2A12铝合金的主要时效强化相为S (Al2CuMg)相[4]。20世纪50年代初,Bagaryatsky[5]最先提出了Al-Cu-Mg系合金的析出序列:过饱和固溶体(SSS)→Guinier-Preston-Bagaryatsky (GPB)区→S'/GPB2→S'→S。在均质形核条件下,S相形貌呈针状或板条状,一般沿[100]S方向延伸,与基体的取向满足[100]S//[100]Al、(001)S//(012)Al的关系[6,7]。S'相一般认为与基体半共格,其结构与S相相同,但晶格常数稍有差别[8,9,10]。由于在结构上S'相与S相本质相同,一些学者对S'和S相常不做区分。Ringer等[11,12]利用原子探针技术发现,时效第一阶段的硬化是由于形成了溶质团簇,并针对Al-Cu-Mg系合金的时效行为,提出了三阶段析出序列:SSS→Cu-Mg团簇→GPB区→S。其中,Cu-Mg团簇对应最初的时效硬化,GPB区是峰值强度的主要强化相,S相则出现在过时效软化阶段。Wang等[13,14]证实了Al-Cu-Mg合金中S''相(正交晶系的中间相)的存在,并在固溶和时效后的合金中发现了2种类型的S相,建议S相析出序列为:SSS→Cu-Mg团簇→S''/GPB区→SⅠ→SⅡ。Sha等[4]利用原子探针技术对2024铝合金原子偏聚和析出行为进行了深入研究,发现峰值硬度条件下合金中小尺度等轴溶质团簇、GPB区以及S相共同存在,其中溶质团簇和GPB区是合金强化的主要原因,并认为基体析出序列为:SSS→Cu-Mg团簇→GPB区+Cu-Mg团簇→GPB区+Cu-Mg团簇+S→S。

目前,国内外学者对Al-Cu-Mg系合金的强化相以及时效脱溶析出序列已进行了大量研究,但仍存在一定争议。2A12铝合金作为一种典型的Al-Cu-Mg系高强铝合金,其人工时效过程中的脱溶析出序列及其强化相的研究鲜有报道。为此,本工作在不同温度和保温时间下对2A12铝合金冷轧板进行了人工时效处理,通过对板材的微观组织分析和力学性能测试,揭示了时效不同阶段的析出相演化规律,阐明了人工时效参数对2A12铝合金冷轧板力学性能的影响规律,总结了2A12铝合金冷轧板的时效脱溶析出序列。

1 实验方法

实验所用材料为2A12铝合金冷轧包铝板,铝板厚度为1.5 mm,其中包铝层厚约65 μm。合金的化学成分(质量分数,%)为:Cu 4.1,Mg 1.48,Mn 0.5,Fe 0.1,Si 0.086,Zn 0.032,Ti 0.045,Al余量。

固溶实验在OTF-1200X-L管式炉中进行,采用到温放样方式,固溶后立即进行水淬,淬火转移时间小于15 s,水温<25 ℃,淬火后将试样立即放入油浴锅(DF-4CD)中进行人工时效。所有试样的固溶制度均为495 ℃保温60 min,人工时效温度范围为155~200 ℃,人工时效时间范围为4~36 h,具体人工时效实验方案如表1所示。

表1 人工时效实验方案

Table 1

No. | Ageing temperature ℃ | Ageing time h | No. | Ageing temperature ℃ | Ageing time h |

|---|---|---|---|---|---|

| 1 | 155 | 4 | 11 | 185 | 4 |

| 2 | 155 | 10 | 12 | 185 | 10 |

| 3 | 155 | 16 | 13 | 185 | 16 |

| 4 | 155 | 24 | 14 | 185 | 24 |

| 5 | 155 | 36 | 15 | 185 | 36 |

| 6 | 170 | 4 | 16 | 200 | 4 |

| 7 | 170 | 10 | 17 | 200 | 10 |

| 8 | 170 | 16 | 18 | 200 | 16 |

| 9 | 170 | 24 | 19 | 200 | 24 |

| 10 | 170 | 36 | 20 | 200 | 36 |

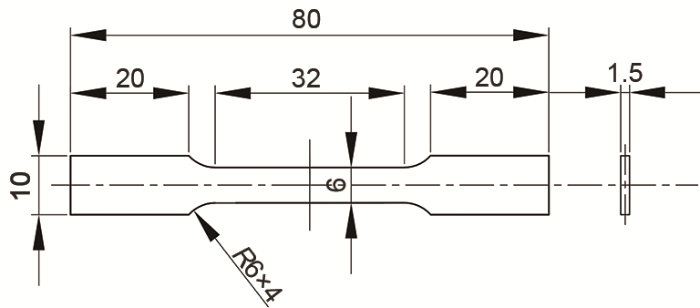

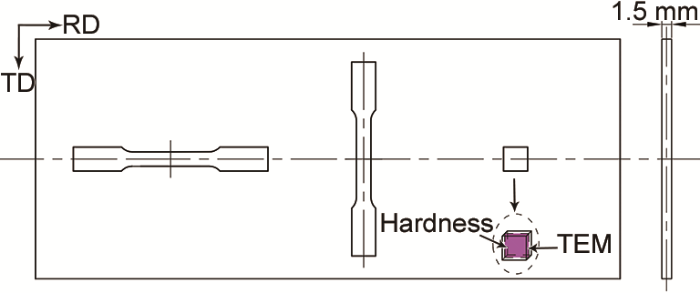

合金拉伸试样按照ASTM E8-M-04标准加工,其形状及尺寸如图1所示,试样标距为25 mm。拉伸实验和微观组织观察的取样位置如图2所示,其中RD表示轧制方向,TD表示垂直于轧制方向。室温力学性能测试在MTS CMT-5015电子万能试验机上进行,拉伸速率1.5 mm/min。利用JSM-7800F场发射扫描电子显微镜(SEM)对拉伸断口进行形貌观察与分析。利用HV-1000 Vickers硬度计进行显微硬度测试,测试位置为板料厚度的中间位置,测试过程中施加的载荷为500 g,保压时间为15 s。采用Tecnai G2 F20 S-TWIN高分辨透射电镜(HRTEM)对样品中的析出相进行观察,加速电压200 kV。制备透射电镜(TEM)试样时,首先通过机械打磨将样品厚度减小至50 μm左右,之后在减薄试样上冲出直径3 mm的圆片并利用双喷电解法制样。

图1

图1

拉伸试样形状及尺寸

Fig.1

Shape and dimension of the sample for tensile test (unit: mm)

图2

图2

微观组织观察与拉伸试样取样位置示意图

Fig.2

Schematic of the sampling locations for microstructure observation and tensile test (RD—rolling direction, TD—transverse direction)

2 实验结果与讨论

2.1 力学性能分析

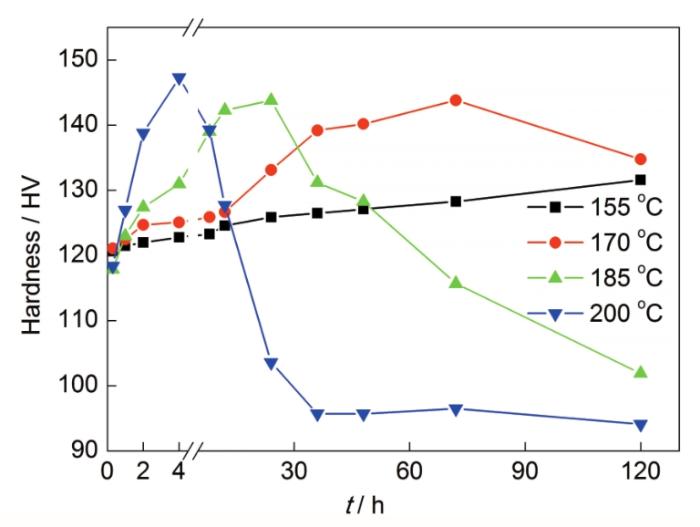

图3给出了时效温度与时间对2A12铝合金冷轧板硬度的影响曲线。从图中可以看出,2A12铝合金冷轧板存在单个时效峰值硬度,且时效温度越高,达到峰值硬度所需时间越短,过时效后合金硬度下降越快。当时效温度为200 ℃时,初期阶段合金硬度快速上升,在4 h时达到峰值硬度147 HV,4 h后则发生过时效,合金硬度随时效时间延长而迅速下降,当时效时间达到36 h后,合金硬度趋于稳定,约为96 HV。当时效温度为185 ℃时,合金在12~24 h之间达到峰值硬度144 HV,而当时效温度为170 ℃时,合金在72 h左右达到峰值硬度143 HV。在低温155 ℃条件下进行人工时效,在所测试时间范围内合金未达到峰值硬度。从以上分析可以看出,峰值硬度随温度的增加而略有提升,但提升幅度较小。

图3

图3

2A12铝合金冷轧板人工时效过程显微硬度曲线

Fig.3

Microhardness curves of the 2A12 cold rolled Al sheet during artificial ageing (t—time)

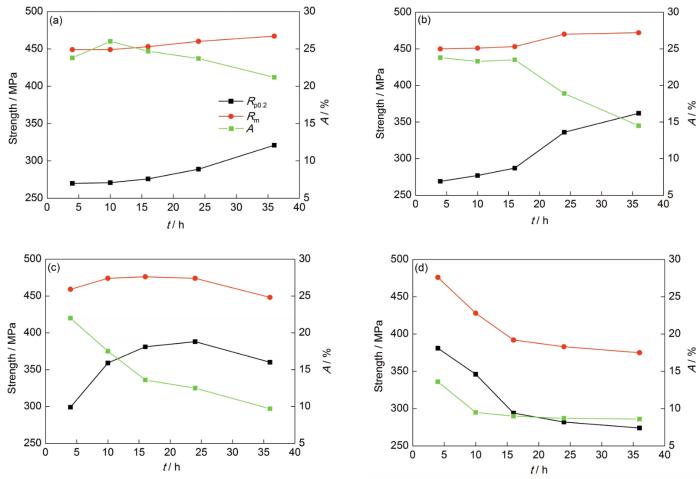

图4为不同时效温度和时效时间下,2A12铝合金冷轧板沿轧制方向上拉伸性能的变化曲线。当时效温度为155 ℃时,抗拉强度(Rm)与屈服强度(Rp0.2)随时效时间的延长逐渐增加,其中屈服强度增加的速度比抗拉强度更明显,而延伸率(A)随时效时间的延长先增加,在10 h达到最大值(26%)后,随时效时间的延长又逐渐下降,但仍保持在较高的水平(>20%),如图4a所示。时效温度为170 ℃时,在时效时间16 h前,合金各项力学性能变化缓慢,当超过16 h之后,屈服强度和抗拉强度逐渐升高,延伸率逐渐降低,如图4b所示。时效温度为185 ℃时,屈服强度与抗拉强度随时效时间的延长先增加后降低,分别在24与16 h左右达到峰值屈服强度(388 MPa)和峰值抗拉强度(476 MPa),合金延伸率则随时效时间的延长不断降低,时效时间36 h时合金延伸率已下降到9.7%,如图4c所示。根据图4c中曲线变化趋势可知,时效温度为185 ℃时,24 h之后合金将发生过时效。时效温度为200 ℃时,合金经4 h时效后,其抗拉强度即达到476 MPa,屈服强度达到381 MPa,4 h之后则发生过时效,各项力学性能迅速降低,如图4d所示。

图4

图4

不同时效温度条件下2A12铝合金冷轧板沿RD方向拉伸性能变化曲线

Fig.4

Tensile property curves along RD of the 2A12 Al cold rolled sheet aged under the temperatures of 155 ℃ (a), 170 ℃ (b), 185 ℃ (c) and 200 ℃ (d) (A—elongation, Rm—tensile strength, Rp0.2—yield strength)

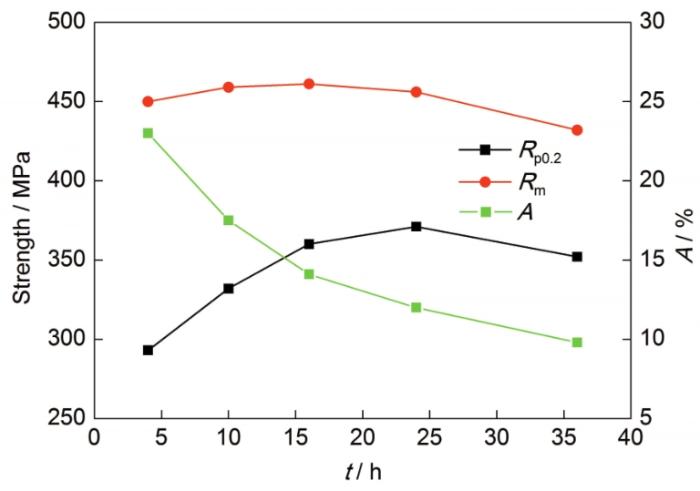

图5给出了时效温度为185 ℃时,2A12铝合金冷轧板沿垂直于轧制方向上拉伸性能的变化曲线。合金的Rp0.2与Rm随时效时间的延长先上升后降低,分别在24与16 h达到峰值屈服强度(371 MPa)和峰值抗拉强度(461 MPa)。合金延伸率则随时效时间的延长不断降低,当时效时间为36 h时,合金延伸率已下降到9.8%。与RD方向强度相比,TD方向的Rp0.2降低21 MPa,Rm降低15 MPa,但总体而言,其下降幅度较小。可见,时效处理后2A12铝合金冷轧板沿RD、TD方向的力学性能差异较小,且2个方向上力学性能随时效时间的变化趋势基本一致。

图5

图5

185 ℃下时效不同时间2A12铝合金冷轧板沿TD方向拉伸性能变化曲线

Fig.5

Tensile property curves along TD of the 2A12 Al cold rolled sheet aged at 185 ℃ for various holding time

综上所述,时效温度与时效时间对2A12铝合金冷轧板的力学性能均有较大影响。当时效温度较低时,达到峰值时效所需的时间较长,在峰值时效附近较宽的时间范围内合金各项力学性能差异不大。当人工时效温度较高时,达到峰值时效所需的时间较短,在峰值时效附近较窄的时间范围内合金的各项力学性能差异十分明显。通过以上分析可知,2A12铝合金冷轧板的最佳峰值时效制度为185 ℃保温16 h,该状态下合金沿RD方向屈服强度为381 MPa、抗拉强度为476 MPa、延伸率为13.6%,沿TD方向屈服强度为360 MPa、抗拉强度为461 MPa、延伸率为14.1%。

2.2 断口形貌分析

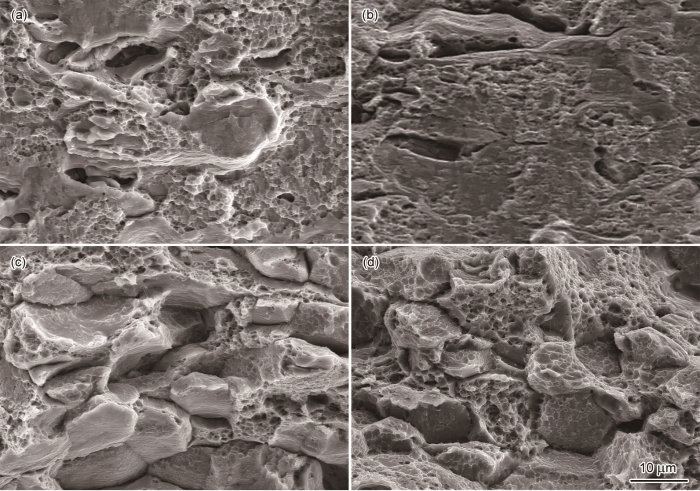

图6为2A12铝合金冷轧板在185 ℃下时效不同时间后,沿RD方向的拉伸断口形貌。随时效时间延长,断口形貌发生了显著变化,说明断裂机理有所不同。时效初期,断口形貌表现出韧性断裂特征,断口存在大量韧窝,孔洞内壁中有“蛇形滑移”,说明合金在时效初期具有良好的塑性,如图6a所示。随时效时间延长,断口中韧窝减少,出现了部分沿晶断裂特征,说明合金有从韧性断裂向脆性断裂转变的趋势,合金塑性降低,如图6b所示。随时效时间进一步延长,断口主要以沿晶韧窝断口为主,明显观察到晶界上存在大量的浅平韧窝,同时部分晶粒发生穿晶断裂,其韧窝大小不均,含有大量孔洞,表明合金中有更多地方萌发裂纹导致其断裂,合金塑性进一步降低,如图6c所示。当时效时间达到36 h后,断口主要以穿晶断裂为主,且还有部分沿晶韧窝断裂,穿晶断口中大量的孔洞表明合金塑性较差,如图6d所示。2A12铝合金冷轧板在时效过程中S相逐渐析出,S相的大小与分布是影响合金断裂形式和导致合金断裂韧性降低的主要因素[15]。随时效时间的延长,晶粒内部S相逐渐长大粗化,更易于裂纹萌生与扩展,导致合金由韧性断裂向沿晶断裂和穿晶断裂转变[16]。

图6

图6

185 ℃下时效不同时间2A12铝合金冷轧板沿RD方向的拉伸断口形貌

Fig.6

Fracture morphologies along RD of the 2A12 cold rolled Al sheet aged at 185 ℃ for various holding time of 4 h (a), 10 h (b), 16 h (c) and 36 h (d)

2.3 析出相观察与分析

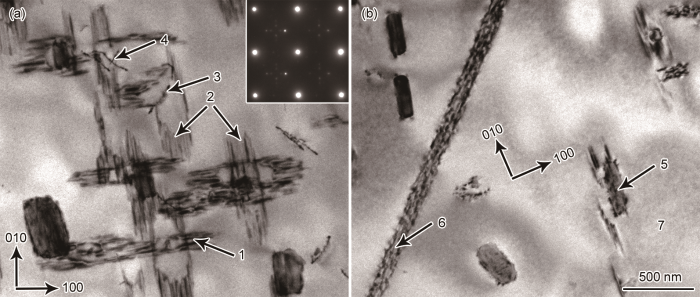

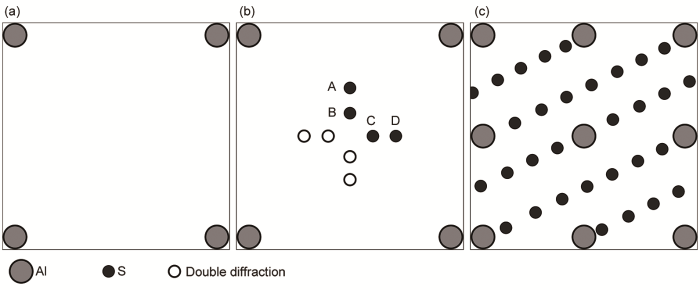

图7给出了2A12铝合金冷轧板在185 ℃人工时效4 h后微观组织的TEM像和选区电子衍射(SAED)花样。该阶段对应合金的欠时效状态,为合金在[001]Al晶带轴下得到的明场像,图中标号1~7表示不同的组织特征。标号1、2为板条状S析出相,沿[001]Al晶带轴方向观察,板条状S相互相垂直,其中板条尺寸较长的[100]S方向分别与基体[010]Al和[100]Al平行。标号3所指也是板条状的S相,但其[100]S方向平行于[001]Al,即板条尺寸较长方向平行于透射电子束方向。S相在脱溶析出过程中,形貌一般呈针状或板条状,沿[100]S方向延伸,与基体的取向关系满足[100]S//[100]Al、(001)S//(012)Al。因此,S相共有12种等效变体,且沿[100]Al、[010]Al和[001]Al方向分别有4种与之平行的S相等效变体[7]。多种板条状S相等效变体的同时析出,导致S相在易于析出的位置聚集并形成团簇。图7a相应的衍射斑点如图右上角所示,衍射斑点除了包括Al基体外还有众多额外S相衍射斑点[13,14],并呈一定规律排列。选区衍射斑点中较强的斑点对应的示意图如图8所示。图8a为Al基体的衍射斑点,图8b和c是对应各种方向S相的衍射斑点,其中图8b中A、B对应平行于[100]Al的S相等效变体,即图7标号1所指S相类型,C、D对应平行于[010]Al的S相等效变体,即标号2所指S相类型,图8c对应平行于[001]Al的S相等效变体,即标号3所指S相类型。

图7

图7

2A12铝合金冷轧板在185 ℃下人工时效4 h后的TEM像及选区电子衍射(SAED)花样

Fig.7

TEM images and the selected area electron diffraction (SAED) pattern (inset) of the grain interior (a) and near grain boundary (b) of the 2A12 cold rolled Al sheet aged at 185 ℃ for 4 h (Points 1~7 represent precipitates)

图8

图8

沿[001]Al方向Al基体及S相衍射斑点示意图

Fig.8

Schematics of the diffraction spots of Al matrix and S phases along [001]Al direction

(a) Al matrix (b) S phases of [100]S//[100]Al (A and B) or [100]S// [010]Al (C and D) (c) S phases of [100]S//[001]Al

图7a中标号4所指的析出相表明,S相在位错处易于非均质形核。对于在位错处析出的S相等效变体类型,Feng等[17]认为,S相的惯析面可能与位错线所在的平面平行,但目前对位错处S相的形成机理仍存在一些争议。图7b中标号5所指的析出相表明,S相在弥散相T相与Al基体的界面处也容易非均质形核。观察发现,在T相上析出的S相呈针状或颗粒状,且针状S相很明显地沿3个相互正交的方向延伸,即<100>Al方向。在T相上析出的针状S相属于何种类型等效变体目前还很难区分。Feng等[7]根据单个针状析出相S相的生长特征和S相12种等效变体的空间分布,认为所有S相等效变体在弥散相周围沿<100>Al方向都可能形核析出,这与本工作观察到的结果一致。图7b中标号6所指的是在晶界处S相的非均质形核,晶界上S相呈球形或透镜状,弥散分布在晶界斜面上。有研究[18]表明,S相通常在基体的缺陷如位错、晶界或弥散相与基体的界面处非均质形核,因为这些缺陷可提供额外的弹性应变场能,并且有利于固溶原子与空位的扩散,这与本研究结果一致。在板条状S相团簇周围呈现出一片空白基体区,通过TEM观察并没有发现析出相粒子,如图7b中标号7所指。进一步观察发现,粗大板条状S相往往在弥散相粒子T相或位错附近优先析出,而不会出现在没有晶体缺陷的位置。以上分析可见,在欠时效态下,2A12铝合金冷轧板S析出相以晶体缺陷处的非均质形核为主。

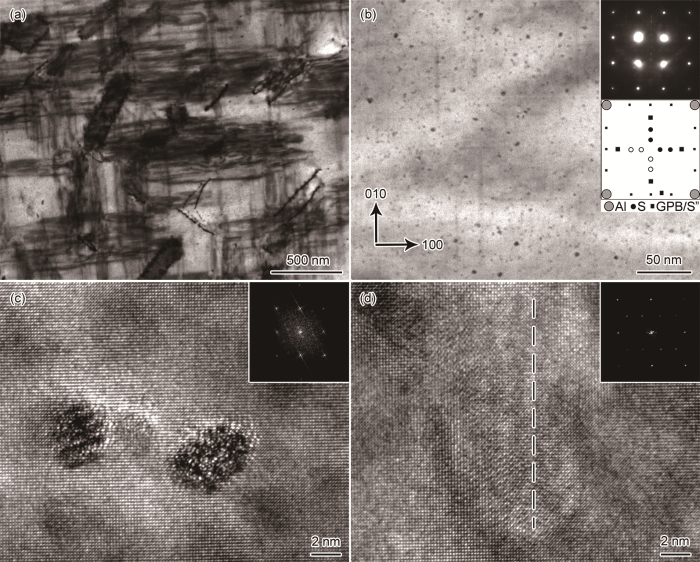

2A12铝合金冷轧板在185 ℃下人工时效16 h后微观组织的TEM像及SAED花样如图9所示,该阶段对应合金峰值时效状态。相比于欠时效,峰值时效状态下合金基体中板条状S相更宽、更厚,密度也更大,造成了合金塑性的降低和脆性断裂的产生,如图6c所示。相应地,无粗大板条状S相的Al基体所占空间更少,合金缺陷处S相非均质形核更多,如位错处S相宽度增加,T相上S相数量更多、密度更大,如图9a所示。与欠时效状态下不同的是,在无粗大板条状S相的Al基体区域观察到了许多尺寸为1~4 nm的弥散分布球形粒子,即在无晶体缺陷区域发生了明显的均质形核。图9b为无粗大板条状S相区域的放大图,该区域除了弥散分布的球形粒子外,还有一些针状析出相沿<100>Al析出。针状析出相的对应SAED花样如图9b右上角插图所示,沿[001]Al晶带轴的S相和GPB/S''所对应的电子衍射花样示意图如图9b中右侧插图所示[13]。观察发现二者具有良好的对应关系。图9c为Al基体中细小球形粒子的HRTEM像及其对应的SAED花样。对比图9b中衍射花样示意图可知,这些细小球形粒子为GPB/S''相。图9c中粒子的HRTEM像与相关文献[19,20]的报道结果相似,可能为富含Cu、Mg元素的GPB区。Tolley等[21]在[110]Al晶带轴下观察发现,这些细小粒子的实际形状为针状,且平行于<100>Al方向。图9d为基体中针状析出相的HRTEM像(虚线位置)及其SAED花样,SAED花样表明其为S相,说明GPB区有向S相转变的趋势。

图9

图9

2A12铝合金冷轧板在185 ℃下人工时效16 h后的TEM像及SAED花样

Fig.9

TEM images of the 2A12 cold rolled Al sheet aged at 185 ℃ for 16 h

(a, b) bright-field TEM images of different zones (Insets in Fig.9b are the SAED pattern (up) and diffraction schematic diagram (down) of precipitates)

(c) HRTEM images of granular precipitates and SAED pattern (inset)

(d) HRTEM images of needle-like precipitates (dashed line) and SAED pattern (inset)

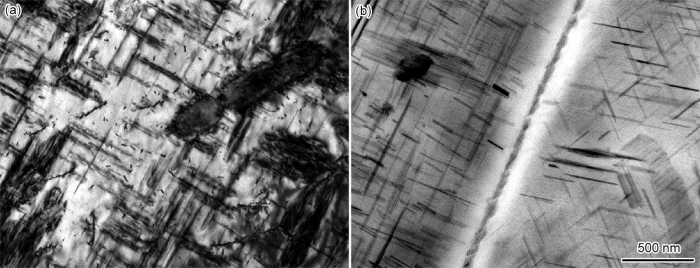

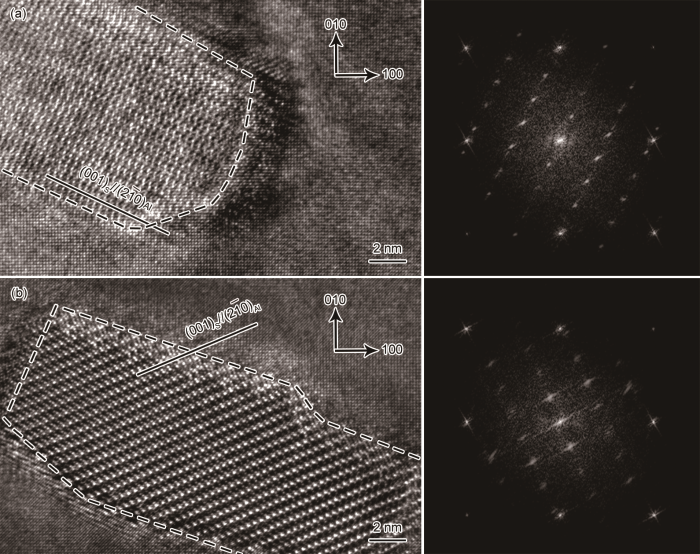

2A12铝合金冷轧板在185 ℃下人工时效64 h后微观组织的TEM像如图10所示,该阶段对应过时效状态。相比于欠时效和峰值时效,过时效条件下,基体中板条状S相以及在位错处和T相上析出的S相更加粗大,粗大板条状S相团簇之间的弥散球形粒子也发生长大,其截面由之前的圆形转变为近似矩形,即针状GPB区转变为粗大板条状S相,如图10a所示。对比图9b可知,过时效后弥散粒子的数量显著减少,说明S相是由粗大GPB区转变而来并吞并GPB区而长大。在晶界处观察到了宽度约为90 nm的无析出区,说明过时效后合金出现了明显的无析出带,如图10b所示。基体中颗粒状析出相的HRTEM像及其对应的SAED花样如图11所示。其中,图11a中粒子与基体的取向关系满足:[100]S//[001]Al,[010]S//[

图10

图10

2A12铝合金冷轧板在185 ℃下人工时效64 h后显微组织的TEM像

Fig.10

TEM images of the 2A12 cold rolled Al sheet aged at 185 ℃ for 64 h

(a) [001]Al zone axis (b) [112]Al zone axis

图11

图11

2A12铝合金在185 ℃下人工时效64 h后基体中颗粒状析出相的HRTEM像及SAED花样

Fig.11

HRTEM images and corresponding SAED patterns of the granular precipitates of the 2A12 cold rolled Al sheet aged at 185 ℃ for 64 h

(a) precipitate with the orientations of [100]S//[001]Al, [010]S//[

(b) precipitate with the orientations of [100]S//[00

通过研究2A12铝合金冷轧板人工时效不同阶段的微观组织可以发现,时效初期S强化相以非均质形核为主,随着时效时间的延长,均质形核逐步起主导作用。因此,2A12铝合金冷轧板在考虑均质形核和与非均质形核共同作用下的时效析出序列为:SSS→Cu-Mg团簇+Sinhomo→Cu-Mg团簇+GPB区+Sinhomo→Cu-Mg团簇+GPB区+Shomo+Sinhomo→S。其中,Sinhomo表示非均质形核的S相,Shomo表示均质形核的S相。

3 结论

(1) 时效温度和时效时间对2A12铝合金冷轧板力学性能均有较大影响。当时效温度较低时,达到峰值时效所需的时间长,峰值时效附近较宽的时间范围内合金各项力学性能差异不大。当人工时效温度较高时,达到峰值时效所需的时间短,峰值时效附近较短的时间范围内合金的各项力学性能差异十分明显。2A12铝合金冷轧板的最佳峰值时效制度为185 ℃保温16 h,该状态下合金沿RD方向屈服强度为381 MPa、抗拉强度为476 MPa、延伸率为13.6%。

(2) 2A12铝合金冷轧板在人工时效过程中S相逐渐析出,S相的大小与分布是影响合金断裂形式和导致合金断裂韧性降低的主要因素。时效初期,S相优先在晶界等缺陷处析出,导致合金断裂方式从韧性断裂向沿晶韧窝断裂转变。随着时效时间的延长,晶粒内部S相逐渐形核与长大,更易于裂纹的萌生与扩展,导致合金断裂方式向穿晶断裂转变,合金韧性逐渐降低。

(3) 人工时效初期以非均质形核为主,随着时效时间的延长,晶粒内部的均质形核逐步起主导作用。人工时效初期合金主要为Cu-Mg团簇强化,峰值时效时为Cu-Mg团簇和GPB区强化,过时效时析出相逐步转化为稳定的S相。2A12铝合金冷轧板在考虑均质形核与非均质形核共同作用下的析出序列为:SSS→Cu-Mg团簇+Sinhomo→Cu-Mg团簇+GPB区+Sinhomo→Cu-Mg团簇+GPB区+Shomo+Sinhomo→S。

参考文献

Hot deformation behaviors and processing maps of 2024 aluminum alloy in as-cast and homogenized states

[J].

Improving joint features and mechanical properties of pinless fiction stir welding of alcald 2A12-T4 aluminum alloy

[J].

Microstructure and anisotropic mechanical behavior of friction stir welded AA2024 alloy sheets

[J].

Nanostructure of aluminium alloy 2024: Segregation, clustering and precipitation processes

[J].in a matrix of alpha-Al and a residual distribution of smaller equiaxed solute clusters. Both the clusters and zones contained predominantly Mg and Cu, with minor concentrations of Si and Zn. The S phase contained small but significant (0.5-1.8 at.%) concentrations of Si, which was non-uniformly distributed in elongated domains within the laths of the S phase. In overaged samples (114 h at 170 degrees C) the microstructure comprised almost exclusively coarse S phase, Al(2)Mg(Cu,Si), in assemblies suggestive of a combination of precipitate coarsening and coalescence. (C) 2010 Acta Materialia Inc. Published by Elsevier Ltd.]]>

Structural changes on aging Al-Cu-Mg alloys

[J].

The competition between metastable and equilibrium S (Al2CuMg) phase during the decomposition of AlCuMg alloys

[J].

HRTEM and HAADF-STEM tomography investigation of the heterogeneously formed S (Al2CuMg) precipitates in Al-Cu-Mg alloy

[J].

Coexistence of clusters, GPB zones, S''-, S'- and S-phases in an Al-0.9% Cu-1.4% Mg alloy

[J].

Crystallographic relationships of T-/S-phase aggregates in an Al-Cu-Mg-Ag alloy

[J].

Multiple twins of a decagonal approximant embedded in S-Al2CuMg phase resulting in pitting initiation of a 2024Al alloy

[J].

Nucleation of precipitates in aged Al-Cu-Mg-(Ag) alloys with high Cu∶Mg ratios

[J].

Response to comments on cluster hardening in an aged Al-Cu-Mg alloy

[J].

Precipitation hardening in Al-Cu-Mg alloys revisited

[J].

Two types of S phase precipitates in Al-Cu-Mg alloys

[J].AbstractTransmission electron microscopy (TEM) and differential scanning calorimetry (DSC) have been used to study S phase precipitation in an Al–4.2 Cu–1.5 Mg–0.6 Mn–0.5 Si (AA2024) and an Al–4.2 Cu–1.5 Mg–0.6 Mn–0.08 Si (AA2324) (wt.%) alloy. In DSC experiments on as solution treated samples two distinct exothermic peaks are observed in the range 250–350 °C, whereas only one peak is observed in solution treated and subsequently stretched or cold worked samples. Samples heated to 270 and 400 °C at a rate of 10 °C/min in the DSC have been studied by TEM. The selected area diffraction patterns show that S phase precipitates with the classic orientation relationship form during the lower temperature peak, and for the solution treated samples, the higher temperature peak is caused by the formation of a second type of S phase precipitates which has an orientation relationship that is rotated by ∼4° to the classic one. The effects of Si and cold work on the formation of the second type of S precipitates have been discussed.]]>

Effects of non-isothermal annealing on microstructure and mechanical properties of severely deformed 2024 aluminum alloy

[J].

Influence of heat treatment on the microstructure, texture and formability of 2024 aluminium alloy

[J].

Variant selection and the strengthening effect of S precipitates at dislocations in Al-Cu-Mg alloy

[J].

STEM-HAADF tomography investigation of grain boundary precipitates in Al-Cu-Mg alloy

[J].

Origins of hardening in aged Al-Cu-Mg-(Ag) alloys

[J].Toxic polycyclic aromatic hydrocarbons (PAHs) can be found in wastewaters and sewages released from industries and/or urban areas. When discharged untreated to stream waters, they can be a problem to human health. This work represents the first attempt to use PAH and metal concentrations in aquatic moss transplants together with land-use information to identify water pollution sources in urban areas. To do this, the moss Fontinalis antipyretica was collected from a natural stream and transplanted to four different streams in a densely populated area of Lisbon, Portugal. After three months of exposure, mosses were collected and analyzed for metals and for the 16 priority PAHs recommended by the U.S. EPA. Urban streams seem to have a scattered contamination of 6-ring PAHs. Correlations among land-use, metal concentrations, and PAH concentrations indicated that areas occupied by activities of tertiary and industrial sectors had higher PAH concentrations in transplanted mosses, mainly for the sum of the 16 EPA-PAHs and for the 2-, 3- and 5-ringed PAHs, than areas occupied by urban and wooded areas. These PAHs were associated with enhanced Zn and Cu and land use activities that linked the sites to high traffic density. Industrial land use influences PAH concentration in water up to 1000 m of distance from the stream, whereas tertiary sector land use influences it up to 500 m.

Defective GP-zones and their evolution in an Al-Cu-Mg alloy during high-temperature aging

[J].

Microstructural characterisation of a commercial Al-Cu-Mg alloy combining transmission electron microscopy and positron annihilation spectroscopy

[J].

Aging behavior of an Al-Cu-Mg alloy

[J].3), and the results of a detailed transmission electron microscopy analysis of all tested alloys.]]>

Influence of electric field on the quenched-in vacancy and solute clustering during early stage ageing of Al-Cu alloy

[J].

Precipitation behaviors and preparation of an advanced Al-0.93Mg-0.78Si-0.20Cu-3.00Zn alloy for automotive application

[J].Y=1-exp[-2.03×1019exp(-23573/T)t2] has been established, which can be greatly used to predict the precipitation behavior. After artificial aging at 185 ℃for 90 min, the peak hardness of 133 HV can be obtained, corresponding to the predicted results. Additionally, the tensile properties in peak aging state, i.e. yield strength, ultimate tensile strength and elongation, are 346 MPa, 383 MPa and 13%, respectively, and ductile fracture is the main fracture feature as observed by SEM examination of fracture surface. Although 3.00%Zn is added in the alloy, yet, Mg-Si precipitates are still the main precipitates formed during artificial aging at 185 ℃. Both β′′ and pre-β′′ precipitates can be observed in the peak aging state, and the presence of the latter ones should be resulted from the formation of Zn-containing clusters. In addition, based on the microstructure evolution of the alloy, a schematic diagram of forming precipitates in the Al-Mg-Si-Cu-Zn alloy is put forwarded.]]>

汽车用新型Al-0.93Mg-0.78Si-0.20Cu-3.00Zn合金的制备及其时效析出行为研究

[J].Y=1-exp[-2.03×1019exp(-23573/T)t2]可以比较准确地预测合金时效析出规律. 185 ℃人工时效90 min即可达到峰值硬度133 HV, 对应的拉伸性能可达σ0.2=346 MPa, σb=383 MPa, δ=13%, 拉伸断口仍以塑性断裂为主. 虽然该合金含有一定量的Zn, 但在185 ℃时效时仍以Mg-Si相的析出为主, 峰时效态分布有结构稳定的β′′相及其前驱体pre-β′′相, 后者的出现主要是由于Zn参与了沉淀相的析出所致. 此外, 根据合金时效过程的组织演化规律, 提出了该新型合金沉淀相形核和析出模型示意图.]]>

In situ natural ageing of Al-Cu-(Mg) alloys: The effect of In and Sn on the very early stages of decomposition

[J].