钛合金具有比强度高、抗疲劳、耐腐蚀等优点,在航空、航天、兵器、石油、化工等领域得到广泛应用[1~3]。航空锻件的大型化、整体化可提高飞机结构及发动机的使用寿命及安全可靠性、降低结构重量、缩短制造周期,是钛合金制造技术重要的发展方向[4,5]。但同时,由于尺寸效应造成的钛合金大型锻件的均匀性及稳定性问题接踵而至。一方面,制备锻件所用的钛合金大规格棒材往往存在低倍组织粗大且不均匀的问题[6,7];另一方面,棒材心部易形成强烈的{100}β织构[8,9]。这些缺陷容易遗传到锻件中,对锻件的性能造成不利影响[8],威胁锻件的安全使用。国内针对钛合金大型制件的均匀性控制主要围绕“工艺-组织-性能”3者关系开展研究工作,形成了有效的组织均匀性控制方法[10~13],但织构控制及检测尚未纳入材料质量评价体系。如何建立起热加工工艺与钛合金织构演变规律之间的关系,并形成有效的织构预测及控制方法成为亟需解决的问题。

众所周知,钛合金主要由bcc结构的β相和hcp结构的α相构成,β相→α相的扩散型相变严格遵循{0002}α //{110}β、<

本工作利用金相及电子背散射衍射(EBSD)技术,观察TC18钛合金在热变形后β相的组织及织构特征以及伴随的变形、动态回复、动态再结晶、晶粒长大行为。目的是研究热变形参数(变形方式、变形温度、变形量、应变速率、保温时间)对TC18钛合金β相组织及织构演变规律的影响,为实现钛合金热变形的织构控制提供理论依据。

1 实验方法

实验所用材料为直径300 mm TC18钛合金棒材,其化学成分(质量分数,%)为Ti-5Al-5Mo-5V-1Cr-1Fe,相变点为870℃。通过线切割在棒材横截面心部位置沿棒材纵向(L向)截取多个直径8 mm、长12 mm的试样。使用Gleeble 1500热模拟试验机对试样进行压缩及拉伸实验,其中变形方向与L向平行,变形完成后水冷,具体使用的热变形参数见表1。将棒材心部原始试样沿L向纵剖、热变形后的试样沿变形方向纵剖,并抛光、侵蚀后,使用配备EBSD探头的Ultra 55场发射扫描电镜(SEM)和Channel 5取向分析软件观察并分析试样的组织及织构特征。

表1 热模拟实验中使用的热变形参数

Table 1

| Deformation mode | Temperature / oC | Reduction / % | Strain rate / s-1 | Holding time / min |

|---|---|---|---|---|

| Compression | 770, 820, 840, 890, 920, 970 | 30, 50, 70 | 0.01, 0.1, 1, 10 | 15, 30, 45 |

| Stretching | 770, 840, 890, 920 | 25, 35, 60, 100 | 0.1 | 15 |

2 实验结果

2.1 棒材心部的组织及织构特征

图1为直径300 mm TC18钛合金棒材横截面心部组织的SEM像。可以看出,心部组织由残余β相、短棒状的αp (初生α相)、针状的αs (次生α相)以及沿原始β相晶界析出的晶界α相构成。其中晶界α相呈不连续分布,但基本可以勾勒出原始β相的形状。

图1

图1

直径300 mm TC18钛合金棒材横截面心部组织的SEM像

Fig.1

Low (a) and high (b) magnified SEM images of center cross section in diameter 300 mm TC18 titanium alloy bar

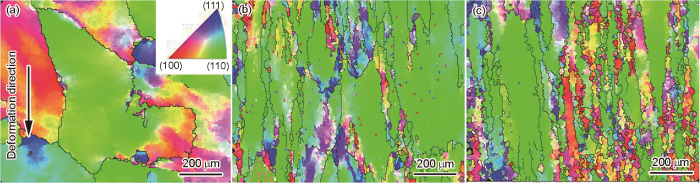

图2为直径300 mm TC18钛合金棒材横截面心部β相的取向分布图。可以看出,棒材心部的β相沿L向伸长,其尺寸均匀性较差,部分大晶粒内部存在较大的取向差,体现出变形或回复状态的特征。β相的织构以{110}织构为主,是典型的bcc结构晶体的拉伸织构。需要说明的是,由于扫描区域较大、α相与β相尺寸差异大,为兼顾效率,本工作所有的EBSD数据均在测试及数据处理阶段忽略了α相的存在。这样虽然会引起一定的偏差,但不会对β相组织及织构特征的表征造成影响。

图2

图2

直径300 mm TC18钛合金棒材横截面心部β相的组织及织构特征

Fig.2

β phase textures of center cross section in diameter 300 mm TC18 titanium alloy bar

2.2 热压缩温度对β相组织及织构的影响

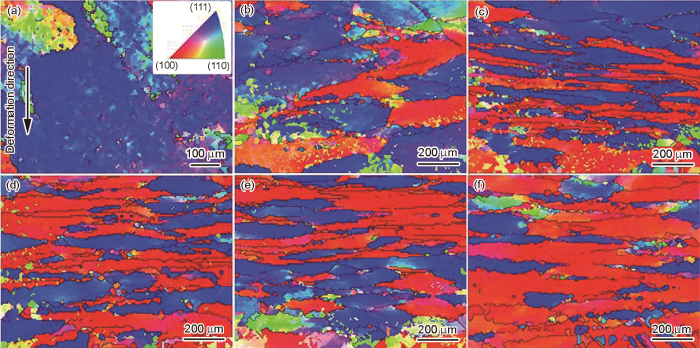

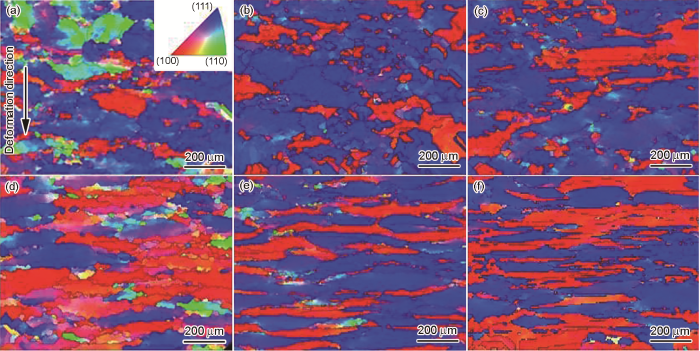

图3

图3

TC18钛合金在不同变形温度保温15 min、变形量50%、应变速率0.1 s-1条件下压缩后β相的取向分布图

Fig.3

β phase textures in TC18 titanium alloy after hot compression at 770oC (a), 820oC (b), 840oC (c), 890oC (d), 920oC (e), and 970oC (f) with 15 min holding, 50% reduction, and 0.1 s-1 strain rate

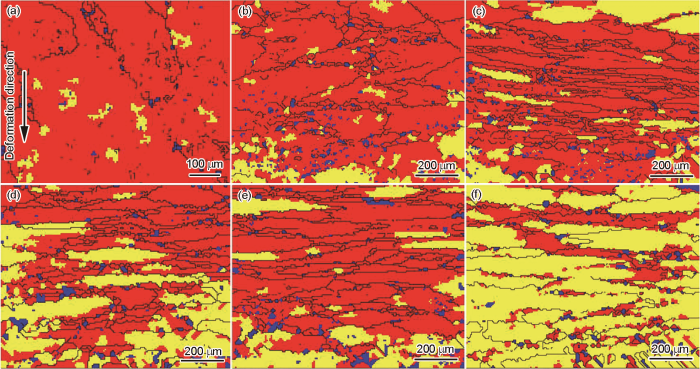

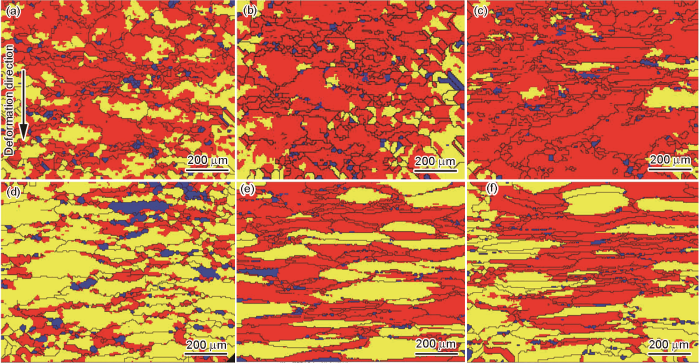

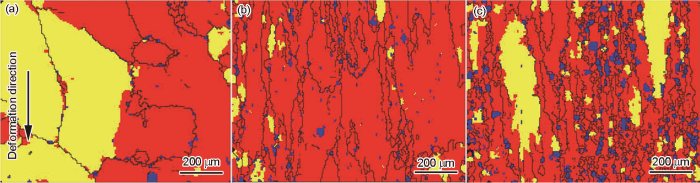

在使用Channel 5软件处理数据时,设定亚晶界判定角度θc为2°,晶界判定角度θGB为10°。即当晶粒中的平均取向差θ0 > 2°,且不存在亚晶时,晶粒被定义为变形晶粒(红色);当晶粒中存在亚晶,每个亚晶中的θ0 > 2°,而亚晶之间的取向差θi > 2°时,晶粒被定义为回复晶粒(黄色);当晶粒中的θ0 ≤ 2°时,晶粒被定义为再结晶晶粒(蓝色)。图4为TC18钛合金在不同温度保温15 min、变形量50%、应变速率0.1 s-1条件下压缩后,β相的回复再结晶晶粒分布图。可以看出,TC18钛合金在该热压缩条件下产生的动态再结晶很少,其晶粒主要处在变形或回复状态,因此形成的织构类型也主要为变形织构。总的趋势是,随着变形温度的升高,β相的再结晶晶粒与回复晶粒逐渐增多,变形晶粒逐渐减少。

图4

图4

TC18钛合金在不同温度保温15 min、变形量50%、应变速率0.1 s-1条件下压缩后β相的回复再结晶

Fig.4

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot compression at 770oC (a), 820oC (b), 840oC (c), 890oC (d), 920oC (e), and 970oC (f) with 15 min holding, 50% reduction, and 0.1 s-1 strain rate

2.3 热压缩变形量对β相组织及织构的影响

图5

图5

TC18钛合金在840和890℃保温15 min、0.1 s-1应变速率条件下不同变形量压缩后β相的取向分布图

Fig.5

β phase textures in TC18 titanium alloy after hot compression at 840oC, 30% (a), 840oC, 70% (b), 890oC, 30% (c), and 890oC, 70% (d) with 15 min holding and 0.1 s-1 strain rate

图6

图6

TC18钛合金在840和890℃保温15 min、应变速率0.1 s-1条件下不同变形量压缩后β相的回复再结晶

Fig.6

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot compression at 840oC, 30% (a), 840oC, 70% (b), 890oC, 30% (c), and 890oC, 70% (d) with 15 min holding and 0.1 s-1 strain rate

2.4 热压缩应变速率对β相组织及织构的影响

图7为TC18钛合金在840及890℃保温15 min、变形量50%、不同应变速率热压缩后β相的取向分布图。可以看出,在单相区压缩时(890℃),随着应变速率的降低,β相的{100}织构逐渐增强而{111}织构逐渐减弱,见图7d~f和图3d。在两相区压缩时(840℃),这一规律并不明显,而且变形晶粒形状也不规则,这主要还是受到α相阻碍作用的影响,见图7a~c和图3c。此外,随着应变速率降低,非典型取向增多,晶粒内局部取向梯度增大,其主要原因是应变速率降低导致变形时间延长、变形抗力降低,晶体有充分的时间转到相对稳定的取向上。在单相区压缩(890℃)时,应变速率越低,发生动态再结晶的β相晶粒较多,如图8d~f和图4d所示;在两相区变形时(840℃),这一规律则不明显,见图8a~c和图4c。

图7

图7

TC18钛合金在840和890℃保温15 min、变形量50%条件下不同应变速率压缩后β相的取向分布图

Fig.7

β phase textures in TC18 titanium alloy after hot compression at 840oC, 0.01 s-1 (a), 840oC, 1 s-1 (b), 840oC, 10 s-1 (c), 890oC, 0.01 s-1 (d), 890oC, 1 s-1 (e), and 890oC, 10 s-1 (f) with 15 min holding and 50% reduction

图8

图8

TC18钛合金在840和890℃保温15 min、变形量50%条件下不同应变速率压缩后β相的回复再结晶

Fig.8

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot compression at 840oC, 0.01 s-1 (a), 840oC, 1 s-1 (b), 840oC, 10 s-1 (c), 890oC, 0.01 s-1 (d), 890oC, 1 s-1 (e), and 890oC, 10 s-1 (f) with 15 min holding and 50% reduction

2.5 热压缩前保温时间对β相组织及织构的影响

图9

图9

TC18钛合金在840和890℃保温不同时间、变形量50%、应变速率0.1 s-1条件下压缩后β相的取向分布图

Fig.9

β phase textures in TC18 titanium alloy after hot compression at 840oC, 30 min (a), 840oC, 45 min (b), 890oC, 30 min (c), and 890oC, 45 min (d) with 50% reduction and 0.1 s-1 strain rate

图10

图10

TC18钛合金在840和890℃保温不同时间、变形量50%、应变速率0.1 s-1条件下压缩后β相的回复再结晶

Fig.10

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot compression at 840oC, 30 min (a), 840oC, 45 min (b), 890oC, 30 min (c), and 890oC, 45 min (d) with 50% reduction and 0.1 s-1 strain rate

2.6 热拉伸温度对β相组织及织构的影响

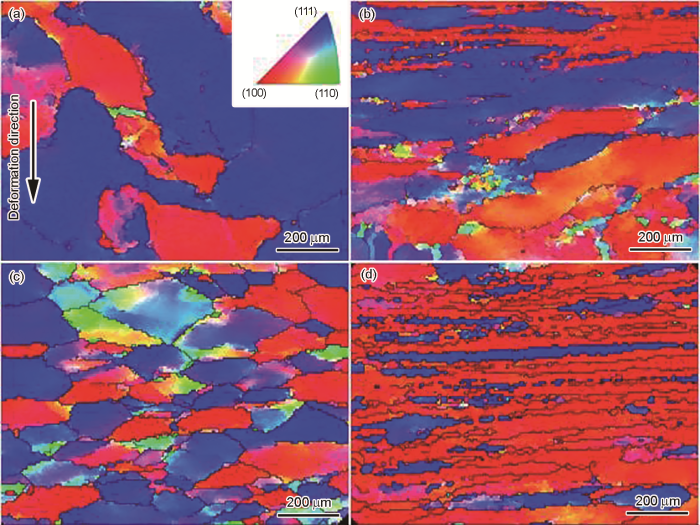

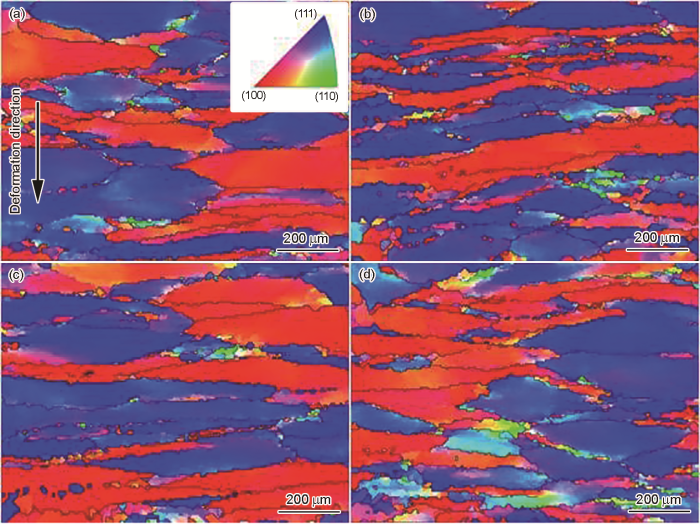

图11

图11

TC18钛合金在不同温度保温15 min、变形量25%、应变速率0.1 s-1条件下拉伸后β相的取向分布图

Fig.11

β phase textures in TC18 titanium alloy after hot stretching at 770oC (a), 840oC (b), 890oC (c), and 920oC (d) with 15 min holding, 25% reduction, and 0.1 s-1 strain rate

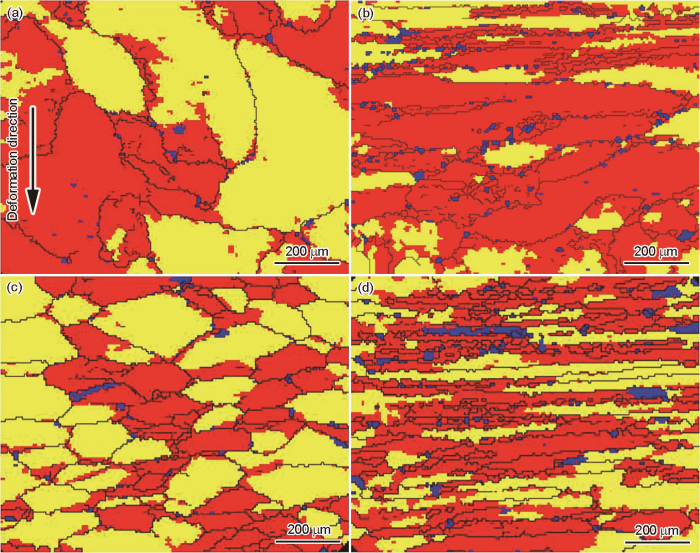

图12

图12

TC18钛合金在不同温度保温15 min、变形量25%、应变速率0.1 s-1条件下拉伸后β相的回复再结晶

Fig.12

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot stretching at 770oC (a), 840oC (b), 890oC (c), and 920oC (d) with 15 min holding, 25% reduction, and 0.1 s-1 strain rate

2.7 热拉伸变形量对β相组织及织构的影响

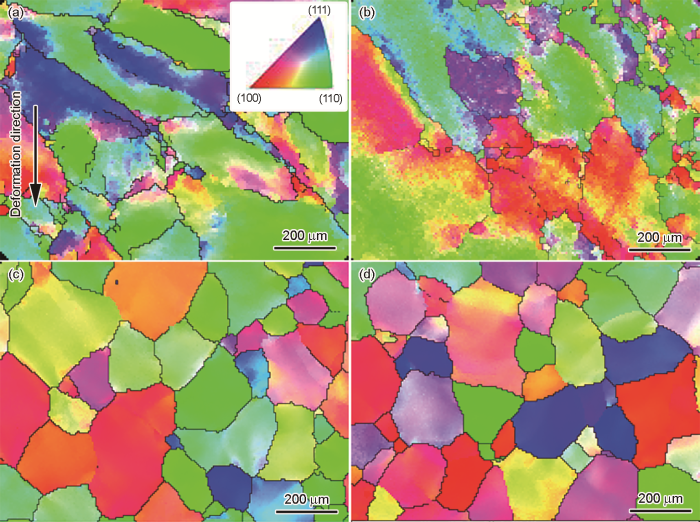

图13

图13

TC18钛合金在840℃保温15 min、应变速率0.1 s-1条件下不同变形量拉伸后β相的取向分布图

Fig.13

β phase textures in TC18 titanium alloy after hot stretching at 35% (a), 60% (b), and 100% (c) with 840oC,15 min holding, and 0.1 s-1 strain rate

图14

图14

TC18钛合金在840℃保温15 min、应变速率0.1 s-1条件下不同变形量拉伸后β相的回复再结晶

Fig.14

Recrystallized (blue), recovery (yellow), and deformed (red) β phase grains in TC18 titanium alloy after hot stretching at 35% (a), 60% (b), and 100% (c) with 840oC,15 min holding, and 0.1 s-1 strain rate

3 分析讨论

3.1 热变形中β相的软化机制及其影响因素

晶体在热变形过程中的软化机制包括动态再结晶和动态回复,其中,动态再结晶是实现组织细化的重要手段。在动态回复过程中,部分位错通过交滑移和攀移与异号位错相互抵消,造成形变储存能不断消耗;而动态再结晶则需要形变储存能达到临界值才能发生;因此,2者存在竞争关系。具有高层错能的Ti及钛合金在热变形过程中,主要发生动态回复,但在特殊条件下(高温高应变速率[22,23]、中温低应变速率[24]、低温高应变速率[25]等)也可以观察到动态再结晶现象。由实验结果可知,TC18钛合金的β相在热变形中发生了动态回复和动态再结晶现象,主要以动态回复为主。而变形方式、变形温度、变形量、应变速率、变形前的保温时间均会对动态再结晶晶粒的比例有所影响。在单相区或两相区压缩时,随着温度和变形量提高、应变速率和保温时间降低,动态再结晶比例升高;在热拉伸时,随着温度及变形量提高,动态再结晶比例升高。在热压缩以及两相区拉伸时,新的动态再结晶晶粒主要在β晶粒的晶界处形核,表现出不连续动态再结晶的特征;在单相区拉伸时,随着变形量增大,弓弯形核的现象逐渐减少,开始形成均匀的再结晶晶粒,表现出连续动态再结晶的特征。在920℃保温15 min、变形量25%、应变速率0.1 s-1条件下拉伸后,β相的连续动态再结晶已经成为主导,见图12d。

3.2 热变形后β相组织及织构的主要影响因素

变形方式主要影响热变形后β相的形貌及织构类型。热压缩后,β相软化机制以动态回复为主,因此β相晶粒趋近于沿垂直变形方向拉长,形成的主要织构类型为典型压缩织构{100}及{111}。在两相区拉伸后,β相仍以动态回复为主,β相晶粒趋近于沿平行变形方向拉长,其主要织构类型为典型拉伸织构{110};在单相区拉伸后,随着温度升高,动态再结晶的比例明显提升,β相等轴化程度提高,织构则由{110}织构向无织构发展。

变形温度、变形量和应变速率主要影响热变形后β相各织构组分比例。在单相区压缩时,随着变形温度升高、变形量提高、应变速率降低,{100}织构比例逐渐提高、{111}织构比例逐渐降低;在两相区压缩时,随着变形温度升高、变形量提高,{100}织构比例逐渐提高、{111}织构比例逐渐降低;在两相区拉伸时,随着变形量提高,{110}织构比例逐渐提高。变形前保温时间主要影响热变形后β相的尺寸。保温时间越长,热压缩后β相的尺寸越大。

4 结论

(1) TC18钛合金在热压缩及两相区热拉伸时,β相均以动态回复为主,部分晶粒发生不连续动态再结晶;在单相区热拉伸时,随着温度升高,β相的连续动态再结晶逐渐成为主导。

(2) TC18钛合金在热压缩后,主要形成{100}及{111}织构,在热拉伸后,主要形成{110}织构;在单相区压缩时,随着变形温度升高、变形量提高、应变速率降低,{100}织构比例提高、{111}织构比例降低;在两相区压缩时,随着变形温度升高、变形量提高,{100}织构比例提高、{111}织构比例降低;在两相区拉伸时,随着变形量提高,{110}织构比例逐渐提高。

参考文献

Recent research and development of titanium alloys for aviation application in China

[J].

我国航空用钛合金技术研究现状及发展

[J].

Production status and development trend of heavy aviation die forging

[J].

大型航空模锻件的生产现状及发展趋势

[J].

Development of large single-piece forgings and heavy forging presses in aerospace forging industry

[J].

大型模锻件和模锻液压机与航空锻压技术

[J].

Effect of heat treatment on microstructure and mechanical properties of TC18 alloy

[J].

热处理对TC18合金显微组织和力学性能的影响

[J].

Modeling of texture evolution during hot forging of alpha/beta titanium alloys

[J].

Recovery and recrystallization behavior of large sized β phase grains in TC18 titanium alloy during annealing process

[J].

Investigation of microstructure and texture of β phase in a forged TC18 titanium alloy bar

[J].

锻态TC18钛合金棒材中β相组织和织构特征研究

[J].

Analysis of bright band formation in Ti-55531 titanium alloy forging

[J].

Ti-55531钛合金自由锻件亮带形成原因分析

[J].

Research on improving structure uniformity of titanium alloy in open-die forging

[J].

改善钛合金自由锻件组织均匀性的研究

[J].

Method of improving structure uniformity of big size titanium open-die forgings

[J].

改善大尺寸钛合金自由锻件组织均匀性的方法

[J].

Study on microstructure control and mechanical property TA15 alloy large-scale whole frame die forging

[J].

TA15钛合金大型整框模锻件组织控制及性能研究

[J].

Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti-6Al-4V

[J].

The effect of β grain coarsening on variant selection and texture evolution in a near-β Ti alloy

[J].

Influence on texture on beta grain growth during continuous annealing of Ti-6Al-4V

[J].

Influence of grain size and crystallographic texture on mechanical behavior of TIMETAL-LCB in metastable β-condition

[J].

Effect of annealing temperature on microstructure and texture evolution of TC18 titanium alloy

[J].46(suppl

.

退火温度对TC18钛合金组织及织构演变规律的影响

[J].

Mechanical behavior and microstructure of TA15 titanium alloy during hot compressive deformation

[J]. J

TA15钛合金高温压缩变形行为与组织研究

[J].

Microstructures and textures of TA15 titanium alloy after hot deformation

[J].

TA15钛合金的热变形微观组织与织构

[J].

Microstructure evolution of thermal deformation TA15 titanium alloy under β phase region heating institution

[J].

β相区加热TA15钛合金热变形显微组织演化

[J].

Dynamic recrystallization of beta-phase in titanium alloy

[J].

High temperature deformation in Ti-5Al-2.5Sn alloy

[J].

Investigation of dynamic recrystallization in two-phase titanium alloy Ti-6Al-4V

[J].