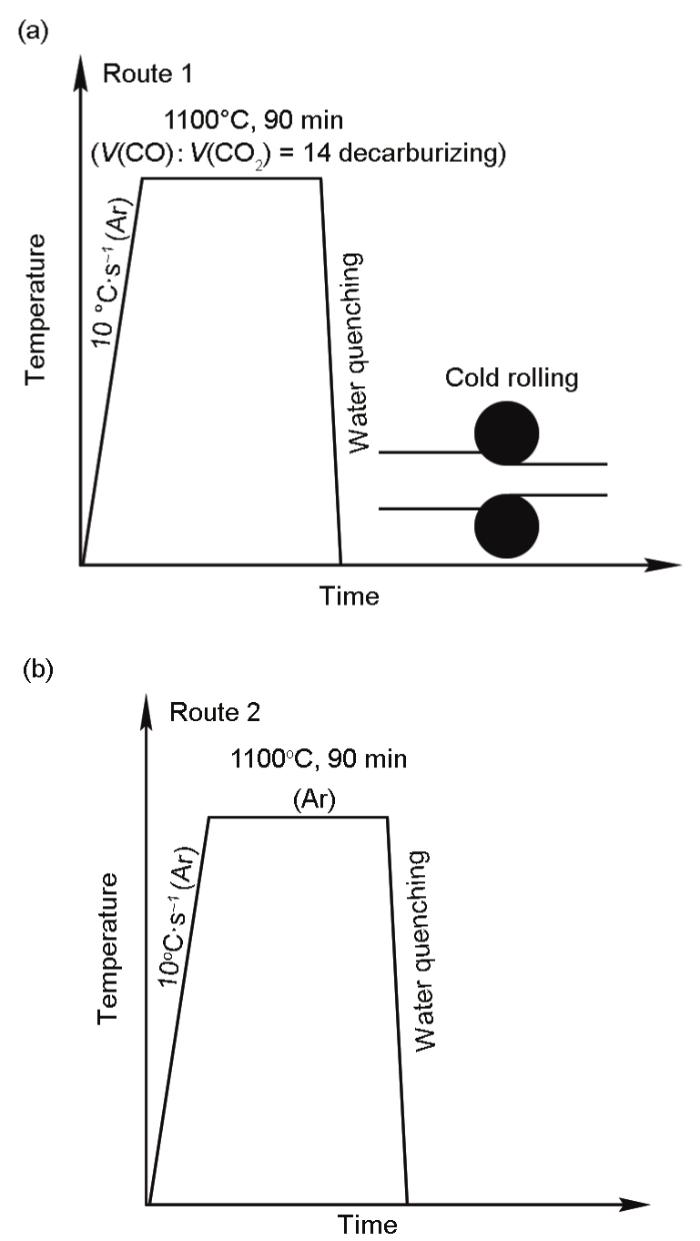

实验用钢为不含贵重元素的35中碳钢,化学成分(质量分数,%,下同)为:C 0.34,Si 0.21,Mn 0.69,P ≤ 0.015,S ≤ 0.003,Fe余量。试样原始组织为珠光体和铁素体。试样初始尺寸为70 mm × 20 mm × 3 mm,在Ar气保护气氛下加热至1100℃奥氏体区进行脱碳处理,脱碳工艺采用气体脱碳法,即在奥氏体化保温过程中通入CO/CO2混合气体,其中体积比V(CO)∶V(CO2) = 14,保温90 min后通入Ar气5 min将脱碳气氛排出,然后将试样立刻取出水淬至室温。室温下用辊径为180 mm的二辊轧机对脱碳淬火后试样进行5道次冷轧,最终厚度为0.9 mm,总压下率为70%,等效应变为1.5。实验工艺如图1a工艺1所示。同时采用图1b工艺2制备均质(无碳梯度)马氏体组织作为对比,工艺2与工艺1的差别在于奥氏体化过程中通入的气体是Ar保护性气氛。将2种工艺下的淬火试样沿中心剖开,使用HV1000A型Vickers硬度计沿厚度方向测量淬火材料和原始材料的硬度,载荷为0.5 kg,加载时间为10 s。各状态试样在Instron 5969拉伸试验机上进行拉伸实验,拉伸方向沿轧制方向,拉伸速率为0.001 s-1。使用4% (体积比)硝酸酒精溶液腐蚀试样轧向-法向截面,利用Axio Scope A1光学显微镜(OM)和加速电压为20 kV的Nova400纳米场发射扫描电子显微镜(SEM)观察试样的微观组织。

图1

图1

脱碳实验工艺以及均质马氏体处理工艺

Fig.1

Rout 1 for decarburization procedures (a) and rout 2 for obtaining homogeneous martensite (b) (V—volume of CO or CO2)

2 实验结果与讨论

2.1 脱碳后组织和硬度演变

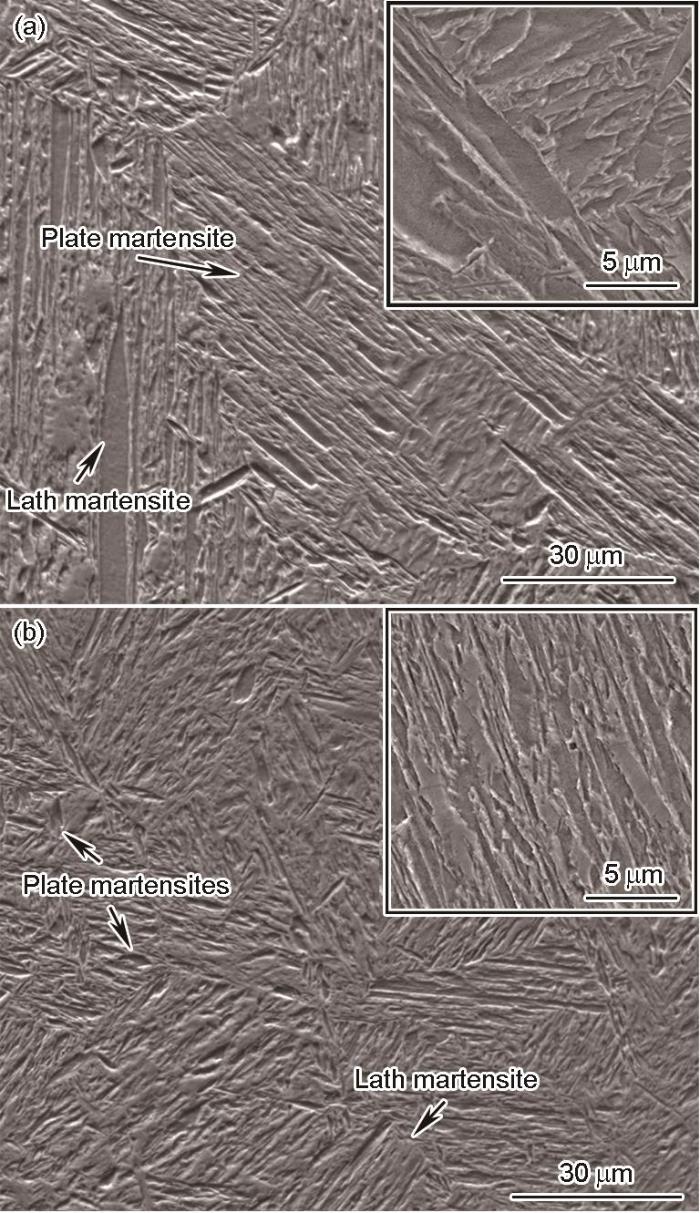

图2给出了奥氏体化过程中通入Ar保护气氛进行处理,淬火后获得的均质马氏体组织。可以看到,微观组织主要是板条马氏体以及少量片状马氏体。

图2

试样在奥氏体化温度下进行脱碳处理,高温下,CO2与试样表面C原子反应式为:

式中,[C]为钢中的C原子。

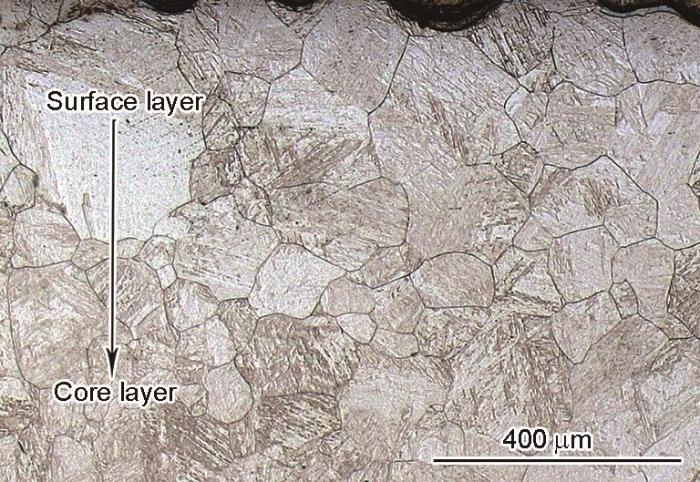

脱碳过程中,由于弱氧化性气体CO2脱去试样表面C原子,使得试样表层C浓度降低,形成了表面和内部C浓度差。在1100℃高温条件下,C原子沿浓度梯度下降的方向定向扩散,由此试样获得一定厚度的扩散层。其特点是试样表面的C浓度最低,靠近芯部,浓度便逐渐上升。C梯度形成后淬火得到的微观组织也由表面逐渐向中心变化,如图3所示。

图3

图3

脱碳淬火马氏体组织的SEM像

Fig.3

SEM images of the decarburized martensite in the surface layer (a) and core layer (b) (Insets show the enlarged microstructure)

由图3可以看出,脱碳后试样表面和芯部组织均为典型的板条马氏体组织加上少量的片状马氏体组织,马氏体取向随机分布,表面马氏体组织粗大,芯部马氏体组织明显细小,如图3右上角放大图所示。导致表层和芯部马氏体尺寸存在明显差异的原因是2个区域原奥氏体晶粒尺寸的不同,如图4所示,表层奥氏体晶粒平均尺寸为150 µm,而过渡到距表层470 µm处晶粒尺寸减小至103 µm。高温下奥氏体化过程中,试样表面由于脱碳反应,试样内部的C原子因下坡扩散而一直处于定向向外扩散状态,一方面使得C原子不易偏聚在晶界处,另一方面也有利于表层组织中渗碳体的溶解,奥氏体晶界迁移速率更快,晶粒尺寸更大。与此同时,芯部组织中存在C原子的偏聚和更难溶解的渗碳体,对晶界的迁移有着强烈的阻碍作用,降低了晶界迁移速率,因此芯部奥氏体晶粒更细小。奥氏体晶粒尺寸进一步限制了马氏体尺寸。

图4

图4

脱碳淬火后试样的显微组织

Fig.4

Microstructure of the decarburized steel from surface layer to core layer

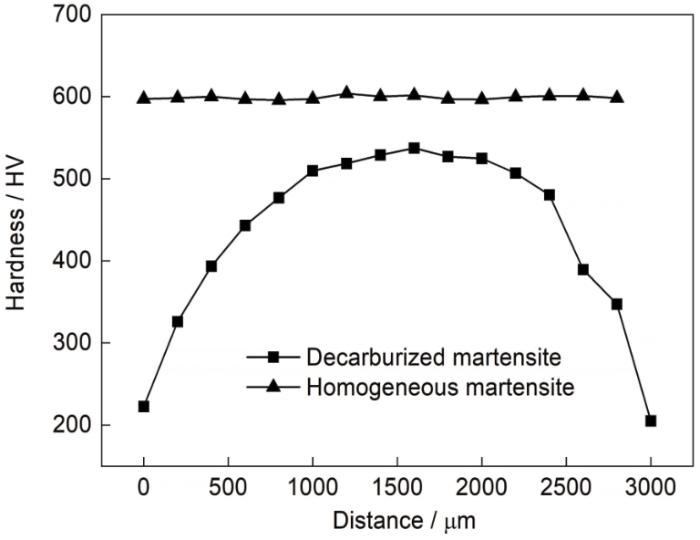

图5为试样脱碳淬火后的梯度马氏体组织以及相同奥氏体化条件下通入保护气氛淬火后均质马氏体组织硬度随厚度方向的变化。可以看出,均质马氏体试样的硬度沿厚度方向基本保持不变,约为600 HV,证实实验过程中气密性良好,在全程通Ar的情况下未发生氧化脱碳的现象。而脱碳处理后,由于C含量在试样内部呈梯度分布,Vickers硬度也从表面到中心逐渐增加,硬度由表面的222 HV增加到芯部的537 HV,硬度差值为315 HV。在距离表面大约1 mm时,硬度变化趋于稳定,由此可见表面脱碳层厚度约为1 mm。

图5

图5

不同气氛下奥氏体化淬火后硬度随厚度方向的变化曲线

Fig.5

Hardness profile of decarburized martensite and homogeneous martensite

2.2 冷轧后组织

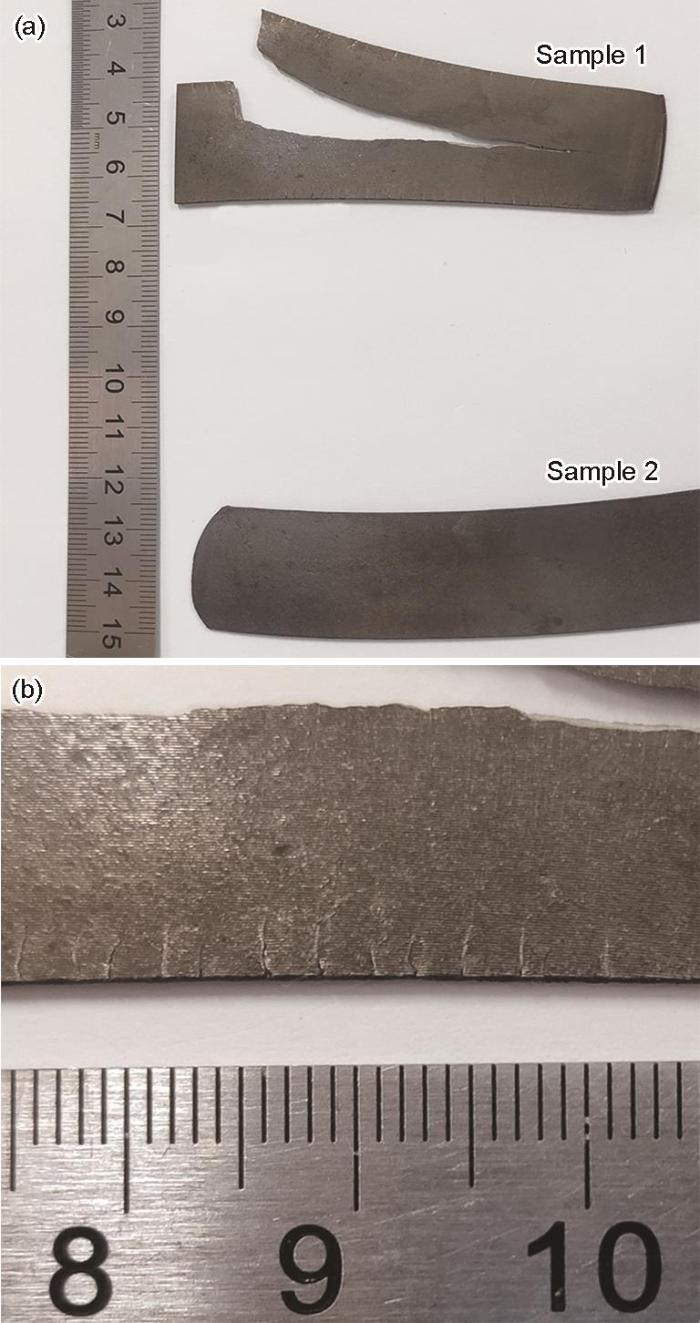

图6

图6

轧制后试样总体形貌图

Fig.6

Morphologies of the cold rolled specimens of homogeneous martensite (sample 1) and compositionally gradient martensite (sample 2) (a) and enlarged view of homogeneous martensite in sample 1 (b)

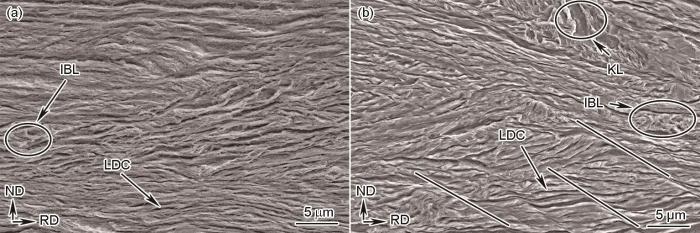

脱碳淬火试样冷轧后轧向-法向截面的组织如图7所示。变形前近似取向随机的马氏体板条经过70%冷轧后发生了转动,大量马氏体板条趋于沿轧向排列,同时马氏体板条厚度较冷轧前减小。其显微组织大部分表现为明显的层片状特征,马氏体板条沿轧向近似平行排列,即为层状位错胞(lamellar dislocation cell,LDC)结构。多数相邻板条间有较大的取向差,板条内存在高密度的位错[17]。此外,组织中还包含无规律弯曲的层状(irregularly bent lamella,IBL)结构。Ueji等[16]研究指出IBL结构与LDC结构的内部均有非常大的局部取向差存在。芯部组织中还能看到弯折的马氏体板条(kinked lath,KL)结构。由于原来的马氏体板条界面法向是平行于试样轧向的,在轧制过程中较其他取向而言难以发生变形,同时在微剪切带的缠结作用下最终以平行于法向的马氏体板条形式存在。Morito等[21]指出IBL和KL结构在超低碳钢中不会出现,马氏体板条的方向也不会影响最终的轧制组织形貌,在C含量高的试样中,马氏体板条界面由于残余奥氏体的存在得以保留下来,在大的塑性变形条件下进一步形成无规律弯曲马氏体和弯折马氏体板条。组织中还能看到明显的波浪纹,这些波纹实质上都是微剪切带,其内部位错密度非常高,它是由板条界面法向平行于轧制方向的马氏体板条在大压下轧制时的崩塌形成的[20]。

图7

图7

脱碳淬火试样轧制梯度马氏体组织的SEM像

Fig.7

SEM images of the cold rolled decarburized martensite in surface layer (a) and core layer (b) (ND—normal direction, RD—rolling direction, LDC—lamellar dislocation cell, IBL—irregularly bent lamella, KL—kinked lath)

对比试样表层和芯部组织形貌可以看到,试样表面组织大部分是被拉长的LDC结构,而微剪切带和IBL、KL结构非常少,芯部的微剪切带结构及IBL、KL结构较多。这种剪切带倾向于在C含量相对较高的芯部形成的现象与芯部板条结构的相对稳定性更高有关,C含量的增加提升了马氏体板条的稳定性[21]。在C含量相对较高的芯部区域内,马氏体板条结构较为稳定,在一定程度的塑性变形条件下,更容易引起组织内部微剪切带的形成以及IBL和KL结构的产生。在C含量相对较低的表面区域,小的塑性变形就能造成马氏体板条结构的消失,形成LDC结构。此外,微剪切带是裂纹萌生的起源,从本实验中的冷轧梯度马氏体组织可以看出,芯部的波浪纹相比表面更加严重,且微剪切带数量较多。而芯部形成的微剪切带向表面扩展传播时,表面LDC结构由于有着更均匀的变形可以阻止剪切带的进一步传播,有效提高整体组织的韧性。若是进一步提高塑性变形程度,使得大量的微剪切带由芯部传播到边部时,裂纹易贯穿整个试样,试样就会开裂。

2.3 拉伸性能

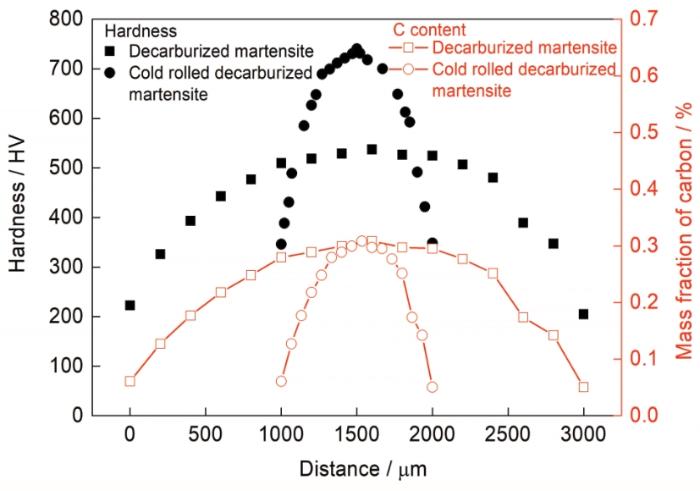

根据文献[22]中大量淬火马氏体硬度数据和对应的C含量,可以拟合得到

图8为根据

图8

图8

硬度和C含量沿试样厚度方向分布图

Fig.8

Hardness and carbon content distributions along sample thickness

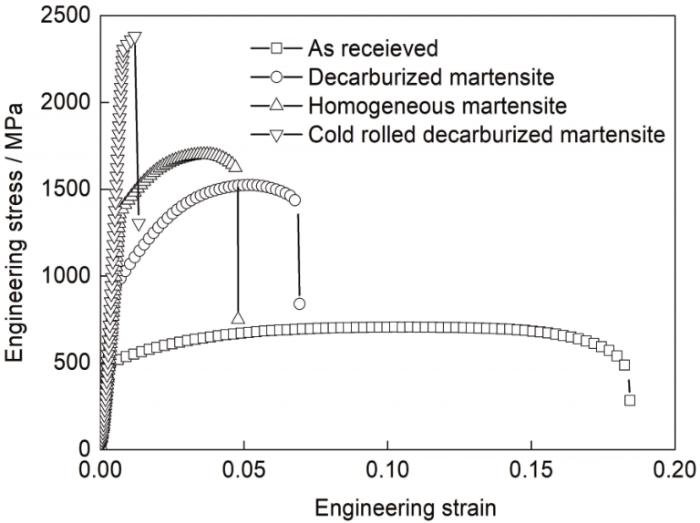

实验用钢原始试样、脱碳淬火试样、冷轧脱碳淬火后试样和均质马氏体试样的拉伸性能如图9所示。可以看出,原始钢抗拉强度较低,仅为706 MPa。淬火处理后获得均质马氏体组织,试样抗拉强度为1700 MPa,脱碳淬火处理后获得的C梯度马氏体组织抗拉强度为1525 MPa,其均匀延伸率相比均质马氏体提高了40%,总延伸率由4.79%提高至6.94%,强塑积由6.1758 GPa·%增大到10.58 GPa·%,比类似成分0.25%的强塑积(7.92 GPa·%)更高[23]。在芯部中碳钢的上下表层构建C含量逐渐变化的低碳层,表层低碳马氏体相对于芯部中碳马氏体为“软相”,形成一种“三明治”结构,在轧制过程中,芯部马氏体变形具有滞后性,也就是说2者的Poisson比由于应变的不同而不同,当表层已经发生塑性变形时,芯部可能还处于弹性阶段,这种应变分布的不均匀性,最终会造成几何必需位错的积累。此外,研究[24]表明“三明治”结构可以导致表面和芯部受2种不同的应力状态,激活更多的位错滑移体系来加强位错的相互作用和累积,这些位错的累积为梯度组织提供额外的加工硬化能力,使梯度钢延伸性能得到改善。

图9

图9

原始钢、C梯度马氏体钢、均质马氏体钢及冷轧C梯度马氏体钢试样工程应力-应变曲线

Fig.9

Engineering stress-strain curves of samples

对碳梯度马氏体进行冷轧后试样抗拉强度高达2381 MPa,但总延伸率仅为1.2%。轧制试样由于加工硬化作用具有很高的强度,同时大塑性变形引入了大量的缺陷和内应力,位错塞积造成了严重的应力集中,因此轧制试样几乎没有塑性,这与其他研究[23]轧制中碳马氏体钢的结果相似。将本工作得到的冷轧梯度组织钢与不同C含量马氏体钢所达到的不同应变进行对比分析,结果见图10。低碳钢易于轧制,大部分文献中对低碳马氏体钢的等效应变可达1.8而不开裂[18,25]。也有尝试更大压下,如Zhao等[26]对0.17%马氏体成功实施等效应变3.17的轧制变形。然而对于中碳马氏体很难进行大压下变形,目前研究发现对含C量0.25%的马氏体组织也仅能实现等效应变1.05的轧制变形[23]。随着C含量的升高,淬火马氏体的变形抗力增大,马氏体组织容易发生轧制开裂,目前还没有对0.34%及以上含C量马氏体钢进行成功冷轧的报道。

图10

图10

轧制不同C含量马氏体等效应变对比图

Fig.10

Equivalent strains as a function of tensile strength of cold rolled martensite in different researches

本工作选用的0.34%C含量的实验用钢通过脱碳梯度处理,构建表面上下2层低碳层,得到的平均含C量为0.22%,最终能在等效应变为1.5塑性变形条件下,试样不开裂。对于这种具有C梯度分布特征的金属材料,其芯部的中碳钢组织可以提高材料的强度,而表层梯度分布的低碳组织可以承担较高的塑性应变,确保材料具有一定的加工硬化能力。这种C梯度组织的制备为大压下轧制中碳钢提供了一种思路,也为后续退火制备中碳超细晶钢提供前期轧制实验基础。

2.4 拉伸断口形貌

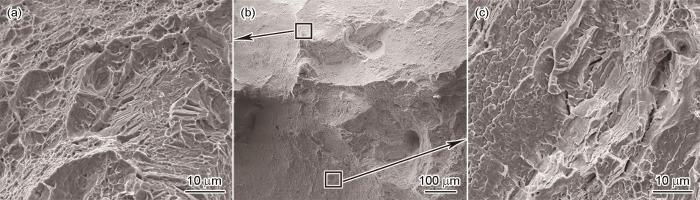

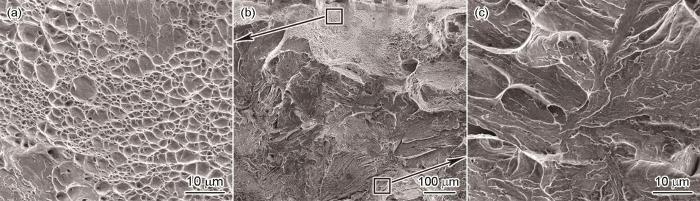

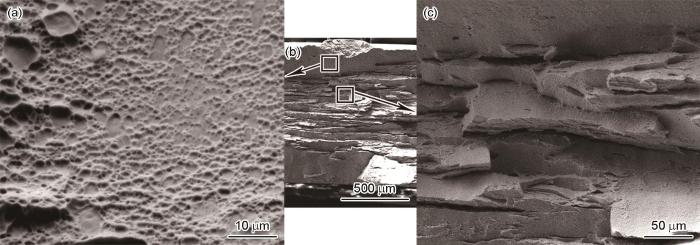

图11为均质马氏体试样的拉伸断口形貌。试样整体形貌均匀,未见分层现象(图11b);表层和过渡区(从表层到芯部的过渡区域)拉伸断口处韧窝均较浅(图11a和c)。当试样经过脱碳淬火后,断口出现分层形貌,如图12b所示。对比图12a表层断口形貌和图12c过渡区域断口形貌可以看出,表层断口处韧窝数量较多,韧窝较深,而过渡区韧窝数量少而浅。图13为冷轧梯度马氏体的断口形貌。可以看出,断裂形貌有2个截然不同的区域。表面为韧性断裂,有大量韧窝聚集,韧窝数量较多,较冷轧前韧窝更浅;过渡区域为典型脆性断裂,断口处出现明显的分层现象,过渡区韧窝尺寸和数目较表层急剧减少,并且出现与轧制面平行的裂纹,大裂纹周围出现分层台阶裂纹,呈现分层断裂特征。

图11

图11

均质马氏体试样拉伸断口形貌

Fig.11

Tensile fracture morphologies of the surface layer (a), the area from surface to core layer (b), and the transition area (c) of homogeneous martensite

图12

图12

脱碳淬火试样拉伸断口形貌

Fig.12

Tensile fracture morphologies of the surface layer (a), the area from surface to core layer (b), and the transition area (c) of decarburized martensite

图13

图13

轧制脱碳淬火马氏体拉伸断口形貌

Fig.13

Tensile fracture morphologies of the surface layer (a), the whole area (b), and the transition area (c) of cold rolled decarburized martensite

经脱碳工艺淬火得到的梯度组织出现分层形貌,其中表层马氏体表现为韧性断裂的特点,这是由于脱碳工艺造成了表层C含量的降低,表层固溶强化作用降低,塑韧性由此提升。冷轧后,表层和芯部组织韧性均大幅降低,这是由于冷轧引入了大量缺陷并造成了应力集中,使其发生屈服后不久即发生断裂。表层相对于芯部的韧性较好,它有效地阻止了芯部断裂裂纹的进一步向外扩展,证实了梯度组织材料有效地利用了表层良好的塑性。

3 结论

(1) 通过脱碳淬火实现C梯度分布后,对中碳马氏体实施等效应变为1.5的大压下轧制,试样表面无微裂纹产生,相比未脱碳均质马氏体钢具有更好的塑性。

(2) 脱碳淬火试样中存在C梯度变化和马氏体尺寸梯度变化。脱碳后,试样中的C含量由表层的0.05%逐渐过渡到芯部的0.32%,整体平均C含量为0.22%。表层由于C扩散速率更快,提高了碳化物的溶解速率,使得奥氏体晶界迁移速率更快,表层的奥氏体晶粒更粗大,最终得到了奥氏体晶粒尺寸的梯度分布,从而进一步获得马氏体的尺寸梯度分布,即表层粗大的低碳马氏体组织逐渐过渡到芯部细小的中碳马氏体组织。

(3) 制备的C梯度马氏体组织相比原始钢种和相当C含量钢种的均质马氏体组织有着更高的强塑积(10.58 GPa·%)。梯度组织更优异的强塑性结合源于低碳层能进一步阻止芯部微剪切带的扩展,当芯部形成的微剪切带向表面扩展传播时,表面层状胞状结构由于有着更均匀的变形可以阻止剪切带的进一步传播,有效提高整体组织的韧性。此外,梯度组织应变的不均匀性也使得试样产生额外的加工硬化能力,从而使整体塑性得到提升。

参考文献

Influence of plastic strain accumulation in continuous ingots during ECAP on structure and recrystallization temperature of AlCu4MgSi alloy

[J].This work attempts to process AlCu4MgSi (AW 2017A) alloy continuous ingots by means of the equal channel angular pressing (ECAP) method. The equal channel angular pressing (ECAP) technique has been widely investigated in recent years as the most promising severe plastic deformation (SPD) method. The presented research was focused on the precise determination of the phase composition of the precipitates formed in the AlCu4MgSi alloy and its influence on intensive plastic deformation. In the second stage, the research was focused on explaining the recrystallization process. With the use of the high-temperature X-ray diffraction (HT-XRD) technique, the changes in the dislocation substructure at various recrystallization annealing temperatures were analyzed.

Microstructure and corrosion behaviors of AZ63 magnesium alloy fabricated by accumulative roll bonding process

[J].

Characterization of spalled AZ31B processed by ECAE

[J].

High strength and high toughness heat-resistant martensitic steel produced by ECAP

[J].The microstructures and mechanical properties ofЭП866 martensite heat-resistant steel submitted to equal channel angular pressing (ECAP) for one pass and subsequent heat treatment were investigated. It was hound that most of the lath martensite has been broken, and the nano-precipitant distributed more uniformly after ECAP deformation. By annealing at 680℃ for 2h, the dislocation density decreased and a great deal of equiaxed subgrains with sizes of several hundred of nanometers were produced, which could be attributed to the dislocation recovery and recrystallization. The yield strength of the ECAPed sample increased significantly, but its ductility decreased a lot. After subsequent annealing treatment, the ductility of the ECAP steel can be improved to the level of initial state. Both the strength and static toughness of the steel after ECAP deformation and subsequent heat treatment can be increased simultaneously compared with those of initial state.

ECAP制备高强高韧马氏体耐热钢

[J].研究了热轧态1Cr16Co5Ni2MoWVNbN马氏体耐热钢经一道次等径角挤压(ECAP)变形+680℃2 h空冷处理后的微观结构和力学性能. 结果表明: 经ECAP变形后, 马氏体板条大部分已碎化成亚晶粒和位错胞, 第二相纳米粒子(M23C6)分布更弥散均匀; 经随后的退火处理, 发生了回复和部分再结晶, 位错密度有所降低, 形成大量尺寸仅几百纳米的等轴亚晶粒. ECAP变形后材料的屈服强度有很大提高(提高至1400 MPa), 但延伸率和静力韧度均大幅度下降(分别降至7.3%和100 MJ/m3); 随后的退火处理可恢复其塑性(15.4%), 其强度(1044 MPa)和静力韧度(181.6 MJ/m3)均较初始态(922 MPa, 160.7 MJ/m3)高.

Effect of asymmetric accumulative roll-bonding process on the microstructure and strength evolution of the AA1050/AZ31/AA1050 multilayered composite materials

[J].This paper aimed to propose the fabrication of light, Al/Mg/Al multilayered composite. Initially prepared three-layered feedstock was subjected to deformation during four rolling cycles (passes) using the conventional and modified accumulative roll bonding (ARB) processes at 400 °C, thanks to which 24-layered composite materials were produced. The modification of the ARB process was based on the application of the rotational speed asymmetry (asymmetric accumulative roll bonding, AARB). It was adopted that the initial thickness of the composite stack amounted to 3 mm (1 mm for each composite). The rolling was done in the laboratory duo D150 rolling mill with the application of the roll rotational speed asymmetry and symmetry av = 1.0 (ARB) and av = 1.25 and 1.5 (AARB). In this manuscript, it was proved that introducing the asymmetry into the ARB process for the tested Al/Mg/Al composite has an impact on the activation of additional shear bands, which results in higher fragmentation of the structure in comparison to the symmetrical process. Due to the application of the AARB, the reduction of the grain size by 17% was obtained, in comparison to the conventional ARB. Not to mention that at the same time there was an increase in strength of the fabricated multilayered composite.

Effect of microstructure refinement on hardness homogeneity of aluminum alloy 1100 processed by accumulative roll bonding

[J].This work examines the effect of grain refinement via accumulative roll bonding (ARB) on the homogeneity of microstructure and hardness through the thickness of commercially pure aluminum AA1100 sheets. The use of 7 cycles of ARB was shown to produce homogeneous ultrafine-grained microstructure, reducing the grain size to 0.46 and 1.03 mu m in normal direction and rolling direction, respectively. Examination by electron backscattered diffraction indicates that continuous dynamic recrystallization was the main mechanism for the formation of submicron equiaxed grains bounded with high-angle grain boundaries (HAGBs). The fraction of HAGBs increased gradually reaching a maximum of 71.6% after 7 cycles. Through-thickness hardness measurements using Vickers and nanoindentation tests show an increase from 43.5 Hv (0.85 GPa) for as-received sample to 63 Hv (1.1 GPa) after 7 cycles. The heterogeneity in hardness through the thickness of the as-received material was shown to restrain the evolution of uniform hardness across the sheet thickness with increasing ARB cycles. Tensile tests showed that the tensile strength is increased to 250 MPa, which is about 2 times its initial value. Owing to the high stacking fault energy of AA1100, strong dynamic recovery occurred with increasing ARB strain which was balanced with the strain hardening property of the material. This resulted in plastic instability at small strains and thus early necking during the tensile test.

Ultrafine grains and the Hall-Petch relationship in an Al-Mg-Si alloy processed by high-pressure torsion

[J].

Grain growth in nanograined aluminum oxide by high-pressure torsion: Phase transformation and plastic strain effects

[J].

Microstructure, texture and mechanical properties of Al-Mg-Si Alloy processed by multiaxial compression

[J].

Effects of combined multiaxial forging and rolling process on microstructure, mechanical properties and corrosion behavior of a Cu-Ti alloys

[J].

Investigation of surface nanocrystallization of a low carbon steel induced by ultrasonic shot peening

[J].

低碳钢超声喷丸表面纳米化的研究

[J].

Microstructural and mechanical properties of magnesium alloy processed by severe plastic deformation (SPD)—A review

[J].

Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening

[J].

Mechanical properties of an ultrafine grained C-Mn steel processed by warm deformation and annealing

[J].

3D-SPD rolling method of 45 steel ultrafine grained bar with bulk size

[J].Based on the limitations of severe plastic deformation (SPD) technology, such as a small effective deformation area and huge forming load, in the preparation of ultrafine grained/nanocrystalline materials, preparing industrial grade bulk ultrafine grained materials is difficult. In this work, a new SPD method, titled 3D-SPD, for preparing bulk ultrafine grained bars is proposed based on the cross-rolling principle. A severe torsion and compression deformation region was constructed using specially-curved conical rolls and guide plates, super large feed angles, and diameter reduction ratios. During the 3D-SPD process, a billet entered the deformation region from the large diameter side of the roll, where the deformation pressure was MPa grade and able to realize the SPD process with effective strains greater than 6.5. A crack control model based on Oyane criteria was established. Through the optimization analysis of damage factors under different deformation conditions, the crack induced by the Mannesmann effect was effectively restrained. Based on theoretical and experimental results, optimal parameters were determined as follows: cone angle 5°, feed angle 24°, diameter reduction ratio 50%, temperature 700oC, ovality coefficient 1.02, and roll speed 40 r/min. A 25 mm-diameter ultrafine grained bar of 45 steel was obtained by the single pass deformation. The average grain size was refined from 46 μm to 1 μm, and the yield and tensile strengths were increased by 46% and 42%, respectively.

45钢块体超细晶棒材3D-SPD轧制法

[J].提出了一种基于斜轧原理的块体超细晶棒材剧烈塑性变形(SPD)成形法,称为3D-SPD法:利用特殊曲面锥形轧辊及导板,坯料从轧辊直径最大端咬入,采用超大送进角及径缩率等变形参数,构建了剧烈扭转压缩复合变形区,单位成形载荷为兆帕级,可实现块体等效应变大于6.5的SPD。建立了基于Oyane损伤准则的裂纹萌生控制模型,通过对不同变形条件下轧件心部损伤值的优化,有效抑制了Mannesmann效应(ME),避免了裂纹的萌生。理论及实验证明:当辊面锥角5°、送进角24°、径缩率50%、温度700℃、椭圆度系数1.02以及轧辊转速40 r/min时,采用单道次轧制方式,可将直径50 mm的45钢轧制为直径25 mm的超细晶棒材,平均晶粒尺寸从46 μm细化至约1 μm,屈服强度和抗拉强度分别提升46%和42%。

Ultragrain refinement of plain low carbon steel by cold-rolling and annealing of martensite

[J].

Ultrafine ferrite grains produced by tempering cold-rolled martensite in low carbon and microalloyed steels

[J].

Effect of rolling reduction on microstructure and property of ultrafine grained low-carbon steel processed by cryorolling martensite

[J].

Fabrication of the ultrafine grained low carbon steel by cold compression and annealing of martensite

[J].

Ultrafine structure and high strength in cold-rolled martensite

[J].

Comparison of deformation structure of lath martensite in low carbon and ultra-low carbon steels

[J].

Martensite in steel: Strength and structure

[J].

Effects of deformation strains and annealing temperatures on mechanical properties of martensitic steels

[J].

Synergetic strengthening by gradient structure

[J].

Effect of rolling reduction on ultrafine grained structure and mechanical properties of low-carbon steel thermomechanically processed from martensite starting structure

[J].

Annealing behavior of nano-layered steel produced by heavy cold-rolling of lath martensite

[J].