镁合金由于具有密度小、比强度高和阻尼性能优异等特点,在航空航天、轨道交通等领域表现出了巨大的应用潜力,并得到了人们的广泛关注[1,2]。但是,目前开发的镁合金材料的力学性能依然不够理想,迫切需要开发出兼备高强度、优良延展性以及好的成形性的新型镁合金[3,4]。一般来说,在镁合金中添加高浓度的稀土元素(如Gd、Y和Nd等),可以在镁合金基体中诱导产生高密度的纳米尺寸第二相,从而有效提高合金的屈服强度和抗拉强度[5,6]。例如,Homma等[7]设计开发了Mg-10Gd-5.6Y-1.6Zn-0.65Zr (质量分数,%,下同)合金,通过挤压变形以及后续的时效处理,合金的抗拉强度高达542 MPa。Wang等[8]设计并制备了Mg-8.5Gd-2.3Y-1.8Ag-0.4Zr铸态合金,其屈服强度也达到了403 MPa。然而,由于稀土元素资源稀缺,价格昂贵,因此高稀土含量镁合金铸锭成本较高,不适用于大规模的工业化应用[9]。与此同时,高稀土含量镁合金的成型能力一般较差,其成型难度相当于7×××系的铝合金,加工成本高[10]。因此,开发力学性能优异的低稀土含量或无稀土元素的新型镁合金材料,已成为该领域发展的重要方向。

近年来,Mg-Sn-Ca系非稀土镁合金由于其优异的耐热性能(MgCaSn等耐热第二相的存在[11])、力学性能可调控(最高可达约440 MPa[10])以及低的成本[12]等优势,引起了人们的广泛关注。这主要归因于Ca元素的添加可以有效细化Mg-Sn系合金的晶粒尺寸,从而大幅度提高Mg-Sn-Ca合金的屈服强度。例如,Nayyeri和Mahmudi[13]指出,在Mg-5Sn合金中添加2%Ca (质量分数,下同)元素可诱导铸态合金中枝晶状组织的细化,从而将铸态合金的平均晶粒尺寸降低至约 240 μm。Chai等[14]研究了Ca元素对Mg-1Sn合金板材微观组织和力学性能的影响,发现添加1%Ca后Mg-Sn-Ca合金的晶粒尺寸从约26 μm细化至约9 μm,其屈服强度也增加至约209 MPa。特别地,Pan等[9]通过常规挤压制备了一种新型的Mg-2Sn-1Ca合金,晶粒尺寸可细化到约0.8 μm,从而将合金抗拉强度提升至约285 MPa,同时保持了高的延伸率(约23%)。基于进一步的成分优化与工艺改进,Pan等[10]还制备了成分为Mg-2Sn-2Ca的挤压态镁合金,实现了屈服强度在360~440 MPa之间可调,该性能可与高性能稀土镁合金相媲美。然而,Mg-2Sn-2Ca合金强度为440 MPa时,合金的延伸率差,仅约为1%。这是因为,超高强Mg-2Sn-2Ca合金经低温(仅约220 ℃)挤压后,基体内部会形成高密度残余位错,极大地损伤塑性;同时,合金中析出的Mg2Ca纳米相与基体无法保持共格关系,因此在提高合金强度的同时,不利于基体保持好的塑性。

近期研究[15~17]表明,在Mg-Ca系合金中添加Al元素可对第二相析出和动态再结晶等行为进行有效调控,从而对合金的力学性能产生影响。例如,Jayaraj等[18]在Mg-Ca合金中添加少量Al元素后,发现了富含Al和Ca元素的盘状第二相。最近,Cihova等[19]通过三维原子探针(APT)技术证实了这种盘状相即为G.P.区,且该G.P.区会逐渐转变为Al2Ca纳米相。这些G.P.区和Al2Ca相与镁合金的基体呈现出共格和半共格关系,可以有效阻碍位错运动产生强化效应[20];与此同时,该类第二相的共格特性有利于新位错的切过运动,利于合金保持好的塑性[21]。鉴于此,Mg-Ca-Al系合金具有同时保持高强度和高塑性的潜力。

综上所述,Mg-Sn-Ca作为一类重要的非稀土高强度变形镁合金,其塑性一般较差;而通过添加适量的Al元素,有望实现Mg-Sn-Ca合金强度和塑性的同时提升。然而目前这类新型的Mg-Sn-Ca-Al系合金仍缺乏系统研究,相关的成分设计与力学性能优化等还未见报道。因此,本工作结合前期的研究基础[20],在Mg-2.5Sn-2Ca合金的基础上添加了较宽成分范围的Al元素(2%、4%和9%),并结合更高的挤压温度(约350 ℃),以期对该体系镁合金的微观组织和力学性能进行有效调控,从而实现优异的强塑性匹配。

1 实验方法

在真空感应熔炼炉中制备铸态Mg-2.5Sn-2Ca-xAl (x=2、4、9)合金,所用原料均为高纯金属(纯度>99.99%)。在熔炼过程中,需要向熔炼炉中通入高纯Ar气进行气体保护,待合金元素全部熔化后,进行充分搅拌和静置,然后将金属溶液浇铸至钢制模具中成型。随后,对制备好的铸锭进行成分检测,表1为各合金的实际成分。将铸锭在500 ℃下进行24 h的均匀化处理后,通过水淬进行快速冷却,得到固溶态的镁合金样品。在挤压之前,需要将样品和模具在电阻炉中进行350 ℃预热30 min。合金的挤压温度为350 ℃,压杆速率为0.5 mm/s,挤压比为20∶1。将直径为5 mm、标距为25 mm的拉伸试样在AG-XPLUS100 KN电子万能试验机上进行力学性能测试,拉伸方向平行于挤压方向,拉伸应变速率为0.001 s-1,每个样品做3组平行实验。通过为GX71光学显微镜(OM)、附带能谱(EDS)的JSM-7001F扫描电镜(SEM)和JEM-2100F场发射透射电镜(TEM)对挤压样品的微观组织进行表征。使用Smart-Lab X射线衍射仪(XRD)对样品进行织构分析。

表1 Mg-2.5Sn-2Ca-xAl合金的实际成分 (mass fraction / %)

Table 1

| Alloy | Sn | Ca | Al | Mg |

|---|---|---|---|---|

| Mg-2.5Sn-2Ca-2Al | 2.32 | 1.83 | 2.05 | Bal. |

| Mg-2.5Sn-2Ca-4Al | 2.48 | 1.95 | 4.25 | Bal. |

| Mg-2.5Sn-2Ca-9Al | 2.59 | 2.12 | 8.63 | Bal. |

2 实验结果

2.1 Mg-2.5Sn-2Ca-xAl合金的力学性能

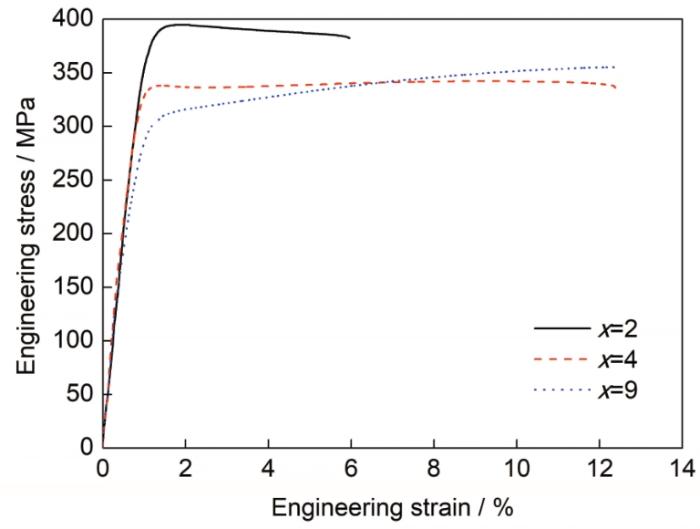

图1为挤压态Mg-2.5Sn-2Ca-xAl合金的拉伸应力-应变曲线。3种合金的屈服强度、抗拉强度和延伸率见表2。可以看出,随着Al含量的增加,合金的屈服强度呈现逐渐下降的趋势,而延伸率逐渐升高。Al含量为2%时,合金的屈服强度和抗拉强度最高,分别为370和400 MPa,但合金的延伸率仅为6.2%;当Al含量增加到4%时,合金的屈服强度和抗拉强度分别降低至325和340 MPa,延伸率增加至11.0%;当Al含量增加到9%时,合金的屈服强度最低,仅为290 MPa,但具有较高的抗拉强度(354 MPa)和最大延伸率(12.0%)。从图1还可以看出,Mg-2.5Sn-2Ca-9Al合金表现出了较强的加工硬化能力。

图1

图1

挤压态Mg-2.5Sn-2Ca-xAl合金的拉伸应力-应变曲线

Fig.1

Engineering stress-strain tensile curves of extruded Mg-2.5Sn-2Ca-xAl alloys

表2 Mg-2.5Sn-2Ca-xAl合金的力学性能

Table 2

| Alloy | σs MPa | σb MPa | δ % |

|---|---|---|---|

| Mg-2.5Sn-2Ca-2Al | 370 | 400 | 6.2 |

| Mg-2.5Sn-2Ca-4Al | 325 | 340 | 11.0 |

| Mg-2.5Sn-2Ca-9Al | 290 | 354 | 12.0 |

2.2 Mg-2.5Sn-2Ca-xAl合金的铸态组织

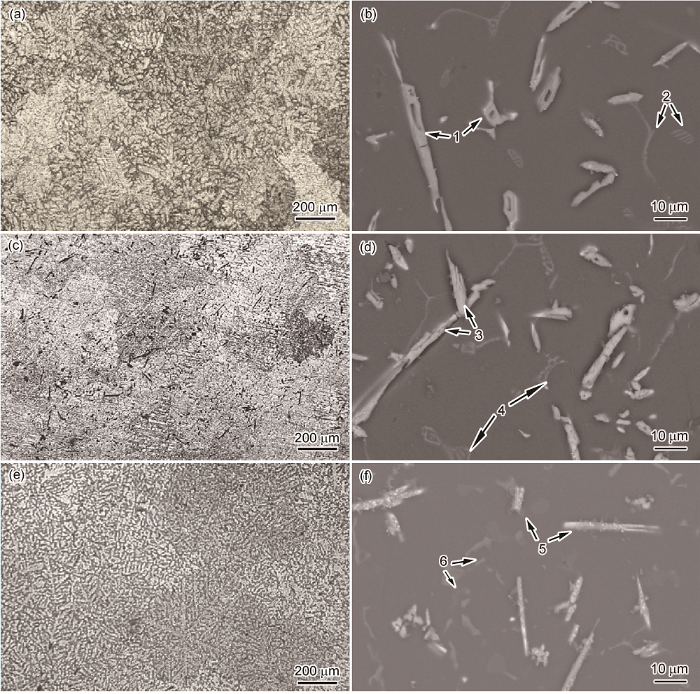

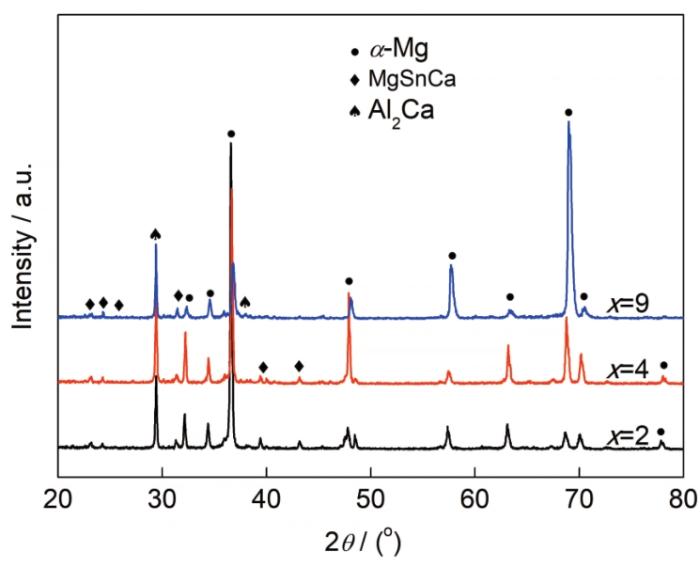

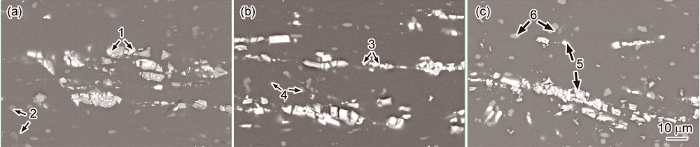

图2示出了铸态Mg-2.5Sn-2Ca-xAl合金显微组织的OM像和SEM像。从图2a、c和e可以看出,铸态合金中有较为粗大的等轴晶晶粒,且随着Al含量的增加,枝晶臂间距明显减小,即Al元素有细化枝晶状组织的效果。从图2b、d和f可以看出,合金中主要存在2种衬度的第二相,即白色衬度的棒状相(如图2中箭头1、3和5所示)和灰色衬度网状相(如图2中箭头2和4所示)。根据表3的EDS分析结果可知,棒状相中含有较高含量的Sn和Ca,且Sn/Ca含量比接近1,可判断其为MgSnCa相,且该相中会有部分原子替换成Al原子。而灰色网状相中的Sn含量几乎为0,Ca含量约为7% (原子分数),Al含量约为Ca的2~3倍;在Mg-2.5Sn-2Ca-9Al合金中(图2f),观察不到网状第二相,取而代之的为不规则块状第二相。结合EDS分析以及XRD谱结果(图3)可以判断,铸态合金中尺寸较大的棒状第二相为MgSnCa相,网状以及不规则灰色第二相为Al2Ca相。

图2

图2

铸态Mg-2.5Sn-2Ca-xAl合金显微组织的OM像和SEM像

Fig.2

OM (a, c, e) and SEM (b, d, f) images of as-cast Mg-2.5Sn-2Ca-xAl alloys with x=2 (a, b), x=4 (c, d) and x=9 (e, f)

表3 图2中1~6处的EDS结果 (atomic fraction / %)

Table 3

| Position | Mg | Sn | Ca | Al | Al/(Sn+Ca) | Phase |

|---|---|---|---|---|---|---|

| 1 | 70.29 | 10.10 | 12.01 | 7.52 | 0.34 | MgSnCa |

| 2 | 75.68 | 0.06 | 7.67 | 16.56 | 2.14 | Al2Ca |

| 3 | 77.29 | 11.10 | 10.05 | 1.54 | 0.07 | MgSnCa |

| 4 | 74.75 | 0.09 | 6.91 | 18.20 | 2.60 | Al2Ca |

| 5 | 75.01 | 11.39 | 10.71 | 2.88 | 0.13 | MgSnCa |

| 6 | 71.77 | 0.11 | 6.91 | 21.26 | 3.03 | Al2Ca |

图3

图3

铸态Mg-2.5Sn-2Ca-xAl合金的XRD谱

Fig.3

XRD spectra of as-cast Mg-2.5Sn-2Ca-xAl alloys

2.3 Mg-2.5Sn-2Ca-xAl合金的挤压态组织

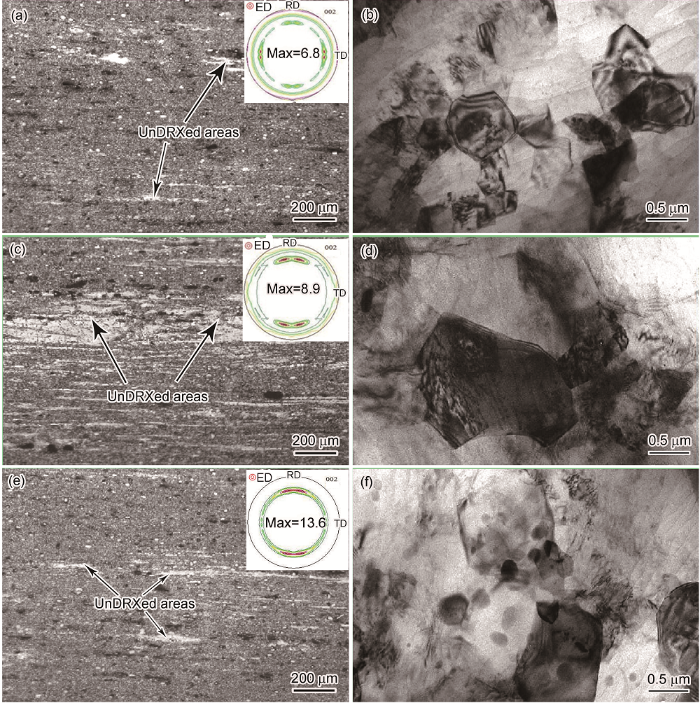

图4为挤压态Mg-2.5Sn-2Ca-xAl合金的OM像、(0002)极图与TEM像。从图4a、c和e可以看出,除细小的动态再结晶晶粒外,沿着挤压方向还流线分布有未再结晶晶粒组织,如箭头所示。在挤压态Mg-2.5Sn-2Ca-2Al合金中,动态再结晶较为充分;而当Al含量增加到4%时,合金中的未再结晶晶粒比例明显增多;有趣的是,当Al含量增加到9%时,镁合金中的未再结晶晶粒又大大减少,未再结晶区域基本消失。结合(0002)极图(图4a、c和e中插图),热挤压后的合金基面平行于挤压方向(ED),这是挤压镁合金的典型特征[22]。一般来说,挤压态镁合金的织构分为未再结晶区的[

图4

图4

挤压态Mg-2.5Sn-2Ca-xAl合金的OM像、(0002)极图和TEM像

Fig.4

OM (a, c, e) and TEM (b, d, f) images of the extruded Mg-2.5Sn-2Ca-xAl alloys with x=2 (a, b), x=4 (c, d) and x=9 (e, f), and (0002) pole figures (insets in Figs.4a, c and e) measured by XRD (ED—extrusion direction, TD—transverse direction, RD—rolling direction, DRX—dynamic recrystallization)

Color online

图5为挤压态Mg-2.5Sn-2Ca-xAl合金的SEM像,可观察到2种衬度的第二相。较亮衬度第二相的Sn/Ca比约为1,即为MgSnCa相。EDS分析结果(表4)显示,挤压态Mg-2.5Sn-2Ca-2Al合金的MgSnCa相中Al元素约为Sn+Ca元素含量的1/4,挤压态Mg-2.5Sn-2Ca-4Al合金的Al在MgSnCa中的含量约为Sn+Ca的1/7,挤压态Mg-2.5Sn-2Ca-9Al合金的Al在MgSnCa相中含量约为Sn+Ca的1/10。相比之下,较暗衬度的第二相中Al含量则呈现相反的分配趋势,Mg-2.5Sn-2Ca-2Al合金该相中Al约为Ca元素含量的2倍,挤压态Mg-2.5Sn-2Ca-4Al合金中约为3倍,挤压态Mg-2.5Sn-2Ca-9Al合金中约为3.2倍。据此可知,挤压态合金中主要存在经变形破碎的MgSnCa相和Al2Ca相。

图5

图5

挤压态Mg-2.5Sn-2Ca-xAl合金的SEM像

Fig.5

SEM images of extruded Mg-2.5Sn-2Ca-xAl alloys with x=2 (a), x=4 (b) and x=9 (c)

表4 图5中1~6处的EDS结果 (atomic fraction / %)

Table 4

| Position | Mg | Sn | Ca | Al | Al/(Sn+Ca) | Phase |

|---|---|---|---|---|---|---|

| 1 | 90.46 | 3.64 | 3.93 | 1.98 | 0.26 | MgSnCa |

| 2 | 51.52 | 0.09 | 15.34 | 33.05 | 2.14 | Al2Ca |

| 3 | 87.65 | 5.52 | 5.28 | 1.55 | 0.14 | MgSnCa |

| 4 | 60.77 | 0.09 | 9.59 | 29.55 | 3.05 | Al2Ca |

| 5 | 56.47 | 21.13 | 18.75 | 3.65 | 0.09 | MgSnCa |

| 6 | 49.31 | 0.02 | 12.12 | 38.55 | 3.18 | Al2Ca |

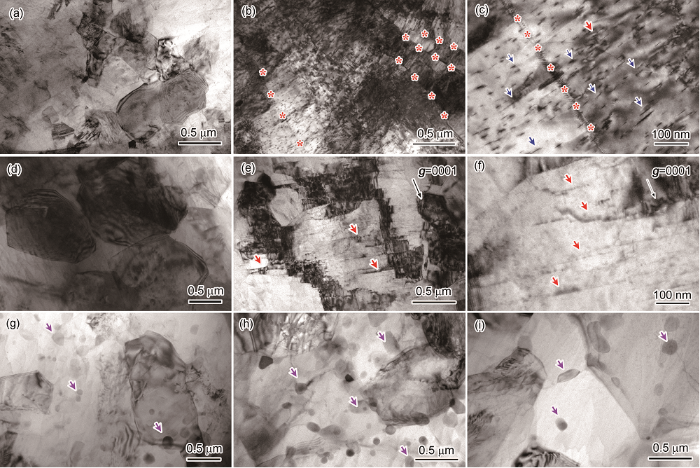

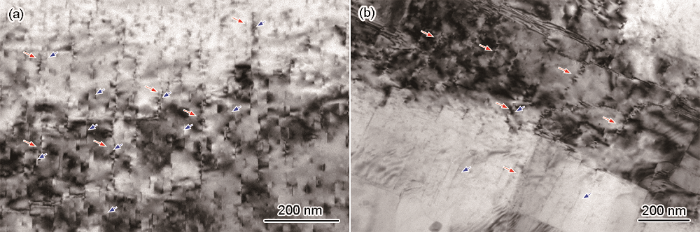

图6为挤压态Mg-2.5Sn-2Ca-xAl合金微观组织的TEM像。在Mg-2.5Sn-2Ca-2Al合金中,再结晶晶粒的尺寸约为0.5 μm (图6a);而在未再结晶区域中,可以观察到间距为0.2~1 μm之间的片层组织,片层界面为小角度晶界,如图6b和c中星号所示。此外,图6b显示这些片层内部存在极高密度的位错,还存在图6c中蓝色箭头所示的纳米第二相。近期研究表明,Mg-Al-Ca-Mn合金体系中存在的第二相为fcc结构的Al2Ca相[18,19],以及平行于基面的单层盘状结构的G.P.区[23,24],并且在时效过程中G.P.区可作为Al2Ca的前驱体[19,25]。图6c中的盘状相尺寸较小,可将Mg-2.5Sn-2Ca-2Al合金中出现的第二相确定为G.P.区。此外,在图6c中还可以观察到<c+a>位错(红色箭头所示)。TEM观察表明,Mg-2.5Sn-2Ca-xAl合金中包括高密度的G.P.区以及由G.P.区阻碍位错运动而得到一定数量的残余位错,如图7所示。Mg-2.5Sn-2Ca-4Al合金微观组织的TEM像如图6d~f所示。当Al含量从2%增加到4%时,合金中再结晶晶粒尺寸有所增加,约为1.0 μm;在未再结晶区域,也可以观察到较高密度的位错。在倒易点阵矢量g=0001双光束条件下仍然有部分位错可见(图6f),而根据平行于反射平面的位移不产生衬度,即g·b=0位错不可见准则(b为点阵平移矢量)[26,27],判断在Mg-2.5Sn-2Ca-4Al合金中存在<c+a>位错。值得注意的是,在Mg-2.5Sn-2Ca-4Al合金中,基体内的纳米尺度G.P.区密度较Mg-2.5Sn-2Ca-2Al合金显著降低。当Al含量继续升高,在Mg-2.5Sn-2Ca-9Al合金中,如图6g~i所示,首先可以明显观察到再结晶晶粒尺寸增大,为1~2 μm;未再结晶区域比例降低,且该合金基体中位错密度较低,在晶界处和晶粒内部存在较高密度的块状第二相。结合选区电子衍射以及EDS分析,可判断该第二相为Mg17Al12相。由此可见,不同含量的Al元素不仅改变了第二相的类型(由G.P.区到Mg17Al12相),还可对再结晶晶粒尺寸和位错密度等产生重要影响。

图6

图6

挤压态Mg-2.5Sn-2Ca-xAl合金微观组织的TEM像

Fig.6

TEM images showing the microstructures of the extruded Mg-2.5Sn-2Ca-xAl alloy with x=2 (a~c), x=4 (d~f) and x=9 (g~i) (The red asterisks in the figure show the low-angular grain boundaries. The blue arrows show the G.P. zones, the red arrows show the dislocations, and the purple arrows show the nano-scaled Mg17Al12 phases)

Color online

图7

图7

挤压态Mg-2.5Sn-2Ca-2Al合金中包括高密度的G.P.区以及残余位错的TEM像

Fig.7

TEM images of the extruded Mg-2.5Sn-2Ca-2Al alloy with the G.P. zones and residual dislocations (a, b) (The blue arrows show the G.P. zones, and the red arrows show the dislocations)

Color online

3 分析讨论

3.1 Al含量及热加工对第二相种类和成分的影响

前期研究[28,29]表明,Mg-Sn-Ca合金中进行Al、Sr和Ce等多元合金化后,原本三元合金中的MgSnCa等第二相内部均会固溶进部分Al、Sr和Ce等第四组元的元素,电子探针以及EDS面扫描的结果都证明了这一点,其主要是以置换固溶体的形式进行。此外,这一现象在诸多其它合金体系的金属间化合物中都是可以观察到的。因此,金属间化合物在保持其特定的晶体结构的同时,其内部的原子占位是可以被其它元素所置换的,从而导致合金元素配比的变化。基于该理论,第四组元Al元素的加入将对Mg-Sn-Ca合金中第二相的类型产生影响,且相的具体形态受成分和热处理工艺共同影响。结合图2和3,3种合金的铸态组织中均含有MgSnCa相和Al2Ca相,但是这2类相的含量存在差异。随着Al含量的增多,MgSnCa相的体积分数降低而Al2Ca相的体积分数增加。值得注意的是,在不同合金中Al元素在不同相中的含量差异显著,在Mg-2.5Sn-2Ca-2Al合金中Al在MgSnCa相中的含量明显高于Mg-2.5Sn-2Ca-4Al和Mg-2.5Sn-2Ca-9Al合金;相反,Mg-2.5Sn-2Ca-2Al合金中Al2Ca相的含Al量相对较低。另外,对比不同状态合金组织可以发现,经过挤压后Al在Al2Ca相中的含量均会升高,这说明经过热处理工艺后Al元素会脱离MgSnCa相而进入Al2Ca相中。

形成这种成分上的差异主要原因在于凝固过程的差异。在Mg-Sn-Ca三元系里,共晶反应L→(Mg)+MgxCa2-xSn+Mg2Ca温度为515 ℃,L→(Mg)+MgxCa2-xSn+Mg2Sn温度为563 ℃[30],且当Sn/Ca<3.3时,不会析出Mg2Sn相[31]。Suzuki等关于Mg-Al-Ca三元系的研究表明,C36结构相的析出温度约为528 ℃,C14结构第二相析出温度接近514 ℃[32],Mg17Al12相析出温度为452 ℃,且随着温度和成分的变化,还会发生一系列的相转化[33]。因此在本工作的合金成分范围内,MgSnCa相优先于Al2Ca相从液相中析出,而当Al含量较低时(Mg-2.5Sn-2Ca-2Al合金),合金凝固区间较窄,部分Al2Ca相会以MgSnCa相作为异质形核核心,包覆在MgSnCa相外围,造成EDS分析结果中MgSnCa相中Al含量较高的现象。随着Al含量逐渐增加,凝固区间变宽,熔液流动性较好,凝固组织中会析出更多的Al2Ca相。500 ℃均匀化处理会使部分第二相由于扩散作用回熔至基体中,基体中固溶元素达到较高水平。合金在350 ℃挤压会使第二相在基体中析出,且变形中高的位错密度有利于纳米第二相的动态析出,同时使得挤压态合金中Al元素更多地进入到Al2Ca相中。

3.2 Al含量对挤压态合金位错密度的影响

Mg-2.5Sn-2Ca-2Al合金(图6b)具有极高的位错密度,Mg-2.5Sn-2Ca-4Al合金(图6e)的位错密度略低于Mg-2.5Sn-2Ca-2Al合金,而在Mg-2.5Sn-2Ca-9Al合金(图6i)中的残余位错密度最低。可见,Al含量的升高使残余位错密度显著降低。研究[18]表明,Mg-Al系是一个具有中等塑性的合金体系,Al原子半径为0.143 nm,小于Mg原子半径0.160 nm,较小的Al原子半径在一定程度上可有效吸收Mg基体在变形过程产生的晶格畸变,使合金容纳位错的能力提高;同时,Al原子在α-Mg中具有较高的扩散速率,位错更加容易滑动,不易堆积。研究[34]表明,AM60合金在温度超过200 ℃时容易发生位错的交滑移和攀移,从而使合金发生再结晶而产生软化与位错密度的降低,即Mg-Al体系合金的热稳定性较低。与此相对,Mg-Ca系合金在变形后往往具有较高的位错密度,这是因为Ca原子半径(0.197 nm)显著大于Mg原子半径,可对位错产生有效的钉扎作用;且Ca原子在α-Mg中的扩散速率低于Al原子在Mg中的扩散速率,所以可能发生的位错处溶质偏聚也不利于位错的动态回复。在本工作中随着Al含量的升高,Al元素与Ca元素结合形成第二相,将使得Mg基体中固溶Ca原子的含量降低;而挤压后合金尚存在余热,会发生短时的静态回复和/或静态再结晶,因此高Al含量的挤压态镁合金的位错密度急剧降低。

3.3 Mg-2.5Sn-2Ca-xAl合金的强韧化机制

图1表明,Mg-2.5Sn-2Ca-2Al合金的屈服强度比Mg-2.5Sn-2Ca-4Al合金高约50 MPa,比Mg-2.5Sn-2Ca-9Al合金高约100 MPa,Mg-2.5Sn-2Ca-2Al合金较高的强度主要归因于该合金中存在大量纳米尺度的G.P.区,以及由于G.P.区的存在和低含量Al元素的添加而导致的晶粒细化[35]。事实上,镁合金再结晶晶粒的尺寸主要受2个因素影响,即形核率与晶粒长大速率。在低Al含量和高Al含量条件下,Mg-2.5Sn-2Ca-2Al和Mg-2.5Sn-2Ca-9Al合金中分别会形成G.P.区和Mg17Al12第二相。对比图6c和i,可以发现Mg-2.5Sn-2Ca-2Al合金中的G.P.区密度远高于Mg-2.5Sn-2Ca-9Al合金中的Mg17Al12相密度,高密度的G.P.区可以有效阻碍位错运动(图7),从而促进更高密度的位错聚集,并为动态再结晶的形核提供更多核心。此外,由于高Al含量镁合金中的位错更容易回复,Mg-2.5Sn-2Ca-9Al合金中的残余位错密度相应更低。据此,低Al含量Mg-2.5Sn-2Ca-2Al合金的动态再结晶晶粒形核率比高Al含量Mg-2.5Sn-2Ca-9Al合金明显更高;而中Al含量Mg-2.5Sn-2Ca-4Al合金由于缺乏有效的纳米相阻碍位错运动,该合金的动态再结晶形核率最低,并导致最终挤压态Mg-2.5Sn-2Ca-4Al合金中的未再结晶晶粒比例最高。图4的OM观察结果也证明了这一点。此外,再结晶晶粒形核后的长大主要受到纳米第二相的尺寸、分布和体积分数等因素控制,具体表现为Zener拖拽模型[36]:

式中,Dlim为颗粒阻碍达到平衡态后的最小晶粒尺寸,Φ为第二相颗粒的平均晶粒尺寸,f为第二相的体积分数。在本工作中,如果假定在2种纳米相的体积分数差异不大的情况下,Mg-2.5Sn-2Ca-2Al合金的G.P.区颗粒尺寸为5~15 nm,而Mg-2.5Sn-2Ca-9Al合金的Mg17Al12纳米相的颗粒尺寸为50~200 nm,即明显大于G.P.区。由此可见,高密度G.P.区阻碍再结晶晶粒的长大比Mg17Al12纳米相更为有效,因此Mg-2.5Sn-2Ca-2Al合金的再结晶晶粒更细小(约为0.5 μm),同时还保留有较高密度的亚晶片层组织(片层厚度0.2~1.0 μm)。

根据镁合金的Hall-Petch关系,Mg-2.5Sn-2Ca-2Al合金中细小的再结晶和亚晶晶粒组织将对位错的运动产生极大的阻碍作用[37];另一方面,高密度的G.P.区以及残余位错密度也将成为新产生位错运动的障碍,这些均会对提高合金的屈服强度做出贡献[20]。在中Al含量的Mg-2.5Sn-2Ca-4Al合金中,第二相和残余位错密度均显著下降,但出现了较高体积分数的未再结晶晶粒,这些晶粒一般表现为(

此外,从图1可以看出,Al元素添加会显著提高合金塑性,且随着Al含量升高,合金延伸率由Mg-2.5Sn-2Ca-2Al合金的6.2%升高到Mg-2.5Sn-2Ca-4Al合金的11.0%,当Al含量为9%时,合金表现出明显的加工硬化效应。金属材料塑性的提高一般伴随着强度的下降,这与本文的研究结果是一致的。由图6可知,高Al含量的镁合金中,残余位错密度更低,对于新产生位错的阻碍作用也较弱,因此可促进更多位错的产生与运动,有利于提高塑性。Mg-2.5Sn-2Ca-9Al合金具有较高的加工硬化效应,一方面由于合金中初始位错密度较低,因此在变形过程中会逐渐堆积位错;另一方面基体中存在大量的纳米级Mg17Al12第二相,与晶界共同作为位错塞积点,从而在工程应力-应变曲线中可见明显的加工硬化效应。最后,需要指出的是,传统认为的晶粒细化可以同时提高金属强度和塑性的观点,在变形镁合金中不一定适用。例如,尽管Mg-2.5Sn-2Ca-2Al合金的晶粒尺寸更小,但是其塑性较粗晶的Mg-2.5Sn-2Ca-9Al合金却降低。这是因为,挤压态Mg-2.5Sn-2Ca-2Al合金内存在更高密度的残余位错,且这些位错与G.P.区伴生。残余位错一般通过阻碍新产生位错的运动,促进新位错分解为不可动的位错,从而降低了Mg-2.5Sn-2Ca-2Al合金基体的塑性。

4 结论

(1) 随着Al含量的升高,Mg-2.5Sn-2Ca-xAl合金的强度有所降低、延伸率增加。Mg-2.5Sn-2Ca-2Al、Mg-2.5Sn-2Ca-4Al和Mg-2.5Sn-2Ca-9Al合金的屈服强度分别为370、325和290 MPa,抗拉强度分别为400、340和354 MPa,延伸率分别为6.2%、11.0%和12.0%。

(2) 第四组元Al元素的加入改变了Mg-Sn-Ca合金中纳米第二相的类型和含量。在低Al和高Al条件下,Mg-2.5Sn-2Ca-2Al和Mg-2.5Sn-2Ca-9Al合金中分别会形成高密度的G.P.区和Mg17Al12的第二相,中Al含量的Mg-2.5Sn-2Ca-4Al合金中未见明显的纳米相析出。

(3) 高密度的G.P.区阻碍再结晶晶粒的长大比Mg17Al12纳米相更为有效,因此Mg-2.5Sn-2Ca-2Al合金的再结晶晶粒更细小(约为0.5 μm),同时还保留有较高密度的亚晶片层组织(片层厚度0.2~1.0 μm)。TEM观察表明,位错一般与G.P.区伴生,但是缠结的位错和晶体内弥散分布的G.P.区,不仅会提高合金的屈服强度,也会损伤合金材料的塑性。在Mg-2.5Sn-2Ca-9Al合金中,由于高含量Al元素的存在以及Mg17Al12纳米相阻碍位错运动能力相对较弱,导致残余位错密度较低,所以Mg-2.5Sn-2Ca-9Al合金表现出了更大的晶粒尺寸、较低的屈服强度以及更高的塑性。

参考文献

Crack behavior in Mg/Al alloy thin sheet during hot compound extrusion

[J].

Comparison of microstructures and mechanical properties of composite extruded AZ31 sheets

[J].

A new high-strength Mg-Zn-Ce-Y-Zr magnesium alloy

[J].

Novel continuous forging extrusion in a one-step extrusion process for bulk ultrafine magnesium alloy

[J].

Precipitation and hardening in magnesium alloys

[J].

High temperature mechanical behavior of low-pressure sand-cast Mg-Gd-Y-Zr magnesium alloy

[J].

Fabrication of extraordinary high-strength magnesium alloy by hot extrusion

[J].

Microstructure and super high strength of cast Mg-8.5Gd-2.3Y-1.8Ag-0.4Zr alloy

[J].

Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn

[J].

Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength

[J].

The Effect of microstructure evolution on the elevated temperature mechanical properties in Mg-Sn-Ca system

[J].

On the improved tensile strength and ductility of Mg-Sn-Zn-Mn alloy processed by aging prior to extrusion

[J].

Effects of Ca additions on the microstructural stability and mechanical properties of Mg-5%Sn alloy

[J].

Effects of Zn and Ca addition on microstructure and mechanical properties of as-extruded Mg-1.0Sn alloy sheet

[J].

Phase selection and mechanical properties of permanent-mold cast Mg-Al-Ca-Mn alloys and the role of Ca/Al ratio

[J].

Ultrahigh strength Mg-Al-Ca-Mn extrusion alloys with various aluminum contents

[J].

Mechanistic investigation of a low-alloy Mg-Ca-based extrusion alloy with high strength-ductility synergy

[J].

Enhanced precipitation hardening of Mg-Ca alloy by Al addition

[J].

Rational design of a lean magnesium-based alloy with high age-hardening response

[J].

Age hardening responses of as-extruded Mg-2.5Sn-1.5Ca alloys with a wide range of Al concentration

[J].

Effect of Al contents on microstructures, tensile and creep properties of Mg-Al-Sr-Ca alloy

[J].

Development of high strength and ductility in Mg-2Zn extruded alloy by high content Mn-alloying

[J].

Origins of high strength and ductility combination in a Guinier-Preston zone containing Mg-Al-Ca-Mn alloy

[J].

Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys

[J].

Magnesium alloys strengthened by nanosaucer precipitates with confined new topologically close-packed structure

[J].

Effects of Ce, Sr alloying on second phases of Mg-Sn-Ca alloy in cast and homogenized states

[J].

Ce、Sr合金化对铸态及均匀化态Mg-Sn-Ca合金第二相的影响

[J].

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.

Phase equilibria, thermodynamics and solidification microstructures of Mg-Sn-Ca alloys, Part 1: Experimental investigation and thermodynamic modeling of the ternary Mg-Sn-Ca system

[J].AbstractThe phase equilibria of the Mg–Sn–Ca system for the entire composition and temperature ranges have been clarified based on the Calphad method. To obtain a reliable thermodynamic description, we performed key experiments for the phase boundary data and also utilized the first-principle results of the finite-temperature properties for the binary and ternary compounds. Experimental works for the phase equilibria, which consist of thermal, crystallographic and microstructural analyses, and the thermodynamic modeling combined with finite-temperature first-principle calculations are reported. The satisfying agreements between the experimental and calculated results support the reliability of the proposed thermodynamic description. The phase diagram for overall composition and temperature ranges of the ternary system based on the thermodynamic calculations is presented. In a second study this result is applied to obtain details of the phase formation during solidification for practically important Mg-rich as-cast alloys.]]>

Phase equilibria, thermodynamics and solidification microstructures of Mg-Sn-Ca alloys, Part 2: Prediction of phase formation in Mg-rich Mg-Sn-Ca cast alloys

[J].AbstractThe basis of this work is a detailed investigation of phase equilibria of the Mg–Sn–Ca system for wide ranges of composition and temperature by means of a combined approach of our own key experiments, first-principles calculations of finite-temperature properties of the compounds and Calphad-type modeling. In this report, the generated thermodynamic description is applied to predict the phase formation and discuss the solidification behavior of practically important Mg-rich alloys. Solidification calculations, based on computational thermochemistry and the present dataset, are successfully applied to the analysis of experimentally observed as-cast microstructures and thermal analysis data for the Mg-rich alloy samples.]]>

Solidification paths and eutectic intermetallic phases in Mg-Al-Ca ternary alloys

[J].AbstractThe solidification of Mg–Al–Ca ternary alloys in the α-Mg solidification region was investigated by microstructural and thermal analysis, and the liquidus projection was determined. The liquidus temperature decreases with additions of Al and Ca. Solidification is terminated with the formation of C14 (Mg2Ca), C36 ((Mg,Al)2Ca) or A12 (β-Mg17Al12) eutectic compounds, in the order of increasing Al content. The L → α + C36 eutectic has a saddle point at 807 K, and with decreasing temperature, two ternary invariant transformations, L → α + C14 + C36 (787 K) and L + C36 → α + A12 (725 K) are observed. The stability of the intermetallic C36 phase during annealing at 573 K was examined in die-cast Mg–5Al–3Ca based alloys. The C36 phase transformed to the C15 (Al2Ca) phase by a shear-assisted mechanism.]]>

Structure and transition of eutectic (Mg, Al)2Ca Laves phase in a die-cast Mg-Al-Ca base alloy

[J].

Modeling of hardening and softening processes in Mg alloys

[J].

Potential of multi-pass ECAP on improving the mechanical properties of a high-calcium-content Mg-Al-Ca-Mn alloy

[J].

Structure and mechanical behavior of ultrafine-grained aluminum-iron alloy stabilized by nanoscaled intermetallic particles

[J].

Influence of grain size and texture on Hall-Petch relationship for a magnesium alloy

[J].

Microstructure, texture, mechanical properties and electromagnetic shielding effectiveness of Mg-Zn-Zr-Ce alloys

[J].

Change of deformation mechanisms leading to high strength and large ductility in Mg-Zn-Zr-Ca alloy with fully recrystallized ultrafine grained microstructures

[J].slip and {10-12} twinning, and the quick decrease of work-hardening rate was mainly due to the early saturation of deformation twins. For the UFG specimens, {10-12} twinning was dramatically suppressed, while non-basal slip systems containing component of Burgers vector were activated, which contributed significantly to the enhanced work-hardening rate leading to high strength and large ductility. It was clarified by this study that limited ductility of hexagonal Mg alloys could be overcome by activating unusual slip systems ( dislocations) in fully recrystallized UFG microstructures.]]>