烧结Nd-Fe-B永磁材料自1983年问世以来发展迅速,目前实验室条件下制备的烧结Nd-Fe-B磁能积高达446 kJ/m3,但是仅有780 kA/m的矫顽力限制了该材料的广泛应用[1]。随着风力发电、新能源汽车、清洁能源等领域的不断发展,在工作过程中烧结Nd-Fe-B的温度有可能会升到200℃[2]。而目前研制的不含重稀土的商用烧结Nd-Fe-B磁体矫顽力低于1200 kA/m,不能满足上述领域高温条件下的使用要求[3,4]。这就要求研制出高温下性能稳定的低重稀土含量的烧结Nd-Fe-B永磁材料。常用的方法是用部分的Dy、Tb重稀土替代Nd,这样虽然提高了磁体的矫顽力,但同时会显著降低剩磁,且大量消耗不可再生的重稀土。因此低重稀土、高矫顽力是近期烧结Nd-Fe-B永磁材料研究的热点[5~8]。

晶界扩散(grain boundary diffusion,GBD)法被认为是一种新型的高效利用重稀土的方法,它可以在几乎不影响磁体剩磁的前提下显著提高磁体的矫顽力。自2000年Park[9]发现此现象以来,掀起了GBD研究的新浪潮[10]。通过将涂布在磁体表面的重稀土扩散进入磁体晶界而很少进入晶粒内,可以制造出表层富集重稀土以提高矫顽力、而心部只有少量的重稀土以保持高的剩磁的特殊结构的磁体。因此,GBD技术不仅使重稀土得到了更有效的利用,而且能同时实现高矫顽力和高磁能积[11,12]。目前有关GBD的研究主要集中在扩散剂的成分优化、添加方式以及热处理工艺等[13~16]。而如何通过晶界扩散前躯体的晶界调控来提高磁性能和重稀土使用率方面鲜有报道。本工作采用添加低熔点的Nd90Al10合金制备晶界扩散用前躯体,并实施Tb晶界扩散;研究了晶界调控后扩散磁体磁性能和微观组织,同时分析了晶界扩散磁体的晶界结构和成分对磁体矫顽力的影响。

1 实验方法

本实验中的主相合金按照名义成分Pr3.5Nd10.3B5.6-Co1.1Ga0.09Zr0.07 Febal. (原子分数,%)进行原材料称重配比。在Ar气保护下,采用中频感应熔炼炉生产铸片。再经过氢破碎处理得到粗粉待用。

晶界调控用合金按照名义成分为Nd90Al10 (原子分数,%)进行称重配比,每次熔炼完冷却后将合金锭翻转,再进行下一次熔炼,每个样品反复熔炼4次以保证合金成分的均匀性。去除合金锭表面的氧化层后,将合金锭剪碎成规格为6~10 mm的块体,然后进行氢破碎工艺制备得到粗粉待用。

主相合金(99.5%,质量分数)和Nd90Al10合金(0.5%)机械混合后,在N2气保护下进行气流磨制得粒度D(5, 0) (粒度累积曲线上颗粒含量为50%处对应的粒径)为3.0 μm左右的细粉。下一步在N2气保护下,在1.6 T取向磁场下压制成块状,并在1323 K下经过10 h高温烧结,采用793 K温度下回火5 h得到晶界扩散用的基材备用。

采用Tb作为晶界扩散工艺扩散源,先将Tb粉末颗粒与溶剂(无水乙醇)混合制得悬浊液,然后通过喷涂方式将悬浊液涂布在磁体表面,烘干待用,在真空烧结炉中采用1203 K热处理10 h。

为保证测试准确,对磁体进行了磨床抛光处理以去除扩散过程中磁体表面的扩散残留及痕量氧化物。为叙述方便,下文将原始合金(即无Nd90Al10晶界调控且无GBD处理合金)、Nd90Al10晶界调控但无GBD处理合金、无Nd90Al10晶界调控但经GBD处理合金、经Nd90Al10晶界调控并GBD处理合金样品分别简记为A0、A1、AG、AMG。将AG和AMG 2种扩散磁体沿扩散方向纵截面剖开后,经Tegramin-25型自动研磨抛光机制样,以备微观组织观察及晶界成分分析。利用NIM 20000磁测仪测试磁体的磁性能,采用DSC8231型差示扫描量热仪(DSC)测试磁体的DSC曲线,采用EMPYREAN型X射线衍射仪(XRD)、MIRA 3扫描电镜(SEM)及X-Max50型能谱(EDS)分析系统、Talos F200X型透射电镜(TEM)对扩散磁体微观组织及成分进行观察表征。

2 实验结果与分析

2.1 相变温度

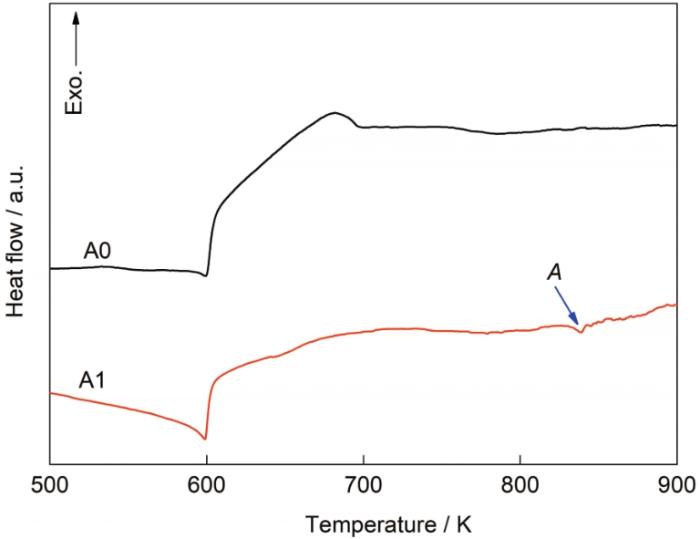

图1

图1

原始合金和晶界调控磁体的DSC曲线

Fig.1

DSC curves of original (A0) and the 0.5%Nd90Al10modified (A1) magnets

起始测量温度为293 K,升温速率为10 K/min,随着温度的逐渐升高,DSC测试曲线随之出现2个吸热峰;曲线上第一个吸热峰对应于烧结Nd-Fe-B磁体的Curie温度(Tc),为烧结Nd-Fe-B主相的原子磁矩由铁磁性转变为顺磁性的临界温度。从图1可以看出,A1磁体对应的第一个吸热峰的温度与未调控的A0磁体基本一致,均在599 K左右。添加晶界调控合金不会影响磁体的Curie温度,说明低熔点的Nd90Al10合金添加后主要富集在晶界相,随低熔点合金一起添加的Al元素没有大量进入到Nd-Fe-B的主相[18]。第二个吸热峰出现在800 K以后,对应于烧结Nd-Fe-B磁体富Nd相的熔点。而A0磁体中富Nd相的熔点的吸热峰难以辨别。当添加0.5%的Nd90Al10合金(A1磁体)后,磁体的三元共晶温度降低到838.53 K,如图1的A点所示;由此可见,添加低熔点的Nd90Al10合金可以降低磁体中富Nd相的熔点。在838.53 K检测到另一吸热峰,说明随着低熔点合金加入磁体中改变了磁体的低温相变行为;磁体的矫顽力是组织结构敏感参量,边界结构优化有利于提高磁体的矫顽力[19~24]。熔点更低的晶界相在晶界扩散过程中熔化为液态,确保了Tb元素晶界扩散的顺利进行。

2.2 相结构

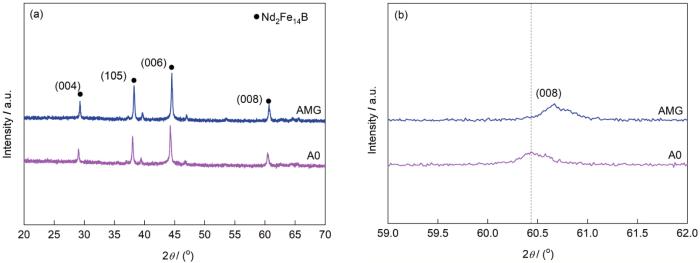

图2

图2

A0和AMG磁体的XRD谱及59°~62°区间的局部放大图

Fig.2

XRD spectra of A0 and AMG magnets (a) and details in the regin of 59°-62° (b) (AMG—0.5%Nd90Al10 modification with grain boundary diffusion (GBD) treatment)

2.3 磁性能和微观组织

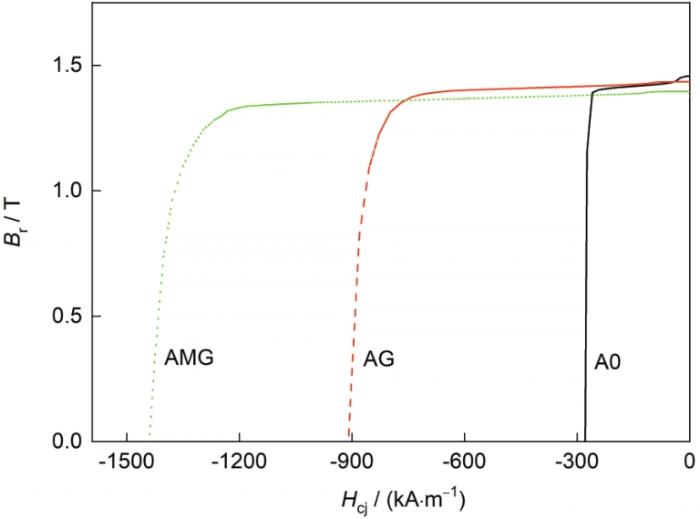

图3给出了A0、AG、AMG磁体在室温(20℃)的磁性能。结果表明,AG磁体矫顽力为909 kA/m,相对于A0的矫顽力(279 kA/m)增加了630 kA/m,而AMG的矫顽力提高到1439 kA/m,相对于晶界扩散处理前增加了1160 kA/m。

图3

图3

A0、AG、AMG磁体的磁性能

Fig.3

Magnetic properties at room temperature of A0, AG, and AMG magnets (AG—unmodified GBD; Br—residual magnetism, Hcj—coercivity)

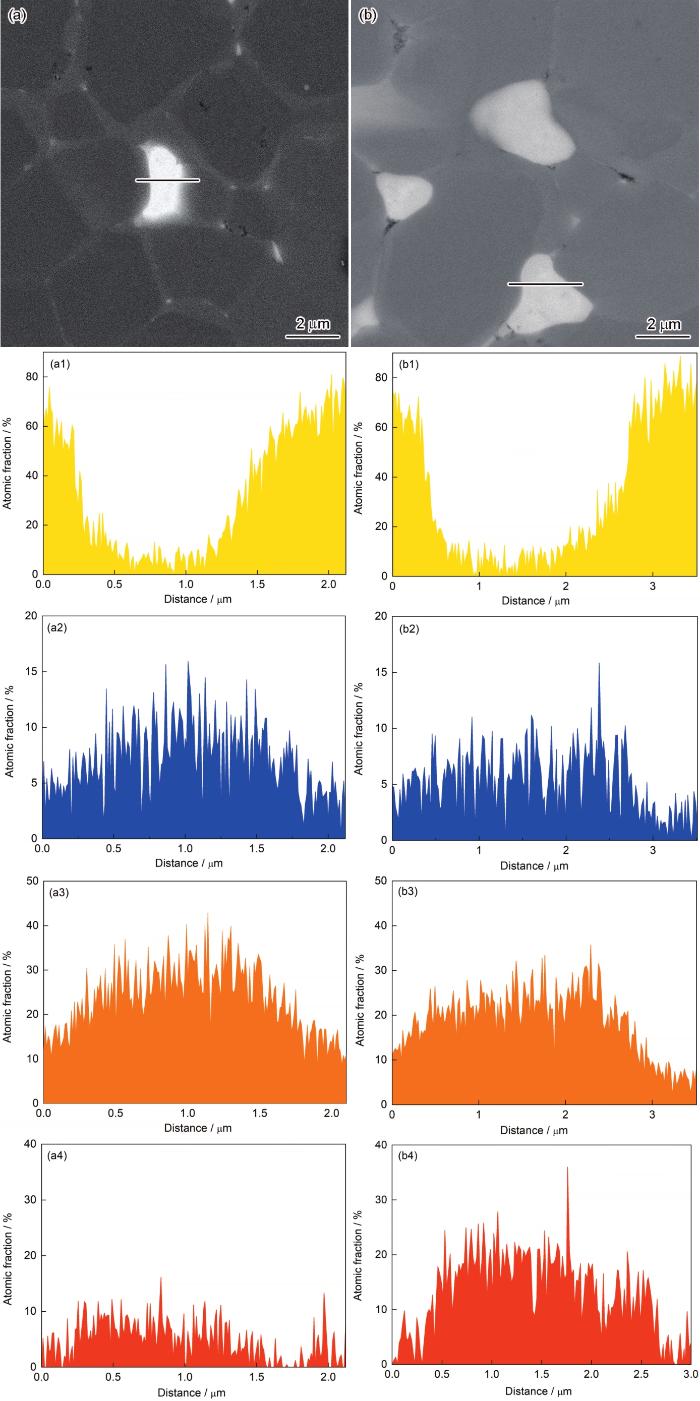

图4所示为以扩散源涂覆面为起点,扩散深度依次为20、100、500和900 μm的背散射电子(BSE)像。在烧结Nd2Fe14B材料中,与较轻的元素相比,较重的元素(如Nd、Tb)在SEM成像中显得更亮。衬度的明暗即可代表该局部区域平均原子序数的高低;衬度较亮区域收集到的背散射电子数量较多,平均原子序数较高,相反,衬度较暗区域的平均原子序数较低。图4中较暗衬度的灰色区域1为Nd2Fe14B相;晶界角隅区域衬度较亮的区域2,稀土含量较高,为磁体的富Nd相。AG和AMG磁体在20 μm处都能清晰观察到灰色的壳核结构,如图中区域3所示。当深度继续增加到100 μm时,AG磁体几乎观察不到富Tb核壳结构的主相晶粒。随着扩散深度增加,主相晶粒外围的富Tb壳层厚度均明显变薄直至消失。距离磁体的表面更远的主相晶粒,AG磁体晶界相出现较多的断点,难以观察到完整连续的晶界相,不能很好地包裹整个晶粒。同时,相同扩散深度下2种扩散磁体(AG、AMG)的组织形貌有明显差别。

图4

图4

AG和AMG磁体距表面不同深度的微观形貌

Fig.4

BSE images of microstructures of AG (a1-a4) and AMG (b1-b4) magnets with different depths from surface (1: Nd2Fe14B, 2: Nb-rich phse, 3: Tb-rich shell)

(a1, b1) 20 μm (a2, b2) 100 μm (a3, b3) 500 μm (a4, b4) 900 μm

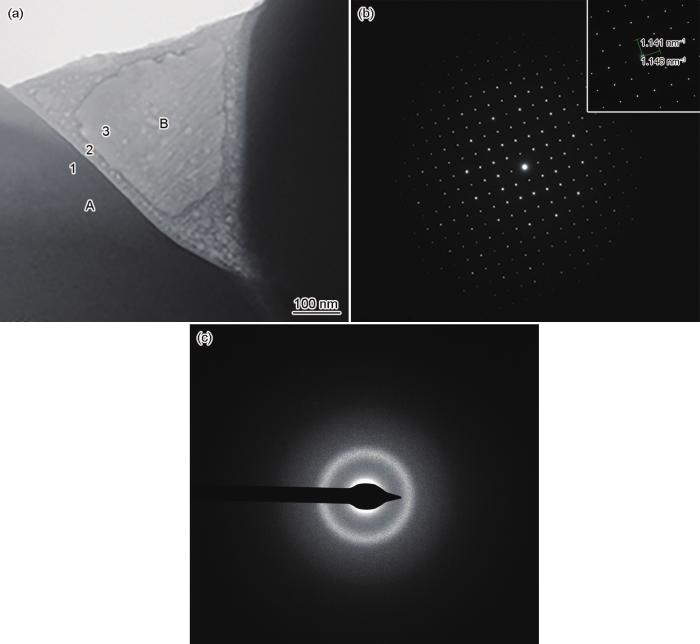

为了进一步探究晶界调控后的扩散磁体显微组织结构与矫顽力的内在联系,利用TEM对磁体的晶界结构进行分析。所观察区域为距离磁体表面约150 μm的位置,结果见图5所示的高角环形暗场(HAADF)像及选区电子衍射(SAED)花样。在图中可以区分出3种衬度的相:(1) Nd2Fe14B主相;(2) 富Tb壳层,并且靠近晶界相一侧具有更明显的衬度;(3) 角隅处富Nd相。扩散磁体中角隅相向两两主相晶界区域延伸,形成了清晰连续、光滑、平直的薄层晶界相,隔绝了主相晶粒直接接触,强化了主相间去磁耦合作用,扩散磁体矫顽力随之提高[11]。同时也说明了经晶界调控后的扩散磁体的晶界相具有良好的润湿性和铺展性。图5a能清晰观察到壳层,经分析,区域A为四方Nd2Fe14B,空间群:P12/mnm,晶带轴:Z = [001],如图5b所示。经Nd90Al10晶界调控的扩散磁体(AMG)中,B区域的富Nd相,SAED结果为非晶环,如图5c所示。非晶态的晶界富Nd相相对较宽,它和基体主相间有着良好的润湿性,在一定程度上有利于隔离相邻主相间的磁耦合[26]。

图5

图5

AMG磁体的高角环形暗场(HAADF)像及选区电子衍射(SAED)花样

Fig.5

High-angle annular dark field (HAADF) image (a) and SAED patterns of area A (b) and area B (c) of AMG magnet (1: Nd2Fe14B, 2: Tb-rich shell, 3: Nd-rich phase) (Inset in Fig.5b shows the interplanar spacing)

经过晶界调控的扩散磁体微观结构对矫顽力提升主要是由于以下方面。

(1) AMG磁体表面的主相晶粒磁硬化层较厚,靠近中心部分的磁硬化层较薄甚至没有磁硬化层,但对反磁化过程和矫顽力影响相对较小[27],在磁体近表面处尽可能多地形成富Tb壳核结构是提高矫顽力的首要条件。

(2) 尽管AG和AMG磁体主相晶粒周围表层都有一圈灰色衬度相的富Tb壳层,但AMG磁体的富Tb壳层更宽。富Nd相的SAED结果为非晶环,它和基体主相间有着良好的润湿性,增强了两两主相晶粒间的去磁耦合,显著提高磁体的矫顽力。

(3) 经Nd90Al10合金晶界调控的磁体(AMG)增强了Tb元素晶界扩散趋势,晶界扩散深度相应提高,使得在深入磁体内部的位置仍能观察到富Tb壳层的存在,有利于减少Tb元素在经扩散的磁体表面聚集,具备Tb壳层的主相晶粒体积增加,有助于提高磁体整体的矫顽力。

2.4 微观成分

图6给出了AG和AMG磁体距离表面20 μm角隅处富Nd相元素分布的线扫描图,显示了Fe元素和稀土元素(Pr、Nd、Tb)的原子浓度分布。图6a和b为元素扫描处的SEM像。扩散后磁体主相中的Fe浓度最高,其原子分数达到约80%,靠近富Nd相一侧Fe原子浓度急剧下降,接近0,如图6a1和b1所示,经晶界调控扩散后的Fe原子分布状况与未经调控扩散磁体类似,Fe原子浓度在富Nd相一侧最低,接近0。就Pr元素的含量而言,2种磁体则几乎无差异,如图6a2和b2所示。Nd是晶界富Nd相的主要成分,在富Nd相中心区域出现峰值,其原子浓度在AG磁体中高达约40%,相对于AMG磁体的含量略高,但差距不明显,如图6a3和b3所示。Tb在晶界富Nd相中出现峰值,其原子浓度在AG磁体中仅约16%,在AMG磁体则高达约35%,如图6a4和b4所示。Oikawa等[28]的微磁学模拟结果表明,扩散磁体矫顽力与富重稀土壳层的磁晶各向异性场紧密相关,从Tb元素的分布情况分析可知,晶界调控促进了Tb的晶界扩散过程,在同样的深度下,晶界中的Tb含量更高,对Tb向磁体内扩散起到至关重要的作用[4]。晶界扩散过程中更多的Tb进入烧结磁体的晶界富Nd相,提高壳层中重稀土元素含量可以显著提高磁体矫顽力[3,4],极大提高了Tb的利用率,为研制低重稀土高性能的磁体提供新的途径。

图6

图6

AG和AMG磁体的SEM像及富Nd相中的元素分布

Fig.6

SEM images (a, b) and element distributions in Nd-rich phase of Fe (a1, b1), Pr (a2, b2), Nd (a3, b3), and Tb (a4, b4) of AG (a-a4) and AMG (b-b4) magnets

3 结论

(1) 经0.5%Nd90Al10合金调控后扩散磁体(AMG)的矫顽力提高到1439 kA/m,相对未调控的扩散磁体(AG)矫顽力提高了530 kA/m,磁性能提升显著。

(2) 晶界调控扩散前躯体磁体中生成了熔点较低的相,基于XRD谱主相衍射峰右移分析,晶界扩散后Tb元素形成了富Tb的壳核结构。

(3) 经Nd90Al10晶界调控的扩散磁体(AMG)不仅在磁体20 μm处主相晶粒富Tb壳层清晰可见,在深入磁体内部100 μm位置仍能观察到富Tb壳层的存在,晶界扩散深度相应地提高。经TEM观察表明,晶界调控的扩散磁体可见衬度明显的富Tb壳层,形成了非晶的富Nd相,增强了两两主相晶粒间的去磁耦合能力。

(4) 经Nd90Al10晶界调控的扩散磁体(AMG)富Nd相中Tb原子浓度更高,在Tb晶界扩散过程中,富Nd相作为Tb扩散通道,促进了Tb元素的晶界扩散。

参考文献

Study of high-coercivity sintered NdFeB magnets

[J].

The preparation of sintered NdFeB magnet with high-coercivity and high temperature-stability

[J].

Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals

[J].The temperature dependence of the saturation magnetization and the magnetocrystalline anisotropy field have been measured on single-crystal samples of the R2Fe14B compounds for R=Y, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, and Tm from 4.2 K to the magnetic ordering temperatures. A spin reorientation transition of the Nd2Fe14B type has been found in Ho2Fe14B at 57.6 K in zero field. Another type of spin reorientation caused by anisotropy compensation between the Fe and the R sublattices exists in Er2Fe14B and Tm2Fe14B. The temperature dependence of the angle of the easy direction of magnetization from the c axis has been measured for R=Nd, Ho, Er, and Tm. The relation between the magnetocrystalline anisotropy and the sublattice magnetization is investigated by employing a simplified two-sublattice molecular field model.

Production of thick high-performance sintered neodymium magnets by grain boundary diffusion treatment with dysprosium-nickel-aluminum alloy

[J].

Research progress on grain boundary fine microstructure and magnetic properties of sintered NdFeB magnet

[J].

烧结NdFeB永磁体的晶界微细结构及性能研究进展

[J].

Influence of dysprosium distribution on properties of sintered and aged Dy-doped NdFeB permanent magnets

[J].

Design and fabrication of Dy-free sintered permanent magnets with high coercivity

[J].

Effect of partial substitution of neodymium with praseodymium on the magnetic and process properties of sintered magnets of type NdFeB

[J].

Effect of metal-coating and consecutive heat treatment on coercivity of thin Nd-Fe-B sintered magnets

[A].

Magnetic properties of extremely small Nd-Fe-B sintered magnets

[J].

Research progress in Grain boundary diffusion modification, microstructures and properties of sintered Nd-Fe-B magnets

[J].

烧结钕铁硼的晶界扩散改性、结构与性能研究进展

[J].

Research progress on grain boundary diffused Nd-Fe-B magnets

[J].

钕铁硼晶界扩散研究进展

[J].

Magnetic properties of a Nd-Fe-B sintered magnet with Dy segregation

[J].

Grain interface modification and magnetic properties of Nd-Fe-B sintered magnets

[J].

Effect of diffusion annealing on the hysteretic properties of sintered Nd-Fe-B magnets

[J].

Effect of dysprosium addition by pack cementation on magnetic properties and microstructure of Nd-Fe-B sintered magnets

[J].

烧结Nd-Fe-B磁体表面渗镀Dy2O3对磁体显微组织和磁性能的影响

[J].

Study on the effect of Al and rare earth grain boundary Co-diffusion on the microstructure and coercivity of sintered Nd-Fe-B magnets

[D].

Al和稀土元素共晶界扩散对烧结Nd-Fe-B磁体微观结构和矫顽力影响的研究

[D].

A study on the Nd-rich phase evolution in the Nd-Fe-B sintered magnet and its mechanism during post-sintering annealing

[J].

Upgraded Nd-Fe-B-AD (AD = Al,Ga) magnets: Wettability and microstructure

[J].

Wettability and interfacial microstructure between Nd2Fe14B and Nd-rich phases in Nd-Fe-B alloys

[J].

Effect of Cu addition on the phase equilibria in Nd-Fe-B sintered magnets

[J].

Effects of Al/Cu co-doping on crystal structure and chemical composition of Nd-rich phases in Nd-Fe-B sintered magnet

[J].

Investigation of the wettability and the interface feature of the melted Nd70Cu30 alloy on the surface of a sintered Nd-Fe-B magnet

[J].

Anisotropic diffusion mechanism in grain boundary diffusion processed Nd-Fe-B sintered magnet

[J].

Microstructure characterization and its relationship with magnetic properties of sintered Nd-Fe-B magnet

[A].

烧结钕铁硼磁体的微结构表征及其与磁性能的关系研究

[A].

Effects of grain boundary structure and chemistry on the coercivity of NdFeB materials

[D].

晶界结构和晶界化学对NdFeB材料矫顽力的影响

[D].

Large-scale micromagnetic simulation of Nd-Fe-B sintered magnets with Dy-rich shell structures

[J].