选区激光熔化(SLM)是一种高精度增材制造技术,通过激光束定向熔化铺设在基板上的粉末床,实现高自由度构件成形[1]。由于铺粉工艺特性以及激光光斑小,SLM通常使用直径15~53 μm的粉末,粒径15 μm以下的粉末少有使用,53 μm以上的粉末则在定向能量沉积中应用广泛。

对于不同粒径SLM铺粉差异,文献[9,10]采用DEM分析了细粒径粉末团聚效应与几何效应的竞争机制,指出适当的团聚黏附可改善粉末床均匀性。文献[11,12]通过实验测量了不同粒径粉末扩散密度、吸湿性、表面能、内聚功等粉末属性,采用粉体流变仪(FT4)、漫反射光谱(DRS)方法定量描述粉末床流动性、激光吸收率差异,系统研究了粒径对实际层厚、成形致密度、尺寸精度、显微硬度、组织演变的影响,指出粗粉更利于SLM成形。将铺粉过程和粉末熔化过程相结合,可以研究粉末床质量对SLM成形的影响。Gu等[13]采用DEM对多种粒径粉末铺设固定层厚粉末床,并将粉末床导入流体模型进行熔化/凝固模拟,结果表明粒径25 μm的粉末能够形成更加平滑和致密的熔道。然而不同的粉末粒径具有不同的铺粉密度,导致实际层厚存在显著差异,激光熔化/凝固过程也存在差异。

为此,本工作以3种粒径(0~20 μm (PSD1)、20~53 μm (PSD2)、53~105 μm (PSD3)) AlSi10Mg粉末为对象,基于DEM的内聚模型建立SLM铺粉模型,考虑粉末层厚仅与粒径相关,研究不同粒径的铺粉行为差异。通过建立DEM与计算流体力学(CFD)模型单向耦合,研究单层粉末床质量对熔道温度、形貌的影响,揭示粒径对于熔化/凝固的影响规律。并开展相关实验验证,进一步研究粉末粒径对SLM成形的影响规律。

1 数值模拟方法

1.1 铺粉数值模拟

式中,E为等效Young's模量,R为Hertz-Mindlin定义的等效半径,a为粒子间接触半径。

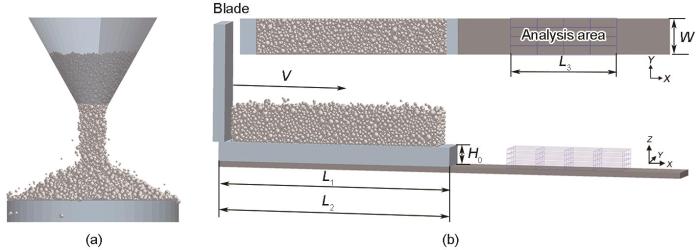

图1

图1

休止角和铺粉离散元方法(DEM)物理模型

Fig.1

Physical model of discrete element method (DEM) for angle of repose (AOR) (a) and powder spreading (b) (V—speed of blade, W—width of substrate, H0—height of layer thickness, L1—length of powder platform, L2—length of substrate, L3—length of analysis area)

1.2 粉末熔化/凝固数值模拟

式中,Slaser为吸收的激光能量,A为激光吸收率,P为激光功率,r为激光束半径,t为时间,vlaser为激光扫描速率,(xi, yi )为激光焦点中心的初始位置。热源直接施加于粉末上表面,通过有限体积(VOF)方法捕获该界面。激光只发生一次吸收,不考虑激光反射、折射和透射。

式中,Evap为蒸发热损失,Erad为辐射热损失,Ecov为对流热损失。

式中,Fdrive为熔池驱动力总和,Fpr为蒸汽反冲压力,Fst为表面张力,Fm为Marangoni力,Fdamp为凝固糊状区的曳力,G为重力,Fbuo为浮力。

2 实验方法

表1 不同粒径AlSi10Mg粉末的化学成分 (mass fraction / %)

Table 1

| Powder | Zn | Si | Ni | Fe | Mn | Mg | Al |

|---|---|---|---|---|---|---|---|

| PSD1 | 0.011 | 10.24 | 0.022 | 0.14 | 0.01 | 0.35 | Bal. |

| PSD2 | 0.010 | 9.66 | 0.020 | 0.10 | 0.20 | 0.42 | Bal. |

| PSD3 | 0.009 | 9.74 | 0.003 | 0.10 | 0.03 | 0.28 | Bal. |

图2

图2

3种粒径AlSi10Mg粉末粒径分布及SEM像

Fig.2

Particle size distribution (a) and SEM images of PSD1 (b), PSD2 (c), and PSD3 (d) (D10, D50, and D90 indicate 10%, 50%, and 90% cumulative particle sizes, respectively)

表2 DEM模型使用参数及参数范围

Table 2

| Parameter | Unit | Value | Variable |

|---|---|---|---|

| range | |||

| Particle density ρ | kg·m-3 | 2680 | - |

| Poisson's ratio ɛ | 0.3 | - | |

| Young's modulus E | MPa | 750 | - |

| Rolling friction coefficient μr | 0.09 | - | |

| Sliding friction coefficient μs | 0.6 | 0.4-0.8 | |

| Restitution coefficient rs | 0.64 | - | |

| Surface energy density γ | mJ·m-2 | 1.2 | 0-15 |

| L1 | mm | 2 | - |

| L2 | mm | 4 | 2-6 |

| W | 10D50 | 2D50-10D50 | |

| H0 | 5D50 | 1D50-5D50 | |

| L3 | mm | 1 | - |

| V | mm·s-1 | 50 | - |

3 结果与讨论

3.1 SLM铺粉动态行为

如图3所示,当铺粉层厚为5D50,粉末在基板上前进时,斜坡与基板形成动态堆积角α。α可表征颗粒流动性,α越小,表明颗粒间相互作用力越小,流动阻力小,具有更好的流动性[25]。根据

图3

图3

DEM模拟铺粉过程的动态堆积角

Fig.3

Dynamic packing angles of PSD1 (a), PSD2 (b), and PSD3 (c) during powder spreading by DEM simulation

3.2 粉末床铺粉质量

图4

图4

DEM模拟的3种粒径粉末床切片图和俯视图

Fig.4

Slices (a1-c1) and top views (a2-c2) of powder bed for PSD1 (magnified) (a1, a2), PSD2 (b1, b2), and PSD3 (c1, c2) by DEM simulation

对比3种粒径粉末床形貌可以发现,PSD1具有非常多的表层空缺和内部空隙,PSD2铺粉质量最好,PSD3铺粉存在少量空隙。从图4a1可见,PSD1中尺寸小于20 μm的粉末发生严重团聚现象,大于20 μm的颗粒未团聚。可见20 μm以下的粒径Van der Waals力主导了颗粒间相互作用力,低流动性抑制了颗粒的平动和转动,刮板刮过的区域均匀性较差,且小颗粒随之团聚,进一步降低了铺粉质量。团聚作用下,粉末床底部和顶部平整度非常差,z方向高度差达到(2~3)D50,不利于下层粉末稳定铺设。当团聚发生在粉末床内部时,将产生大量内部空隙,铺粉不均匀。从图4a2可知,不仅竖直平面存在空隙,水平面也存在大空隙。粒径增加到20~53 μm,Van der Waals力减弱,粉末流动性加强,粉末床均匀,也为下层铺粉提供了平整的基材环境。当然,由于刮板与颗粒间的壁面效应[7],SLM铺粉过程中刮板与粉末床之间必定存在表层空缺,即图4b1切片上方空缺区域,经过多层铺粉后,该空缺能够得到缓解。随着粒径增加至53 μm以上,Van der Waals力对颗粒间作用力可忽略不计。但球体形状导致相邻大颗粒存在50 μm以内几何间隙,由于PSD3粉末中直径小于50 μm的颗粒较少,大的几何间隙无法填充,如图4c1和c2所示,粉末床内部产生较大的空隙,降低了铺粉质量。

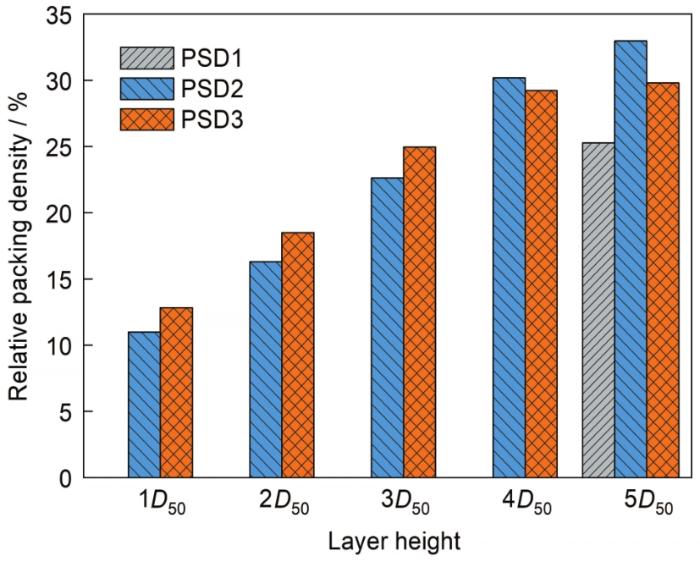

DEM模拟的3种粒径AlSi10Mg铺粉的相对密度如图5所示。由于团聚作用,PSD1在铺粉层厚为(1~4)D50时,团聚形成的小块粉末团厚度接近4D50,无法形成有效粉末床,铺粉相对密度为0,这与实验观察结果一致。仅在5D50厚度时形成粉末床(图4a),团聚导致的大量铺粉缺陷使其密度最低。铺粉层厚从1D50增加至3D50时,PSD2铺粉相对密度略低于PSD3,可能是由于中等粒径的AlSi10Mg颗粒质量轻,受壁面效应影响较强,表层空缺占比略大。4D50层厚时,层厚的增加使得空缺得到弥补,PSD2铺粉密度稳定增加并超过PSD3。5D50层厚时,PSD2铺粉相对密度为32.97%,比PSD1高7.69%,比PSD3高3.17%。AlSi10Mg粉末粒径低于20 μm时,Van der Waals力作用下,铺粉难以形成均匀粉末床。粒径介于20~53 μm的颗粒有良好流动性,但壁面效应降低了铺粉密度。粒径介于53~105 μm的颗粒能够弱化壁面效应,却存在较大的球体几何间隙。因此可以考虑在20~105 μm颗粒中定制粒径分布,以弱化壁面效应和减小几何间隙,实现高密度铺粉。

图5

图5

DEM模拟的3种粉末床相对密度

Fig.5

Relative packing densities of powder bed by DEM simulation

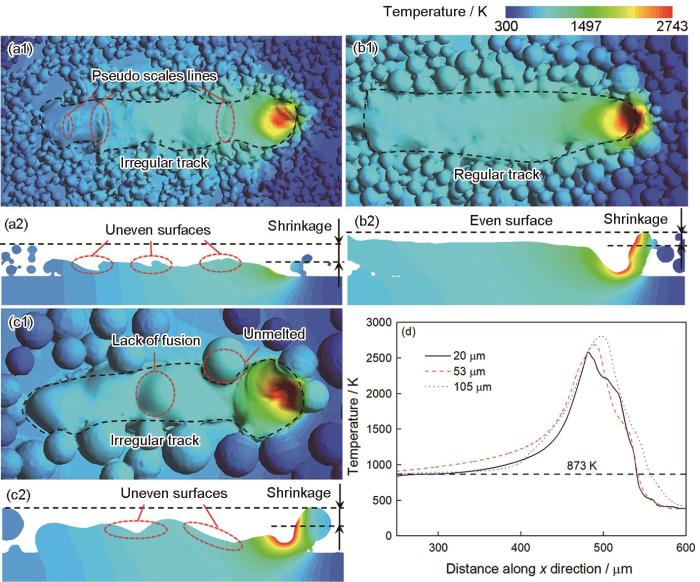

3.3 SLM熔道轮廓与温度分布

图6a1~c1为80 μm铺粉厚度,激光功率290 W,扫描速率1300 mm/s的单层粉末熔化/凝固后熔道轮廓及温度分布。图6a1中PSD1熔道形状不规则,沿激光扫描方向呈现出“伪鱼鳞纹”,宽度变化较大。熔池内高温蒸汽对熔池内壁产生反冲压力,迫使熔融液体向熔池后部流动至熔道[26],同时,由于沿熔道方向及垂直方向温度梯度不同,冷却速率不同,熔融液体会形成锥形凝固形态,即鱼鳞纹。而AlSi10Mg热导率高达130 W/(m·K),黏度低且熔点低,实际熔道中鱼鳞纹较浅且间距大,非图6a1所示。PSD1中“伪鱼鳞纹”是由于粉末床不均匀导致的,颗粒团聚形成的粉团松散分布,激光扫描粉团区域时充分熔化并堆积,空腔区域只能通过液体流动填充,形成了凹凸不平的熔道。粉末床的团聚与空缺导致熔融液体体积发生变化,形成的熔道宽度不均匀。如图6b1所示,粒径增加至20 μm以上时,粉末床致密度高,表面平坦,内部空隙少,使得熔池表面平坦,熔宽变化小,熔池呈现良好的拖尾现象,可见铺粉质量对熔道形貌至关重要。当粉末粒径为53 μm以上时,图6c1中PSD3熔道产生欠熔合现象。由于激光扫描速率快,大颗粒熔液尚未完全流动便凝固,形成堆积形式的欠熔。颗粒间大的间隙分布不均匀,会被熔融液体填充,同时熔液也受大颗粒分布影响,因此PSD3熔道前进方向并不一定与激光扫描方向一致,熔道方向不稳定。此外激光扫描大粒径颗粒区域时,无法完全照射多个颗粒,并且Gaussian光束边缘能量密度低,导致熔道边缘存在部分未熔化大颗粒,不利于熔道搭接。

图6

图6

计算流体力学模拟的选区激光熔化熔道形貌及熔池温度分布曲线

Fig.6

Molten track and temperature distribution (a1-c1) of PSD1 (a1, a2), PSD2 (b1, b2), and PSD3 (c1, c2); corresponding slices (a2-c2); and temperature distribution curves of molten pool (d)

图6a2~c2显示不同粒径的熔道表面平整度各不相同,与粉末床铺设质量密切相关。PSD1熔化/凝固后形成了与粉末床相似的大量凸起状轮廓,如图6a2所示。PSD1粉末床的低密度意味着粉末总质量小,只能形成较浅的熔池。粒径上升到20 μm以上时,粉末床表面平整,颗粒分布均匀,大部分颗粒受热过程稳定,形成了平坦的熔道表面,如图6b2所示,为下一层铺粉及熔化提供了较为平整的基材形貌。从图6c2可见,PSD3熔道表面存在较大的高低起伏。PSD3颗粒间大空隙区域被溶液填充,大颗粒由表至内的熔化产生了液体流动性差异,激光高速扫描导致表面冷却凝固,困住了内部液体流动,而外部流动液体不足以填充大空隙,形成了凹坑或斜坡轮廓。此外,受大颗粒不规则的空间分布影响,熔池形态与深度均不如PSD2好,导致熔道表面的不规则情况产生。

图6d显示了熔池区域沿激光扫描方向温度分布曲线。可见,粉末床的不均匀导致熔池区域存在温度差异。PSD1熔池温度最低,PSD3最高,PSD2介于2者之间。虽然小粒径粉末具有较大的表面积以吸收更多的激光能量,但是松散的粉末床由于铺粉密度低,包含的颗粒总量较少,导致能量吸收不足。同时,粉末床中存在的大量空隙使得基板反射了部分能量,导致PSD1整体吸收能量较低,熔池温度低。PSD3大部分粉末粒径接近甚至超过光斑直径80 μm,激光照射颗粒时,大部分能量被单个颗粒吸收,并且AlSi10Mg与保护气的比热、热导率差异使得能量在大的空隙中扩散较慢,熔池温度高于其余2种粒径。PSD2粉末床均匀且粒径为激光光斑一半,其熔池温度介于2者之间,与AlSi10Mg蒸发温度相当。此外,沿激光扫描方向,PSD2高于液相线的熔道长度大于PSD1和PSD3,能够为金属液体铺展提供更大的润湿范围。因此,熔道形貌与温度分布对不同粉末粒径导致的粉末床均匀性较为敏感[26],中等粒径能够提供更好的SLM成形性。

3.4 实验结果

为了进一步分析粉末粒径对AlSi10Mg多层多道实际成形效果的影响,开展了系列成形实验。发现PSD1粉末初始铺粉过程非常不稳定,粉末堆呈现明显团聚并形成较高粉末堆,与图4a1和a2及文献[25]一致。前几层很少粉末铺设到基板上,5层之后开始有粉末团块非常稀疏地铺展,基板边缘缝隙的存在降低了粉末在该区域的停留。铺粉至30层左右,粉末基本铺设至基板表面。PSD3由于初始几层层厚小,大粒径粉末被刮出基板。PSD2和PSD3均在10层铺粉时达到稳定。SLM成形过程中,20 μm以下AlSi10Mg粉末质量非常轻,DiMetal-100H设备基板边缘靠近风循环系统的出风口,粉末易被吹走,导致边缘粉末不均匀,该区域未能进行有效铺展,易发生激光多次重熔样品表面,热量累积使表面发生翘曲,打印失败。

图7

图7

3种粒径样品上表面轮廓高度和超景深三维显微镜像

Fig.7

Top surface contour heights (a1-c1) and images (a2-c2) of PSD1 (a1, a2), PSD2 (b1, b2), and PSD3 (c1, c2) samples showed by ultra-depth three-dimensional microscope

图8

图8

3种粒径样品上表面形貌的SEM像

Fig.8

Top surface SEM images of PSD1 (a), PSD2 (b), and PSD3 (c) samples

图9显示了3种粒径样品内部缺陷分布的OM像。Van der Waals力作用下,小粒径粉末倾向于团聚成团块,粉末不易在粉末床完全铺展开,形成较多的空隙。同时,与大粒径粉末相比,其流动性较低,会在刮刀前方形成陡峭粉末堆,阻碍刮刀铺粉过程,进一步降低了粉末床致密度。因此,即使PSD1上表面平坦,内部必然存在较多的孔隙。从图9a1和a2可见,PSD1样品内部存在较多孔隙,虽然较薄的熔融层厚能够带来更多的热传导,但是粉末床内大量孔隙仍然受困,难以逸出至熔池表面。图9b1和b2显示PSD2样品内部仅有非常少量的孔隙,因为PSD2粉末床自身仅存在少量空隙,平整且均匀的粉末床为熔液流动和填充提供了良好的渗透环境。如图9c1和c2所示,PSD3样品内部存在少量孔隙和尺寸较大的未熔合缺陷。PSD3中粒径超过激光直径的大颗粒粉末稀疏分布在粉末床内,激光能量无法完全熔化该颗粒,形成非常不均匀的熔道,下层粉末熔化也未能完全填充该区域,从而降低了成形质量,并且粉末床内部的大空隙导致了样品孔隙增加。

图9

图9

3种粒径样品水平和竖直截面孔隙分布的OM像

Fig.9

OM images showing horizontal (a1-c1) and vertical (a2-c2) pore distributions of PSD1 (a1, a2), PSD2 (b1, b2), and PSD3 (c1, c2) samples

图10统计了几个不同能量密度下成形样品的相对密度。经过表面粗磨后,PSD2和PSD3相对密度均超过99%,其中PSD2相对密度可达到99.8%,比PSD3高0.4%,比PSD1高1.4%。PSD1因其内部较多的孔隙,成形密度最低,且能量密度为130 J/mm3时,密度明显下降,对能量密度变化更为敏感,说明AlSi10Mg粒径对SLM成形质量影响显著。

图10

图10

不同能量密度下3种粒径样品相对密度

Fig.10

Relative densities of samples with different energy densities

4 结论

(1) 开发了基于离散元方法的SLM铺粉物理模型和基于流体热力学的粉末熔化/凝固模型。细粒径粉末Van der Waals力主导了颗粒间相互作用力,粉末团聚程度加剧,流动能力减弱。铺粉将产生大量不均匀的空隙和空缺,严重降低粉末床密度。由于团聚效应,小粒径粉末铺粉所需的层厚至少为5D50。大粒径粉末由于球体间大的几何间隙无法得到填充,铺粉稳定后,粉末床致密度略低于中等粒径粉末。

(2) 不同粒径粉末床存在的缺陷在多层熔化/凝固过程中通过熔融液体流动扩散,可得到一定缓解。

(3) 细粉末样品具有最平坦的表面,但由于其粉末床内存在大量空隙,SLM成形时内部气孔无法全部逸出,形成较多孔隙,致密度最低。而粗粉末由于粒径接近或超过激光光斑直径,易产生成未熔,降低了致密度。

(4) SLM成形AlSi10Mg对粉末粒径敏感性强。中等粒径粉末SLM可加工性最好,相对密度可达到99.8%,分别比细粒径和粗粒径粉末高1.4%和0.4%。

参考文献

Mechanical properties of AlSiMg alloy specifically designed for selective laser melting

[J].Using complex shapes and precise structural parts is becoming a strong trend in modern advanced manufacturing. However, traditional manufacturing technology hardly achieves the complex geometric parts directly. Selective laser melting (SLM) is an advanced manufacturing technology for metallic materials, enables production parts with complex geometry combined with the enhancement of design flexibility. The cooling rate of molten pool can reach 103~106 K/s during the SLM process. In this case, the solid solubility of the alloying elements in the matrix can be greatly enhanced. Aluminum alloy has been widely used in industry. At present, the strength of SLM-formed aluminum alloys is far lower than that of high-strength aluminum alloys obtained from a traditional process. It is necessary to develop high-strength aluminum alloy composition based on SLM technical characteristics. The present study is devoted to design high-strength AlSiMg1.5 aluminum alloy specifically for SLM using the local structure model based on the liquid-solid structural compatibility of the alloy and the technical characteristics of the liquid quenching in SLM. The effect of the ageing treatment on the microstructure, the hardness, and the compressive properties of the SLM-formed AlSiMg1.5 alloy was systematically studied. Almost completely dense samples were obtained by adjusting the parameters of SLM process. When the ageing temperature was 300 ℃, the super-solid solution Si precipitated and grew in the island-like Al-rich structure, and the reticular Si-rich structure decomposed and spheroidized gradually with the increases of ageing time of SLM-formed AlSiMg1.5 samples. In this case, the hardness and the strength of the samples decreased, but the elongation increased significantly. The microstructures of the SLM-formed AlSiMg1.5 samples did not change obviously when the ageing temperature was 150 ℃. But the hardness and yield strength of the samples significantly increased first and then decreased slightly. The maximum microhardness and compressive yield strength of SLM-formed AlSiMg1.5 samples aged at 150 ℃ were (169±1) HV and (453±4) MPa, respectively, and the elongation of samples exceeds 25%. In this study, a special Al91.0Si7.5Mg1.5 (mass fraction, %) aluminum alloy specifically for SLM with excellent formability and mechanical properties was designed.

选区激光熔化专用AlSiMg合金成分设计及力学性能

[J].应用“团簇+连接原子”模型,基于合金液-固局域结构相容性和金属选区激光熔化(SLM)工艺熔体急冷的技术特性,设计高Mg含量SLM专用AlSiMg1.5合金新成分,系统研究时效温度和时间对SLM成形AlSiMg1.5合金显微组织和力学性能的影响。结果表明,通过调整工艺参数,可获得近乎全致密的SLM成形样品。当时效温度为300 ℃时,随着时效时间的延长,SLM成形样品岛状富Al组织中过固溶Si逐渐析出长大,网格状富Si组织逐渐分解球化,样品的硬度和压缩屈服强度逐渐降低,塑性明显增加。当时效温度为150 ℃时,不同时效时间下SLM成形样品的显微组织没有发生明显变化,但硬度和屈服强度随时效时间的延长先增大后略有降低。SLM成形AlSiMg1.5样品经150 ℃时效处理后的最大显微硬度和压缩屈服强度分别为(169±1) HV和(453±4) MPa,样品延伸率超过25%。本工作设计获得了成形性和力学性能优异的SLM专用铝合金新成分Al<sub>91.0</sub>Si<sub>7.5</sub>Mg<sub>1.5</sub> (质量分数,%)。

Numerical simulation of the flow behavior and powder spreading mechanism in powder bed-based additive manufacturing

[J].

Packing quality of powder layer during counter-rolling-type powder spreading process in additive manufacturing

[J].

Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe

[J].

Numerical simulation of the effect of fine fraction on the flowability of powders in additive manufacturing

[J].

Discrete element simulation of powder layer thickness in laser additive manufacturing

[J].

Powder-spreading mechanisms in powder-bed-based additive manufacturing: Experiments and computational modeling

[J].The packing density of the powder layer plays a key role in the final quality of the parts fabricated via powder-bed-based (PBB) additive manufacturing. This paper presents a combined experimental and computational modeling study on the scraping type of powder-spreading process, in order to understand the fundamental mechanisms of the packing of the powder layer. The deposition mechanisms at the particulate scale, including particle contact stress and particle velocity, are investigated, using the discrete element method, while the macro-scale packing density is validated by experiments. It is found that there is a stress-dip at the bottom of powder pile scraped by the rake. This stress-dip makes the powder particles uniformly deposited. Three kinds of deposition mechanisms dominating the powder spreading process are identified: cohesion effect, wall effect, and percolation effect. The cohesion effect, which leads to particle agglomerations and thus reduces the packing density, becomes stronger with the decrease of particle size. The wall effect, which leads to more vacancies in the powder layer, becomes stronger with the decrease of layer thickness or the increase of particle size. The percolation effect exists in bimodal powder particles, which leads to particle segregation within the powder layer and thus reduces the packing density. The three kinds of deposition mechanisms compete with each other during the powder-spreading process and make combined effects on the packing density of the powder layer. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Dynamic investigation on the powder spreading during selective laser melting additive manufacturing

[J].

Combined effect of particle size and surface cohesiveness on powder spreadability for additive manufacturing

[J].

Adhesion effects on spreading of metal powders in selective laser melting

[J].

A comprehensive approach to powder feedstock characterization for powder bed fusion additive manufacturing: A case study on AlSi7Mg

[J].

Role of powder particle size on laser powder bed fusion processability of AlSi10Mg alloy

[J].

On the role of powder flow behavior in fluid thermodynamics and laser processability of Ni-based composites by selective laser melting

[J].

Computer simulation of model cohesive powders: Influence of assembling procedure and contact laws on low consolidation states

[J].

Development of a multi-compartment population balance model for high-shear wet granulation with discrete element method

[J].

Effects of heat treatments on microstructure and mechanical properties of AlSi10Mg alloy produced by selective laser melting

[J].The urgent need for lightweight, high-accuracy, and personalized products has led to the rapid development of additive manufacturing. Selective laser melting (SLM), which is a very promising additive manufacturing technique, has attracted remarkable attention. The mechanical properties of SLM parts are highly related to the formation of pores and cracks. In this work, SLM parameters for AlSi10Mg alloy were optimized, and the SLM AlSi10Mg sample with a high relative density of 99.63% was obtained. The SLM sample exhibited good properties, including an ultimate tensile strength (UTS) of approximately 478 MPa, a total elongation of 8%, and an average hardness of 122 HV along the horizontal direction. However, due to a high cooling rate, an inhomogeneous microstructure with refined grains and a Si network was obtained. To achieve a homogeneous microstructure and further improve the elongation of the SLM samples, the effect of heat treatments on the microstructure and mechanical properties of the SLM samples along the horizontal direction was analyzed. After the heat treatments, the strength of the samples changed significantly and the elongation was significantly improved. Further, after a solid solution treatment at 540oC for 1 h, the UTS significantly decreased to approximately 246 MPa and the elongation increased to more than 22%. For the sample annealed at 236oC for 10 h, a UTS of approximately 368 MPa and elongation of approximately 17% were obtained. Moreover, the sample subjected to ageing at 130oC for 4 h exhibited a high strength similar to the level of the SLM sample, the elongation was increased to approximately 11.9%, and the hardness was approximately 133 HV which is 10% higher than that of the SLM sample. The improved performance of the aged samples can be attributed to the combination of solution strengthening, microstructural refinement, and precipitation strengthening. The results show that low-temperature ageing is the optimized heat-treatment method for SLM samples with fine microstructures.

热处理对激光选区熔化AlSi10Mg合金显微组织及力学性能的影响

[J].

An open-architecture metal powder bed fusion system for in-situ process measurements

[J].

A numerical investigation on the physical mechanisms of single track defects in selective laser melting

[J].

Modeling of solidification microstructure evolution in laser powder bed fusion fabricated 316L stainless steel using combined computational fluid dynamics and cellular automata

[J].This work presents a novel modeling framework combining computational fluid dynamics (CFD) and cellular automata (CA), to predict the solidification microstructure evolution of laser powder bed fusion (PBF) fabricated 316 L stainless steel. A CA model is developed which is based on the modified decentered square method to improve computational efficiency. Using this framework, the fluid dynamics of the melt pool flow in the laser melting process is found to be mainly driven by the competing Marangoni force and the recoil pressure on the liquid metal surface. Evaporation occurs at the front end of the laser spot. The initial high temperature occurs in the center of the laser spot. However, due to Marangoni force, which drives high-temperature liquid flowing to low-temperature region, the highest temperature region shifts to the front side of the laser spot where evaporation occurs. Additionally, the recoil pressure pushes the liquid metal downward to form a depression zone. The simulated melt pool depths are compared well with the experimental data. Additionally, the simulated solidification microstructure using the CA model is in a good agreement with the experimental observation. The simulations show that higher scan speeds result in smaller melt pool depth, and lack-of-fusion pores can be formed. Higher laser scan speed also leads to finer grain size, larger laser-grain angle, and higher columnar grain contents, which are consistent with experimental observations. This model can be potentially used as a tool to optimize the metal powder bed fusion process, through generating desired microstructure and resultant material properties.

Numerical simulation and experimental calibration of additive manufacturing by blown powder technology. Part I: thermal analysis

[J].

A novel method for the molten pool and porosity formation modelling in selective laser melting

[J].

On the role of energy input in the surface morphology and microstructure during selective laser melting of Inconel 718 alloy

[J].

Multiscale and multiphysics explorations of the transient deposition processes and additive characteristics during laser 3D printing

[J].Laser directed energy deposition (DED) involves complex physical processes, and the trial and error examinations are time consuming and cost expensive. The research paradigm can be reshaped using advanced phenomenological models via computing the spatiotemporal variations of the build features. In this work, multi-layer and multi-track laser DED of Ti-6Al-4V were systematically explored on multiple scales including the 1D track, the 2D layer and the 3D full build considering the complex transport of energy, mass, and momentum in the moving freeform molten pool. The results showed that convex, near-flat, and wavy builds were generated using gradually larger hatch spacings. The profiles of individual tracks and layers were extracted through the unique advantages of the model. The individual tracks exhibited various patterns and rotated with specific inclinations to form distinct layer profiles. The net increments of the deposit generated upon the printing of a new track during the continuous deposition process showed that the smaller hatch spacing caused higher overlap rate of horizontally adjacent tracks but lower remelting rate of vertically adjacent tracks in neighboring layers. The 3D numerical model was validated with corresponding experiments for various process conditions. The scientific findings can provide useful insights for further researches of DED.

Thermoelectric magnetohydrodynamic model for laser-based metal additive manufacturing

[J].

Flow behavior of powder particles in layering process of selective laser melting: Numerical modeling and experimental verification based on discrete element method

[J].

Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones

[J].

A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends

[J].Selective laser melting (SLM) is an attractive rapid prototyping technology for the fabrication of metallic components with complex structure and high performance. Aluminum alloy, one of the most pervasive structural materials, is well known for high specific strength and good corrosion resistance. But the poor laser formability of aluminum alloy restricts its application. There are problems such as limited processable materials, immature process conditions and metallurgical defects on SLM processing aluminum alloys. Some efforts have been made to solve the above problems. This paper discusses the current research status both related to the scientific understanding and technology applications. The paper begins with a brief introduction of basic concepts of aluminum alloys and technology characterization of laser selective melting. In addition, solidification theory of SLM process and formation mechanism of metallurgical defects are discussed. Then, the current research status of microstructure, properties and heat treatment of SLM processing aluminum alloys is systematically reviewed respectively. Lastly, a future outlook is given at the end of this review paper.

On the role of processing parameters in thermal behavior, surface morphology and accuracy during laser 3D printing of aluminum alloy

[J].