先进核反应堆技术经历了多代际的发展,其能效、经济性、安全性等不断得到提高。与此同时,更高的反应温度与辐照效应要求所用结构材料具有比传统核结构材料(如锆合金、奥氏体不锈钢)更高的高温力学性能、更优良的抗辐照性能、以及低活化等特性[1,2,3,4,5]。基于粉末冶金方法制备的氧化物弥散强化(oxide dispersion strengthened,ODS)合金成为极具应用前景的核用结构材料研究方向。粉末冶金制备工艺可有效改善传统合金的成分偏析与加工性能;同时高度热稳定性、分布弥散、尺寸细小的氧化物增强相粒子为ODS合金提供了高效的强化渠道[6,7,8,9];此外,由于ODS合金中大量纳米结构(纳米级沉淀及纳米晶)的存在,使得辐照空位及辐照间隙原子被捕获并湮灭的几率大大提高,从而提高了抗辐照损伤的能力[10,11,12,13,14,15]。

9Cr-ODS钢中合金元素及氧化物主要包括Cr、W、Ti、Y2O3等。Cr元素是马氏体/铁素体钢中添加量最多的合金元素,因其与Fe原子半径相差不大,可以形成无限固溶体,是有效的固溶强化元素。Cr元素还可以提高材料的耐腐蚀性能。但Cr元素含量过高,材料在辐照环境中易产生Cr元素的偏聚,发生脆化,韧脆转变温度升高。一般,当Cr含量在9% (质量分数,下同)时,合金具有较低的韧脆转变温度[23,24,25]。W元素也是常用的固溶强化元素,添加W可以提高铁素体/马氏体钢的强度;但当W的添加量超过2%时易与Fe元素形成Fe2W结构的Laves相,降低材料的力学性能[26]。因此,ODS钢中W的添加量一般控制在2%以下。Ti元素可以促进Y2O3的分解,并与之结合析出更细小的Ti-Y-O复合氧化物,能够更加有效地阻碍位错和晶界的移动,提高合金的高温性能[27,28]。此外,Ti的加入还能够在一定程度上消除过量O对高温性能的不利影响。Y2O3因其良好的热稳定性和化学稳定性成为ODS钢成分设计最常用的氧化物之一,主要作用是在钢基体中形成均匀分布的纳米级氧化物增强颗粒。细小的纳米氧化物颗粒均匀分散于基体中,阻碍晶粒长大和位错运动,细化合金晶粒。添加少量Y2O3就能提高铁素体耐热钢的高温强度同时不会影响材料加工性能[29,30]。ODS钢中Y2O3添加量通常为0.30%~0.50% (本工作Y2O3含量为0.35%)。C作为钢中的奥氏体稳定元素,同时C元素易与钢中的Cr等元素形成M23C6[31,32],因此成分设计时应充分考虑C与合金元素之间的相互作用。钢中C的含量通常根据Cr的含量多少来确定,一般在0.1%~0.2%。

1 实验方法

采用粉末冶金工艺制备Fe-9Cr-2W-0.18Ti-0.35Y2O3 (质量分数,%)的9Cr-ODS钢。主要制备流程包括机械合金化、真空包套和热等静压烧结。机械合金化工艺在行星式球磨机上完成,球磨工艺参数为:球磨机转速250 r/min、球磨时间48 h、球料比为10∶1;球磨后的合金粉末密封在低碳钢罐中进行真空包套处理,在450 ℃下抽真空至0.002 Pa,将包套封焊;包套后试样进行热等静压烧结成形,烧结温度1150 ℃,烧结压力150 MPa,烧结时间3 h。由于烧结后ODS钢中O含量直接影响氧化物弥散粒子的体积分数和尺寸分布,而C元素含量会影响碳化物的生成,因此对烧结后的9Cr-ODS钢进行元素测定。各元素的测定方法为:Cr元素通过电位滴定法测量;Ti和W含量通过火花放电原子发射光谱法分析;Y元素由电感耦合等离子体原子发射光谱法分析;C和O元素含量则通过在感应炉中燃烧后,使用脉冲加热惰性气体熔融法测得。实验制备的9Cr-ODS钢试样实际化学成分(质量分数,%)为:Cr 9.04,W 1.87,Ti 0.12,Y 0.23,O 0.10,C 0.14,Fe余量。

烧结成型后的ODS钢试样在SX-GO7122热处理炉中进行时效处理,时效温度为 650 ℃ (核电与热电机组高温结构材料的服役温度),时效时间分别为50、100、200、500、1000、2000和4000 h,在时效相应时间后取出试样并快速水冷以保持其高温下的微观组织状态。

烧结态试样和不同时效态试样的微观组织和晶粒分布特征由GX51倒置金相显微镜(OM)观察;试样微米级析出相以及拉伸断口的微观形貌由S4800冷场发射扫描电镜(SEM)观察,并使用D8 Advanced X射线衍射仪(XRD)对试样进行组织分析。OM、SEM以及XRD分析试样制样使用的腐蚀剂为FeCl3-HCl溶液,腐蚀时间为90 s。

使用Tecnai G2 F20场发射透射电子显微镜(TEM)观察试样中氧化物析出相的尺寸和分布特征,并对析出相的类型和结构进行选区电子衍射(SAED)分析与能谱(EDS)分析。采用线切割方法将试样切割成厚0.3 mm左右的薄片,然后手工研磨至50 μm左右,双喷电解减薄之后再进行离子减薄,最终获得可供观察的TEM试样。

使用NH-6L型Vickers显微硬度计进行硬度测试,测试条件为载荷1 N,保压10 s,每个时效试样进行12次测试,试样显微硬度取平均值。

2 实验结果及讨论

2.1 时效过程基体组织的研究

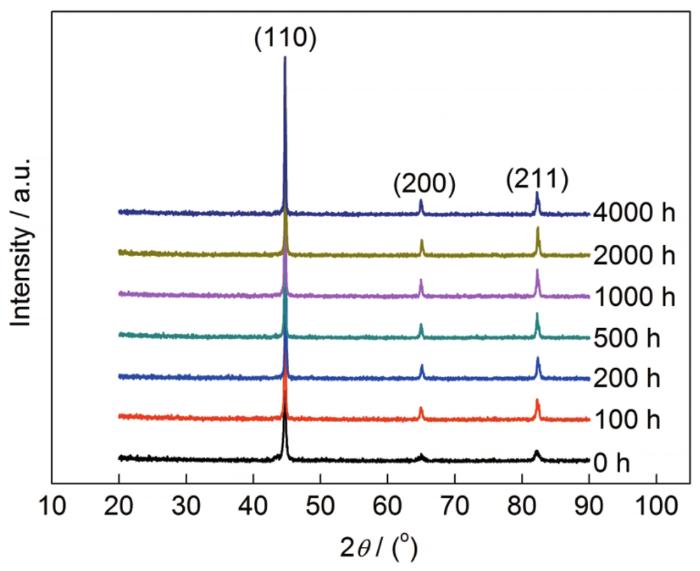

图1

图1

9Cr-ODS钢在650 ℃不同时效时间的XRD谱

Fig.1

XRD spectra of 9Cr-ODS steel under different ageing time at 650 ℃

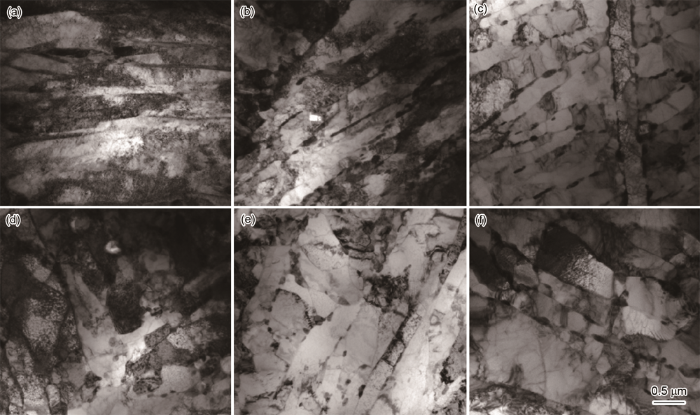

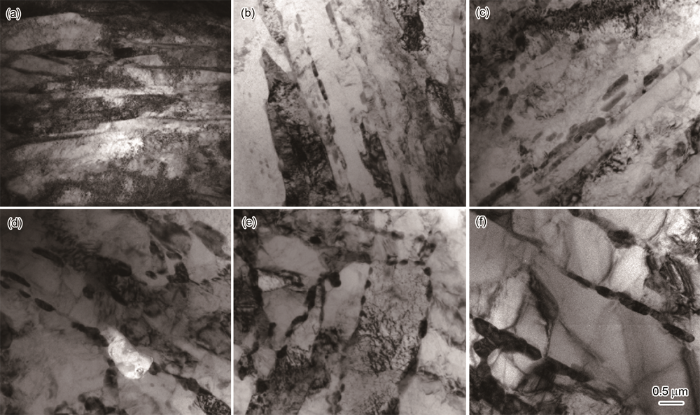

图2

图2

9Cr-ODS钢在650 ℃不同时效时间下的TEM明场像

Fig.2

TEM bright-field images of 9Cr-ODS steel with different ageing time at 650 ℃

(a) 0 h (b) 200 h (c) 500 h (d) 1000 h (e) 2000 h (f) 4000 h

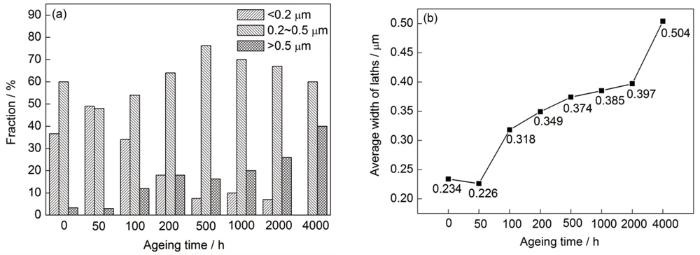

图3

图3

9Cr-ODS钢在650 ℃不同时效时间下的马氏体板条尺寸统计图和平均尺寸图

Fig.3

Statistical histogram of martensite laths size (a) and average size of laths (b) in 9Cr-ODS steel with different ageing time at 650 ℃

2.2 时效过程析出相的研究

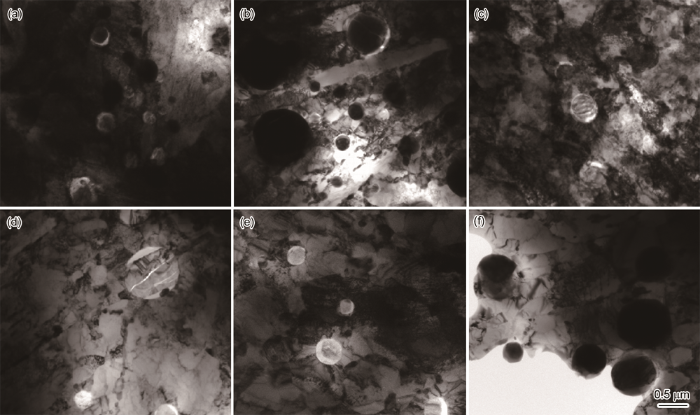

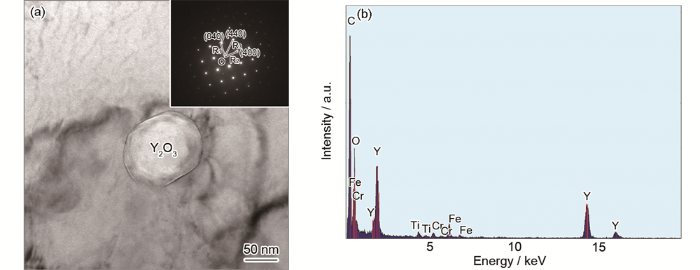

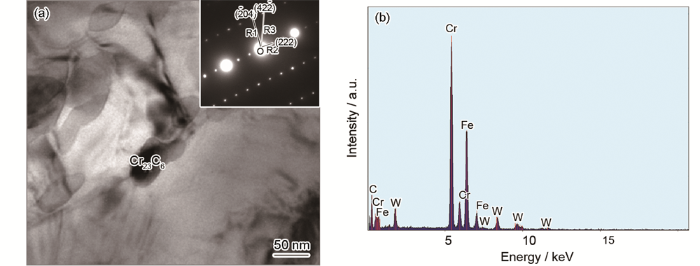

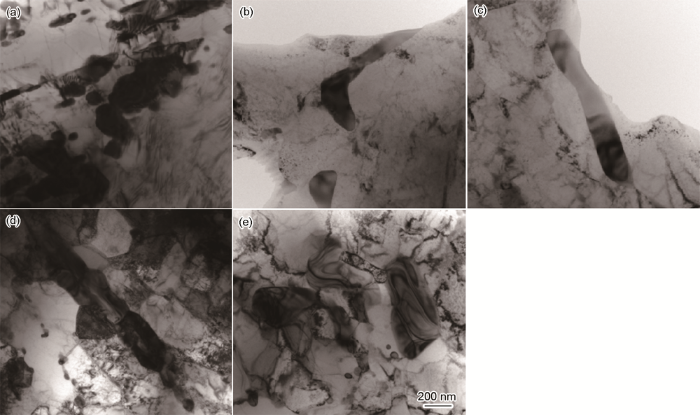

氧化物析出粒子在高温下的组织稳定性对于弥散强化效应至关重要。图4所示为9Cr-ODS钢烧结态和650 ℃时效200、500、1000、2000和4000 h后的TEM明场像。可以看出,时效前后基体中都弥散分布着尺寸较大的球形析出相粒子。

图4

图4

9Cr-ODS钢中氧化物在650 ℃不同时效时间的TEM明场像

Fig.4

TEM Bright-field images of oxides with different ageing time at 650 ℃

(a) 0 h (b) 200 h (c) 500 h (d) 1000 h (e) 2000 h (f) 4000 h

图5

图5

9Cr-ODS钢中氧化物的TEM像和EDS

Fig.5

TEM image (a) and EDS (b) of oxides in 9Cr-ODS steel (Inset shows the SAED pattern of oxides)

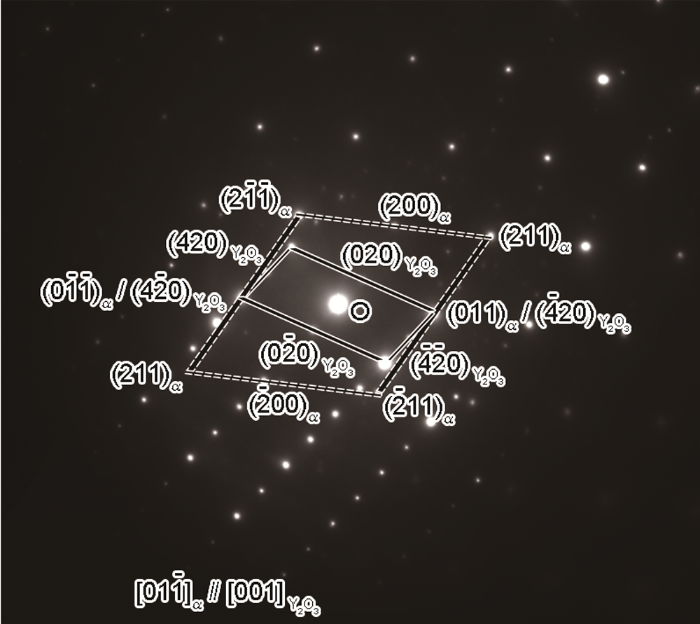

图6为Y2O3析出相与Fe-Cr基体的SAED分析。SAED斑点标定结果表明Y2O3析出相与基体之间的位向关系为:(210)

图6

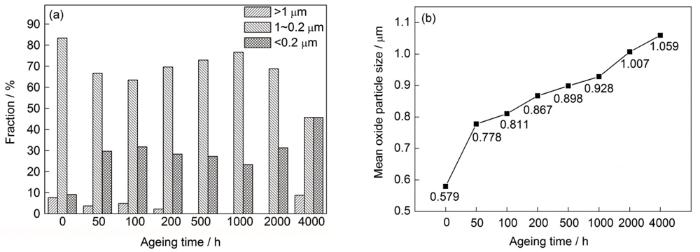

图7

图7

9Cr-ODS钢在650 ℃不同时效时间下的Y2O3尺寸统计图和平均尺寸图

Fig.7

Statistical histogram (a) and average size (b) of Y2O3 in 9Cr-ODS steel with different ageing time at 650 ℃

图8

图8

9Cr-ODS钢在650 ℃不同时效时间下的碳化物TEM明场像

Fig.8

TEM bright-field images of carbides in 9Cr-ODS steel with different ageing time at 650 ℃

(a) 0 h (b) 200 h (c) 500 h (d) 1000 h (e) 2000 h (f) 4000 h

图9

图9

9Cr-ODS钢中碳化物的TEM像和EDS

Fig.9

TEM image (a) and EDS (b) of carbides in 9Cr-ODS steel (Inset shows the SAED pattern of carbides)

图10

图10

9Cr-ODS钢在650 ℃不同时效时间下的Laves相TEM明场像

Fig.10

TEM bright-field images of Laves

(a) 50 h (b) 200 h (c) 500 h (d) 1000 h (e) 2000 h

图11

图11

9Cr-ODS钢中Laves相的TEM像和EDS

Fig.11

TEM image (a) and EDS (b) of Laves phases in 9Cr-ODS steel (Inset shows the SAED pattern of Laves phases)

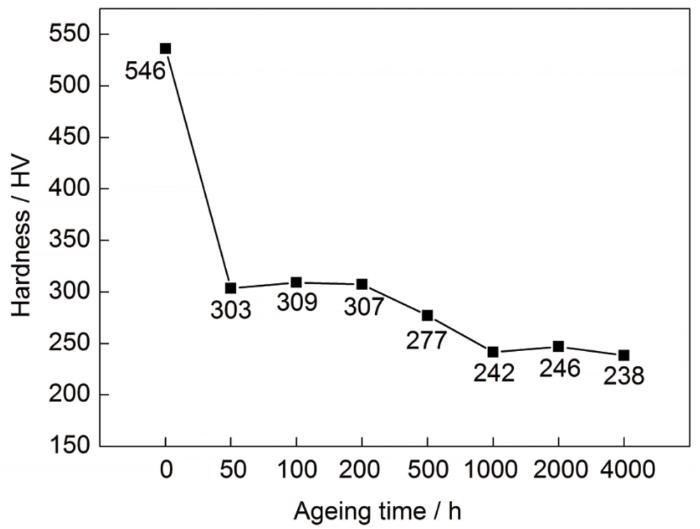

2.3 时效过程对硬度的影响

图12

图12

650 ℃时效时硬度随时效时间的变化

Fig.12

Vickers hardness change of 9Cr-ODS steel during ageing at 650 ℃

3 结论

(1) 9Cr-ODS钢在650 ℃时效过程中,随时效时间的增加,马氏体板条宽度从烧结态的0.234 μm增加到时效4000 h后的0.504 μm,马氏体板条逐渐粗化。

(2) 时效过程中,较小尺寸(小于0.2 μm)的Y2O3粒子逐渐从基体中析出;时效4000 h时,小尺寸Y2O3粒子几乎接近氧化物析出相总量的一半。统计结果表明,随着时效时间的延长,Y2O3析出粒子的平均粒径逐渐增加。

(3) 时效过程中,碳化物Cr23C6快速在晶界处析出,并逐渐聚集长大呈链珠状;同时,大尺寸的Laves相W2C也快速析出,逐渐粗化。

(4) 时效初期,Vickers硬度大幅下降;随时效时间的延长,硬度降低速率逐渐趋缓。这一变化过程与基体中马氏体板条尺寸随时效时间的粗化规律一致。

参考文献

Generation-IV nuclear power: A review of the state of the science

[J].AbstractThe Generation-IV consortium seeks to develop a new generation of nuclear energy systems for commercial deployment by 2020–2030. These systems include both the reactors and their fuel-cycle facilities. The aim is to provide significant improvements in economics, safety, sustainability, and proliferation resistance. The systems selected for development are the very high-temperature gas-cooled reactor (VHTR), the sodium-cooled fast reactor (SFR), the gas-cooled fast reactor (GFR), the lead-cooled fast reactor (LFR), the molten salt reactor (MSR) and the super-critical water-cooled reactor (SCWR). UK organisations plan to contribute to the first three of these systems because of its existing capabilities and experience with gas-cooled systems, graphite cores, and SFRs. The science base for the VHTR and SFR systems is reasonably established, although there are gaps. For the VHTR, these include the performance of graphite at high neutron doses, and the performance of the fuel. For the SFR, the behaviour of fuels containing minor actinides, and processes for their recycling and refabrication into new fuel, must be established. The GFR presents many technical challenges, because it would need fuel and structural materials capable of withstanding extremes of fast neutron flux and high temperatures. Adequate heat removal from the core under fault conditions is likely to determine its feasibility.]]>

Materials needs for fusion, Generation IV fission reactors and spallation neutron sources-similarities and differences

[J].

The development of fast reactor technology, to ensure the sustainable development of nuclear energy

[J].

发展快堆技术, 保证核能可持续发展

[J].

Critical questions in materials science and engineering for successful development of fusion power

[J].

Evolution of nuclear fission reactors: Third generation and beyond

[J].

Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength

[J].

Formation of Y-Ti-O nanoclusters in nanostructured ferritic alloys: A first-principles study

[J].

Atomic structure of nanoclusters in oxide-dispersion-strengthened steels

[J].Oxide-dispersion-strengthened steels are the most promising structural materials for next-generation nuclear energy systems because of their excellent resistance to both irradiation damage and high-temperature creep. Although it has been known for a decade that the extraordinary mechanical properties of oxide-dispersion-strengthened steels originate from highly stabilized oxide nanoclusters with a size smaller than 5 nm, the structure of these nanoclusters has not been clarified and remains as one of the most important scientific issues in nuclear materials research. Here we report the atomic-scale characterization of the oxide nanoclusters using state-of-the-art Cs-corrected transmission electron microscopy. This study provides compelling evidence that the nanoclusters have a defective NaCl structure with a high lattice coherency with the bcc steel matrix. Plenty of point defects as well as strong structural affinity of nanoclusters with the steel matrix seem to be the most important reasons for the unusual stability of the clusters at high temperatures and in intensive neutron irradiation fields.

Microstructure and tensile properties of a 14Cr ODS ferritic steel

[J].

Oxide particle-dislocation interaction in 9Cr-ODS steel

[J].

Y2O3 evolution and dispersion refinement in Co-base ODS alloys

[J].AbstractCo-base ODS alloys are potential materials for high-temperature applications. The evolution of Y2O3 during mechanical alloying (MA) and subsequent annealing were studied with the main focus on the refinement of particle size by the addition of minor alloying elements. The results reveal that the MA powder is characterized by ultrafine grains and high dislocation density, which facilitate the decomposition of Y2O3. The decomposed Y2O3 thermally precipitates at about 690 °C. Ti, Zr and Ca cause the coarsening of oxide, while Hf refines the oxide particle size and improves the homogeneity. The optimum Hf content is 1.2 wt.% and the resulting particle size is reduced to 9.6 nm with the precipitation of partially coherent Y2Hf2O7 oxides. Higher Al content tends to result in the formation of Al2O3 and Y3Al5O12 oxides, which are of larger size. The threshold stress is predicted to be enhanced by the reduction of inter-particle spacing. The refinement effect is also verified by hardness measurements.]]>

Microstructures and tensile properties of an austenitic ODS heat resistance steel

[J].

Study on precipitation behavior of strengthening phase and microstructure thermal stability of austenitic ODS steel

[D].

奥氏体ODS钢的强化相析出行为及其组织热稳定性研究

[D].

Effects of Zr addition on strengthening mechanisms of Al-alloyed high-Cr ODS steels

[J].

Effect of hafnium addition on the microstructure and tensile properties of aluminum added high-Cr ODS steels

[J].

Fabrication and characterization of reference 9Cr and 12Cr-ODS low activation ferritic/martensitic steels

[J].For the purpose of arranging reference alloys available for various characterization efforts by Japanese fusion research groups, fabrication of reference 9Cr and 12Cr-ODS steels have been carried out with similar manufacturing processes followed by various characterizations. The fabrication proceeded with powder mixing, MA, encapsulation into mild steel cases, hot extrusion and hot forging, followed by final heat treatments. Each alloy was extruded into three bars. The characterization included chemical composition analysis, SEM and TEM microstructural observations, hardness tests, tensile tests at RT and 973 K, and relatively short-term thermal creep tests at 973 K. Room temperature hardness for 9Cr-ODS was larger than 12Cr-ODS, the former showing large increase when annealing temperature exceeded 1200 K and the latter showing no significant change with annealing temperature. Tensile strength of 9Cr-ODS was significantly larger than that of 12Cr-ODS at RT but comparable at 973K. 9Cr-ODS showed longer and shorter creep rupture time than 12Cr-ODS at high and low stress levels, respectively. The mechanism of the difference in creep properties of the two alloys was discussed. (C) 2014 Elsevier B.V.

Grain structural characterization of 9Cr-ODS steel aged at 973 K up to 10,000 h by electron backscatter diffraction

[J].

Effects of Hf addition on the thermal stability of 16Cr-ODS steels at elevated aging temperatures

[J].

High-temperature mechanical properties and microstructure of 9Cr oxide dispersion strengthened steel compared with RAFMs

[J].In this work, high-temperature mechanical properties and microstructure of a 9Cr-ODS steel were studied. The properties were compared with those of the current reduced activation ferritic/martensitic steels (RAFMs) of CLAM and JLF-1. The tensile strength of the 9Cr-ODS steel was almost twice the values of the RAFMs at all the test temperatures, and the strength level at 923-973 K was comparable to those of the RAFMs at 823 K. The 9Cr-ODS steel also exhibited superior creep strength. Prediction with Larson-Miller parameter for the typical blanket conditions suggested that the 9Cr-ODS steel can successfully extend the maximum operation temperature to similar to 923-973 K. The 9Cr-ODS steel has a tempered martensitic structure with uniform oxide particles in the matrix. After creep tests, the mean diameter and density of the oxide particles did not change significantly by different creep temperatures and stresses, suggesting the stability of the microstructure. (C) 2011 Elsevier B.V.

Microstructure characteristic and mechanical property of transformable 9Cr-ODS steel fabricated by spark plasma sintering

[J].

Formation of residual ferrite in 9Cr-ODS ferritic steels

[J].

Nano-mesoscopic structural control in 9Cr ODS ferritic/martensitic steels

[J].

Study on strengthening mechanism and performance evaluation of 9Cr oxide dispersion strengthened steel

[D].

9Cr氧化物弥散强化的强化机理研究及性能评价

[D].

Enhancement of tensile properties due to microstructure optimization in ODS steels by zirconium addition

[J].

Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants

[J].It is crucial for the carbon concentration of 9% Cr steel to be reduced to a very low level, so as to promote the formation of MX nitrides rich in vanadium as very fine and thermally stable particles to enable prolonged periods of exposure at elevated temperatures and also to eliminate Cr-rich carbides M23C6. Sub-boundary hardening, which is inversely proportional to the width of laths and blocks, is shown to be the most important strengthening mechanism for creep and is enhanced by the fine dispersion of precipitates along boundaries. The suppression of particle coarsening during creep and the maintenance of a homogeneous distribution of M23C6 carbides near prior austenite grain boundaries, which precipitate during tempering and are less fine, are effective for preventing the long-term degradation of creep strength and for improving long-term creep strength. This can be achieved by the addition of boron. The steels considered in this paper exhibit higher creep strength at 650 degrees C than existing high-strength steels used for thick section boiler components.

Development of oxide dispersion strengthened ferritic steels for fusion

[J].

Influence of Zr addition on the microstructures and mechanical properties of 14Cr ODS steels

[J],

EFTEM and spectrum imaging of mechanically alloyed oxide-dispersion-strengthened 12YWT and 14YWT ferritic steels

[J].

Directional recrystallization of ODS alloys by means of zone annealing

[J].

Microstructure evolution and tensile properties of an Al added high-Cr ODS steel during thermal aging at 650 ℃

[J].

Stability of ferritic MA/ODS alloys at high temperatures

[J].

Microstructure degradation and properties evolution of T91 steel during aging

[J].

T91钢时效过程中的组织老化和性能变化

[J].

Corrosion behavior of an Al added high-Cr ODS steel in supercritical water at 600 ℃

[J].

Characterization of nanosized precipitates in 9Cr-ODS steels by SAXS and TEM

[J].23 m-3 in 9Cr-ODS steel ball milled for 20 h. The maximum value of distribution density of pyrochlore structure Y2Ti2O7 is the highest (1.03×1022 m-3) in 9Cr-ODS steel ball milled for 8 h. Some large-scale Ti-Al-O-rich precipitates are observed and show core/shell structure. Their distribution density increases with ball milling time. With increasing ball milling time, the grain size decreases and the yield strength increases. The contribution of Y-Ti-O-rich nanosized precipitates to yield strength is dominated.]]>

9Cr-ODS钢中纳米析出相的SAXS和TEM研究

[J].23 m-3; 烧绿石结构Y2Ti2O7相的分布密度峰值在球磨8 h样品中最高(1.03×1022 m-3); 少量大尺寸富Ti, Al和O的析出相的分布密度随着球磨时间延长而增加, 出现核壳结构. 晶粒尺寸随着球磨时间的延长而细化, 屈服强度随着球磨时间的延长而升高. 富Y-Ti-O纳米析出相对材料强度的贡献占主导地位.]]>

Production and properties of nano-scale oxide dispersion strengthened (ODS) 9Cr martensitic steel claddings

[J].

The research of nano-scale particles in the oxide dispersion strengthened steels

[J].

ODS钢中纳米氧化物颗粒成分与结构研究

[J].

Characterization of the oxide particles in Al-added high-Cr ODS ferritic steels

[J].

Microstructure and mechanical properties of aged T/P92 steel

[J].

T/P92钢的时效组织与性能

[J].23C6;马氏体板条的基体组织形貌在长期时效后开始分解。]]>

Structure stability of a newly designed martensitic heat-resistant steel

[J].

新设计的马氏体耐热钢的组织稳定性

[J].