Evolution of δ phase microstructure in alloy 718 [A]. 7th International Symposium on Superalloy 718 and Derivatives

2

2010

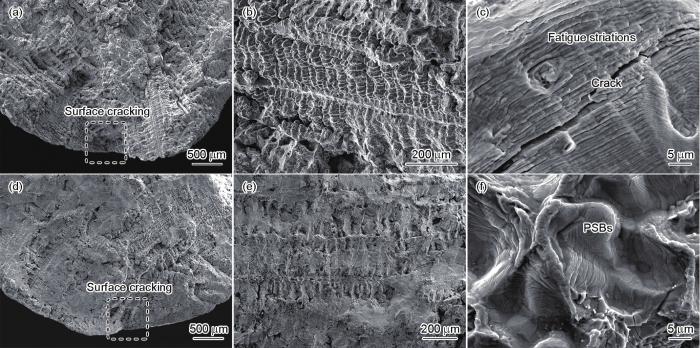

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

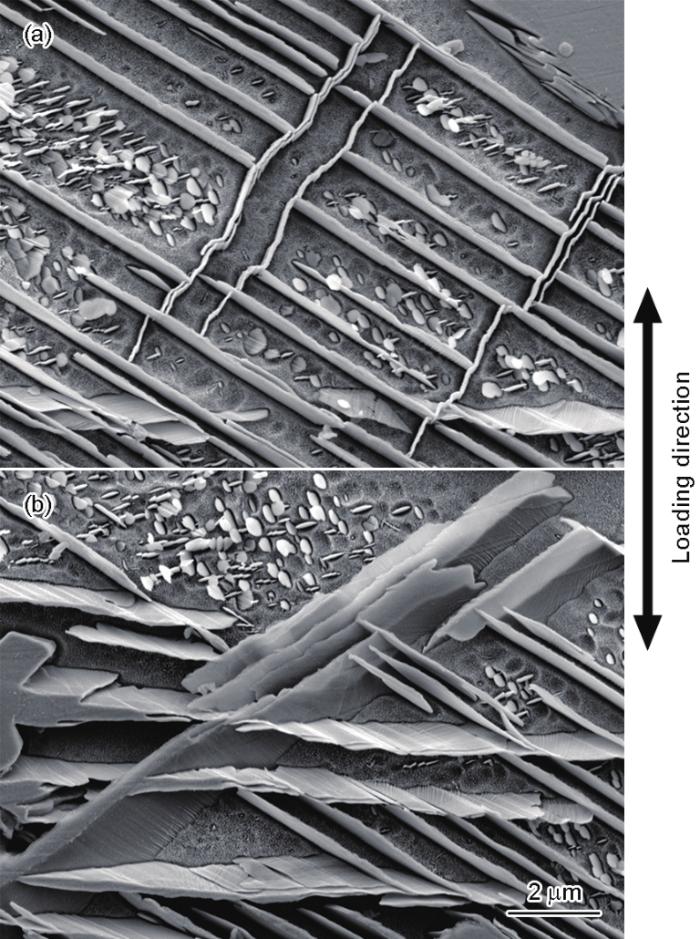

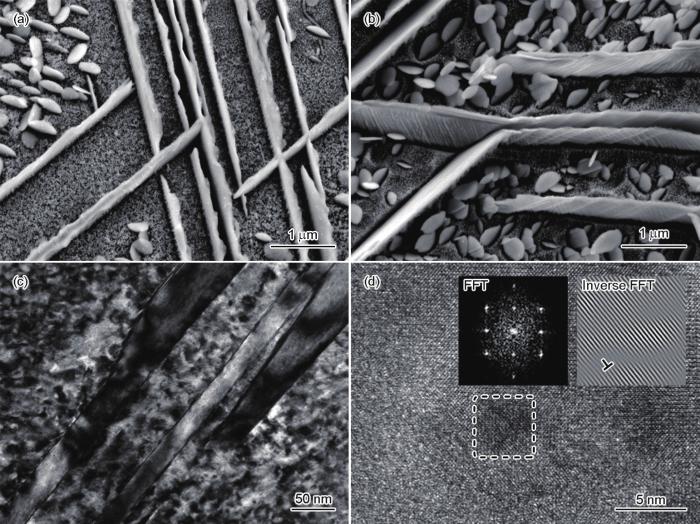

... K4169合金中的δ-Ni3Nb相普遍具有层片状的三维形貌,其长、宽、厚3个方向的尺寸差异较大,而且本身属于正交晶系结构,因此各向异性明显,这也是δ-Ni3Nb相在循环加载后会出现2种类型形貌演变的原因.图10展示了δ-Ni3Nb层片在不同方向上的变形特征,沿长度方向(以下用“平行方向”指代),δ-Ni3Nb层片表现为分叉断裂,而垂直于宽度方向和厚度方向组成的平面(以下用“垂直方向”指代),则表现为弯曲变形.进一步对比了不同循环寿命试样,发现平行方向的分叉断裂在较少的循环周次下已经出现,但没有发生弯曲,说明此时δ-Ni3Nb层片只发生沿长度方向的断裂,而没有在其表面产生滑移,如图10a所示.此外,在稍远离断口和显微疏松的区域,垂直方向的δ-Ni3Nb相出现因显微疏松体积分数不同而变化的变形特征,即当显微疏松体积分数较大时,循环周次较短,未断裂的δ-Ni3Nb相表面出现少量滑移迹线.随着显微疏松体积分数减少,循环周次增加,未断裂的δ-Ni3Nb相表面滑移迹线逐渐增多(图10b).这说明δ-Ni3Nb层片的垂直方向比平行方向有更好的抵抗循环断裂的能力.由δ-Ni3Nb相与γ-Ni基体的取向关系可知,其长度方向为[100]δ方向,宽度方向和厚度方向组成的平面为(010)δ面[1],该面是δ-Ni3Nb的密排面,同时也是易滑移面,滑移系为(010)δ[100]δ[33~36].Hagihara等[37]在对Ni3Nb单晶的压缩变形研究中发现,Ni3Nb单晶在室温变形时出现[100]螺型位错,当温度超过一定值时(视压缩轴与单晶体取向而定),螺型位错逐渐向刃型位错转变.本工作通过对循环变形后的δ-Ni3Nb层片进行HRTEM分析,也发现刃型位错(图10d).虽然本工作不涉及到高温,并且拉压循环加载与文献[37]中的单向压缩也存在区别,但不排除由于循环加载导致螺型位错向刃型位错转变. ...

Some features of anisothermal solid-state transformations in alloy 718

2010

Microstructural features controlling the variability in low-cycle fatigue properties of alloy Inconel 718DA at intermediate temperature

3

2016

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... [3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

In-plane and out-of-plane deformation at the sub-grain scale in polycrystalline materials assessed by confocal microscopy

7

2019

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... [4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... [4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... [4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... 本工作在断口附近的纵剖面和断口形貌中均观察到Laves相的层状断裂特征,如图7所示.进一步通过EBSD分析了Laves颗粒的晶粒取向及其周围的应变局部化特征,如图9所示.图9b为Laves相的反极图(IPF)和三维晶粒取向示意图.可见,加载后单个Laves颗粒断裂成几个小部分,但是每个部分都具有几乎相同的晶粒取向(图9b中各部分的三维晶粒取向一致).因此,Laves相的断裂并不是塑性变形累积的过程,而是具有明显的脆断特征[4,30].图9b中个别取向差异较大的位置(如图9b中绿色区域)可能是因为在加载中受到基体的挤压,导致这些断裂的小块Laves相发生晶粒偏转[31].此外,这种取向特征说明Laves相的断裂并不是随机的,可能是沿某组平行晶面扩展.由于Laves相破坏了γ-Ni基体的连续性,在其周围基体中产生应力集中或塑性应变累积[21].随着循环加载的进行,Laves相周围基体中的塑性应变累积程度不断增加,尤其是在尖锐位置累积非常严重的应力集中,最终导致Laves相断裂,且裂纹沿着特定晶面扩展[21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

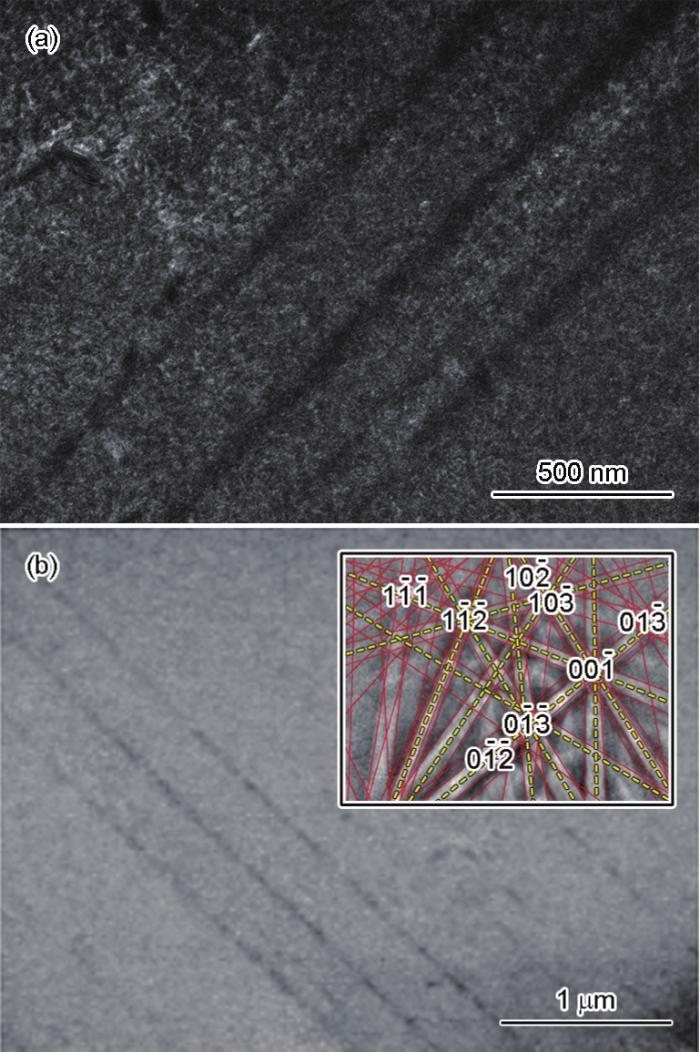

... 由图9c可知,在Laves相周围的γ-Ni基体中存在明显的基体取向偏差.由于δ-Ni3Nb相与Laves相共生(图9a),所以γ-Ni基体中的取向偏差也存在于δ-Ni3Nb相周围(图9a和c).由此可以推断出δ-Ni3Nb层片受到γ-Ni基体应变局部化的影响.与Laves相不同的是δ-Ni3Nb相的塑性变形能力更好,因此即使Laves相在疲劳早期发生断裂,部分δ-Ni3Nb相却还能维持其原本的层片状形貌,直至弯曲和滑移开裂[21].本工作通过截取δ-Ni3Nb层片周围的基体组织进行TEM和TKD观察,都发现该区域有明显的孪生变形痕迹,如图11所示.γ-Ni基体作为典型的fcc结构,当循环加载应力幅低于屈服强度时,应变局部化倾向于首先在Σ3孪晶界附近出现,所以在孪晶附近观察到明显的结构变化特征[4].又由于δ-Ni3Nb相与γ-Ni基体具有明显的位相关系,基体中的应变局部化会导致δ-Ni3Nb相产生变形,所以在δ-Ni3Nb层片周围观察到明显的应变局部化效应[4]. ...

... [4]. ...

γ′′和γ′相强化的Ni-Fe基高温合金GH4169的研究与发展

1

2010

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

γ′′和γ′相强化的Ni-Fe基高温合金GH4169的研究与发展

1

2010

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Alloy 718 at Pratt & Whitney-Historical perspective and future challenges [A]. 5th International Symposium on Superalloys 718, 625, 706, and Derivatives

1

2001

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Application of alloy 718 in GE aircraft engines: Past, present and next five years [A]. 5th International Symposium on Superalloys 718, 625, 706, and Derivatives

2001

Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting

1

2016

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Effect of heat treatment on Coffin-Manson relationship in LCF of superalloy IN718

1

2008

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Effect of heat treatment on low cycle fatigue of IN718 superalloy at the elevated temperatures

4

2017

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... ,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

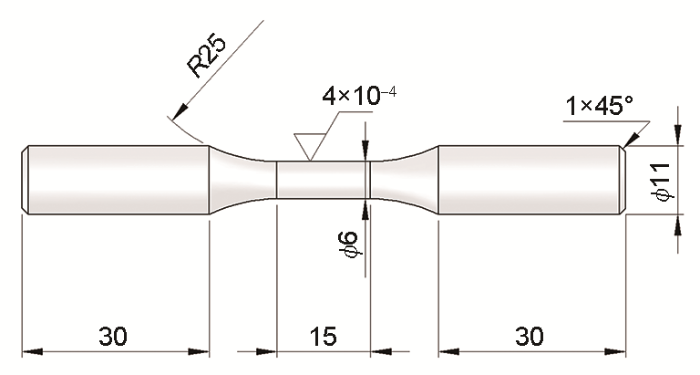

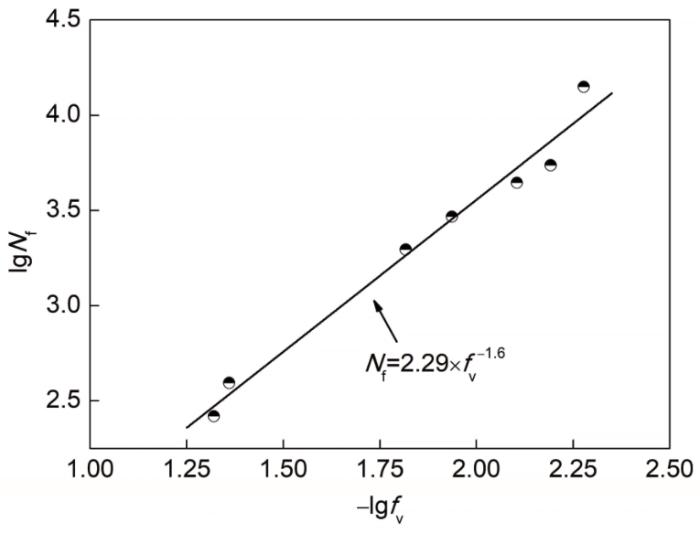

... 实验用K4169合金的化学成分(质量分数)为:Cr 19%,Fe 18.55%,Mo 3%,(Nb+Ta) 5%,Ti 0.9%,Al 0.5%,C 0.05%,Ni 余量.采用熔模精密铸造方法制造试棒,大致流程为:试棒形状和尺寸设计、蜡模模具设计与制作、注蜡、蜡模组装、蘸浆和喷砂、焙烧脱蜡、陶瓷模壳成型、熔炼浇注[23].本研究设计了7组不同尺寸的试棒,主要尺寸差异在试棒中间部位,即热节直径不同,目的是改变平行段内的凝固速率,分别编号为1#~7#,热节直径分别为41.8、35.8、21.7、19.6、18.1、16.5和11.8 mm.热节直径较大(凝固速率较慢)的试棒预期会产生更多的显微疏松等铸造缺陷,反之则更少[24~26].由此可以得到不同循环加载寿命的试样,为研究微观组织的演变规律提供便利.热处理前,从每组精铸试棒的热节区域取8 mm×8 mm×1.5 mm薄片,利用BX51M光学显微镜(OM)观察显微疏松形貌,并统计显微疏松面积分数(近似认为是体积分数).经水磨砂纸(120~2000号)机械研磨至光亮且无显见划痕,显微疏松体积分数统计方法参考航标HB 20058-2011.根据所观察到的显微疏松尺寸特征,对每个试样拍摄4张50倍OM照片,并在显微疏松区域框选1 mm×1 mm范围,用来统计面积分数,最后计算平均值.之后将所有精铸试棒封管填充Ar气,在管式炉中进行标准热处理:1095 ℃×2 h,955 ℃×1 h,720 ℃×8 h,随后炉冷(约56 ℃/h)至620 ℃×8 h,随后空冷至室温[10]. ...

Structural characterization of the aged Inconel 718

1

2000

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Effect of standard heat treatment on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718

2003

Effect of service exposure on fatigue crack propagation of Inconel 718 turbine disc material at elevated temperatures

1

2014

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Microstructure based fatigue life prediction framework for polycrystalline nickel-base superalloys with emphasis on the role played by twin boundaries in crack initiation

2

2016

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

... ,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Effects of grain size and precipitate size on the fatigue crack growth behavior of alloy 718 at 427 ℃

1

1987

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Effect of boron on fatigue crack growth behavior in superalloy IN 718 at RT and 650 ℃

1

2006

... K4169合金(对应国外牌号Inconel 718)是γ/γ"沉淀强化型铸造镍基高温合金[1~5].该合金综合性能优异:在650 ℃时仍具有较高的强度、塑性以及良好的抗疲劳、耐腐蚀、耐氧化等特性,且铸造成型性、铸件质量可控性、焊接性能极佳[3,4].因此K4169在航空领域有重要应用,可用于制造复杂形状承热结构件,如机匣、叶片、盘件等[6~8].K4169合金用作航空部件,服役时会受到振动、转动或频繁起停等循环加载工况的影响,这使合金内部受到循环应力的作用,产生区别于单向加载的微观组织演变[9,10].特别是在远低于合金屈服强度的循环应力幅作用下,也会产生局部区域的严重塑性变形或裂纹萌生.这显然与循环加载过程中微观组织的演变有关,因此研究循环加载时的微观组织演变及其对合金局部变形或断裂的影响,一直是一项重要课题[3,10].K4169合金经标准热处理后,微观组织由基体γ-Ni、主要强化相γ"-Ni3Nb、次要强化相γ′-Ni3(Al, Ti)、δ-Ni3Nb相、MC型碳化物和少量未完全消除的脆性Laves相组成[11~13].此外,合金中还可能存在显微疏松等铸造缺陷.作为典型的fcc结构材料,K4169合金对循环加载的响应主要表现为γ-Ni基体中特定滑移系的开动,即{111}γ<>γ[4].随着循环加载的进行,局部区域位错增殖和累积,塑性应变累积,逐渐演变为驻留滑移带(PSBs),成为裂纹萌生的潜在区域[4,14].在理想情况下(比如热等静压或锻造高温合金中,排除了缺陷的影响,或远离缺陷的区域),镍基高温合金这种fcc结构材料中的孪晶界附近是裂纹萌生的高发区域,同时也是应变局部化比较严重的区域,会对周围微观组织产生影响[4,14].显然,微观组织在循环加载中产生形貌和结构演变,进而影响合金在循环加载中的应变局部化、裂纹萌生、扩展等变形和断裂特性,因而一直得到广泛研究.然而,过去的研究主要集中于基体与强化相,即γ/γ"的相互作用,而对其它微观相的研究还不充分,比如对δ-Ni3Nb相、Laves相以及它们与基体γ-Ni的相互作用的研究还不十分明确[15,16]. ...

Characterizing precipitation defects in nickel based 718 alloy

3

2010

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

... [17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

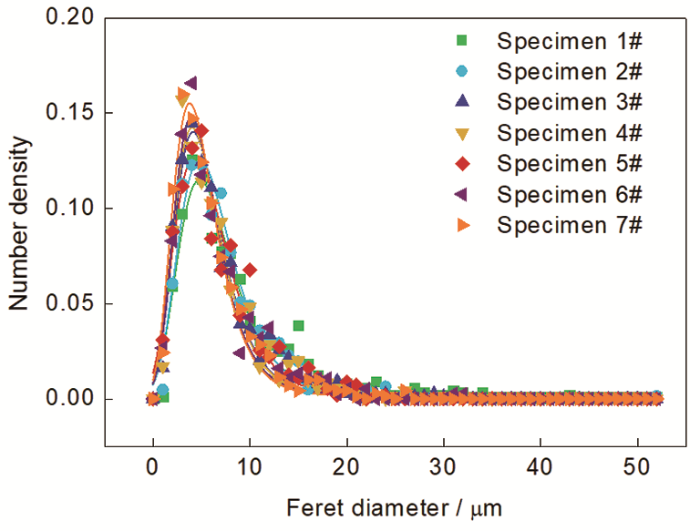

... 标准热处理后,虽然显微偏析程度大幅减轻,但分布于枝晶间的析出相还有残留,这些微米尺度的析出相呈枝晶状的分布特征(图3a).SEM和TEM形貌观察结果显示,枝晶间的不规则块状析出相为Laves相,而其周围伴生的层片为δ-Ni3Nb相(图3b和c).由选区电子衍射(SAED)花样(图3d)可确定δ-Ni3Nb相与γ-Ni基体的取向关系为:()γ //()δ,[]γ //[100]δ,与两者经典的取向关系相符[17,27].热处理组织中基体为γ-Ni固溶体,体心四方结构的γ"-Ni3Nb颗粒弥散分布于基体中,如图3e和f所示.γ"-Ni3Nb作为强化相为合金提供了足够的强度,但在循环加载过程中需要综合考虑多种析出相的作用,如γ"-Ni3Nb相与δ-Ni3Nb相化学成分相同,局部含量近似成反比关系,这会改变局部区域的塑性变形累积过程.δ-Ni3Nb相不仅与γ"-Ni3Nb相成分相同,又与Laves相伴生,显然也需要重点分析其在循环加载过程中的形貌和结构演变规律.Laves相作为脆性相,应该重点分析其循环变形特征,尤其是应变局部化导致的断裂特征.这需要考虑Laves相的尺寸效应,一般长条状的Laves相比颗粒状的危害更大.利用OM对7组试样中的Laves相尺寸进行了统计,采用的尺寸为Feret直径[28],统计结果如图4所示.可以看出,Laves相尺寸从几微米到几十微米不等,但每组试样的Laves相Feret直径分布几乎一致,4~15 μm范围内的颗粒最多,而长条状Laves相的数量较少.此外,不同的热节直径(凝固速率)并没有显著改变Laves相在合金中的尺寸分布,可能是因为热节直径变化范围较小(直径41.8~11.8 mm).同时,也可能与Laves相的形成条件有关,因为其总是在凝固最后阶段形成[29]. ...

TEM study of high-temperature precipitation of delta phase in Inconel 718 alloy

2

2011

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

... ,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

服役条件下镍基高温合金应力松弛微观机制

1

2019

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

服役条件下镍基高温合金应力松弛微观机制

1

2019

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

Effects of microporosity and precipitates on the cracking behavior in polycrystalline superalloy Inconel 718

1

2017

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

The influence of Laves phases on the high-cycle fatigue behavior of laser additive manufactured Inconel 718

5

2017

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

... 本工作在断口附近的纵剖面和断口形貌中均观察到Laves相的层状断裂特征,如图7所示.进一步通过EBSD分析了Laves颗粒的晶粒取向及其周围的应变局部化特征,如图9所示.图9b为Laves相的反极图(IPF)和三维晶粒取向示意图.可见,加载后单个Laves颗粒断裂成几个小部分,但是每个部分都具有几乎相同的晶粒取向(图9b中各部分的三维晶粒取向一致).因此,Laves相的断裂并不是塑性变形累积的过程,而是具有明显的脆断特征[4,30].图9b中个别取向差异较大的位置(如图9b中绿色区域)可能是因为在加载中受到基体的挤压,导致这些断裂的小块Laves相发生晶粒偏转[31].此外,这种取向特征说明Laves相的断裂并不是随机的,可能是沿某组平行晶面扩展.由于Laves相破坏了γ-Ni基体的连续性,在其周围基体中产生应力集中或塑性应变累积[21].随着循环加载的进行,Laves相周围基体中的塑性应变累积程度不断增加,尤其是在尖锐位置累积非常严重的应力集中,最终导致Laves相断裂,且裂纹沿着特定晶面扩展[21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

... [21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

... [21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

... 由图9c可知,在Laves相周围的γ-Ni基体中存在明显的基体取向偏差.由于δ-Ni3Nb相与Laves相共生(图9a),所以γ-Ni基体中的取向偏差也存在于δ-Ni3Nb相周围(图9a和c).由此可以推断出δ-Ni3Nb层片受到γ-Ni基体应变局部化的影响.与Laves相不同的是δ-Ni3Nb相的塑性变形能力更好,因此即使Laves相在疲劳早期发生断裂,部分δ-Ni3Nb相却还能维持其原本的层片状形貌,直至弯曲和滑移开裂[21].本工作通过截取δ-Ni3Nb层片周围的基体组织进行TEM和TKD观察,都发现该区域有明显的孪生变形痕迹,如图11所示.γ-Ni基体作为典型的fcc结构,当循环加载应力幅低于屈服强度时,应变局部化倾向于首先在Σ3孪晶界附近出现,所以在孪晶附近观察到明显的结构变化特征[4].又由于δ-Ni3Nb相与γ-Ni基体具有明显的位相关系,基体中的应变局部化会导致δ-Ni3Nb相产生变形,所以在δ-Ni3Nb层片周围观察到明显的应变局部化效应[4]. ...

Nb含量对GH4169合金钢锭凝固及均匀化过程相演化规律的影响

1

2014

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

Nb含量对GH4169合金钢锭凝固及均匀化过程相演化规律的影响

1

2014

... δ-Ni3Nb相属于正交晶系(oP8),与γ"-Ni3Nb相化学成分相近,区别在于密排面(010)δ、(111)γ"的堆垛顺序不同[17,18].在980 ℃以下(如955 ℃)时效,纳米尺度的亚稳γ"-Ni3Nb颗粒中产生层错,以纯几何方式转变为稳定的δ-Ni3Nb层片[17,18].所以,δ-Ni3Nb相的形成会消耗γ"-Ni3Nb相,在其周围出现γ"-Ni3Nb贫化区[3].基于此现象,有关δ-Ni3Nb相对合金的循环加载承受能力产生2种观点:一是认为贫化区的出现使得局部区域缺少γ"-Ni3Nb相的强化作用,抵抗循环变形能力减弱;二是认为γ"-Ni3Nb相的贫化使局部区域位错不易塞积,有利于循环软化,减弱应变局部化效应,从而提高循环加载寿命[10,19].目前,还没有相关报道明确指出δ-Ni3Nb相的实际效应,而且对δ-Ni3Nb相形貌和结构演变的相关研究还较少.Laves相是K4169合金中一种典型的hcp结构脆性相,主要化学成分可表示为(Fe, Ni)2(Mo, Nb),是由于凝固最后阶段Nb、Mo等元素在枝晶间区域偏聚而形成[20~22].通常认为颗粒状的Laves相不会成为循环加载时裂纹萌生的敏感区域,而长条状Laves相则可能因为外加载荷幅值的不同而导致裂纹萌生或扩展[21]. ...

Developments in investment casting process—A review

1

2012

... 实验用K4169合金的化学成分(质量分数)为:Cr 19%,Fe 18.55%,Mo 3%,(Nb+Ta) 5%,Ti 0.9%,Al 0.5%,C 0.05%,Ni 余量.采用熔模精密铸造方法制造试棒,大致流程为:试棒形状和尺寸设计、蜡模模具设计与制作、注蜡、蜡模组装、蘸浆和喷砂、焙烧脱蜡、陶瓷模壳成型、熔炼浇注[23].本研究设计了7组不同尺寸的试棒,主要尺寸差异在试棒中间部位,即热节直径不同,目的是改变平行段内的凝固速率,分别编号为1#~7#,热节直径分别为41.8、35.8、21.7、19.6、18.1、16.5和11.8 mm.热节直径较大(凝固速率较慢)的试棒预期会产生更多的显微疏松等铸造缺陷,反之则更少[24~26].由此可以得到不同循环加载寿命的试样,为研究微观组织的演变规律提供便利.热处理前,从每组精铸试棒的热节区域取8 mm×8 mm×1.5 mm薄片,利用BX51M光学显微镜(OM)观察显微疏松形貌,并统计显微疏松面积分数(近似认为是体积分数).经水磨砂纸(120~2000号)机械研磨至光亮且无显见划痕,显微疏松体积分数统计方法参考航标HB 20058-2011.根据所观察到的显微疏松尺寸特征,对每个试样拍摄4张50倍OM照片,并在显微疏松区域框选1 mm×1 mm范围,用来统计面积分数,最后计算平均值.之后将所有精铸试棒封管填充Ar气,在管式炉中进行标准热处理:1095 ℃×2 h,955 ℃×1 h,720 ℃×8 h,随后炉冷(约56 ℃/h)至620 ℃×8 h,随后空冷至室温[10]. ...

Fatigue of 8630 cast steel in the presence of porosity

2

2004

... 实验用K4169合金的化学成分(质量分数)为:Cr 19%,Fe 18.55%,Mo 3%,(Nb+Ta) 5%,Ti 0.9%,Al 0.5%,C 0.05%,Ni 余量.采用熔模精密铸造方法制造试棒,大致流程为:试棒形状和尺寸设计、蜡模模具设计与制作、注蜡、蜡模组装、蘸浆和喷砂、焙烧脱蜡、陶瓷模壳成型、熔炼浇注[23].本研究设计了7组不同尺寸的试棒,主要尺寸差异在试棒中间部位,即热节直径不同,目的是改变平行段内的凝固速率,分别编号为1#~7#,热节直径分别为41.8、35.8、21.7、19.6、18.1、16.5和11.8 mm.热节直径较大(凝固速率较慢)的试棒预期会产生更多的显微疏松等铸造缺陷,反之则更少[24~26].由此可以得到不同循环加载寿命的试样,为研究微观组织的演变规律提供便利.热处理前,从每组精铸试棒的热节区域取8 mm×8 mm×1.5 mm薄片,利用BX51M光学显微镜(OM)观察显微疏松形貌,并统计显微疏松面积分数(近似认为是体积分数).经水磨砂纸(120~2000号)机械研磨至光亮且无显见划痕,显微疏松体积分数统计方法参考航标HB 20058-2011.根据所观察到的显微疏松尺寸特征,对每个试样拍摄4张50倍OM照片,并在显微疏松区域框选1 mm×1 mm范围,用来统计面积分数,最后计算平均值.之后将所有精铸试棒封管填充Ar气,在管式炉中进行标准热处理:1095 ℃×2 h,955 ℃×1 h,720 ℃×8 h,随后炉冷(约56 ℃/h)至620 ℃×8 h,随后空冷至室温[10]. ...

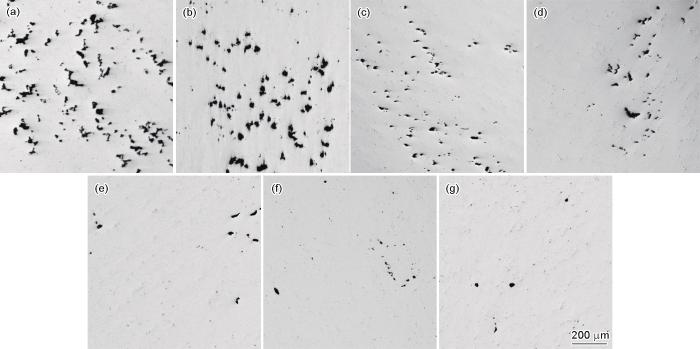

... 图2为不同热节直径精铸K4169试棒(1#~7#)显微疏松的典型OM像.定量金相法统计的1#~7#试样显微疏松平均体积分数分别为4.78%、4.36%、1.52%、1.16%、0.79%、0.64%和0.53%.可以看出,随着热节直径减小,显微疏松体积分数逐渐减小.此结果与显微疏松形成的机理吻合,即热节直径越大,在凝固时越可能因为金属液来不及补充最后凝固区域(枝晶间)而产生显微疏松[24~26]. ...

Porosity in cast equiaxed alloy 718 [A]. Superalloys 718, 625, 706, and Various Derivatives

1994

Solidification Processing

2

2006

... 实验用K4169合金的化学成分(质量分数)为:Cr 19%,Fe 18.55%,Mo 3%,(Nb+Ta) 5%,Ti 0.9%,Al 0.5%,C 0.05%,Ni 余量.采用熔模精密铸造方法制造试棒,大致流程为:试棒形状和尺寸设计、蜡模模具设计与制作、注蜡、蜡模组装、蘸浆和喷砂、焙烧脱蜡、陶瓷模壳成型、熔炼浇注[23].本研究设计了7组不同尺寸的试棒,主要尺寸差异在试棒中间部位,即热节直径不同,目的是改变平行段内的凝固速率,分别编号为1#~7#,热节直径分别为41.8、35.8、21.7、19.6、18.1、16.5和11.8 mm.热节直径较大(凝固速率较慢)的试棒预期会产生更多的显微疏松等铸造缺陷,反之则更少[24~26].由此可以得到不同循环加载寿命的试样,为研究微观组织的演变规律提供便利.热处理前,从每组精铸试棒的热节区域取8 mm×8 mm×1.5 mm薄片,利用BX51M光学显微镜(OM)观察显微疏松形貌,并统计显微疏松面积分数(近似认为是体积分数).经水磨砂纸(120~2000号)机械研磨至光亮且无显见划痕,显微疏松体积分数统计方法参考航标HB 20058-2011.根据所观察到的显微疏松尺寸特征,对每个试样拍摄4张50倍OM照片,并在显微疏松区域框选1 mm×1 mm范围,用来统计面积分数,最后计算平均值.之后将所有精铸试棒封管填充Ar气,在管式炉中进行标准热处理:1095 ℃×2 h,955 ℃×1 h,720 ℃×8 h,随后炉冷(约56 ℃/h)至620 ℃×8 h,随后空冷至室温[10]. ...

... 图2为不同热节直径精铸K4169试棒(1#~7#)显微疏松的典型OM像.定量金相法统计的1#~7#试样显微疏松平均体积分数分别为4.78%、4.36%、1.52%、1.16%、0.79%、0.64%和0.53%.可以看出,随着热节直径减小,显微疏松体积分数逐渐减小.此结果与显微疏松形成的机理吻合,即热节直径越大,在凝固时越可能因为金属液来不及补充最后凝固区域(枝晶间)而产生显微疏松[24~26]. ...

Slip and fracture behavior of δ-Ni3Nb plates in a polycrystalline nickel-based superalloy during fatigue

1

2019

... 标准热处理后,虽然显微偏析程度大幅减轻,但分布于枝晶间的析出相还有残留,这些微米尺度的析出相呈枝晶状的分布特征(图3a).SEM和TEM形貌观察结果显示,枝晶间的不规则块状析出相为Laves相,而其周围伴生的层片为δ-Ni3Nb相(图3b和c).由选区电子衍射(SAED)花样(图3d)可确定δ-Ni3Nb相与γ-Ni基体的取向关系为:()γ //()δ,[]γ //[100]δ,与两者经典的取向关系相符[17,27].热处理组织中基体为γ-Ni固溶体,体心四方结构的γ"-Ni3Nb颗粒弥散分布于基体中,如图3e和f所示.γ"-Ni3Nb作为强化相为合金提供了足够的强度,但在循环加载过程中需要综合考虑多种析出相的作用,如γ"-Ni3Nb相与δ-Ni3Nb相化学成分相同,局部含量近似成反比关系,这会改变局部区域的塑性变形累积过程.δ-Ni3Nb相不仅与γ"-Ni3Nb相成分相同,又与Laves相伴生,显然也需要重点分析其在循环加载过程中的形貌和结构演变规律.Laves相作为脆性相,应该重点分析其循环变形特征,尤其是应变局部化导致的断裂特征.这需要考虑Laves相的尺寸效应,一般长条状的Laves相比颗粒状的危害更大.利用OM对7组试样中的Laves相尺寸进行了统计,采用的尺寸为Feret直径[28],统计结果如图4所示.可以看出,Laves相尺寸从几微米到几十微米不等,但每组试样的Laves相Feret直径分布几乎一致,4~15 μm范围内的颗粒最多,而长条状Laves相的数量较少.此外,不同的热节直径(凝固速率)并没有显著改变Laves相在合金中的尺寸分布,可能是因为热节直径变化范围较小(直径41.8~11.8 mm).同时,也可能与Laves相的形成条件有关,因为其总是在凝固最后阶段形成[29]. ...

Fatigue life estimation of cast aluminium alloys considering the effect of porosity on initiation and propagation phases

1

2019

... 标准热处理后,虽然显微偏析程度大幅减轻,但分布于枝晶间的析出相还有残留,这些微米尺度的析出相呈枝晶状的分布特征(图3a).SEM和TEM形貌观察结果显示,枝晶间的不规则块状析出相为Laves相,而其周围伴生的层片为δ-Ni3Nb相(图3b和c).由选区电子衍射(SAED)花样(图3d)可确定δ-Ni3Nb相与γ-Ni基体的取向关系为:()γ //()δ,[]γ //[100]δ,与两者经典的取向关系相符[17,27].热处理组织中基体为γ-Ni固溶体,体心四方结构的γ"-Ni3Nb颗粒弥散分布于基体中,如图3e和f所示.γ"-Ni3Nb作为强化相为合金提供了足够的强度,但在循环加载过程中需要综合考虑多种析出相的作用,如γ"-Ni3Nb相与δ-Ni3Nb相化学成分相同,局部含量近似成反比关系,这会改变局部区域的塑性变形累积过程.δ-Ni3Nb相不仅与γ"-Ni3Nb相成分相同,又与Laves相伴生,显然也需要重点分析其在循环加载过程中的形貌和结构演变规律.Laves相作为脆性相,应该重点分析其循环变形特征,尤其是应变局部化导致的断裂特征.这需要考虑Laves相的尺寸效应,一般长条状的Laves相比颗粒状的危害更大.利用OM对7组试样中的Laves相尺寸进行了统计,采用的尺寸为Feret直径[28],统计结果如图4所示.可以看出,Laves相尺寸从几微米到几十微米不等,但每组试样的Laves相Feret直径分布几乎一致,4~15 μm范围内的颗粒最多,而长条状Laves相的数量较少.此外,不同的热节直径(凝固速率)并没有显著改变Laves相在合金中的尺寸分布,可能是因为热节直径变化范围较小(直径41.8~11.8 mm).同时,也可能与Laves相的形成条件有关,因为其总是在凝固最后阶段形成[29]. ...

The effect of casting conditions on the high-cycle fatigue properties of the single-crystal nickel-base superalloy PWA 1483

1

2007

... 标准热处理后,虽然显微偏析程度大幅减轻,但分布于枝晶间的析出相还有残留,这些微米尺度的析出相呈枝晶状的分布特征(图3a).SEM和TEM形貌观察结果显示,枝晶间的不规则块状析出相为Laves相,而其周围伴生的层片为δ-Ni3Nb相(图3b和c).由选区电子衍射(SAED)花样(图3d)可确定δ-Ni3Nb相与γ-Ni基体的取向关系为:()γ //()δ,[]γ //[100]δ,与两者经典的取向关系相符[17,27].热处理组织中基体为γ-Ni固溶体,体心四方结构的γ"-Ni3Nb颗粒弥散分布于基体中,如图3e和f所示.γ"-Ni3Nb作为强化相为合金提供了足够的强度,但在循环加载过程中需要综合考虑多种析出相的作用,如γ"-Ni3Nb相与δ-Ni3Nb相化学成分相同,局部含量近似成反比关系,这会改变局部区域的塑性变形累积过程.δ-Ni3Nb相不仅与γ"-Ni3Nb相成分相同,又与Laves相伴生,显然也需要重点分析其在循环加载过程中的形貌和结构演变规律.Laves相作为脆性相,应该重点分析其循环变形特征,尤其是应变局部化导致的断裂特征.这需要考虑Laves相的尺寸效应,一般长条状的Laves相比颗粒状的危害更大.利用OM对7组试样中的Laves相尺寸进行了统计,采用的尺寸为Feret直径[28],统计结果如图4所示.可以看出,Laves相尺寸从几微米到几十微米不等,但每组试样的Laves相Feret直径分布几乎一致,4~15 μm范围内的颗粒最多,而长条状Laves相的数量较少.此外,不同的热节直径(凝固速率)并没有显著改变Laves相在合金中的尺寸分布,可能是因为热节直径变化范围较小(直径41.8~11.8 mm).同时,也可能与Laves相的形成条件有关,因为其总是在凝固最后阶段形成[29]. ...

Slip system characterization of Inconel 718: Using in-situ scanning electron microscopy

1

2010

... 本工作在断口附近的纵剖面和断口形貌中均观察到Laves相的层状断裂特征,如图7所示.进一步通过EBSD分析了Laves颗粒的晶粒取向及其周围的应变局部化特征,如图9所示.图9b为Laves相的反极图(IPF)和三维晶粒取向示意图.可见,加载后单个Laves颗粒断裂成几个小部分,但是每个部分都具有几乎相同的晶粒取向(图9b中各部分的三维晶粒取向一致).因此,Laves相的断裂并不是塑性变形累积的过程,而是具有明显的脆断特征[4,30].图9b中个别取向差异较大的位置(如图9b中绿色区域)可能是因为在加载中受到基体的挤压,导致这些断裂的小块Laves相发生晶粒偏转[31].此外,这种取向特征说明Laves相的断裂并不是随机的,可能是沿某组平行晶面扩展.由于Laves相破坏了γ-Ni基体的连续性,在其周围基体中产生应力集中或塑性应变累积[21].随着循环加载的进行,Laves相周围基体中的塑性应变累积程度不断增加,尤其是在尖锐位置累积非常严重的应力集中,最终导致Laves相断裂,且裂纹沿着特定晶面扩展[21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

The failure mechanism of 50% laser additive manufactured Inconel 718 and the deformation behavior of Laves phases during a tensile process

2

2017

... 本工作在断口附近的纵剖面和断口形貌中均观察到Laves相的层状断裂特征,如图7所示.进一步通过EBSD分析了Laves颗粒的晶粒取向及其周围的应变局部化特征,如图9所示.图9b为Laves相的反极图(IPF)和三维晶粒取向示意图.可见,加载后单个Laves颗粒断裂成几个小部分,但是每个部分都具有几乎相同的晶粒取向(图9b中各部分的三维晶粒取向一致).因此,Laves相的断裂并不是塑性变形累积的过程,而是具有明显的脆断特征[4,30].图9b中个别取向差异较大的位置(如图9b中绿色区域)可能是因为在加载中受到基体的挤压,导致这些断裂的小块Laves相发生晶粒偏转[31].此外,这种取向特征说明Laves相的断裂并不是随机的,可能是沿某组平行晶面扩展.由于Laves相破坏了γ-Ni基体的连续性,在其周围基体中产生应力集中或塑性应变累积[21].随着循环加载的进行,Laves相周围基体中的塑性应变累积程度不断增加,尤其是在尖锐位置累积非常严重的应力集中,最终导致Laves相断裂,且裂纹沿着特定晶面扩展[21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

... ,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

Fracture mechanisms induced by microporosity and precipitates in isothermal fatigue of polycrystalline nickel based superalloy

1

2018

... 本工作在断口附近的纵剖面和断口形貌中均观察到Laves相的层状断裂特征,如图7所示.进一步通过EBSD分析了Laves颗粒的晶粒取向及其周围的应变局部化特征,如图9所示.图9b为Laves相的反极图(IPF)和三维晶粒取向示意图.可见,加载后单个Laves颗粒断裂成几个小部分,但是每个部分都具有几乎相同的晶粒取向(图9b中各部分的三维晶粒取向一致).因此,Laves相的断裂并不是塑性变形累积的过程,而是具有明显的脆断特征[4,30].图9b中个别取向差异较大的位置(如图9b中绿色区域)可能是因为在加载中受到基体的挤压,导致这些断裂的小块Laves相发生晶粒偏转[31].此外,这种取向特征说明Laves相的断裂并不是随机的,可能是沿某组平行晶面扩展.由于Laves相破坏了γ-Ni基体的连续性,在其周围基体中产生应力集中或塑性应变累积[21].随着循环加载的进行,Laves相周围基体中的塑性应变累积程度不断增加,尤其是在尖锐位置累积非常严重的应力集中,最终导致Laves相断裂,且裂纹沿着特定晶面扩展[21,31,32].为了进一步讨论Laves相的断裂与其周围基体应力集中的关系,利用EBSD数据提取相关区域的局部取向差角度(local misorientation angle,LMO angle)的分布,如图9c所示.LMO angle可以用来表征局部区域的位错塞积密度,进而表征应力集中水平,其值越大应力集中程度越大.可以看出,Laves相内部的裂纹扩展都是源于外部应力集中程度较大的位置.此外,Laves相尖端的应力集中还可能导致裂纹在其内部和基体中同时扩展.综合不同循环寿命试样观察结果,发现Laves相的断裂特征与循环加载次数没有明显对应关系,而只受到显微疏松的影响.即只要因为显微疏松而发生循环断裂,Laves相的断裂特征是一致的.hcp结构Laves相的塑性变形能力显著弱于fcc结构的γ-Ni基体,Laves相改变了基体原有的循环变形连续性和协调性,导致该相周围出现应力集中,产生应变局部化[21].这一方面使Laves相自身发生开裂,另一方面使基体在局部大应力的作用下产生开裂或与Laves相分离. ...

Operative slip systems and anomalous strengthening in Ni3Nb single crystals with the D0astructure

1

2001

... K4169合金中的δ-Ni3Nb相普遍具有层片状的三维形貌,其长、宽、厚3个方向的尺寸差异较大,而且本身属于正交晶系结构,因此各向异性明显,这也是δ-Ni3Nb相在循环加载后会出现2种类型形貌演变的原因.图10展示了δ-Ni3Nb层片在不同方向上的变形特征,沿长度方向(以下用“平行方向”指代),δ-Ni3Nb层片表现为分叉断裂,而垂直于宽度方向和厚度方向组成的平面(以下用“垂直方向”指代),则表现为弯曲变形.进一步对比了不同循环寿命试样,发现平行方向的分叉断裂在较少的循环周次下已经出现,但没有发生弯曲,说明此时δ-Ni3Nb层片只发生沿长度方向的断裂,而没有在其表面产生滑移,如图10a所示.此外,在稍远离断口和显微疏松的区域,垂直方向的δ-Ni3Nb相出现因显微疏松体积分数不同而变化的变形特征,即当显微疏松体积分数较大时,循环周次较短,未断裂的δ-Ni3Nb相表面出现少量滑移迹线.随着显微疏松体积分数减少,循环周次增加,未断裂的δ-Ni3Nb相表面滑移迹线逐渐增多(图10b).这说明δ-Ni3Nb层片的垂直方向比平行方向有更好的抵抗循环断裂的能力.由δ-Ni3Nb相与γ-Ni基体的取向关系可知,其长度方向为[100]δ方向,宽度方向和厚度方向组成的平面为(010)δ面[1],该面是δ-Ni3Nb的密排面,同时也是易滑移面,滑移系为(010)δ[100]δ[33~36].Hagihara等[37]在对Ni3Nb单晶的压缩变形研究中发现,Ni3Nb单晶在室温变形时出现[100]螺型位错,当温度超过一定值时(视压缩轴与单晶体取向而定),螺型位错逐渐向刃型位错转变.本工作通过对循环变形后的δ-Ni3Nb层片进行HRTEM分析,也发现刃型位错(图10d).虽然本工作不涉及到高温,并且拉压循环加载与文献[37]中的单向压缩也存在区别,但不排除由于循环加载导致螺型位错向刃型位错转变. ...

Identifying close-packed planes in complex crystal structures

2010

Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy

2010

Alloying behavior of Ni3M-type compounds with D0a structure

1

2011

... K4169合金中的δ-Ni3Nb相普遍具有层片状的三维形貌,其长、宽、厚3个方向的尺寸差异较大,而且本身属于正交晶系结构,因此各向异性明显,这也是δ-Ni3Nb相在循环加载后会出现2种类型形貌演变的原因.图10展示了δ-Ni3Nb层片在不同方向上的变形特征,沿长度方向(以下用“平行方向”指代),δ-Ni3Nb层片表现为分叉断裂,而垂直于宽度方向和厚度方向组成的平面(以下用“垂直方向”指代),则表现为弯曲变形.进一步对比了不同循环寿命试样,发现平行方向的分叉断裂在较少的循环周次下已经出现,但没有发生弯曲,说明此时δ-Ni3Nb层片只发生沿长度方向的断裂,而没有在其表面产生滑移,如图10a所示.此外,在稍远离断口和显微疏松的区域,垂直方向的δ-Ni3Nb相出现因显微疏松体积分数不同而变化的变形特征,即当显微疏松体积分数较大时,循环周次较短,未断裂的δ-Ni3Nb相表面出现少量滑移迹线.随着显微疏松体积分数减少,循环周次增加,未断裂的δ-Ni3Nb相表面滑移迹线逐渐增多(图10b).这说明δ-Ni3Nb层片的垂直方向比平行方向有更好的抵抗循环断裂的能力.由δ-Ni3Nb相与γ-Ni基体的取向关系可知,其长度方向为[100]δ方向,宽度方向和厚度方向组成的平面为(010)δ面[1],该面是δ-Ni3Nb的密排面,同时也是易滑移面,滑移系为(010)δ[100]δ[33~36].Hagihara等[37]在对Ni3Nb单晶的压缩变形研究中发现,Ni3Nb单晶在室温变形时出现[100]螺型位错,当温度超过一定值时(视压缩轴与单晶体取向而定),螺型位错逐渐向刃型位错转变.本工作通过对循环变形后的δ-Ni3Nb层片进行HRTEM分析,也发现刃型位错(图10d).虽然本工作不涉及到高温,并且拉压循环加载与文献[37]中的单向压缩也存在区别,但不排除由于循环加载导致螺型位错向刃型位错转变. ...

Plastic deformation behaviour and operative slip systems in Ni3Nb single crystals

2

2000

... K4169合金中的δ-Ni3Nb相普遍具有层片状的三维形貌,其长、宽、厚3个方向的尺寸差异较大,而且本身属于正交晶系结构,因此各向异性明显,这也是δ-Ni3Nb相在循环加载后会出现2种类型形貌演变的原因.图10展示了δ-Ni3Nb层片在不同方向上的变形特征,沿长度方向(以下用“平行方向”指代),δ-Ni3Nb层片表现为分叉断裂,而垂直于宽度方向和厚度方向组成的平面(以下用“垂直方向”指代),则表现为弯曲变形.进一步对比了不同循环寿命试样,发现平行方向的分叉断裂在较少的循环周次下已经出现,但没有发生弯曲,说明此时δ-Ni3Nb层片只发生沿长度方向的断裂,而没有在其表面产生滑移,如图10a所示.此外,在稍远离断口和显微疏松的区域,垂直方向的δ-Ni3Nb相出现因显微疏松体积分数不同而变化的变形特征,即当显微疏松体积分数较大时,循环周次较短,未断裂的δ-Ni3Nb相表面出现少量滑移迹线.随着显微疏松体积分数减少,循环周次增加,未断裂的δ-Ni3Nb相表面滑移迹线逐渐增多(图10b).这说明δ-Ni3Nb层片的垂直方向比平行方向有更好的抵抗循环断裂的能力.由δ-Ni3Nb相与γ-Ni基体的取向关系可知,其长度方向为[100]δ方向,宽度方向和厚度方向组成的平面为(010)δ面[1],该面是δ-Ni3Nb的密排面,同时也是易滑移面,滑移系为(010)δ[100]δ[33~36].Hagihara等[37]在对Ni3Nb单晶的压缩变形研究中发现,Ni3Nb单晶在室温变形时出现[100]螺型位错,当温度超过一定值时(视压缩轴与单晶体取向而定),螺型位错逐渐向刃型位错转变.本工作通过对循环变形后的δ-Ni3Nb层片进行HRTEM分析,也发现刃型位错(图10d).虽然本工作不涉及到高温,并且拉压循环加载与文献[37]中的单向压缩也存在区别,但不排除由于循环加载导致螺型位错向刃型位错转变. ...

... d).虽然本工作不涉及到高温,并且拉压循环加载与文献[37]中的单向压缩也存在区别,但不排除由于循环加载导致螺型位错向刃型位错转变. ...