作为一个新兴的材料研究领域,异构材料的力学性能已被广泛研究并取得了相当大的进展[1,2,4],但对其功能特性的研究还处于萌芽期[3]。从磁性材料[6]、热电材料[7]和催化材料[8]的角度来看,异构设计理念在解决材料饱和磁化强度-矫顽力、电导率-Seebeck系数、活性位点密度-离子迁移率的倒置关系以及高电导率与低热导率相互冲突方面都将有重要的作用[3]。如果进一步将异构材料中不同尺寸的基元结构或构成原子进行有序排列来构筑有序异构材料,可以提供一个多维度空间来调控材料的性能,并通过基元间空前的有序耦合产生变革性功能[9,10]。为此,本观点文章聚焦功能材料,以永磁材料为例简要评述有序异构功能材料所产生的新的物理机制和优异的性能,并展望其发展前景和挑战。

1 有序异构功能材料的定义、分类和范例

1.1 定义和分类

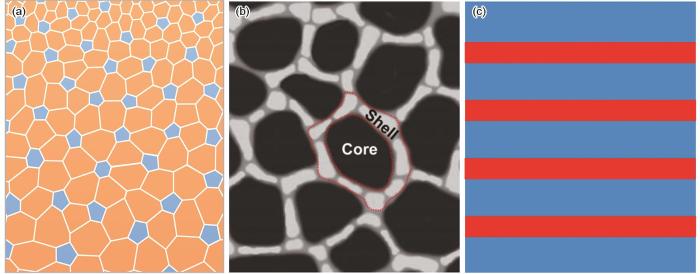

有序异构功能材料(ordered heterostructured functional materials)是指异构功能材料中构成基元(含功能基元和组成元素)在一个或多个尺度上有序排列,并因基元的序构导致材料性能进一步增强或产生全新的功能。具体来说,这些基元可以是元素/成分、结构和功能组元(如晶粒、孪晶、相和畴结构)等,而基元序构主要指基元及其结构特性如尺寸、含量(浓度)或取向等的有序排列。

异构材料通常强调通过不同尺寸的结构或功能基元间的相互耦合作用来产生优异的力学和物理性能[1]。早些年,国家自然科学基金委员会发布了“功能基元序构的高性能材料基础研究重大研究计划”[11],从另一个角度,即基元序构,来探索材料发展的新理念和新范式。简而言之,异构材料和序构材料分别采用不同的维度,即“异构”和“序构”,来调控材料的宏观性能,因此,它们在材料结构设计的理念上有所不同。异构旨在利用不同尺寸的结构或功能基元间的协同耦合效应来提高材料的性能或产生新功能。而序构侧重于通过结构或功能基元的有序排列来获得性能增强和变革性功能,基元的尺寸可以相同。有序异构材料则将异构和序构这2个维度有机结合,创造更大的空间来调控材料性能和发展新材料。

图1

1.2 范例——有序异构永磁材料

高性能永磁材料是变革性技术,如电动汽车、风能发电和超薄便携式电脑等,不可缺少的关键材料。最大磁能积(BH)max (即能量密度)是衡量永磁材料性能优劣的一个重要指标[14]。要获得一个高的(BH)max,材料需要具有高饱和磁化强度(Ms)和高矫顽力(Hc),而Ms与Hc内在的倒置关系限制了永磁材料可能获得的(BH)max[14]。发展由软、硬磁相组成的纳米复合永磁材料,利用软磁相的高Ms和硬磁相的高Hc,通过软、硬磁纳米晶间的交换耦合可以获得一个空前高的磁能积,超过现有的永磁材料[15]。最近,在有效控制块体材料中随机混合的软、硬磁基元的尺寸、分布、含量和晶体取向的基础上[6,16],软、硬磁基元序构高性能永磁材料成为一个探索性研究方向。

早期的2∶17型钐钴稀土永磁材料的研究结果[17,18]表明,磁体中原子尺度元素(如Cu等)浓度的梯度变化可以极大地提高材料的Hc,而不牺牲Ms。研究[13]表明,纳米尺度核-壳有序异构可以增强软、硬磁纳米晶间的交换耦合,获得一个好的剩余磁化强度和Hc的结合。另外,研究[12]发现,纳米尺度软、硬磁晶粒尺寸的梯度有序排列可以产生定向磁化反转新机制;这一新的磁化反转机制导致了一个少有的高Ms和高Hc的结合,从而获得了当前各向同性永磁材料最高的磁能积208 kJ/m3 (26 MGOe)。在各向异性块体纳米复合永磁材料中引入微米尺度的层状有序结构[19],可以产生新奇的多步钉扎机制,在不牺牲材料Ms的条件下,提高了Hc,从而获得了当前低稀土块体永磁材料最高的磁能积 248 kJ/m3 (31 MGOe)[19],可与相应的商业钐钴稀土磁体相媲美[20],但少用稀土20%~30% (质量分数)。尽管这些在原子尺度、纳米尺度和微米尺度的有序化异构永磁材料在微结构上有很大的不同,但是它们对永磁材料磁性能的提高的机制却有着共性规律,即通过调节永磁材料反磁化过程中的热力学能垒和动力学行为,来提高反向磁畴的形核能,并通过新的物理机制钉扎畴壁移动,阻碍反向磁畴的长大。这些通过功能基元的序构所实现的新的磁化反转机制和优异的磁性能是无序结构永磁材料不能获得的。因此,有序异构材料的设计为永磁材料的发展提供了变革性理念,为发展下一代超强永磁材料提供了新机会。

本文将以永磁材料为例,分别从功能基元的原子尺度、纳米尺度和微米尺度的序构来探讨有序异构功能材料的性能增强和新奇的物理机制。

2 原子尺度有序异构

原子尺度的序构指材料中元素/成分的有序变化,比如成分梯度。

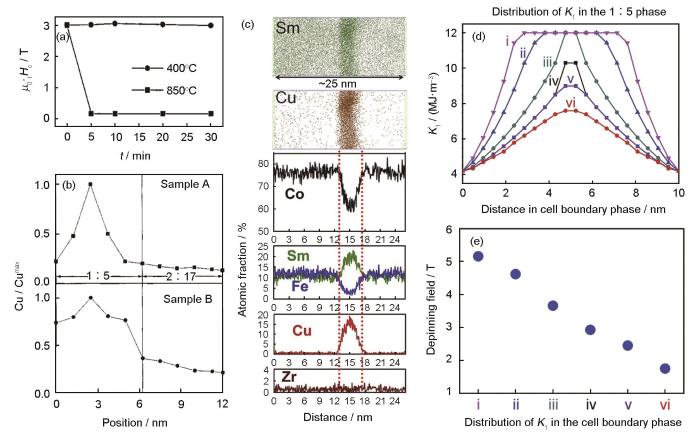

Sm2Co17型(2∶17)稀土永磁材料因具有高的Hc和优良的高温磁性能,在航空航天和国防等领域得到了广泛的应用。其微结构特征是Sm(Co0.74Fe0.1-Cu0.12Zr0.04)7.5合金通过调幅分解产生的胞壁结构:Sm2Co17相(2∶17)为胞相(cell phase),SmCo5相(1∶5)为胞壁相(cell boundary phase)[20],它是一种典型的异构材料。传统的观点认为,胞壁结构中1∶5胞壁相的高各向异性常数使2∶17型SmCo磁体获得了高的Hc (≥ 3 T),但缺乏对其微观机理的深入研究。最近的研究[18]发现,在这种异构材料中存在原子尺度的序构,它是Hc增强的主要因素。如图2a[17]所示,将2∶17型SmCo永磁材料在850℃保温5 min后淬火,材料的Hc损失了95%[17],而其胞-壁结构特征基本无变化[18]。将淬火后的样品再进行850℃保温,然后进行传统的多级退火处理,“消失”了的高Hc又能重新再现[18]。这些实验结果暗示,1∶5胞壁相中原子尺度元素浓度的变化可能控制了磁体的Hc。

图2

图2

原子尺度序构(成分梯度)对2∶17型SmCo异构磁体性能的影响[17,18]

Fig.2

Effects of atomic-scale ordered structure (composition gradient) on the magnetic properties of 2∶17-type SmCo heterostructured magnets

(a) coercivity of the magnet as a function of annealing time at 850oC (μ0—magnetic constant,iHc—intrinsic coercivity, t—annealing time)[17]

(b) EDX results of Cu concentration profile for samples before (sample A) and after (sample B) annealing for 5 min (The y-axis represents normalized atomic concentration of Cu)[17]

(c) 3D atom maps of Sm and Cu, and the composition profiles of constituent elements selected from the 1∶5 cell boundary phase[18] (d, e) simulation results of 6 different anisotropy constant gradients (d), and their corresponding effects on the depinning field (e) (K1—first anisotropy constant)[18]

微区X射线能谱分析(EDX)发现,热处理前后Cu元素在1∶5胞壁相中的分布发生了显著的变化(图2b[17])。退火前1∶5胞壁相中存在明显的Cu元素浓度的梯度变化(即序构),这种梯度变化在850℃退火5 min后基本消失。最近,三维(3D)原子探针分析给出了1∶5相中更为详细的元素浓度的梯度序构(图2c[18])。显然,Cu和Fe元素的原子尺度梯度序构可以导致1∶5相中磁晶各向异性常数(K1)的梯度变化,从而产生一个畴壁能密度(γw)梯度,γw =

3 纳米尺度有序异构

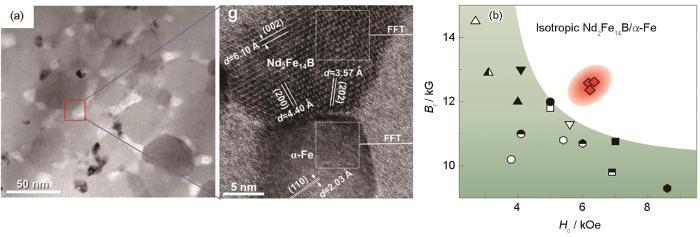

图3

图3

纳米尺度NdFeB/α-Fe核-壳有序结构的TEM和HRTEM像及其导致的高矫顽力(Hc)和高剩磁(Br)的结合[13]

Fig.3

TEM and high-resolution TEM (HRTEM) images of a nano-scale core-shell ordered structure which enables a good combination of high coercivity (Hc) and large remanence (Br) in NdFeB/α-Fe nanocomposite magnets[13]

(a) TEM (left) and HRTEM (right) images of the core-shell structure (d—interplanar spacing, FFT—fast Fourier transform)

(b) coercivity and remanence of the core-shell NdFeB/α-Fe nanocomposite magnets (marked with the red color) and the representative isotropic NdFeB/α-Fenanocomposites

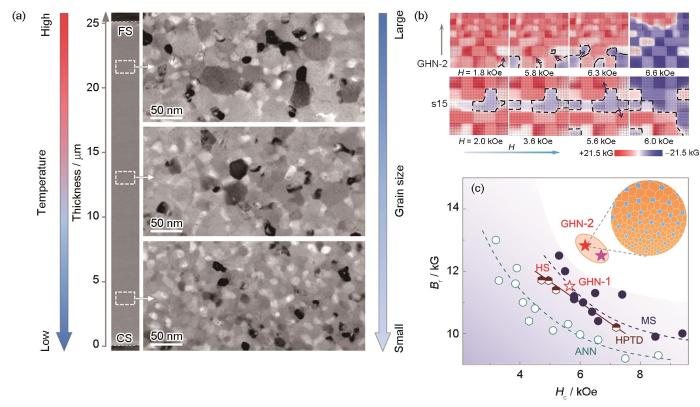

图4

图4

纳米尺度晶粒尺寸序构导致的定向磁化反转及其对NdFeB/α-Fe纳米复合磁体磁性增强的影响[12]

Fig.4

Effect of nano-scale ordered structure with grain-size gradient on the magnetization reversal and enhanced properties of NdFeB/α-Fe nanocomposite magnets[12]

(a) TEM images along the grain-size gradient from the free side (FS) to the cooling side (CS) of melt-spun ribbons

(b) micromagnetic simulations of the directional magnetization reversal in the dual-gradients ordered structure (GHN-2) (H—applied reverse field)

(c) a rare combination of high coercivity and large remanence resulted from the directional magnetization reversal in the ordered nanocomposite magnets (Inset shows the schematics of ordered gradient nanostructures. HS—homogeneous structure, MS—spin melting, ANN—thermal annealed, HPTD—high pressure thermal deformation, GHN-1—single-gradient structure)

对于传统的晶粒尺寸随机分布的Nd2Fe14B/α-Fe纳米复合磁体,其磁化反转通常始于缺陷和大的α-Fe晶粒,呈现一个随机不均匀的磁反转过程,并伴随着晶粒团簇的协同反转(图4b[12],s15)。该磁化反转行为极大地减小材料的Hc并恶化材料退磁曲线的正方度,导致低的磁能积。如果Nd2Fe14B/α-Fe纳米复合磁体中软、硬磁相的晶粒尺寸呈有序分布,比如形成纳米尺度的晶粒梯度有序结构,材料将发生定向磁化反转(图4b[12],GHN-2),即磁化反转将从大的α-Fe晶粒开始,然后随着反向场的增加,较小的晶粒沿梯度方向逐渐反转。这是因为软、硬磁纳米晶之间的交换耦合随软磁相尺寸的减小而逐渐加强[14],另外,永磁材料反向畴的形核场随晶粒尺寸的减小而增大[20]。这种定向磁化反转能够较好地抑制晶粒尺寸无序混合的纳米复合磁体中通常发生的晶粒团簇的协同反转,因此,磁体在较高软磁体积分数(≥ 25%)下能够保持一个高的Hc、高的剩磁和大的(退磁曲线)正方度(图4c[12]),从而获得了当前各向同性永磁材料最高的磁能积208 kJ/m3 (26 MGOe)。Lorenz电镜原位观察直接证实了这种由纳米尺度序构导致的新的定向磁化反转行为[12]。

4 微米尺度有序异构

若将序构的基元尺寸扩大到微米尺度,则可制备微米尺度有序异构纳米复合磁体。

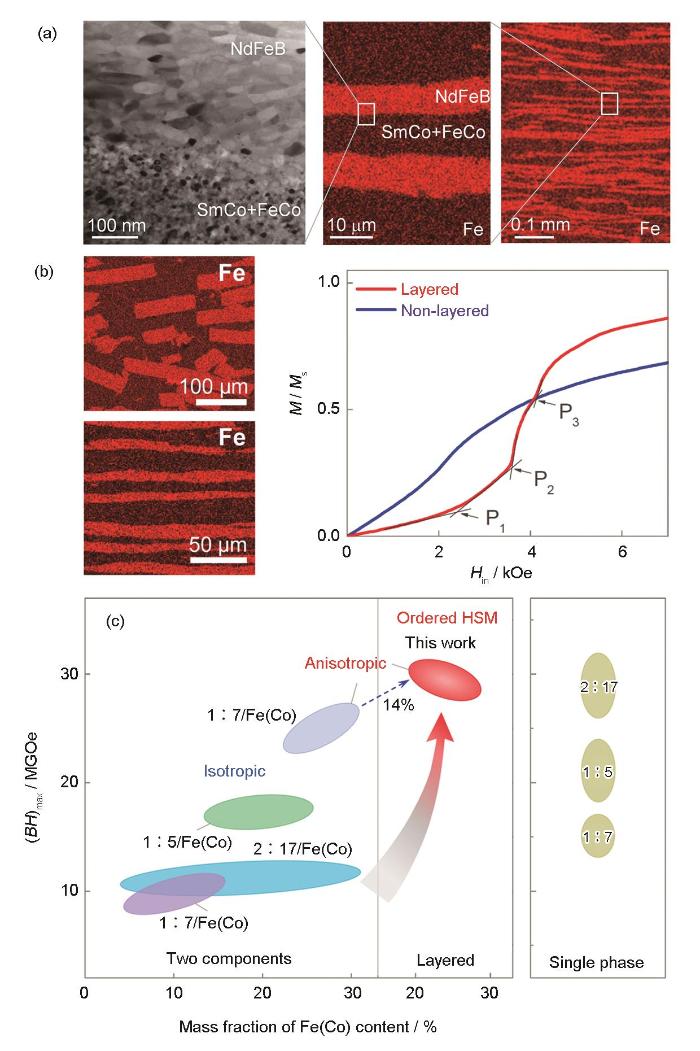

通过在球磨后的SmCo + FeCo粉体中加入NdFeB纳米晶条带,并将均匀混合的前驱体冷压成块,再经高压热压缩变形,可以制备出一种由(FeCo + SmCo)复合纳米晶和NdFeB纳米晶交替有序排列的各向异性块体层状有序(FeCo + SmCo)/NdFeB纳米结构(图5a[19])。微米尺度厚的NdFeB纳米晶层的交替有序排列构成微米尺度有序异构材料。这种各向异性层状有序结构不仅能增强软、硬磁基元之间的交换耦合,而且还能产生一种新型的多步钉扎磁化机制(图5b[19]),在不降低剩磁的条件下提高材料的Hc。从而获得了当前低稀土(软磁含量高于20%,质量分数)块体永磁材料最高的磁能积248 kJ/m3 (31 MGOe),可与相应的商业钐钴稀土磁体相媲美(图5c[19]),但少用稀土20%~30% (质量分数) [19]。

图5

图5

微米尺度层状序构引发的多步钉扎磁化机制及其对纳米复合永磁材料磁能积增强的作用[19]

Fig.5

Effect of micro-scale layered ordered structure on magnetization process and improvement of the energy product of (FeCo + SmCo)/NdFeB nanocomposite magnets[19]

(a) TEM image and EDX mapping of the layered ordered structure

(b) random and ordered layered structures (the left panel) and their magnetization processes (the right panel), the layered ordered structure shows a multi-step pinning magnetization process (M—magnetization, Ms—saturation magnetization, Hin—intrinsic coercivity)

(c) ultrahigh energy product resulted from the multi-step pinning mechanism in the layered ordered nanocomposite magnets ((BH)max—maximum energy product, HSM—heterostructured material)

这种多组元块体层状有序结构的构筑较好地诠释了有序异构高性能永磁材料的新理念。

5 结论与展望

虽然本文只是以永磁材料为例来讨论有序异构设计及其对材料宏观性能和物理机制的影响,但是,该理念具有普适性,可以应用到其他功能材料。与结构材料相比,尽管功能材料的种类繁多,功能特性产生的机制各不相同,但是,它们都有一个共性,即材料的功能特性,如磁、光、电和热等,都涉及某个特定功能过程发生的热力学能垒和动力学行为,如同材料的力学性能涉及位错的产生和运动一样。例如,永磁材料的性能涉及反向畴的成核和畴壁位移[12,20],而热电材料的性能与材料中电子和声子的输运过程密切相关[21]。有序异构材料设计的本质就是企图通过在材料中有目的地引入异构并使其(或构成原子)有序化来调控不同功能过程(磁、光、电、热等)的热力学能垒大小和动力学进程,从而获得优异的性能。因此,从这点来说该理念具有普适性,适用于其他功能材料。除永磁材料外,近些年来人们采用有序异构设计理念在热电材料[7,21]、催化材料[22]和电池材料[23]等功能材料领域均取得了重要进展。这些结果进一步表明了该理念的普适性,体现了有序异构理念在提高功能材料性能方面的巨大潜力,极有可能由此产生一系列的变革性功能材料[24]。

多尺度异构设计在解决热电功能材料的基本科学问题——高电导率与低热导率的冲突[25]方面取得了重要进展[7]。最近,人们又发现原子尺度的序构能改变Fermi能级位置,提高材料的电导率,同时产生的微区应变波纹可以降低热导率,从而增强了材料的热电性能[21]。由此可见,多尺度有序异构设计在提高功能材料性能和产生新功能方面有着巨大潜力和发展空间。遗憾的是,由于当前有序异构功能材料的研究工作才刚刚开始,本文也只涉及到单一尺度的有序化对异构永磁材料性能增强和磁化反转机制的影响。尽管如此,最近的研究工作[26]表明,双尺度(纳米和介观尺度)梯度有序结构材料具有“额外”的强化和加工硬化机制,从而获得了一个不同寻常的、优异的强度与塑性的结合。

有序异构功能材料同时采用了异构设计和序构的策略来发展高性能功能材料。它具有以下优势:(1) 突破了长期以来人们依赖化学元素/成分设计来发展材料的范式,可以在不改变材料成分或减少使用昂贵的、关键合金元素的条件下,通过结构设计和有序构筑来提高材料的性能,使材料性能更优、成本更低、更具可持续发展。(2) 通过引入异构和序构作为新维度来构建材料性能调控的多维度空间,使人们有可能解决长期以来依靠化学成分设计而无法解决的诸多材料基本特性相互冲突的矛盾,突破功能材料发展的性能瓶颈,产生变革性材料和全新的功能特性。同时,还可以进一步增大材料性能调控的“窗口”,使人们能在更大的空间来调控材料的性能。(3) 通过功能基元的有序排列,可以产生空前的基元协同耦合效应,导致全新的物理机制(如定向磁化反转),从而产生增强的性能或颠覆性的功能。

当前有序异构功能材料的研究还处于“萌芽”期,其发展面临许多科学与技术难题需要解决。首先,现有的有序异构功能材料通常只包含1~2个功能基元,有序化一般只涉及单一尺度,而多种功能基元和多尺度序构将为高性能和颠覆性功能材料的发展提供更多的机会和更大的探索空间。为了获得这种新型复杂有序结构特别是宏观块体有序异构功能材料,人们需要发展有序异构材料制备的新原理、新技术和新方法。建立外场辅助加工方法,例如,温度场、应力-应变场、电场和磁场等辅助的功能基元序构技术将是一个重要的研究方向。其次,为了透彻地理解有序异构功能材料的结构-性能之间的关系,尤其是单个基元(组元)的作用、不同基元之间的耦合效应以及基元序构对材料性能的影响,迫切要求实验研究与理论模拟相结合。后者能从理论上解决实验研究中无法解决的复杂和极端序构问题,为此,需要发展多尺度有序异构材料的模拟仿真方法和技术。而跨越原子、纳米、介观、微米甚至毫米尺度的多尺度模拟是当前材料计算领域的一个重大挑战。最后,与传统结构材料的发展一样,有序异构功能材料的发展需要建立它们的“成分/加工-结构-性能”的关系。显然,要解决这些挑战,需要材料、物理、化学、计算和加工等多学科的交叉合作。总之,从调控材料功能过程的热力学能垒和动力学行为来说,有序异构材料的设计理念具有普适性,将为变革性功能材料和结构材料的发展提供新的机会。

参考文献

Heterostructured materials: Superior properties from hetero-zone interaction

[J].

Stabilizing nanostructures in metals using grain and twin boundary architectures

[J].

Heterostructures: New opportunities for functional materials

[J].

Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys

[J].

Improving sustainability with simpler alloys

[J].

Novel bimorphological anisotropic bulk nanocomposite materials with high energy products

[J].

High-performance bulk thermoelectrics with all-scale hierarchical architectures

[J].

Ordered macro-microporous metal-organic framework single crystals

[J].We constructed highly oriented and ordered macropores within metal-organic framework (MOF) single crystals, opening up the area of three-dimensional-ordered macro-microporous materials (that is, materials containing both macro- and micropores) in single-crystalline form. Our methodology relies on the strong shaping effects of a polystyrene nanosphere monolith template and a double-solvent-induced heterogeneous nucleation approach. This process synergistically enabled the in situ growth of MOFs within ordered voids, rendering a single crystal with oriented and ordered macro-microporous structure. The improved mass diffusion properties of such hierarchical frameworks, together with their robust single-crystalline nature, endow them with superior catalytic activity and recyclability for bulky-molecule reactions, as compared with conventional, polycrystalline hollow, and disordered macroporous ZIF-8.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Strong magnets with ordered structures

[J].

Reconfigurable perovskite nickelate electronics for artificial intelligence

[J].

2019 annual project guide for the major research program for basic research of high-performance materials with ordered functional primitive structure

[EB/OL]. (

功能基元序构的高性能材料基础研究重大研究计划2019年度项目指南

[EB/OL]. (

Directional magnetization reversal enables ultrahigh energy density in gradient nanostructures

[J].

Three-dimensional self-assembly of core/shell-like nanostructures for high-performance nanocomposite permanent magnets

[J].Core/shell nanostructures are fascinating for many advanced applications including strong permanent magnets, magnetic recording, and biotechnology. They are generally achieved via chemical approaches, but these techniques limit them to nanoparticles. Here, we describe a three-dimensional (3D) self-assembly of core/shell-like nanocomposite magnets, with hard-magnetic Nd2Fe14B core of ∼45 nm and soft-magnetic α-Fe shell of ∼13 nm, through a physical route. The resulting Nd2Fe14B/α-Fe core/shell-like nanostructure allows both large remanent magnetization and high coercivity, leading to a record-high energy product of 25 MGOe which reaches the theoretical limit for isotropic Nd2Fe14B/α-Fe nanocomposite magnets. Our approach is based on a sequential growth of the core and shell nanocrystals in an alloy melt. These results make an important step toward fabricating core/shell-like nanostructure in 3D materials.

Materials science: The pull of stronger magnets

[J].

Controllably manipulating three-dimensional hybrid nanostructures for bulk nanocomposites with large energy products

[J].Hybrid nanostructures that comprise two or more nanoscale functional components are fascinating for applications in electronics, energy conversion devices, and biotechnologies. Their performances are strongly dependent on the characteristics of the individual components including the size, morphology, orientation, and distribution. However, it remains challenging to simultaneously control these structural properties in a three-dimensional (3D) hybrid nanostructure. Here, we introduce a robust strategy for concurrently manipulating these characteristics in a bulk SmCo/Fe(Co) nanocomposite. This method can tune nanocrystals in size (down to sub-10 nm), morphology (sphere, rod, or disc), and crystallographic orientation (isotropic or anisotropic). We have therefore achieved the desired nanostructures: oriented hard magnetic SmCo grains and homogeneously distributed soft magnetic Fe(Co) grains with high fractions (∼26 wt %) and small sizes (∼12.5 nm). The resulting anisotropic nanocomposite exhibits an energy product that is approximately 50% greater than that of its corresponding pure SmCo magnet and 35% higher than the reported largest value in isotropic SmCo/Fe(Co) systems. Our findings pave a new way to manipulating 3D hybrid nanostructures in a controllable manner.

Microchemistry and magnetization reversal mechanism in melt-spun 2∶17-type Sm-Co magnets

[J].

Correlation of microchemistry of cell boundary phase and interface structure to the coercivity of Sm(Co0.784Fe0.100Cu0.088Zr0.028)7.19 sintered magnets

[J].

Engineering bulk, layered, multicomponent nanostructures with high energy density

[J].

Perspective and prospects for rare earth permanent magnets

[J].

Enhanced atomic ordering leads to high thermoelectric performance in AgSbTe2

[J].High thermoelectric performance is generally achieved through either electronic structure modulations or phonon scattering enhancements, which often counteract each other. A leap in performance requires innovative strategies that simultaneously optimize electronic and phonon transports. We demonstrate high thermoelectric performance with a near room-temperature figure of merit, ~ 1.5, and a maximum ~ 2.6 at 573 kelvin, by optimizing atomic disorder in cadmium-doped polycrystalline silver antimony telluride (AgSbTe). Cadmium doping in AgSbTe enhances cationic ordering, which simultaneously improves electronic properties by tuning disorder-induced localization of electronic states and reduces lattice thermal conductivity through spontaneous formation of nanoscale (~2 to 4 nanometers) superstructures and coupling of soft vibrations localized within ~1 nanometer around cadmium sites with local strain modulation. The strategy is applicable to most other thermoelectric materials that exhibit inherent atomic disorder.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Ordered nanostructure enhances electrocatalytic performance by directional micro-electric field

[J].

Dynamics of particle network in composite battery cathodes

[J].Improving composite battery electrodes requires a delicate control of active materials and electrode formulation. The electrochemically active particles fulfill their role as energy exchange reservoirs through interacting with the surrounding conductive network. We formulate a network evolution model to interpret the regulation and equilibration between electrochemical activity and mechanical damage of these particles. Through statistical analysis of thousands of particles using x-ray phase contrast holotomography in a LiNiMnCoO-based cathode, we found that the local network heterogeneity results in asynchronous activities in the early cycles, and subsequently the particle assemblies move toward a synchronous behavior. Our study pinpoints the chemomechanical behavior of individual particles and enables better designs of the conductive network to optimize the utility of all the particles during operation.

Bridging functional nanocomposites to robust macroscale devices

[J].

Complex thermoelectric materials

[J].Thermoelectric materials, which can generate electricity from waste heat or be used as solid-state Peltier coolers, could play an important role in a global sustainable energy solution. Such a development is contingent on identifying materials with higher thermoelectric efficiency than available at present, which is a challenge owing to the conflicting combination of material traits that are required. Nevertheless, because of modern synthesis and characterization techniques, particularly for nanoscale materials, a new era of complex thermoelectric materials is approaching. We review recent advances in the field, highlighting the strategies used to improve the thermopower and reduce the thermal conductivity.