增材制造(additive manufacturing,AM)技术可突破诸如铸造、锻造、轧制和挤压等传统制造工艺的限制,实现高几何复杂度金属零件的直接近净成形[1]。金属AM技术主要包括以同步送粉(或送丝)激光熔覆为主要技术特征的激光立体成形技术和以粉末床为主要技术特征的选区激光(或电子束)熔化技术(selective laser melting,SLM或selective electron beam melting,SEBM)[2]。SLM技术基于分层制造、层层叠加的成形原理,采用高功率密度激光对金属粉末进行选择性熔化,直接获得高性能、高致密度的金属零件,可实现复杂金属零件的近净成形[3,4]。SLM成形过程中熔体的冷却速率极快(103~106 K/s)[5],可获得具有独特微观组织和远超元素固溶极限的高过饱和固溶体合金,从而为合金组织和性能的优化提供了契机[6]。

目前,SLM技术已经成熟应用于钛合金、高温合金、不锈钢等多种合金体系[7]。铝合金因其高比强度和耐大气腐蚀等优点,广泛应用于航空航天和汽车制造等领域[8]。由于铝合金粉末存在激光反射率高、分散性差和导热率高等特点,其与SLM工艺的融合性较差[9]。2xxx、6xxx和7xxx系高强铝合金是航空航天领域常用的铝合金材料,然而,高浓度的合金化元素和宽的凝固区间使得这些沉淀强化铝合金在SLM成形过程中容易产生热裂纹,恶化其力学性能。虽然Zr和Si等合金化元素的加入可增加铝合金凝固过程中的形核点,减少或消除铝合金在SLM成形过程中产生的热裂纹,但其强度远低于其传统变形铝合金[10~13]。因此,当前获得应用的SLM成形铝合金主要集中在以Al-Si和Al-Si-Mg为代表的4xxx铸造铝合金和基于5xxx的Al-Mg-(Sc, Zr)变形铝合金体系。Al-Si系铝合金具有优异的SLM成形性和宽的工艺窗口,所获得合金具有独特的亚微米胞状显微组织及高Si固溶度,从而使得合金的力学性能明显优于同成分的铸造合金,但该类SLM成形合金的屈服强度(YS)往往低于300 MPa,延伸率低于10%[14~17]。虽然高温时效处理可以有效提升SLM成形Al-Si系铝合金的塑性,但由于网格状共晶Si组织的分解和粗化,导致合金的强度降低明显[18,19]。尽管在前期工作中[6,20,21],基于SLM技术熔体快速凝固的特点,通过增加Al-Si-Mg合金中的Mg含量有效提升了合金的强度,使得SLM成形AlSiMg1.4合金的YS超过340 MPa,抗拉强度(UTS)超过520 MPa,并保持约7%的延伸率,但该类合金的力学性能依然有待提高。

Al-Mg-(Sc, Zr)铝合金具有优良的耐腐蚀和焊接性能,为国内外超塑性成形研究焦点合金体系之一[22~24]。Scalmalloy®为欧洲空客集团开发的SLM专用高强Al-Mg-Sc-Zr铝合金[25]。该合金以Al-Mg-(Sc, Zr)为基础,通过增加Sc和Zr元素来提升合金的力学性能,其YS超过500 MPa,延伸率大于14%。Spierings等[26~28]对Scalmalloy®合金的组织和力学性能进行了系统的研究,结果表明,SLM成形Al-Mg-(Sc, Zr)合金由熔池底部的细小等轴晶和熔池内部的较粗大柱状晶构成,初生的Al3(Sc, Zr)纳米颗粒为α-Al晶粒提供了大量的随机形核点,促进了等轴晶的形成,有效抑制了SLM成形过程中热裂纹的产生,增加了合金的SLM成形性和力学性能。经适当时效处理后,由于次生Al3Sc纳米颗粒的析出,使得样品的强度大幅提升。考虑到Al-Mg相的腐蚀敏感性,Jia等[29,30]用Mn替代Mg,研究了SLM成形Al-(Mn, Mg)-(Sc, Zr)合金的力学性能。一次Al6Mn和Al3(Sc, Zr)纳米颗粒在晶界处的析出,抑制了α-Al晶粒在高温下的回复再结晶及长大,该合金经300℃时效处理后具有最佳的力学性能,其YS超过570 MPa,延伸率超过15%,明显优于Scalmalloy®合金。Li等[31]通过增加Al-Mg-(Sc, Zr)铝合金中Mg的含量及引入合金化元素Si,设计了成形性和力学性能优异的Al-8.0Mg-1.3Si-0.5Mn-0.5Sc-0.3Zr (质量分数,%,下同)铝合金,经适当时效处理后,该合金的YS超过520 MPa,UTS可达550 MPa。前期工作[32~34]研究了高Mg含量(~15%)Al-Mg-(Sc, Zr)铝合金的SLM成形性和力学性能。结果表明,该合金具有良好的SLM成形性,最低孔隙率约为0.3%,Mg含量的增加有效提升了合金的强度,使其明显高于相同Sc和Zr含量的SLM成形Al-Mg-(Sc, Zr)铝合金[35]。Wang等[36]的研究结果表明,SLM成形Al-Mg-(Sc, Zr)铝合金中等轴晶和柱状晶带间的特殊应变分配导致附加背应力硬化,提高了材料的应变硬化能力,使得该类材料具有强度和塑性的良好结合。尽管SLM成形Al-Mg-(Sc, Zr)铝合金因其良好的SLM成形性、高强度、低各向异性和高组织稳定性而受到广泛的研究,但其强度依然低于传统变形高强铝合金[37]。因此,有必要进一步提升SLM成形铝合金的强度。

基于SLM成形技术熔体快速凝固的特点,同时增加固溶强化元素和析出强化元素的含量是提升SLM成形铝合金力学性能的有效手段[25,34],但固溶元素含量的提高会增加SLM成形合金中的内应力,降低合金的成形性。增加合金熔体凝固过程中形核点的数量,细化晶粒是提升铝合金SLM成形性的关键因素之一[28]。对于含Sc和Zr改性的SLM成形Al-Mg合金,其成形过程中一次析出的Al3(Sc, Zr)纳米颗粒作为α-Al凝固过程中的形核点,可起到细化晶粒的效果,从而有效释放合金成形过程中产生的内应力,增加合金的SLM成形性和塑性。Jia等[29]的研究结果表明,在SLM成形Al-Mg-(Sc, Zr)铝合金中加入Mn元素可降低合金的腐蚀敏感性,同时,一次析出的Al6Mn纳米颗粒同时分布于等轴晶和柱状晶的晶界处,可有效抑制合金的回复再结晶,增强合金的热稳定性。因此,本工作基于Al-Mg-Sc-Zr合金,用Mn部分替代Mg,并同时提高Al-(Mn, Mg)-(Sc, Zr)合金中固溶强化元素(Mn + Mg)和时效析出强化元素(Sc + Zr)的含量,设计了Al-5.5Mn-2.7Mg-1.0Sc-0.9Zr新成分SLM专用铝合金,系统研究了合金的SLM成形性及时效温度对合金组织和力学性能的影响。

1 实验方法

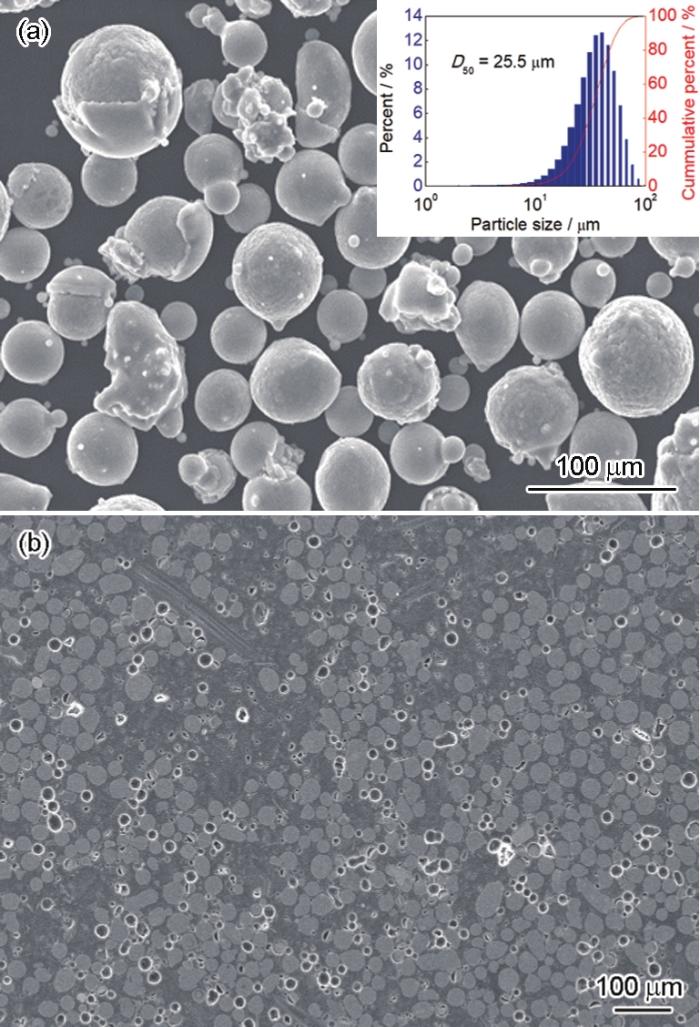

采用真空N2雾化方法制备Al-(Mn, Mg)-(Sc, Zr)合金粉末,用Icp2060t等离子体扫描光谱仪(ICP)测试粉末和SLM成形样品的化学成分,测量结果见表1。铝合金粉末和SLM成形样品的成分接近。筛取直径15~53 μm区间(平均粒径为25.5 μm)的合金粉末进行SLM成形实验,实验所用设备型号为FS121M。样品的SLM成形工艺参数为:激光功率190 W,激光扫描速率700~1300 mm/s,光斑直径100 μm,激光扫描间距100 μm,铺粉厚度30 μm,相位角67°。成形样品尺寸为:长 × 宽 × 高 = 35 mm × 15 mm × 35 mm。应用Axioskop2 型金相显微镜(OM)和JSM-6480扫描电子显微镜(SEM)观察SLM成形样品的显微组织。应用SEM附带的能谱仪(EDS)分析样品的成分。应用电子背散射衍射(EBSD)分析样品的取向关系和晶粒尺寸。应用D8 Focus X 射线衍射仪(XRD,CuKα,波长0.15406 nm)测试SLM成形样品的晶体结构。采用Archimedes排水法测量样品的密度。样品的相对密度由测量密度/理论密度获得。样品的理论密度通过以下公式进行计算[28]:

表1 Al-(Mn, Mg)-(Sc, Zr)粉末及选区激光熔化(SLM)成形样品的化学成分 (mass fraction / %)

Table 1

| Specimen | Mn | Mg | Sc | Zr | Fe | Al |

|---|---|---|---|---|---|---|

| Powder | 5.5 | 2.7 | 1.0 | 0.9 | 0.1 | Bal. |

| SLM-formed | 5.4 | 2.6 | 1.1 | 0.8 | 0.1 | Bal. |

式中,D为合金的密度;Al%、Mn%、Mg%、Sc%、Zr%和Fe%分别为Al、Mn、Mg、Sc、Zr和Fe元素的质量分数;DAl、DMn、DMg、DSc、DZr和DFe分别为Al、Mn、Mg、Sc、Zr和Fe单质的密度。依据

2 实验结果与讨论

2.1 粉末及成形样品

图1

图1

Al-(Mn, Mg)-(Sc, Zr)粉末样品表面及剖面SEM像及粉末尺寸分布

Fig.1

Surface (a) and section (b) SEM images of Al-(Mn, Mg)-(Sc, Zr) powder (Inset in Fig.1a shows the size distribution of powder, D50—average particle diameter)

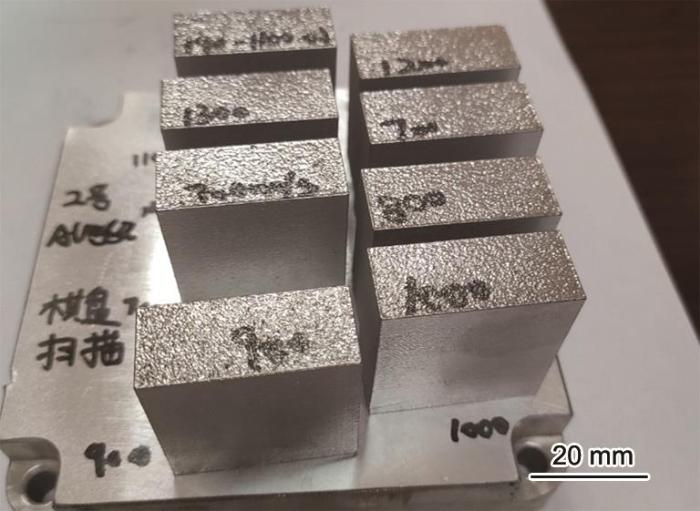

图2

图2

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品宏观照片

Fig.2

Photography of SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples

2.2 样品的成形性及显微组织

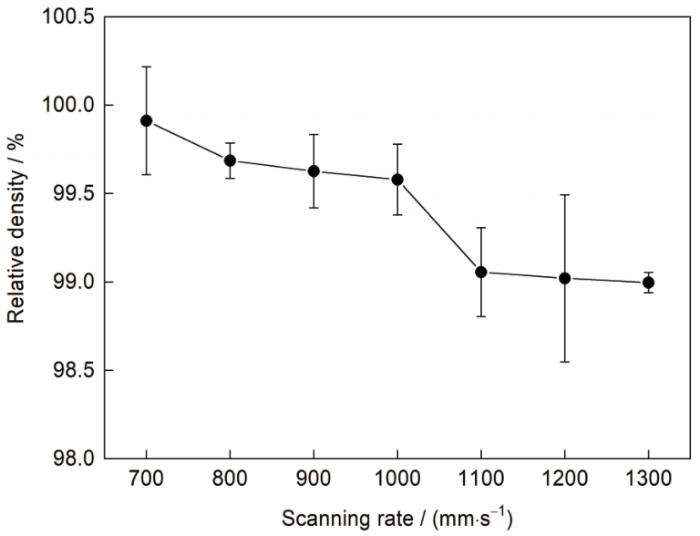

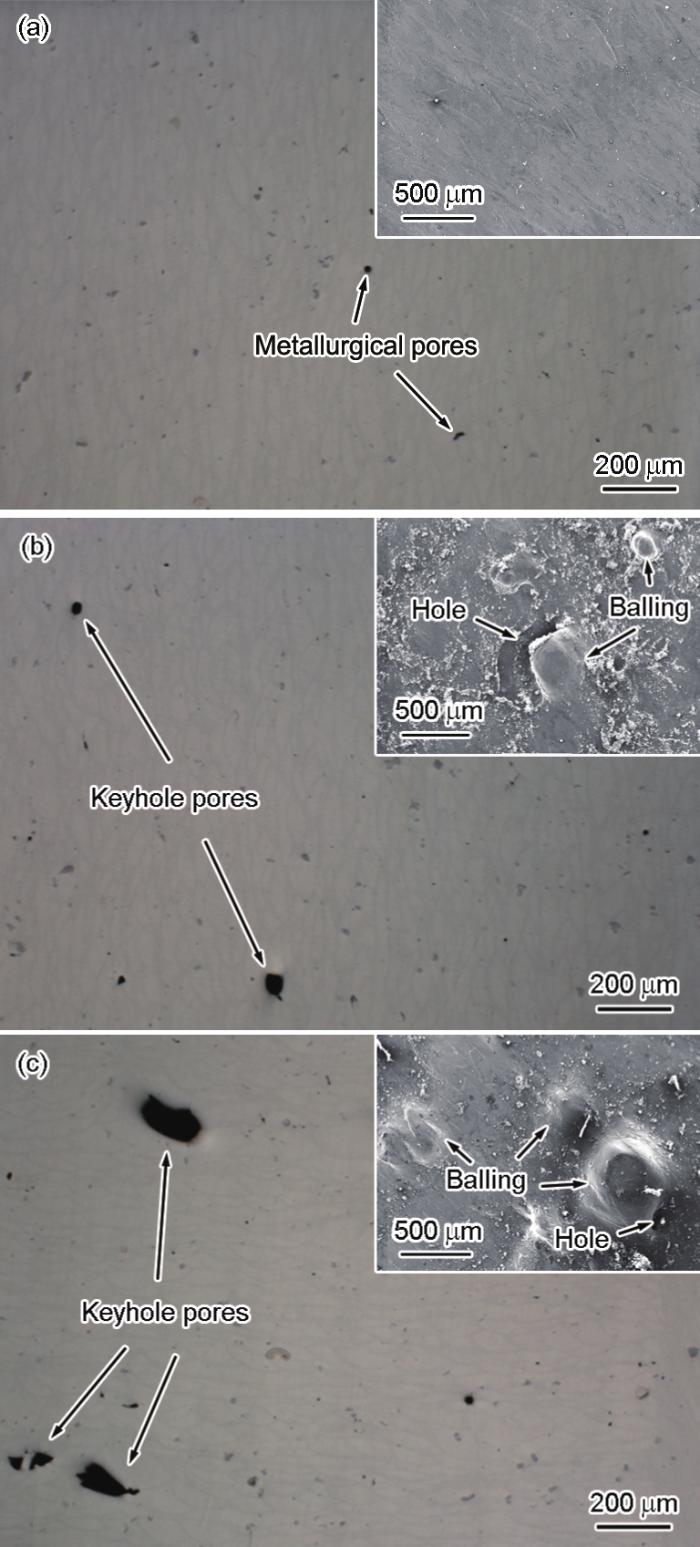

SLM成形性反映的是样品成形质量的好坏,一般利用样品的相对密度直观地表征样品的成形性[39]。图3为SLM成形Al-(Mn, Mg)-(Sc, Zr)样品的相对密度随激光扫描速率的变化曲线。可知,样品的相对密度随激光扫描速率的增加逐渐降低,由700 mm/s时的99.9%降低至1300 mm/s时的99.0%,但整体表现出良好的SLM成形性。为分析样品相对密度变化的原因,图4给出了激光扫描速率分别为700、900和1100 mm/s时获得样品横截面的OM像及对应样品上表面的SEM像(插图)。当激光扫描速率为700 mm/s时,样品上表面光滑,样品内部只存在少量细小的冶金孔(图4a),这些冶金孔主要是由于粉末中的水蒸气经高温分解后产生的H2或Mg蒸气残存在样品中所致[40]。当激光扫描速率增加到900和1100 mm/s时,成形样品表面出现球化现象(图4b和c)。样品上表面小直径球化颗粒的产生主要是由于在高激光扫描速率下,熔池内部熔体不稳定性增加,小颗粒熔滴溅到样品表面所致[41],见图4b。而样品表面大直径球化颗粒的产生是由于在高激光扫描速率下,激光输入能量密度降低,不足以熔化大颗粒粉末,这些大颗粒粉末被周围熔体包覆,使得其尺寸可达数百微米。这些大直径球化颗粒底部往往伴随熔体未填充缝隙,再加之样品表面的过渡球化也会导致下一层粉末的不当沉积,在激光进行下一层扫描的过程中,熔融金属很难完全填充到样品中的缝隙,最终导致样品中产生跨越几个熔池的未熔合孔(钥匙孔)[42],见图4b和c。未熔合孔一旦产生,其数量和尺寸会随激光扫描速率的增加而增加,从而增加样品的孔隙率,降低样品的相对密度[43]。

图3

图3

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品相对密度随激光扫描速率的变化曲线

Fig.3

Evolution of the relative density of the SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples with the scanning rate

图4

图4

不同激光扫描速率下获得SLM成形Al-(Mn, Mg)-(Sc, Zr)样品的OM像及样品上表面SEM像

Fig.4

OM and upper surface SEM images (insets) of the SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples manufacturing at the scanning rates of 700 mm/s (a), 900 mm/s (b), and 1100 mm/s (c)

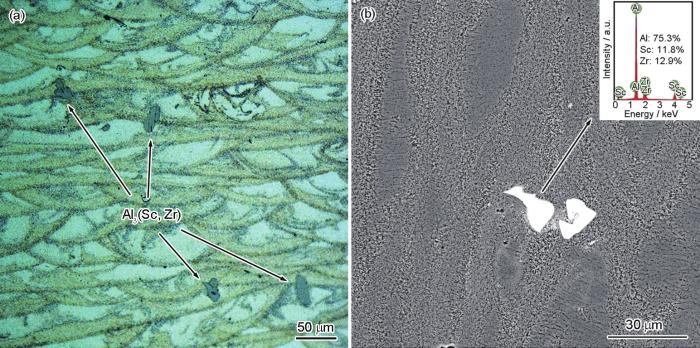

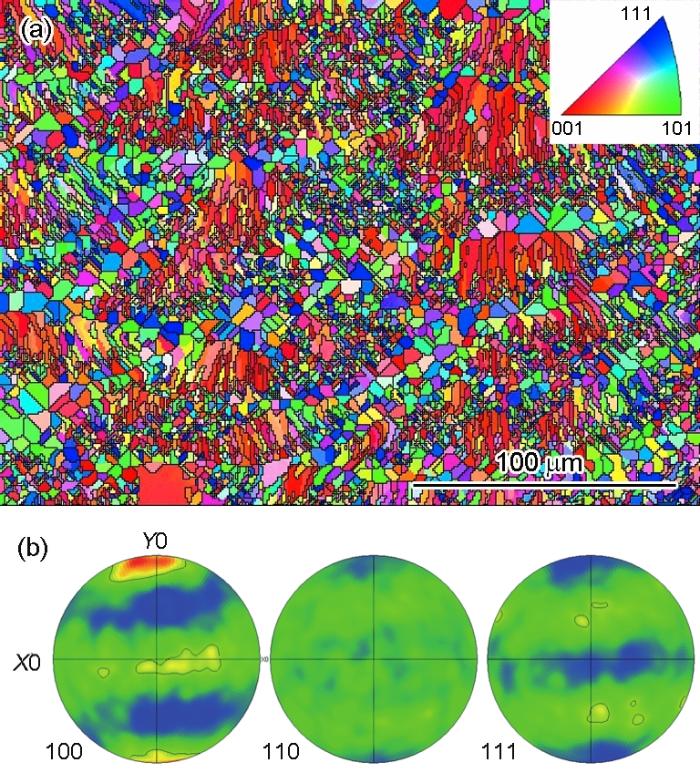

图5为SLM成形Al-(Mn, Mg)-(Sc, Zr)样品纵剖面的OM像和SEM像。样品具有SLM成形合金典型的叠层分布熔池结构[44],经金相腐蚀液(Keller试剂)腐蚀后,熔池内部为亮白色,熔池边界颜色较暗(图5a)。样品中有不规则块状组织析出,经EDS分析其成分为Al75.3Sc11.8Zr12.9 (原子分数) (图5b中插图),接近Al3(Sc, Zr)析出相的化学成分,表明合金中的Sc和Zr含量已经超过了SLM技术熔体快冷的固溶极限。EBSD分析表明,样品熔池边界为细小等轴晶,熔池内部为较粗大柱状晶粒带(图6a),柱状晶具有明显<100>取向,晶粒的平均尺寸约为4 μm。等轴晶的形成是由于熔池边界冷却速率较慢,当合金熔体凝固时,Al3(Sc, Zr)首先在熔体中析出[31],这些纳米粒子作为α-Al晶粒的形核中心,产生强烈的晶粒细化效果,细小随机取向等轴晶的存在也是SLM成形Al-Mg-(Sc, Zr)铝合金具有良好SLM成形性和低力学各向异性的主要原因[45,46]。随着凝固的进行,熔体冷却速率增加,由于熔体内Sc和Zr元素浓度降低及Al3(Sc, Zr)粒子析出动力学受限,熔池内部不再有Al3(Sc, Zr)粒子析出,在形核剂减少的情况下,熔池内部熔体沿冷却方向形成择优取向的柱状晶粒。

图5

图5

激光扫描速率为900 mm/s时SLM成形Al-(Mn, Mg)-(Sc, Zr)样品纵剖面的OM像和SEM像及析出相成分分析

Fig.5

Longitudinal section OM (a) and SEM (b) images of the SLM-formed Al-(Mn, Mg)-(Sc, Zr) sample manufacturing at a scanning rate of 900 mm/s (Inset in Fig.5b shows the composition analysis (atomic fraction) of precipitates)

图6

图6

激光扫描速率为900 mm/s时SLM成形Al-(Mn, Mg)-(Sc, Zr)样品EBSD分析结果

Fig.6

EBSD orientation map (a) and pole figures (b) of the SLM-formed Al-(Mn, Mg)-(Sc, Zr) sample manufacturing at a scanning rate of 900 mm/s

2.3 时效温度对样品组织和力学性能的影响

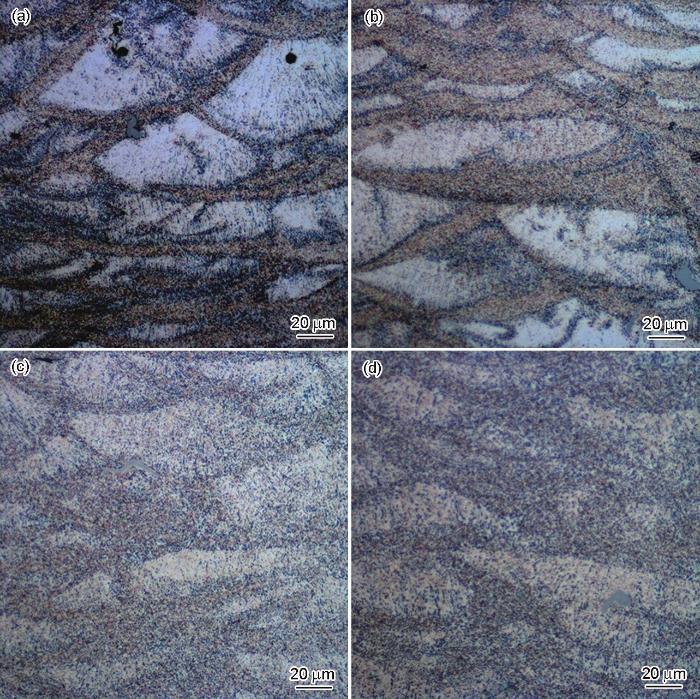

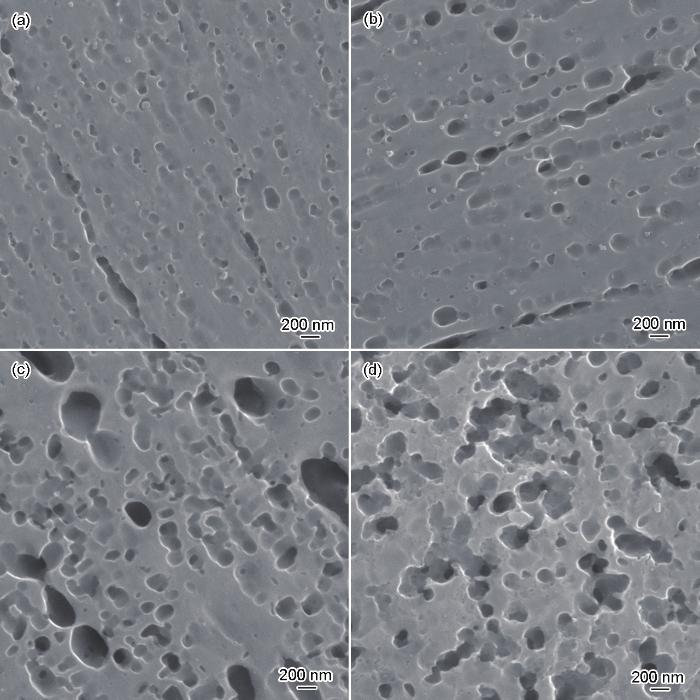

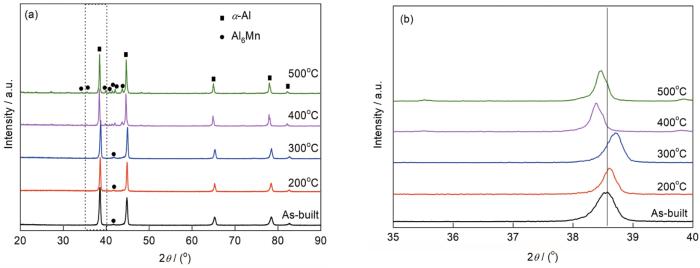

图7给出了SLM成形样品经不同温度时效2 h后的OM像。可知,随着时效温度的升高,样品熔池内部衬度逐渐变暗,熔池边界逐渐模糊。SEM观察结果表明,随着时效温度的增加,熔池内部点蚀坑的数量逐渐变多,深度逐渐变深(图8),在OM像中表现为衬度变暗,表明样品的耐蚀性逐渐降低。XRD测试结果表明,未经时效处理样品主要由α-Al和Al6Mn相构成(图9),当时效温度为200和300℃时,Al6Mn衍射峰的强度稍有增加,α-Al衍射峰向高角度偏移。这主要是由于合金中大尺寸Sc原子在时效过程中析出,与Al原子形成了Al3Sc纳米颗粒,降低了α-Al固溶体的晶格常数,使得α-Al的衍射峰向高角度偏移,由于Al3Sc纳米颗粒极为细小(约几个纳米),且其衍射峰与α-Al的衍射峰重叠,很难在XRD谱中进行标定[29,47]。当时效温度升高到400和500℃时,样品中开始有大量Al6Mn化合物析出,由于α-Al中小尺寸Mn原子的含量降低,导致α-Al的衍射峰向低角度偏移。铝合金中Al6Mn含量的增加和晶粒的长大会降低其在Keller试剂中的耐蚀性,经金相腐蚀液腐蚀后会在α-Al晶粒内部和晶界处出现大量的点蚀坑。

图7

图7

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品经200、300、400和500℃时效处理2 h后的OM像

Fig.7

OM images of SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples aged at 200oC (a), 300oC (b), 400oC (c), and 500oC (d) for 2 h

图8

图8

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品经200、300、400和500℃时效处理2 h后熔池内部的SEM像

Fig.8

SEM images of molten pool of SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples aged at 200oC (a), 300oC (b), 400oC (c), and 500oC (d) for 2 h

图9

图9

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品经不同温度时效2 h后的XRD谱

Fig.9

XRD spectra (a) and local enlargement (b) of the SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples aged at different temperatures for 2 h

随着时效温度的升高,SLM成形样品的Vickers硬度先增大后减小,当时效温度为350℃时,样品的硬度具有最大值,约为(218 ± 5) HV (图10a)。样品的压缩屈服强度和抗压强度随时效温度的变化趋势与硬度一致,时效温度为300℃时具有最大值,分别为(653 ± 3) MPa和(752 ± 7) MPa (图10c)。所有样品的压缩延伸率均超过60% (图10b)。当时效温度超过200℃时,样品在压缩后期均出现了不同程度的加工软化现象,其中以300℃时效样品最为明显。这可能是由于当时效温度超过200℃时,α-Al晶粒内部开始有Al3Sc纳米粒子析出,这些第二相粒子提供了更多的形核质点和储存能,使得样品在压缩过程中容易发生动态回复再结晶,发生加工软化。由于300℃时效样品具有最高浓度的第二相粒子,因此其加工软化现象更加明显。图10d给出了本工作获得的合金力学性能与典型SLM成形铝合金及传统变形AA7075铝合金[6,12,33,48]力学性能的对比结果。可知,本工作的Al-(Mn, Mg)-(Sc, Zr)合金具有最大的压缩屈服强度,超过传统T6时效处理后的AA7075铝合金。

图10

图10

SLM成形Al-(Mn, Mg)-(Sc, Zr)样品经不同温度时效处理后的Vickers硬度、压缩真应力-真应变曲线、压缩力学性能及与其他铝合金压缩性能对比结果

Fig.10

Vickers hardnesses (a), compressive true stress-true strain curves (b), compressive mechanical properties (c) of SLM-formed Al-(Mn, Mg)-(Sc, Zr) samples aged at different temperatures for 2 h, and a comparison with others aluminum alloys (d)

2.4 强化机理

SLM成形Al-(Mn, Mg)-(Sc, Zr)合金高强度的获得是细晶强化、固溶强化和析出强化共同作用的结果。

合金晶粒的细化主要是由于:(1) SLM成形过程中熔体急速冷却大幅提升了合金的温度过冷,增加了α-Al晶粒的随机形核点,细化了晶粒;(2) SLM成形合金的凝固始于熔池边缘并向熔池内部扩展,在此过程中,溶质元素从晶粒中排出,从而在凝固界面前沿的液相区形成扩散场,当铝合金中的溶质元素的平衡分配系数k0小于1时,会在合金凝固前沿的液相处发生成分过冷[49],由于铝合金中Mg、Mn和Sc元素的k0均小于1[50],其在Al-(Mn, Mg)-(Sc, Zr)合金中含量的提升会增加成分过冷度,促进晶体的随机形核,细化晶粒;(3) 由于Al3(Sc, Zr)纳米颗粒会首先在熔池边界处析出,这些纳米粒子作为α-Al晶粒的形核中心,也会产生强烈的晶粒细化效果[45]。因此本工作获得的SLM成形铝合金的晶粒尺寸远小于传统铸造或变形Al-Mg-(Sc, Zr)合金[51]。依据经典的Hall-Petch关系,晶粒的细化会在合金中引入高密度的晶界,从而阻碍位错的移动,增加合金的强度[52]。

在低温时效过程中,由于Sc的扩散系数远高于Zr元素,Al3Sc纳米颗粒首先在α-Al晶粒内部析出[30]。而α-Al中超高的Sc固溶量也为高密度Al3Sc的析出创造了条件。这些Al3Sc纳米颗粒尺寸往往较小,为1~2 nm[29],且与基体共格。Al3Sc纳米颗粒在合金中的强化为有序强化、共格强化、模量错配强化和位错切过强化机制的共同作用结果[31],其中模量错配强化为SLM成形Al-(Mn, Mg)-(Sc, Zr)铝合金的主要强化机制[29]。因此,高密度Al3Sc纳米颗粒的析出是合金经低温时效后硬度和强度获得大幅提升的主要原因。当时效温度超过400℃时,(1) Al6Mn晶粒的大量析出及晶粒尺寸的长大(图8),使得Mn元素的固溶强化效果降低;(2) Al3Sc颗粒长大并逐渐与α-Al基体失共格,析出强化作用减弱;(3) 由于基体中的Sc和Zr元素不断向Al3Sc颗粒扩散,并形成Al3(Sc, Zr)核壳结构(颗粒内部富Sc外部富Zr)[54],导致α-Al中Sc和Zr元素固溶量降低,Sc和Zr元素的固溶强化作用减弱。最终使得样品的强度迅速降低。

3 结论

(1) SLM成形Al-(Mn, Mg)-(Sc, Zr)样品的相对密度随激光扫描速率的增加而降低。当激光扫描速率为700 mm/s时样品具有最大相对密度99.9%。在高激光扫描速率下,由于激光能量密度的降低,无法完全熔化大颗粒粉末,导致样品中未熔合孔洞的产生,相对密度降低。

(2) SLM成形Al-(Mn, Mg)-(Sc, Zr)样品具有细等轴晶和较粗大柱状晶组织,平均晶粒尺寸约为4 μm。由于合金中Mn、Sc和Zr元素的含量超过了其在α-Al中的固溶极限,使得样品中有Al6Mn和块状Al3(Sc, Zr)相析出。

(3) 当时效温度≤ 350℃时,由于Al3Sc纳米颗粒的大量析出导致SLM成形Al-(Mn, Mg)-(Sc, Zr)样品的硬度和强度大幅提高。当时效温度为300℃时,样品的压缩屈服强度和抗压强度分别达到(653 ± 3)和(752 ± 7) MPa,超过现有报道的大多数铝合金。继续升高时效温度后,由于二次Al6Mn晶粒的析出与长大、Al3Sc粒子的粗化及部分合金元素固溶强化作用失效,导致样品的强度降低。

(4) 极细的晶粒、达到α-Al固溶极限的溶质含量及高密度Al3Sc粒子的共同作用使SLM成形Al-(Mn, Mg)-(Sc, Zr)合金具有高硬度和高强度。

(5) 本工作获得的SLM专用Al-(Mn, Mg)-(Sc, Zr)铝合金的SLM成形性和力学性能优异,具有广阔的应用前景。

参考文献

Manufacture by selective laser melting and mechanical behavior of a biomedical Ti-24Nb-4Zr-8Sn alloy

[J].

Laser additive manufacturing of high-performance metal components

[J].

高性能金属构件的激光增材制造

[J].

Rapid in situ fabrication of Fe/SiC bulk nanocomposites by selective laser melting directly from a mixed powder of microsized Fe and SiC

[J].

Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement

[J].

Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs

[J].

Mechanical properties of AlSiMg alloy specifically designed for selective laser melting

[J].

选区激光熔化专用AlSiMg合金成分设计及力学性能

[J].应用“团簇+连接原子”模型,基于合金液-固局域结构相容性和金属选区激光熔化(SLM)工艺熔体急冷的技术特性,设计高Mg含量SLM专用AlSiMg1.5合金新成分,系统研究时效温度和时间对SLM成形AlSiMg1.5合金显微组织和力学性能的影响。结果表明,通过调整工艺参数,可获得近乎全致密的SLM成形样品。当时效温度为300 ℃时,随着时效时间的延长,SLM成形样品岛状富Al组织中过固溶Si逐渐析出长大,网格状富Si组织逐渐分解球化,样品的硬度和压缩屈服强度逐渐降低,塑性明显增加。当时效温度为150 ℃时,不同时效时间下SLM成形样品的显微组织没有发生明显变化,但硬度和屈服强度随时效时间的延长先增大后略有降低。SLM成形AlSiMg1.5样品经150 ℃时效处理后的最大显微硬度和压缩屈服强度分别为(169±1) HV和(453±4) MPa,样品延伸率超过25%。本工作设计获得了成形性和力学性能优异的SLM专用铝合金新成分Al<sub>91.0</sub>Si<sub>7.5</sub>Mg<sub>1.5</sub> (质量分数,%)。

Research progress of metal materials for 3D printing

[J].

3D打印金属材料研究进展

[J].

High performance metal additive manufacturing technology applied in aviation field

[J].

应用于航空领域的金属高性能增材制造技术

[J].

Fusion-based additive manufacturing for processing aluminum alloys: State-of-the-art and challenges

[J].

A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties

[J].

Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting

[J].

Changing the alloy composition of Al7075 for better processability by selective laser melting

[J].

3D printing of high-strength aluminium alloys

[J].

Study on the selective laser melting of AlSi10Mg

[J].

AlSi10Mg的激光选区熔化成形研究

[J].利用激光选区熔化(selective laser melting, SLM)成形技术对AlSi10Mg铸造铝合金的成形进行了工艺研究,获得了致密的成形,并对其沉积态和热处理态试样进行了静态拉伸性能测试和显微组织分析。结果表明:对于AlSi10Mg, 其SLM沉积态的常温拉伸强度远高于铸件标准,延伸率与铸态相当;退火工艺对SLM试样的组织及力学性能有着重要的影响,随着退火温度的提高,试样微观组织发生改变,在300 ℃、2 h退火工艺下,原本均匀分布的颗粒状Si聚集长大为针状,使得试样的强度下降,延伸率升高。抗拉强度由沉积态的507~518 MPa下降到378~406 MPa,延伸率由沉积态的3.0%~3.5%增加到6.5%~9.0%。

Comparative study of performance comparison of AlSi10Mg alloy prepared by selective laser melting and casting

[J].

Influence of scan strategy and molten pool configuration on microstructures and tensile properties of selective laser melting additive manufactured aluminum based parts

[J].

Influence of static magnetic field on microstructure and mechanical behavior of selective laser melted AlSi10Mg alloy

[J].

A selective laser melting and solution heat treatment refined Al-12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility

[J].

Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy

[J].

A high-strength AlSiMg1.4 alloy fabricated by selective laser melting

[J].

Selective laser melting of AlSiMg3 alloy with super-hardness

[J].

选区激光熔化成形高硬度AlSiMg3合金

[J].

High strain rate superplasticity in a continuously recrystallized Al-6%Mg-0.3%Sc alloy

[J].

Mechanical behavior of Al-6Mg-0.2Sc aluminum alloys at elevated temperature

[J].

Al-6Mg-

Formation and mechanical properties of Al-Mg-Sc-Zr alloy prepared by selective laser melting

[J].

选区激光熔化Al-Mg-Sc-Zr合金成形性及力学性能

[J].

Process and mechanical properties: Applicability of a scandium modified Al-alloy for laser additive manufacturing

[J].

SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment

[J].

Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition

[J].

Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc- and Zr-modified Al-Mg alloys

[J].

Selective laser melting of a high strength Al-Mn-Sc alloy: Alloy design and strengthening mechanisms

[J].

Precipitation kinetics, microstructure evolution and mechanical behavior of a developed Al-Mn-Sc alloy fabricated by selective laser melting

[J].

Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms

[J].

Design, preparation and properties of Al-Mg-(Sc, Zr) alloys for SLM

[D].

SLM专用Al-Mg-(Sc, Zr)合金成分设计、制备及性能研究

[D].

Processability and mechanical properties of high Mg-content Al-Mg-Sc-Zr alloy produced by selective laser melting

[J].

高Mg含量Al-Mg-Sc-Zr合金选区激光熔化成形及力学性能研究

[J].

Mechanical properties of high Mg-content Al-Mg-Sc-Zr alloy fabricated by selective laser melting

[J].

Selective laser melting of a novel Sc and Zr modified Al-6.2Mg alloy: Processing, microstructure, and properties

[J].

Strength-ductility synergy of selective laser melted Al-Mg-Sc-Zr alloy with a heterogeneous grain structure

[J].

Scandium in aluminium alloys

[J].

Microstructure and properties of AlSi10Mg powder for selective laser melting

[J].

激光选区熔化用AlSi10Mg粉末显微组织与性能

[J].

Comparison of density measurement techniques for additive manufactured metallic parts

[J].

Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg

[J].

Effects of processing parameters on properties of selective laser melting Mg-9%Al powder mixture

[J].

Problems and issues in laser beam welding of aluminum-lithium alloys

[J].

Reducing porosity in AlSi10Mg parts processed by selective laser melting

[J].

3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting

[J].

Effect of laser rescanning on the grain microstructure of a selective laser melted Al-Mg-Zr alloy

[J].

Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting

[J].

Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting

[J].

Work-softening mechanism of Cu-Cr-Ti-Si alloy

[J].

Cu-Cr-Ti-Si合金加工软化的机理

[J].

Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting

[J].

Microstructural formation and characterization mechanisms of selective laser melted Al-Si-Mg alloys with increasing magnesium content

[J].

Preparation of high purity metals by crystallization methods

[J].

Research advance on new Al-Mg-Sc-Zr and Al-Zn-Mg-Sc-Zr alloys

[J].

新型Al-Mg-Sc-Zr和Al-Zn-Mg-Sc-Zr合金的研究进展

[J].

Grain boundary stability governs hardening and softening in extremely fine nanograined metals

[J].Conventional metals become harder with decreasing grain sizes, following the classical Hall-Petch relationship. However, this relationship fails and softening occurs at some grain sizes in the nanometer regime for some alloys. In this study, we discovered that plastic deformation mechanism of extremely fine nanograined metals and their hardness are adjustable through tailoring grain boundary (GB) stability. The electrodeposited nanograined nickel-molybdenum (Ni-Mo) samples become softened for grain sizes below 10 nanometers because of GB-mediated processes. With GB stabilization through relaxation and Mo segregation, ultrahigh hardness is achieved in the nanograined samples with a plastic deformation mechanism dominated by generation of extended partial dislocations. Grain boundary stability provides an alternative dimension, in addition to grain size, for producing novel nanograined metals with extraordinary properties.Copyright © 2017, American Association for the Advancement of Science.

Solute strengthening in random alloys

[J].

Rapid precipitation of dispersoids during extrusion of an Al-0.91 wt.%Mn-0.13 wt.%Zr-0.17 wt.%Sc-alloy

[J].