兼具轻质、高强度和高韧性的轻量化先进金属基复合材料,更是空天、电子及国防等国家重大战略领域不可或缺的关键性基础材料之一。以铝基复合材料为例:我国正在研制的长征9号重型运载火箭是满足载人登月、空间站建设、深空探测等战略领域需求的国之重器。采用高强韧铝基复合材料替代现役铝合金材料,可实现结构减重20%~25%,运载能力提升15%~20%。以“玉兔”、“祝融”为代表的外星探测车在极端环境下着陆、行走、勘探、采样,面临低温、交变温度、极端过载等严酷环境条件,只有高强韧多功能铝基复合材料才能满足某些关键构件的应用要求。未来5~10年,我国在深空探测、载人航天、5G通讯、卫星互联网、新能源车辆、高铁、核电等国家安全与国民经济重点领域将会迎来跨越式发展,从过去取得的应用成效看,先进金属基复合材料所具有的性能优势,必将促进其在关键战略领域的更宽范围的应用。

然而,金属基复合材料存在强度/模量和塑性/韧性之间的倒置关系,这不仅抑制了金属基复合材料性能优势的充分发挥,而且大大限制了其规模化发展与关键应用[10~12]。因此,破解强-韧性倒置难题、发展高强韧匹配的新型金属基复合材料是本研究领域亟需解决的共性关键科学问题。金属基复合材料强-韧性倒置关系的本质在于增强相与金属基体的局域性应力集中及形变失配。传统的金属基复合材料设计理念多以追求单相、单尺度的增强体与基体的“均匀化复合”为目标,通过消除基体未充分致密化[13]、纳米增强体团聚[14]、增强体结构损伤[15]、过度界面反应[16]等缺陷,改善金属基复合材料的强-韧性倒置关系。然而,这种“均匀化复合”无法从根本上缓解增强相与金属基体的局域形变失配,难以实现强度与韧性的大幅同步提升。如何通过复合设计缓解局域形变适配突破高强-韧性匹配是复合材料领域要解决的核心科学问题。

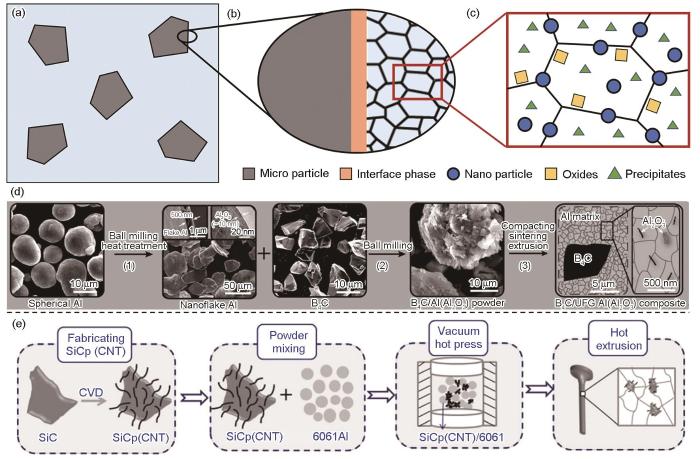

启迪于自然生物材料“组分简单、构型精细”的构型化复合高强韧匹配效应,以材料微结构为首要设计要素的“构型化复合”发展理念,成为目前突破强-韧性倒置关系的最重要途径。近年来,国内外研究团队围绕金属基复合材料的构型化复合设计及强韧化效益开展了探索研究,通过对增强相尺寸、种类及分布特性、基体组织等结构参量进行有序调控,提出叠层(laminate)[22~26]、多芯(multicore)[27,28]、梯度(gradient)[29~31]、网状(network)[32~39]、微纳混杂(micro-nano hybrid)[40~47]、微纳砖砌(brick-mortar)[48~55]、基体梯度异构(gradient grain size)[56]、基体双/多峰(bi/multi modal)[57~64]等典型的构型化金属基复合材料(architectured metal matrix composites)设计理念(图1),使得金属基复合材料的强-韧性匹配有了显著改善。本文将对典型构型化金属基复合材料的发展历程、结构设计、性能特点以及强韧化机制进行综述分析。

图1

图1

典型构型化金属基复合材料示意图:叠层构型、多芯构型、梯度构型、网状构型、微纳混杂构型、微纳砖砌构型、基体梯度异构、基体双/多峰构型

Fig.1

Illustration of the typical heterogeneous architecture design in metal matrix composites: laminate architecture, multicore architecture, gradient architecture, network architecture, micro-nano hybrid architecture, brick-mortar architecture, gradient grain size, and bi-/multi- modal grains

1 增强体宏观非均匀构型强韧化

早期的构型化复合通过降低基体内部过高的硬化状态来达到提高金属基复合材料塑韧性的目的,将复合材料组织分化为硬相区(含大量增强体)和软相区(少含或不含增强体),通过硬相-软相界面开裂和软相区塑性变形来偏转和钝化复合材料内部的裂纹,起到阻碍裂纹扩展的作用。典型代表有叠层、多芯、梯度、环状等构型,其硬相区与软相区的尺度通常在毫米级以上,因此称为增强体宏观非均匀构型。硬相与软相在尺寸、性能、空间分布等方面的匹配特性决定了复合构型的强韧化效果。例如借鉴层合板结构设计理念的叠层构型,从宏观尺度不同载荷环境下的应力-应变响应行为研究[22],到细观、微观尺度的层间界面结合强度调控与强韧化机制揭示[23~25],再到基于应变梯度塑性理论的界面影响区(interface affected zone,IAZ)-软相区尺寸匹配设计[26],结构尺度精细化与力学模型定量化推动着叠层构型的设计优化。叠层构型的增韧效益显著,但是硬相对软相的束缚作用仅仅局限于界面法向,即使通过调整软层宽度至界面影响区宽度的2倍来弥补加工硬化[26],对软层提前颈缩失效的抑制效果也十分有限。多芯构型通过设计增强体的富集分布,解除了叠层构型中硬相-软相界面对软相的束缚,但是仍具有良好的增韧效果,这得益于增强体含量高的硬质增强芯与基体之间的界面脱黏[27,28]。梯度构型通过设计增强体含量梯度,缓解传统叠层构型层间界面的应力集中,并通过梯度塑性变形诱发几何必需位错(geometrically necessary dislocations,GNDs)增殖与长程背应力强化,塑韧性提高显著[29],但是合适的梯度大小与制备工艺仍有待探索[29~31]。

将增强体富集区域视为一个整体,定性调控硬相-软相界面结合强度,或基于应变梯度塑性理论定量优化硬相、软相的尺寸,是增强体宏观非均匀构型发展至今提出的主要优化策略。但是在这种视角与设计理念下,对复合构型力学行为的认识大多止步于细观层次,忽视了不同增强体之间以及增强体与基体在分布、尺寸、形状等结构参量方面的匹配关系。如果不能细化构型设计尺度,则无法有效缓解硬相-软相形变失配导致的应力集中,无法突破强度-韧性倒置关系,这是叠层、多芯、梯度等早期复合构型设计理念的不足之处。后续研究[65]表明,将软相区的尺寸细化至数微米,多芯构型演化成双峰(bimodal)分级构型,相比于均匀复合材料,断裂延伸率和断裂韧度分别提高约421%和349%,屈服强度损失仅约8%,强-韧性匹配效果显著提升。

2 增强体微观非均匀构型强韧化

增强体微观非均匀构型考虑到了微纳尺度上增强体之间以及增强体与基体在分布、尺寸、形状等结构参量方面的匹配关系,设计尺度更为精细。典型代表有网状构型、微纳混杂构型、微纳砖砌构型等。这些构型的特点是增强体分布宏观上看是均匀的,但在微纳尺度上按设计有序排布。

网状构型的设计理念经历了由连续增强体网络[32,33]到准连续与非连续增强体网络的转变。早期设计的(Al3Zr + Al2O3np)/2024Al连续网状复合构型,增强体在基体晶界和晶界附近的富集分布会导致严重的应力集中,因此这种设计并不合理,即使改变烧结温度和压力等工艺参数、优化增强体之间的尺寸匹配,仍无法获得良好的强-韧性匹配[34]。而在(Ti5Si3 + TiBw)/Ti64、(Re2O3 + TiBw)/Ti64等准连续网状构型中,纳米尺度的Ti5Si3可以抑制基体α-β相界面开裂与高温迁移[35],TiB晶须主要分布在复合粉末之间形成的界面,La、Y、Nd等稀土元素形成的晶界氧化物可以弥补TiB晶须对晶界的有限钉扎效果[36~38],并与TiB晶须协同诱导裂纹桥联增韧。Ti5Si3/Ti64的室温屈服强度约为1030 MPa,均匀伸长率不足2%,而(Ti5Si3 + TiBw)/Ti64的室温屈服强度约1130 MPa,均匀伸长率约4%,准连续网状增强体之间的分布匹配设计可以同步提高钛基复合材料的室温强度和塑性[35]。另外,在Cu基体中构建石墨烯三维非连续网络存储GNDs,并诱导裂纹桥联,Young's模量、屈服强度、抗拉强度、断裂延伸率、韧性模量分别由基体的78 GPa、98 MPa、206 MPa、38.2%、72.8 MJ/m3,提高至116 GPa、221 MPa、287 MPa、53.8%、126.2 MJ/m3,模量、强度、塑性、韧性得到同步提升[39]。由此可见网状构型打破增强体富集,优化增强体的分布,可获得良好的强韧化效益。除了增强体分布特征外,如果能进一步调控尺寸、形状等结构参量,则有望实现强度和韧性的进一步提高。

微纳混杂构型设计理念通过引入2种尺度/尺寸的增强体,使其在加载过程中发挥协同强韧化的作用。大尺寸颗粒的载荷转移能力强,在其附近的基体中存储应变能,激活再结晶[40];小尺寸颗粒能够缓解大尺寸颗粒界面影响区的应力集中,有效钉扎晶界迁移,纳米颗粒还可以进入晶粒内部诱发Orowan强化[41],如图2[43,46]所示。但是不同尺寸的颗粒难以协同分散,传统的分散策略难以兼顾纳米增强体的团聚与结构完整性,严重限制了微纳混杂构型的塑韧性[42]。分步球磨与粉末组装是解决多相多尺度增强体协同分散难题的重要方法,由此方法制备的(B4Cp + Al2O3np)/Al微纳混杂复合材料具有约8.9%的断裂延伸率,远高于单尺度微米B4Cp/Al的4%,亚微米晶内的Al2O3纳米颗粒存储Orowan位错环,被视为维系加工硬化和均匀塑性变形的重要机制[43]。实际上,不仅晶内纳米颗粒可以改善微米颗粒增强复合材料的塑性,微米或亚微米颗粒也可以改善纳米颗粒增强复合材料的塑性,比如在(Al2O3p + AlNnp)/Al微纳混杂复合材料中,Al2O3亚微米颗粒有利于改善AlN纳米颗粒的分散,并激活部分晶粒再结晶与粗化,恢复一部分位错存储与加工硬化能力,实现了强度和塑性的同步提高[44]。

图2

图2

微纳混杂构型中微米颗粒与纳米颗粒的尺寸匹配设计与协同分散[43,46]

Fig.2

Size-matching design and cooperative dispersion of micron particles and nanoparticles in the micro-nano hybrid architecture

(a-c) illustration of the micro-nano hybrid architecture[43]

(d) multi-step ball milling and powder assembly route to fabricate (B4Cp + Al2O3np)/Al[43]

(e) fabricate SiCp (CNT)/6061 composite by in-situ growing CNTs on SiC particles (CNT—carbon nanotube, CVD—chemical vapor deposition)[46]

选用高模量、高强度纳米碳材料作为纳米增强体时,其分散方法又有所不同。早期制备工艺为了抑制纳米碳的机械损伤,一般采用低能球磨制备微纳混杂增强体,但是纳米碳的团聚严重限制了复合材料的塑性[45]。如果在SiC微米颗粒表面原位生长CNTs造粒,再与6061Al基体共球磨制备(SiCp + CNT)/6061Al微纳混杂复合材料,Young's模量、屈服强度、抗拉强度、断裂延伸率由SiCp/6061Al的85 GPa、340 MPa、405 MPa、7.8%,同时提高至98 GPa、365 MPa、428 MPa、8.5%[46,47]。由此可见,无论是网状构型还是微纳混杂构型,多相多尺度增强体之间的结构参量匹配设计,必须以增强体合理分布为前提。如果增强体分布不合理,例如增强体过度集中分布于晶界附近、纳米增强体团聚等,那么仅仅依靠增强体之间的尺寸或形状优化,难以突破金属基复合材料强-韧性倒置瓶颈。

启迪于珍珠贝壳层的微纳砖砌构型设计理念,同时考虑到了增强体分布、尺寸以及增强体与基体的形状匹配,通常由纳米尺度的增强体(泥)和亚微米尺度的晶粒(砖)组装而成。在这样的特征尺度下,叠片粉末冶金技术是复合构型结构参量精细调控的主要方法[48]。片状粉末为纳米增强体的分散提供更多位点,且宽度为几百纳米、长度为数微米的晶粒的位错存储能力优于等轴超细晶,Al2O3、CNTs、GNSs等纳米增强体分布于长条晶界,在复合界面附近诱发GNDs形核与存储,提供长程随动硬化与短程等向硬化效果,补偿超细晶的加工硬化损失[49~51]。通过搭建仿生矿物桥[52]、原位生长增强体[53]等方法改善界面机械互锁与载荷传递,还可以进一步提高复合材料的强度。值得注意的是,GNSs因为其二维层状结构与基体仿生砖砌式结构具有良好的几何相容性,被视为微纳砖砌构型的理想增强体。例如,在GNS/Al微纳砖砌复合材料中,GNSs与基体的形状匹配可以有效降低位错在晶界的湮灭概率,在纳米尺度GNS-Al界面和亚微米尺度复合粉末界面存在多尺度外禀韧化效应,相比于均匀复合材料,抗拉强度由201 MPa提高至302 MPa,而断裂延伸率几乎没有损失[51,54]。由此可见,微纳砖砌构型通过亚微米晶粒与纳米增强体的形状、尺寸匹配设计,一方面改善基体在增强体几何约束下的位错存储能力和缺陷敏感性[48,66],另一方面耦合增强体与基体中的多尺度外禀韧化机制[54,55],可以实现优异的强-韧性匹配。

在增强体微观非均匀构型中,纳米增强体具有优异的本征力学性能,且可以与微米/亚微米增强体和基体相互配合,激活多尺度强韧化机制,优化强-韧性匹配效果。增强体纳米化是构型化金属基复合材料未来发展的必然趋势[67,68],但是还存在增强体分散困难、超细晶加工硬化能力不足等问题。即使将等轴超细晶替换为长条超细晶、选用GNSs匹配基体晶粒构型,亚微米尺度晶粒变形受增强体约束的结构特征也必然导致复合材料加工硬化能力无法与数微米晶粒尺寸的合金媲美。在亚微米晶粒内部引入纳米增强体捕获Orowan位错环,即增强体晶内化,是进一步提高复合材料加工硬化能力的有效方法[69~71],但是实现这种构型优化策略的工艺条件还有待探索[72]。

从目前的研究来看,增强体宏观非均匀与微观非均匀构型在平衡金属基复合材料强度-韧性方面有一定效果,但仅仅依靠增强体非均匀构型,难以真正突破强-韧性倒置瓶颈,因此有必要探寻新的弥补加工硬化的强韧化机制。

3 基体本征异构强韧化

调控多相多尺度增强体的非均匀分布与结构参量匹配设计可以优化金属基复合材料的强-韧性关系,但是基体加工硬化不充分限制了复合构型强度、塑性和韧性进一步提升。与传统金属材料晶粒由数十微米细化至数微米,同时提高强度、塑性和韧性不同,构型化金属基复合材料的细晶强化是以牺牲塑性和韧性为代价的。这是因为金属基复合材料的晶粒细化可能发生在亚微米甚至纳米尺度[73],尤其在粉末冶金制备工艺中,机械球磨的能量输入、动态再结晶[74]、晶界增强体Zener钉扎效应[75]等因素,会导致基体晶粒细化至亚微米甚至纳米尺度,难以在晶内存储位错。而在其他的塑性变形机制中,大量层错与孪晶的形核条件(如低温、高应力、低层错能等)相对苛刻[76,77],依赖于成分与组织结构的应力诱发相变只能在少数复合材料中实现[78,79],晶粒转动、晶界迁移、晶界滑动、位错攀移等对金属基复合材料室温加工硬化的贡献相对较小[49],因此晶内硬化效果必然减弱,伴随塑性与韧性损失。如果想要在几乎不损失屈服强度的条件下提高均匀伸长率,势必要采取措施弥补亚微米晶或纳米晶的加工硬化能力。

近年来的研究[80~83]表明,基体本征异构诱发异质变形诱导(heterogeneous deformation induced,HDI)硬化在改善纳米增强金属基复合材料强-韧性匹配方面起到良好效果。即构建晶粒尺寸不同的晶区,通过晶区间彼此塑性变形能力的差异激活HDI硬化,包含软相(微米晶)的背应力强化和硬相(亚微米晶)的前应力软化[83]。背应力强化是指GNDs等不可动缺陷组态向后续可动位错施加反向长程内应力,并抑制位错增殖;软相的位错塞积也会对硬相施加前应力以维系力学平衡,改变硬相的应力状态,激活滑移系以协调塑性变形,表现为硬相变软。在基体本征异构设计中,晶粒尺寸、晶区尺寸以及异质界面结合状态等因素均会对复合材料的加工硬化、裂纹形核与扩展等行为产生影响,而增强体的Zener钉扎效应可以有效调控晶粒尺寸,比合金的溶质、位错、析出相等钉扎晶界效果更好[84],这为复合材料的结构设计与力学性能调控提供了极大的自由度。

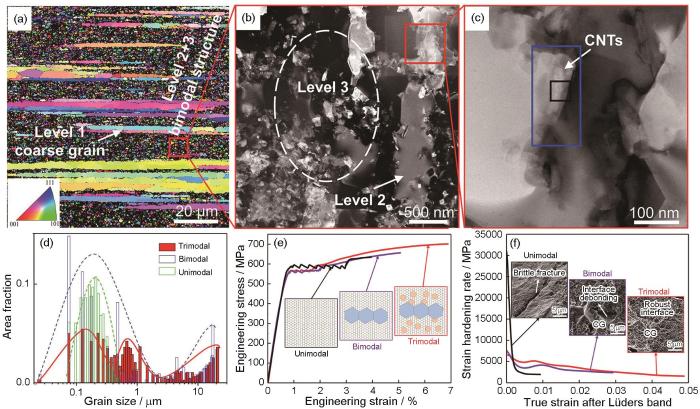

图3

图3

基于IAZ理论和弹塑性断裂力学的基体双峰异构晶区匹配优化[60,61]

Fig.3

Structure optimization of bimodal grain architecture based on interface affected zone (IAZ) theory and elastoplastic fracture mechanics

(a-c) bimodal microstructure of CNT/5083Al (a); best strength and ductility combination is obtained when the size of the coarse-grain (CG) zone approaches to about double of that of IAZ (b, c)[60] (d-f) bimodal microstructure of CNT/2009Al (d), and schematic of toughening mechanism in heterogeneous materials: stress concentration at the micro-crack tip induced plastic zone in coarse grain and crack blunting by joint action of multiple neighboring coarse grains when the size of the course-grain zone is close to that of the plastic zone (e-f)[61] (DZ—ductile zone, BZ—brittle zone, R0—size of the plastic deformation zone, a—half length of the crack, SC—stress concentration)

HDI硬化源于硬相-软相异质界面的非均匀塑性变形,因此异质界面的含量会对HDI硬化效果造成很大影响。在基体双峰异构基础上设计多峰异构,提高异质界面含量,可以进一步提高复合材料的塑性和韧性。例如在超细晶和粗晶两级间引入细晶,构建三峰晶粒CNT/2024Al复合材料[63,64],缓解超细晶区-粗晶区异质界面应力集中,且新增的超细晶区-细晶区异质界面可以积累更多GNDs,可实现优于双峰异构基体复合材料的HDI硬化效果,如图4[63]所示。三峰晶粒CNT/2024Al的屈服强度、抗拉强度、均匀伸长率分别为561 MPa、723 MPa、6.7%,显著优于双峰晶粒CNT/2024Al的532 MPa、625 MPa、3.8%。

图4

值得注意的是,基体梯度异构有很大的强韧化潜力[85],但是受限于现有的金属基复合材料制备工艺及增强体对晶粒的Zener钉扎效应,难以真正实现类似于合金的梯度晶粒尺寸控制。

在纳米增强基体本征异构复合材料的基础上,结合增强体非均匀构型,可以引入更多的强韧化机制,为突破强-韧性倒置难题提出新方法。目前,增强体构型与基体本征异构的耦合及强韧化效果已在“微纳混杂+双峰基体”多相多尺度复合构型中得以验证,如半固态搅拌铸造制备的(SiCp + SiCnp)/AZ31B[86]和分步球磨组装的(B4Cp + CNT)/6061Al[87],多尺度强韧化机制竞合关系非常复杂,目前的研究主要在探索结构参量调控工艺方面,增强体-基体、增强体之间以及基体晶区之间的结构参量匹配优化策略尚未见诸报道。增强体构型与基体本征异构的联合设计不局限于“微纳混杂+双峰基体”。理论上,任何增强体构型与基体本征异构都可以联系起来,包括目前尚未真正实现的基体梯度异构[56]。建立合适的工艺路线、揭示多尺度强韧化机制、提炼设计理念与构型优化策略等,是增强体构型-基体异构联合设计面临的共性问题。

4 基于能量耗散的构型化复合设计与制备

构型化复合设计理念虽在一定程度上改善了金属基复合材料的强-韧性失配,但目前构型化复合研究大多根据“复合构型-力学性能”经验关系进行实验试错,现有力学理论不能解耦复杂外场和跨尺度复合构型的多因素之间错综复杂的耦合关系,存在设计准则模糊、强韧化机理不清的问题,在强-韧性匹配设计、可控制备方面顾此失彼,导致所创制的金属基复合材料的强-韧性匹配与自然生物材料相比仍相去甚远。究其原因,通过照搬自然生物材料构型,只是“知其然,不知其所以然”,人们并未找到其强-韧性关联重构之匙。因此,亟需从创新视角探寻同步提升强-韧性的内在科学原理,发展新型构型化复合设计理论和技术原型,开展重大原始创新和革命性材料的设计与制备研究,做到“知其然,知其所以然,得其然”,以理论指导创制新型高强韧金属基复合材料。

材料的变形、断裂等力学行为,本质上是材料系统对外场能量输入的耗散过程。仿生多尺度构型设计理念有助于材料充分发挥多尺度能量耗散机制,强韧化效果已经在金属材料[88,89]和以微纳砖砌为代表的典型仿生构型化金属基复合材料[51~55]中得到验证。但是仿生只是实现优异强-韧性匹配的手段之一,如何利用材料系统最大化耗散外场载荷的能量,才是优化复合构型设计、解决金属基复合材料强-韧性倒置难题的根本方法。在能量耗散视角下,应围绕2方面问题建立能量耗散理论,完善复合构型优化设计策略。第一,避免裂纹萌生,实现稳态变形能量耗散最大化。通过复合界面、复合构型设计,耦合形变过程的多尺度能量耗散机制,使复合材料整体参与能耗过程,避免局部应变集中,有效抑制裂纹萌生。第二,抑制裂纹扩展,实现裂纹尖端能量耗散最大化。在微纳尺度上开展复合构型设计,在裂纹尖端及其扩展路径上,预先引入多尺度增强体、非均匀界面等异质结构,激活裂尖屏蔽、裂纹偏转与桥联等增韧机制,增加裂纹扩展额外能耗,使其难扩展、甚至不扩展。

而基于能量耗散最大化的构型化复合制备势必需要充分关注微结构的作用机制,如材料体系中缺陷(界面、位错、裂纹、局部塑性变形区等)对变形行为与能量耗散的影响。这就要求对复合构型精细结构进行更为精准的跨尺度、局域化调控,获得符合力学和能耗设计要求的复合构型。然而,由于复合体系的复杂性,多相多尺度构型化可控制备主要面临“控形”与“控性”2方面技术挑战。

5 总结与展望

本文主要介绍了金属基复合材料增强体宏观非均匀构型、增强体微观非均匀构型、基体本征异构的构型设计理念及相应的强韧化机制。纵观典型构型化金属基复合材料的发展历程,尺度精细化、尺寸定量化和结构参量多元化是复合构型设计的主要特征和未来发展趋势。未来研究可从能量耗散的创新视角出发,开发能量耗散及形变非局域化的定量化分析技术,刻画复合材料中强韧机制的全局性物理图像,揭示抑制裂纹萌生和扩展的跨尺度能耗机理,提出力学性能和使役行为的能量学判据,指导多相多尺度增强相与基体复合构型/界面反向设计,开发可实现复合构型/界面精细化、局域化调控的多尺度构型化复合新技术原理,优化宏观、细观、微观等不同尺度下的应力-应变分配,突破金属基复合材料的强-韧性倒置瓶颈。

参考文献

The current state and trend of metal matrix composites

[J].

金属基复合材料的现状与发展趋势

[J].

Opportunities and challenges for metal matrix composites in the context of equipment upgrading

[J].

装备升级换代背景下金属基复合材料的发展机遇和挑战

[J].

Particulate reinforced metal matrix composites—A review

[J].

Metal-matrix composites for space applications

[J].

Metal matrix composites—From science to technological significance

[J].

Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets

[J].

Multiscale architecture and superior high-temperature performance of discontinuously reinforced titanium matrix composites

[J].

Recent advances in aluminium matrix composites reinforced with graphene-based nanomaterial: A critical review

[J].

Research progress on principle of dimensional stability and stabilization design of Al and its composites

[J].Dimensional stability refers to the materials' ability to maintain their original size during long-term storage or under service conditions. The key components of the angle, velocity and position sensors, such as the gyroscopes, star sensors and optical observation devices, are extreme sensitive to the micro-deformation of the materials, and the dimensional instability of the present materials has become to be the bottleneck problem that restricts the accuracy of the equipment. Deep research has been carried out abroad from the aspect of the microstructure modification by heat-treatment and pretension deformation treatment of metals since 1970s. However, the domestic research on the dimensional stability is rather weak, which was mainly focused on the effect of the residual stress, and the corresponding engineering application effect is not pronounced. In the present work, the research experience and main results of the authors and coworkers on dimensional stability for decades have been introduced, including novel characterization method of dimensional stability during long-term storage (without stress), and the basic evolution process of the phase-stability, microstructure-stability and the anisotropy behavior of the Al alloys, which was revealed by the novel characterization method. Furthermore, the basic design principles of high dimensional stability and the design ideas based on the dispersivity of reinforcements of the Al matrix composites have been introduced. Moreover, the microstructure characters and the application effect in practical engineering of the high dimensional stability optical-grade and instrument-grade SiC/2024Al composites have been described. Based on the theoretical analysis and the practice effects, it indicates that the accuracy and accuracy stability of the instruments is mainly depended on dimensional stability of the used materials, and the dimensional stability of the materials was mainly affected by its intrinsic deformation characteristics, while the effect of the residual stress was subordinate. The present work also indicates that the application of the dimensional stability principle is also instructive to the technology upgrading of the high precision components, such as precision bearings.

Al及其复合材料尺寸稳定性原理与稳定化设计研究进展

[J].尺寸稳定性是指材料在长期贮存或者服役环境下保持原始尺寸不变的能力。陀螺仪、星敏感器、光学观瞄设备等角度、速度、位置传感器的关键零部件对材料的微变形十分敏感,材料的尺寸不稳定性问题已经成为制约装备精度的“卡脖子”问题。国外自20世纪70年代从金属的热处理、预拉伸变形等组织调控方法入手做了较深入的研究,我国关于材料尺寸稳定性的研究十分薄弱,主要集中于残余应力的影响上,工程效果不明显。本文介绍作者及其团队长期从事材料尺寸稳定性研究的体会与成果,包括长期贮存(无应力)条件下尺寸稳定性的表征新方法,基于该方法发现了铝合金相稳定、组织稳定及其各向异性的基本规律;总结了铝基复合材料尺寸稳定性设计的基本原理和基于增强体弥散度的设计思路;高尺寸稳定性的光学级、仪表级SiC/2024Al复合材料的微观构型特征及其在实际工程中应用的效果。理论和实践表明,仪表精度及其精度稳定性取决于材料的尺寸稳定性,而材料的稳定性首要因素是其内禀变形特性,而残余应力是次要的。本工作也表明,尺寸稳定性原理的应用对于精密轴承一类高精度零件的技术提升也将有启发性。

Carbon nanotube reinforced metal matrix composites—A review

[J].

Fatigue and damage in structural materials studied by X-ray tomography

[J].

Improving the tensile ductility of metal matrix composites by laminated structure: A coupled X-ray tomography and digital image correlation study

[J].

An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites

[J].

A theory of plasticity for carbon nanotube reinforced composites

[J].

Investigation of carbon nanotube reinforced aluminum matrix composite materials

[J].

In situ synthesized Al4C3 nanorods with excellent strengthening effect in aluminum matrix composites

[J].

The conflicts between strength and toughness

[J].The attainment of both strength and toughness is a vital requirement for most structural materials; unfortunately these properties are generally mutually exclusive. Although the quest continues for stronger and harder materials, these have little to no use as bulk structural materials without appropriate fracture resistance. It is the lower-strength, and hence higher-toughness, materials that find use for most safety-critical applications where premature or, worse still, catastrophic fracture is unacceptable. For these reasons, the development of strong and tough (damage-tolerant) materials has traditionally been an exercise in compromise between hardness versus ductility. Drawing examples from metallic glasses, natural and biological materials, and structural and biomimetic ceramics, we examine some of the newer strategies in dealing with this conflict. Specifically, we focus on the interplay between the mechanisms that individually contribute to strength and toughness, noting that these phenomena can originate from very different lengthscales in a material's structural architecture. We show how these new and natural materials can defeat the conflict of strength versus toughness and achieve unprecedented levels of damage tolerance within their respective material classes.

Structural biological materials: Critical mechanics-materials connections

[J].Spider silk is extraordinarily strong, mollusk shells and bone are tough, and porcupine quills and feathers resist buckling. How are these notable properties achieved? The building blocks of the materials listed above are primarily minerals and biopolymers, mostly in combination; the first weak in tension and the second weak in compression. The intricate and ingenious hierarchical structures are responsible for the outstanding performance of each material. Toughness is conferred by the presence of controlled interfacial features (friction, hydrogen bonds, chain straightening and stretching); buckling resistance can be achieved by filling a slender column with a lightweight foam. Here, we present and interpret selected examples of these and other biological materials. Structural bio-inspired materials design makes use of the biological structures by inserting synthetic materials and processes that augment the structures' capability while retaining their essential features. In this Review, we explain this idea through some unusual concepts.

Structure and mechanics of interfaces in biological materials

[J].

Advanced structural materials by bioinspiration

[J].

Mass production of bulk artificial nacre with excellent mechanical properties

[J].

Laminated metal composites—High temperature deformation behavior

[J].

Fabrication and superior ductility of laminated Ti-TiBw/Ti composites by diffusion welding

[J].

Bending behaviors and fracture characteristics of laminatedductile-tough composites under different modes

[J].

Tensile and bending behaviors and characteristics of laminated Ti-(TiBw/Ti) composites with different interface status

[J].

Interface affected zone for optimal strength and ductility in heterogeneous laminate

[J].

Preparation of high fracture performance SiCp-6061A1/6061A1 composite

[J].

Micromechanical properties of high fracture performance SiCp-6061Al/6061Al composite

[J].

High strength and high ductility copper matrix composite reinforced by graded distribution of carbon nanotubes

[J].

Bending mechanical properties and its evaluation of aluminium alloy matrix gradient composites reinforced with SiC particles

[J].

SiC颗粒增强铝合金基梯度复合材料弯曲力学性能及其评价

[J].

Fabrication of ceramics/high-entropy alloys gradient composites by combustion synthesis in ultra-high gravity field

[J].

Al-Al2O3 composites with interpenetrating network structures: Composite modulus estimation

[J].

Evaluation of Cu-Cr3C2 composite with interpenetrating network

[J].

In situ (Al3Zr + Al2O3np)/2024Al metal matrix composite with novel reinforcement distributions fabricated by reaction hot pressing

[J].

Controllable two-scale network architecture and enhanced mechanical properties of (Ti5Si3 + TiBw)/Ti6Al4V composites

[J].Novel Ti6Al4V alloy matrix composites with a controllable two-scale network architecture were successfully fabricated by reaction hot pressing (RHP). TiB whiskers (TiBw) were in-situ synthesized around the Ti6Al4V matrix particles, and formed the first-scale network structure (FSNS). Ti5Si3 needles (Ti5Si3) precipitated in the beta phase around the equiaxed a phase, and formed the secondary-scale network structure (SSNS). This resulted in increased deformation compatibility accompanied with enhanced mechanical properties. Apart from the reinforcement distribution and the volume fraction, the ratio between Ti5Si3 and TiBw fraction were controlled. The prepared (Ti5Si3 + TiBw)/Ti6Al4V composites showed higher tensile strength and ductility than the composites with a one-scale microstructure, and superior wear resistance over the Ti6Al4V alloy under dry sliding wear conditions at room temperature.

Microstructure and tensile properties of Y2O3-dispersed titanium produced by arc melting

[J].

Microstructural characterization of Nd2O3 in in situ synthesized multiple-reinforced (TiB + TiC + Nd2O3)/Ti composites

[J].

Creep behaviors and stress regions of hybrid reinforced high temperature titanium matrix composite

[J].

Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network

[J].Graphene or graphene-like nanosheets have been emerging as an attractive reinforcement for composites due to their unique mechanical and electrical properties as well as their fascinating two-dimensional structure. It is a great challenge to efficiently and homogeneously disperse them within a metal matrix for achieving metal matrix composites with excellent mechanical and physical performance. In this work, we have developed an innovative in situ processing strategy for the fabrication of metal matrix composites reinforced with a discontinuous 3D graphene-like network (3D GN). The processing route involves the in situ synthesis of the encapsulation structure of 3D GN powders tightly anchored with Cu nanoparticles (NPs) (3D GN@Cu) to ensure mixing at the molecular level between graphene-like nanosheets and metal, coating of Cu on the 3D GN@Cu (3D GN@Cu@Cu), and consolidation of the 3D GN@Cu@Cu powders. This process can produce GN/Cu composites on a large scale, in which the in situ synthesized 3D GN not only maintains the perfect 3D network structure within the composites, but also has robust interfacial bonding with the metal matrix. As a consequence, the as-obtained 3D GN/Cu composites exhibit exceptionally high strength and superior ductility (the uniform and total elongation to failure of the composite are even much higher than the unreinforced Cu matrix). To the best of our knowledge, this work is the first report validating that a discontinuous 3D graphene-like network can simultaneously remarkably enhance the strength and ductility of the metal matrix.

Effect of bimodal size SiC particulates on microstructure and mechanical properties of AZ31B magnesium matrix composites

[J].

Influence of B4C particles on processing and strengthening mechanisms in aluminum metal matrix composites—A review

[J].

Mechanical properties of tri-modal Al matrix composites reinforced by nano- and submicron-sized Al2O3 particulates developed by wet attrition milling and hot extrusion

[J].

Strong and ductile particulate reinforced ultrafine-grained metallic composites fabricated by flake powder metallurgy

[J].

Increasing the ductility of heat-resistant AlNp/Al composites by submicron Al2O3 particles

[J].

Mechanisms governing the mechanical behavior of an AlSi-CNTs-SiCp hybrid composite

[J].

Enhanced mechanical behavior and fabrication of silicon carbide particles covered by in-situ carbon nanotube reinforced 6061 aluminum matrix composites

[J].

Microstructural characteristics and mechanical behavior of SiC(CNT)/Al multiphase interfacial micro-zones via molecular dynamics simulations

[J].

Development of flake powder metallurgy in fabricating metal matrix composites: A review

[J].

Microstructure-based modeling on structure-mechanical property relationships in carbon nanotube/aluminum composites

[J].

A flake powder metallurgy approach to Al2O3/Al biomimetic nanolaminated composites with enhanced ductility

[J].

Interface-induced strain hardening of graphene nanosheet/aluminum composites

[J].

Towards the strength-ductility synergy of Al2O3/Al composite through the design of roughened interface

[J].

Aligning graphene in bulk copper: Nacre-inspired nanolaminated architecture coupled with in-situ processing for enhanced mechanical properties and high electrical conductivity

[J].

Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure

[J].Bulk graphene (reduced graphene oxide)-reinforced Al matrix composites with a bioinspired nanolaminated microstructure were fabricated via a composite powder assembly approach. Compared with the unreinforced Al matrix, these composites were shown to possess significantly improved stiffness and tensile strength, and a similar or even slightly higher total elongation. These observations were interpreted by the facilitated load transfer between graphene and the Al matrix, and the extrinsic toughening effect as a result of the nanolaminated microstructure.

Bioinspired multiscale Al2O3-rGO/Al laminated composites with superior mechanical properties

[J].

Fabrication and properties of dual-gradient nanostructured copper matrix composites reinforced by silicon carbide particles

[J].

碳化硅颗粒强化铜基双梯度纳米结构复合材料的制备及性能

[J].

A tri-modal aluminum based composite with super-high strength

[J].

Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles

[J].

Enhancing strength and ductility synergy through heterogeneous structure design in nanoscale Al2O3 particulate reinforced Al composites

[J].

Enhanced strain hardening by bimodal grain structure in carbon nanotube reinforced Al-Mg composites

[J].

Structure optimization for improving the strength and ductility of heterogeneous carbon nanotube/Al-Cu-Mg composites

[J].

Enhancement of the strength-ductility relationship for carbon nanotube/Al-Cu-Mg nanocomposites by material parameter optimisation

[J].

Trimodal grain structure enables high-strength CNT/Al-Cu-Mg composites higher ductility by powder assembly & alloying

[J].

Powder assembly & alloying to CNT/Al-Cu-Mg composites with trimodal grain structure and strength-ductility synergy

[J].

Evading strength and ductility trade-off in an inverse nacre structured magnesium matrix nanocomposite

[J].

Materials become insensitive to flaws at nanoscale: Lessons from nature

[J].

Current research and future prospect on the preparation and architecture design of nanomaterials reinforced light metal matrix composites

[J].In recent years, nanomaterials reinforced light metal matrix composites (LMMCs) have been researched widely, due to the enhancement in strength and ductility at room temperature, good wear resistance, excellent high temperature performance and structural-functional integration. However, there remain many challenges in developing high-performance nanomaterials reinforced LMMCs to date. The challenges mainly concentrate in the attainment of homogeneous dispersion or a controlled inhomogeneous microstructure of nanomaterials reinforcements, and the formation of the strong interfacial bonding. In the present review, therefore, current developments in fabrication, multi-scale hybrid reinforcement, novel architecture design and new processing method have been addressed. Moreover, further research interests related to the designs of nanomaterials reinforced LMMCs exhibiting high strength and plasticity, optimal architecture design and structural-functional integration have been proposed.

纳米增强体强化轻合金复合材料制备及构型设计研究进展与展望

[J].纳米增强体强化轻合金复合材料以其室温强度高、塑性好,耐磨损和优异的高温性能等特点,并兼有结构和功能一体化特性,成为近年来金属基复合材料(MMCs)领域的研究热点之一。实现纳米增强体的弥散分布或构型设计、改善界面结合是纳米增强体强化轻合金复合材料可控制备的重要挑战。本文重点概述了纳米增强体强化轻合金复合材料在制备策略、多尺度混杂增强、增强体构型设计以及新型加工制备技术等方面的研究进展,展望了轻合金复合材料在高强塑性能、构型优化以及结构功能一体化等方面的发展方向。

Progress on multi-dimensional carbon nanomaterials reinforced aluminum matrix composites: A review

[J].Metal matrix composites (MMCs), especially aluminum matrix composites (AMCs), are widely used in the applications of aerospace, automotive, mechatronics and other areas due to the advantages of high specific strength, high specific modulus, and excellent thermal and electrical conductivity. In recent years, carbon nanomaterials as the reinforcement of MMCs, have attracted great attention for their outstanding mechanical and functional properties. This review focuses on the progress on preparation methods and mechanical properties of different dimensional carbon nanomaterials (0-D carbon nano-onions, 1-D carbon nanotubes, 2-D graphene et al.) reinforced AMCs. The design ideas of aluminum matrix composites with high strength and toughness through the structural construction have been summarized ranging from single- to multi-dimensional hybrid reinforcements, and the future research trends of MMCs have been prospected.

多维度碳纳米相增强铝基复合材料研究进展

[J].以铝基复合材料为代表的金属基复合材料,具有高的比强度、比模量及优异的导热、导电性能,在航空航天、汽车制造、机械电子及其它民用领域具有广泛的应用前景。近年来,碳纳米相作为复合材料的增强体凭借其优异的力学性能和物理性能以及自身结构特点,引起人们极大关注而成为铝基复合材料研究领域的新热点。本文从不同维度结构的碳纳米相(零维碳纳米洋葱、一维碳纳米管、二维石墨烯等)为增强相的角度,概述了这些碳纳米相增强铝基复合材料的制备方法及其在力学性能方面的研究进展,阐述了从单一相增强到多元多维度混杂增强的铝基复合材料在力学性能方面的优势,旨在阐明通过碳纳米相的结构设计和空间构筑实现高强韧性铝基复合材料的设计思路,并展望了高强韧轻金属基复合材料未来的研究趋势。

Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility

[J].The high-temperature stability and mechanical properties of refractory molybdenum alloys are highly desirable for a wide range of critical applications. However, a long-standing problem for these alloys is that they suffer from low ductility and limited formability. Here we report a nanostructuring strategy that achieves Mo alloys with yield strength over 800 MPa and tensile elongation as large as ~ 40% at room temperature. The processing route involves a molecular-level liquid-liquid mixing/doping technique that leads to an optimal microstructure of submicrometre grains with nanometric oxide particles uniformly distributed in the grain interior. Our approach can be readily adapted to large-scale industrial production of ductile Mo alloys that can be extensively processed and shaped at low temperatures. The architecture engineered into such multicomponent alloys offers a general pathway for manufacturing dispersion-strengthened materials with both high strength and ductility.

Intragranular dispersion of carbon nanotubes comprehensively improves aluminum alloys

[J].

Reinforcement with intragranular dispersion of carbon nanotubes in aluminum matrix composites

[J].

Effect of thermomechanical treatment and length-scales on spatial distribution of CNTs in Al matrix

[J].

Ultrafine grained metals and metal matrix nanocomposites fabricated by powder processing and thermomechanical powder consolidation

[J].

Research on hot deformation behaviors of discontinuously reinforced aluminum composites

[J].This paper describes the research progress in hot deformation behaviors of discontinuously reinforced aluminum (DRA) composite, including research method, deformation mechanism and hot workability. The reliability of constitutive equation and processing map for description of flowing behaviors and deformation mechanisms in the previous studies were discussed. Based on that, the strain rate and temperature sensitivities of flow stress were introduced to further identify the deformation mechanisms. Deformation characteristics and microstructures of the composites with different reinforcements were illustrated. Finally, the future researches of hot deformation of DRA composite are suggested.

非连续增强铝基复合材料的热变形行为研究进展

[J].本文综述了非连续增强铝基复合材料的热变形行为理论研究方法,并描述了典型铝基复合材料的热变形机制和可加工性特征。对本构方程、加工图理论方法对流变行为和变形机制研究的可靠性进行了讨论,同时介绍了引入应变速率敏感指数和温度敏感指数作为基体合金变形机制演化辅助判据的方法。根据铝合金常见变形机制,讨论了不同类型增强体的铝基复合材料热加工变形行为特征。最后,对该领域未来的研究方向进行了展望。

Phase-field study of zener drag and pinning of cylindrical particles in polycrystalline materials

[J].

Extended twinning phenomena in Al-4%Mg alloys/B4C nanocomposite

[J].

Multiple strengthening mechanisms in high strength ultrafine-grained Al-Mg alloys

[J].

A transforming metal nanocomposite with large elastic strain, low modulus, and high strength

[J].Freestanding nanowires have ultrahigh elastic strain limits (4 to 7%) and yield strengths, but exploiting their intrinsic mechanical properties in bulk composites has proven to be difficult. We exploited the intrinsic mechanical properties of nanowires in a phase-transforming matrix based on the concept of elastic and transformation strain matching. By engineering the microstructure and residual stress to couple the true elasticity of Nb nanowires with the pseudoelasticity of a NiTi shape-memory alloy, we developed an in situ composite that possesses a large quasi-linear elastic strain of over 6%, a low Young's modulus of ~28 gigapascals, and a high yield strength of ~1.65 gigapascals. Our elastic strain-matching approach allows the exceptional mechanical properties of nanowires to be exploited in bulk materials.

Shape memory alloy-reinforced metal-matrix composites: A review

[J].

Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength

[J].

Back stress strengthening and strain hardening in gradient structure

[J].

Heterogeneous materials: A new class of materials with unprecedented mechanical properties

[J].

Perspective on hetero-deformation induced (HDI) hardening and back stress

[J].

Segregation and precipitation stabilizing an ultrafine lamellar-structured Al-0.3%Cu alloy

[J].

Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys

[J].

Significantly improved strength and ductility in bimodal-size grained microstructural magnesium matrix composites reinforced by bimodal sized SiCp over traditional magnesium matrix composites

[J].

Micro/nano-reinforcements in bimodal-grained matrix: A heterostructure strategy for toughening particulate reinforced metal matrix composites

[J].

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Friction stir welding of discontinuously reinforced aluminum matrix composites: A review

[J].

A review about friction stir welding of metal matrix composites

[J].

A comprehensive overview on the latest progress in the additive manufacturing of metal matrix composites: Potential, challenges, and feasible solutions

[J].

Additive manufacturing of aluminum-based metal matrix composites—A review

[J].

A review of self-healing metals: Fundamentals, design principles and performance

[J].

Ordered structures with functional units as a paradigm of material design

[J].

Progress in high throughput fabrication and characterization of metal matrix composites

[J].The "material genetic engineering" plan, based on the large data, is to investigate the high throughput design, fabrication and characterization techniques with the aim to shift the material research from traditional mode to high throughput mode with low cost and fast response speed, and to accelerate the research and development of new materials and achieve the goal of "double reduction halves". As the metal matrix composites (MMCs) exhibit multi-components and a thermodynamically non-equilibrium state during fabrication, some key issues occur and need to be addressed including: (1) for high throughput fabrication, currently developed high throughput technologies based on thermodynamically equilibrium conditions, such as spray printing and multi-node diffusion methods, are not applicable for MMCs; (2) for high throughput characterization, there is a lack of multi- dimensional, field and scale acquisition technique for the composition, morphology, microstructure and property of MMCs. In order to solve these problems, the progress on the research and development of high throughput fabrication and characterization techniques of MMCs was reviewed, especially, in the field of gradient reinforced MMCs and their high throughput combination characterization methods, which may promote the application of high throughput fabrication and characterization techniques in MMCs. Finally, the bottlenecks and prospects in the high throughput fabrication and characterization of MM Cs are proposed.

金属基复合材料高通量制备及表征技术研究进展

[J].“材料基因工程”计划是以大数据作为支撑,采用高通量设计、制备和表征技术,促使材料研究从传统的试错模式转向低成本、快速响应的新模式,从而加快新材料的研发速度,实现研发成本和周期“双减半”的目标。金属基复合材料由于组分复杂、制备过程为热力学非平衡状态,带来一些新的问题需要解决,包括:(1) 高通量制备方法方面,针对合金块体样品开发的喷印合成法、多元结扩散法等基于热力学平衡理论的高通量制备技术无法直接用于金属基复合材料构件块体坯料的制造;(2) 高通量表征技术方面,缺乏针对金属基复合材料单一样品成分、形貌、组织、结构和性能的多维、多场、多尺度同步采集技术,以及针对阵列样品成分、形貌、组织与结构的快速表征技术。鉴于上述问题,本文综述了金属基复合材料高通量制备及表征技术发展现状及已取得的进展,特别是在增强体呈梯度分布的金属基复合材料制备技术与高通量组合表征方法上取得的突破,推动了高通量制备及表征技术在金属基复合材料领域的应用。最后指出了金属基复合材料高通量计算、制备方法和表征技术方面存在的瓶颈问题,并对高通量制备与表征技术的发展进行了展望。

Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications

[J].

Structural modelling and mechanical behaviors of graphene/carbon nanotubes reinforced metal matrix composites via atomic-scale simulations: A review

[J].