为保证大规格螺栓的服役性能,要求材料要具有良好的淬透性,即淬火后心部马氏体组织达到90%以上。虽然可通过控制生产工艺改善材料的淬透性,但是影响材料淬透性的根本原因是材料的化学成分[12,13]。目前通过添加化学成分来提高钢的淬透性方法一般有2种方式:一是通过添加Ni、Mo、Mn等合金元素提高淬透性[14~18],但是此类元素添加含量过多会形成大量碳化物,成为铁素体珠光体形核核心,反而对淬透性产生有害影响,同时也会提高材料的成本;二是通过添加微量B元素代替大量合金元素的添加来提高材料的淬透性[19],研究[20,21]表明,B有效添加含量在0.0007%~0.0015% (质量分数)即可明显改善材料的淬透性,但是B作为微量元素添加,在工业生产过程中难以控制其含量,另外B属于活泼元素,易与钢中N元素结合形成BN析出,影响B在钢中的固溶量,从而降低B对淬透性的促进作用。近年来,日本学者石原悠太郎等[22]研究发现,Al在钢中以固溶形式存在也可以提高钢的淬透性,张娟等[23]和潘涛等[24]研究发现,当Al的添加含量较高时可以作为固N元素在含微B钢中影响钢的淬透性。考虑到Al作为炼钢过程使用的脱氧元素,不增加材料成本,且目前通过喂Al线可精确控制其含量,因此本工作针对大规格螺栓钢淬透性问题,研究了Al添加对42CrMo钢淬透性和淬火组织以及性能的影响,并与含B钢进行对比,揭示Al对不同尺寸42CrMo钢淬透性的影响规律。

1 实验方法

实验以42CrMo钢作为基础钢,其基本成分(质量分数,%,下同)为:Fe-0.41C-0.29Si-0.84Mn-1.10Cr-0.40Mo。按照特级优质钢标准,控制P<0.020%、S<0.010%。为研究Al在钢中对淬透性的影响,在其化学成分基础上添加微量合金元素,其中2#钢中配合添加0.040%Al-0.028%Ti,3#钢中配合添加0.074%Al-0.0012%B。并控制2#、3#钢中N含量在0.0070%,最终冶炼检测的化学成分如表1所示。

表1 实验用钢的化学成分 (mass fraction / %)

Table 1

| Sample | Steel | Als | B | Ti | N |

|---|---|---|---|---|---|

| 1# | 42CrMo | - | - | - | 0.0028 |

| 2# | Al-Ti | 0.040 | - | 0.028 | 0.0065 |

| 3# | Al-B | 0.074 | 0.0012 | - | 0.0076 |

按照材料设计成分,采用50 kg真空电弧炉进行冶炼,之后锻造成直径30 mm、长200 mm圆棒,依照GB/T225-2006《钢的淬透性末端淬火试验方法》进行末端淬火实验,毛坯880 ℃、0.5 h正火,端淬试样奥氏体化温度870 ℃,保温0.5 h。淬火后在平行于试样轴线方向磨制出2个互相平行的平面,磨削深度为0.4~0.5 mm,沿此平面使用HP-300型洛氏硬度计分别测量距淬火端面1.5、3、5、7、9、11、13、15 mm直至50 mm处的洛氏硬度(HRC)。锻造成直径分别为56、48和42 mm的圆棒进行截面硬度(U曲线)的测定实验,热处理制度为870 ℃、1 h油淬,热处理后截取试样纵向中间位置横截面,并在横截面上沿十字线测定不同位置的洛氏硬度。取端淬试样及不同直径截面试样淬火后不同部位制备金相试样,经机械磨抛后,用2% (体积分数)硝酸酒精腐蚀,采用Quanta 650热场发射扫描电子显微镜(SEM)观察组织以及析出相形貌,通过SEM自带的能谱仪(EDS)确定析出相类型。

其余部分锻造成直径16 mm的圆棒,经热处理后进行室温拉伸实验和低温冲击实验。热处理制度为:870 ℃、30 min油冷+450 ℃/500 ℃/550 ℃/600 ℃/ 650 ℃、2 h空冷。采用WE-300万能液压拉伸试验机参照GB/T 228.1-2010进行室温拉伸实验,试样直径为5 mm,标距为25 mm,每种热处理制度的试样取2个进行拉伸实验,实验结果取平均值。冲击实验在JBN-300B型摆锤式冲击试验机上参照GB/T229-2007进行,试样为标准Charpy V型缺口试样,最大测试能量为300 J,低温冲击实验温度为-40 ℃。

通过热膨胀方法测定实验用钢的等温转变曲线(即TTT曲线)。利用相分析方法对实验用钢析出的氮化物进行定性、定量分析。相分析实验试样为直径8~14 mm、长60~100 mm的圆柱,一端刻有沟槽,用来捆绑导电线,总重量要求为30~150 g。通过D8 Advance X射线衍射仪(XRD)进行结构分析,通过ICP-AES (IRIS Advantage型全谱直读电感耦合等离子体发射光谱仪)测定析出相中各金属元素的含量。

2 实验结果

2.1 淬透性

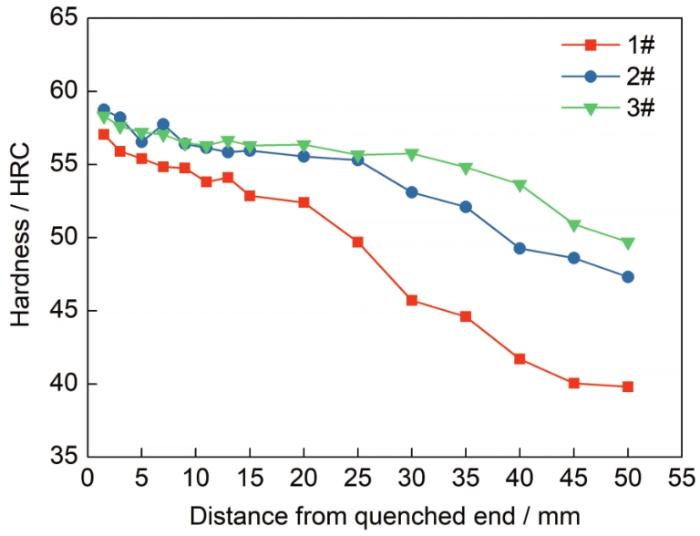

实验用钢的末端淬火曲线如图1所示,2#和3#钢的整体硬度较1#钢高,在距淬火端25 mm范围内2#和3#钢的硬度差异不大,1#钢的硬度则有明显下降;3种钢的J25 (距淬火端25 mm的HRC硬度)分别为49.7、55.3、55.7 HRC。可以看出,0.074%Al-B配合添加的3#钢淬透性最好,0.040%Al-Ti配合添加的2#钢在距淬火端30 mm处时硬度开始降低,但对比1#基础钢淬透性已有明显增加。

图1

图1

实验用钢的末端淬火淬透性曲线

Fig.1

Hardenability curves of the tested steels by Jominy method

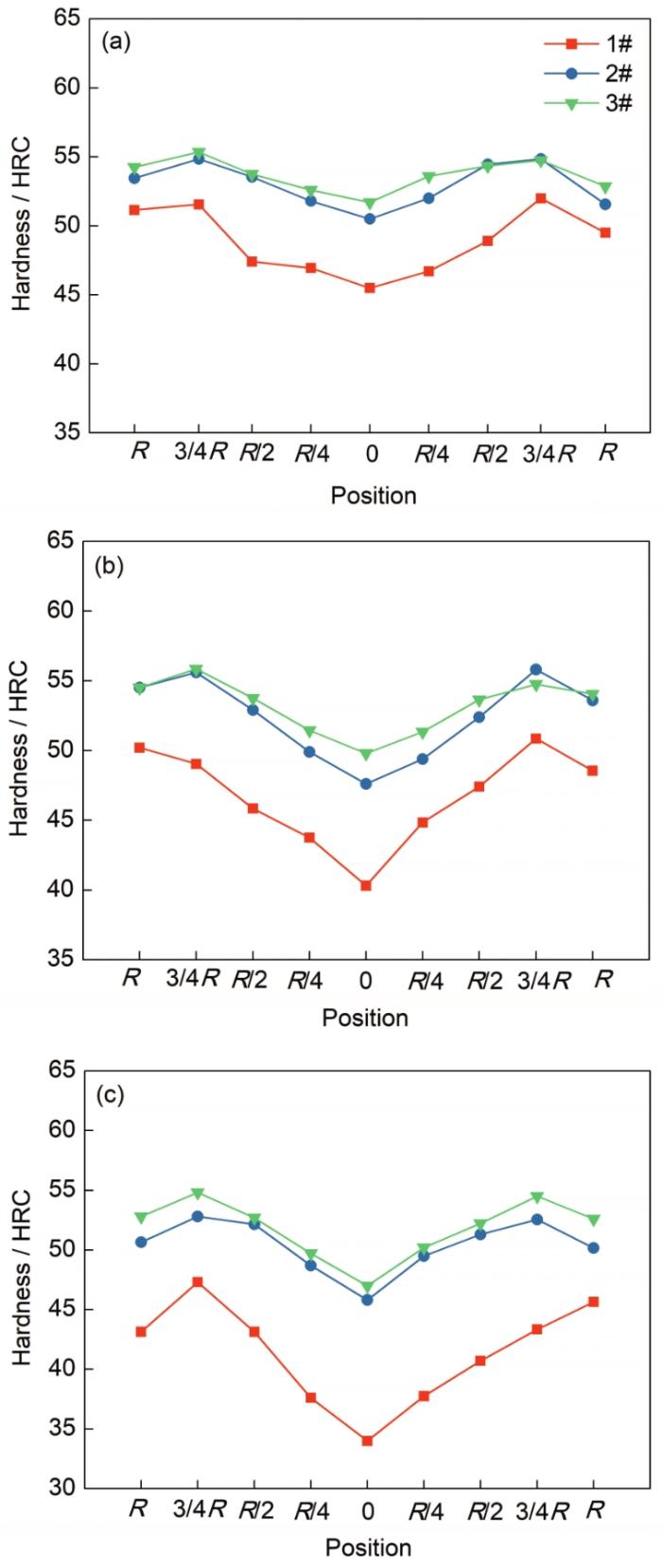

通过U曲线法(截面硬度实验)直接测定淬火钢的淬火硬度及其分布,可以真实反映钢件在一定尺寸和冷却条件下的淬透情况[30]。实验用钢的U曲线如图2所示。将同一直径上心部两边的硬度取平均值,可以看到,试样的硬度从边部到心部逐渐降低,这是由于试样内部冷速降低,心部热量向外扩散,发生马氏体自回火,从而获得不完全淬火组织,造成硬度下降。可以看到,不同尺寸的钢添加Al-Ti、Al-B后心部硬度均有提高,其中Al-B提高的更加明显。当直径为42 mm时,2#和3#钢的硬度范围为52~56 HRC,1#钢硬度范围为45~53 HRC,心部硬度提高7 HRC;当直径为48 mm时,2#和3#钢的硬度范围为50~56 HRC,1#钢硬度范围为40~50 HRC,心部硬度提高10 HRC;当直径为56 mm时,2#和3#钢的硬度范围为47~55 HRC,1#钢的硬度范围为33~47 HRC,心部硬度提高14 HRC。可知,随着试样截面直径增加,实验用钢心部硬度随之减少,其中1#钢心部的硬度降低较明显,2#和3#钢硬度分布较均匀,随着尺寸增加,截面硬度变化较稳定。通过U曲线说明2#和3#钢心部与边部性能差异较小,具有良好的淬透性。

图2

图2

实验用钢的截面硬度曲线

Fig.2

Cross-sectional hardness curves of the tested steels with the diameters of 42 mm (a), 48 mm (b) and 56 mm (c) (R—radius of cross section)

2.2 微观组织

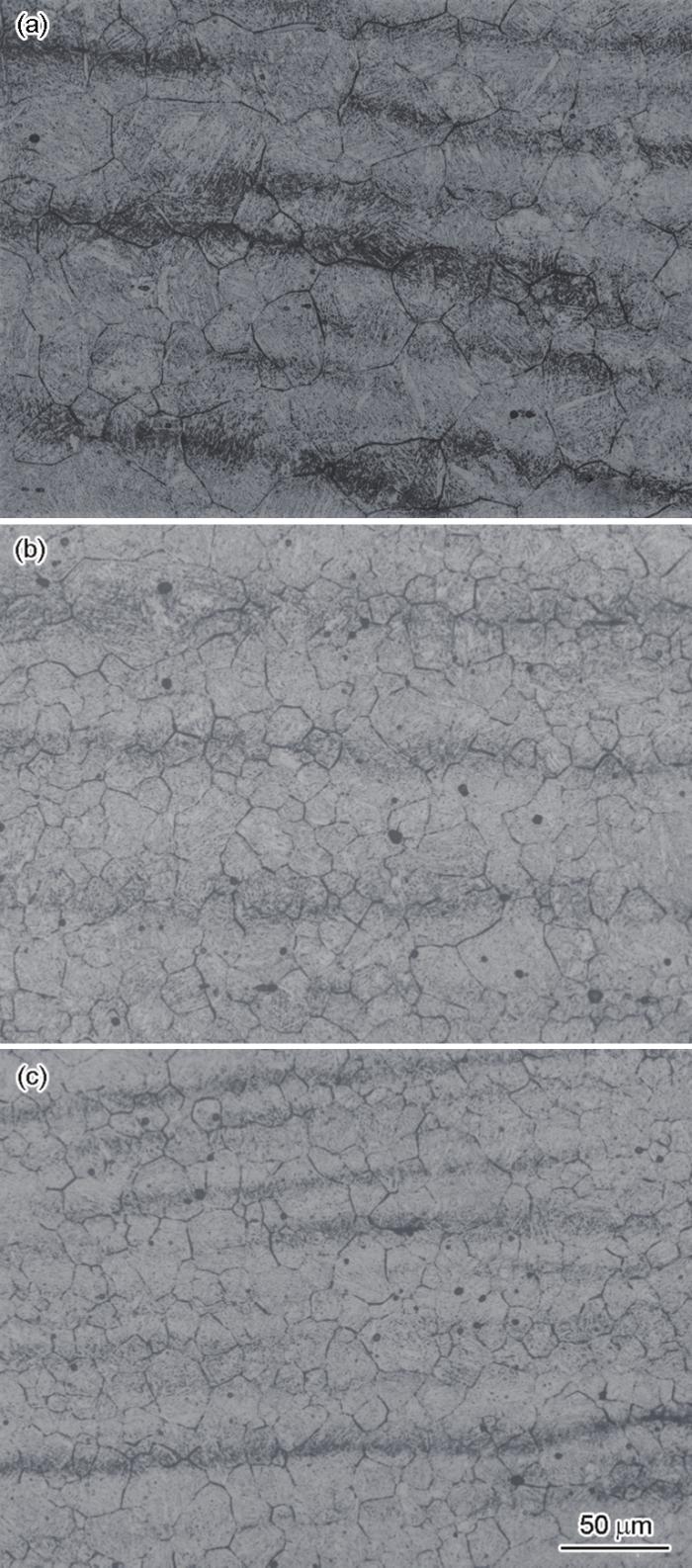

图3

图3

实验用钢的晶粒形貌

Fig.3

Grain morphologies of the tested steels of 1# (a), 2# (b) and 3# (c)

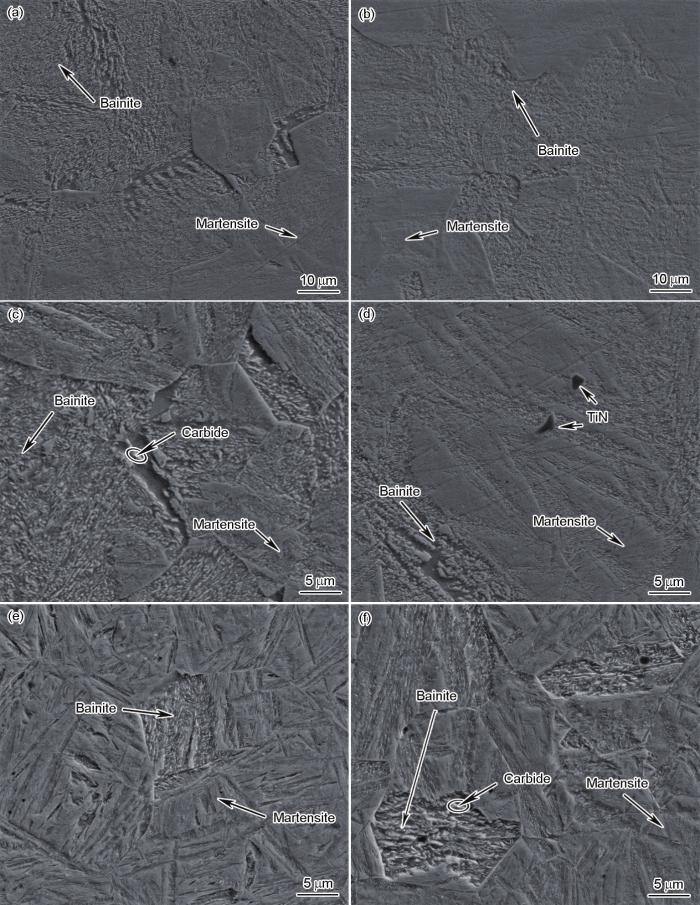

图4

图4

实验用钢距淬火端不同距离显微组织

Fig.4

Microstructures of the tested steels of 1# (a, b), 2# (c, d) and 3# (e, f) at 25 mm (a, c, e) and 35 mm (b, d, f) distances from the quenched end

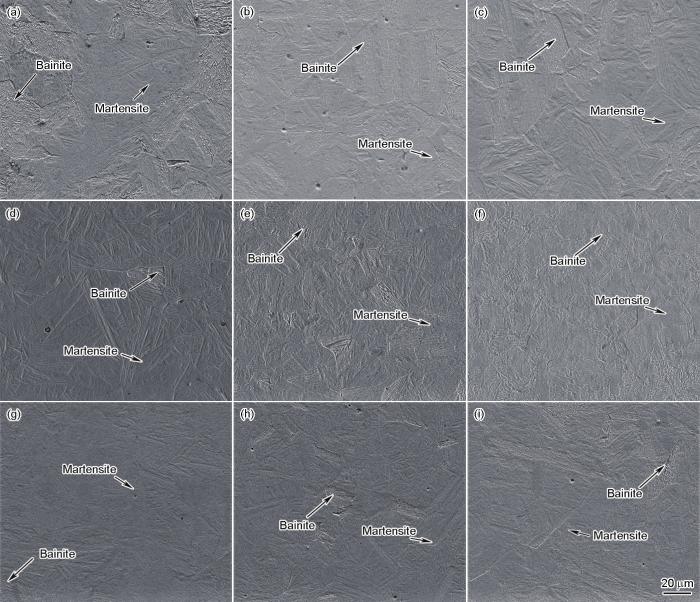

图5为3种实验用钢不同规格淬火后横截面的心部组织。可以看到,3种钢随着截面直径的增加,心部组织的贝氏体组织含量增多。当截面直径为42 mm时,1#钢心部贝氏体组织较多,碳化物颗粒粗大,2#钢心部出现少量贝氏体组织[38],且尺寸较小,均匀分布在各晶粒内,未有粗大贝氏体产生,3#钢心部组织基本为马氏体组织,只有极少量的贝氏体产生;当截面直径为48 mm时,1#和2#钢心部贝氏体组织增加,而3#钢组织未有明显变化;当截面直径为56 mm时,2#钢中贝氏体组织的碳化物颗粒变粗,贝氏体组织含量未有明显增加,3#钢心部贝氏体组织略有增加,但仍以马氏体组织为主。表明2#、3#钢的淬透性较基础钢(1#钢)均有提高,心部淬火组织可获得90% (面积分数)以上的马氏体组织。其中添加Al-B元素的3#钢淬火深度较添加Ti-Al元素的2#钢更好,其淬透性能更高,可以实现直径56 mm完全淬透。

图5

图5

实验用钢不同横截面心部组织对比

Fig.5

Comparisons of cross-sectional core structures of 1# (a~c), 2# (d~f) and 3# (g~i) steels with the diameters of 42 mm (a, d, g), 48 mm (b, e, h) and 56 mm (c, f, i)

2.3 力学性能

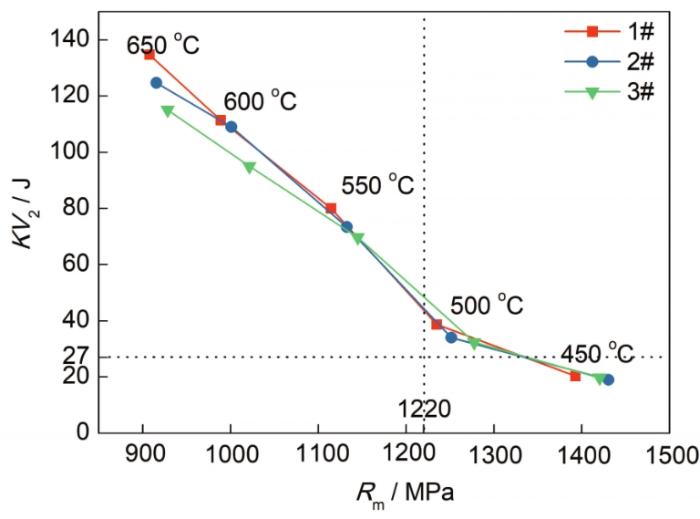

3种实验用钢不同回火温度下的抗拉强度和低温(-40℃)冲击性能如图6所示。随着回火温度升高,抗拉强度逐渐降低,低温冲击韧性逐渐升高[39]。2#钢中添加Al、Ti元素形成AlN、Ti(C, N)析出相,3#钢中添加Al、B元素形成AlN、BN析出相,通过析出相在晶界处的钉扎作用细化晶粒,从而增加钢的强度[19]。当回火温度为500 ℃时,3种钢的抗拉强度分别为1235、1252和1278 MPa,均大于1220 MPa;低温冲击功(KV2)分别为39、34和32 J,均大于27 J;当回火温度为550 ℃时,3种钢的抗拉强度分别为1114、1132和1145 MPa,均大于1040 MPa;低温冲击功分别为80、73和70 J,均大于27 J。可见,在钢中添加提高淬透性元素后,钢的力学性能没有发生明显的变化,在提高淬透性的同时,可以满足螺栓钢使用的需求。

图6

图6

不同回火温度下实验用钢的抗拉强度和低温(-40℃)冲击性能

Fig.6

Tensile strength and low temperature (-40 ℃) impact properties of the tested steels at different tempering temperatures (Rm—tensile strength, KV2—Charpy V-notch impact energy)

3 分析讨论

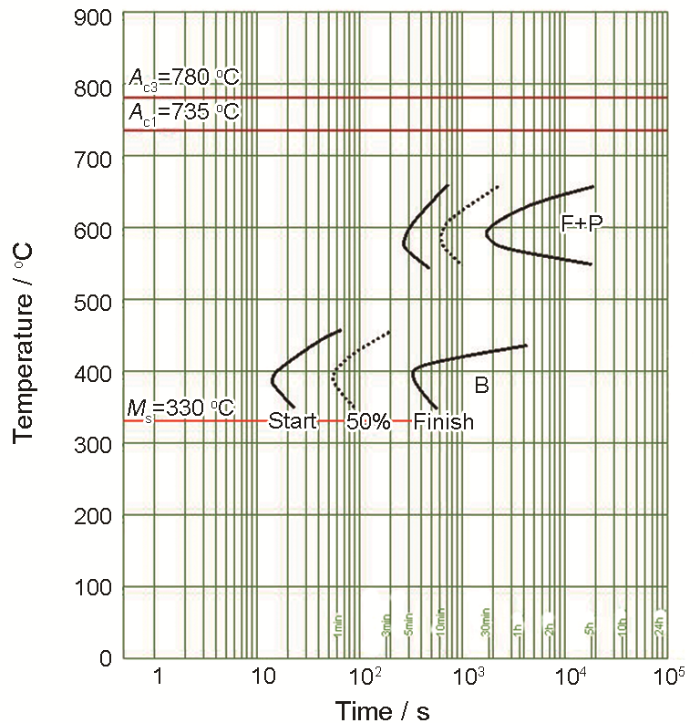

已有研究[17]表明,钢的最大淬火硬度只决定于C的含量,而合金元素的添加仅影响钢淬火后的淬硬深度。合金元素(如Cr、Ni等)的存在会阻碍C在钢中的扩散[12,40],抑制珠光体、贝氏体转变,促进马氏体的形成并允许以较低的淬火速率形成马氏体,从而提高钢的淬透性[41]。42CrMo钢中由于合金元素的添加,高温区的珠光体转变和中温区的贝氏体转变为2组基本上分开的C曲线,出现2个“鼻子”,此时过冷奥氏体的临界冷却速率决定于这2个“鼻子”的相对位置[30]。由42CrMo钢的奥氏体TTT曲线可知(图7),其珠光体转变曲线的“鼻子”比贝氏体转变曲线的“鼻子”右移更多,42CrMo钢的淬透性为贝氏体淬透性。所以抑制贝氏体的形成是提高42CrMo钢淬透性的主要因素。由于贝氏体可以在整个晶粒内成核,晶粒尺寸的变化对实验用钢的淬透性影响较小,因此添加Al、Ti虽然使得晶粒细化,但并未降低钢的淬透性。

图7

图7

42CrMo钢过冷奥氏体等温转变曲线

Fig.7

Isothermal transformation curves of 42CrMo steel undercooled austenite (F—ferrite, B—bainite, P—pearlite, Ac1—start temperature of austenite formation during heating, Ac3—finish temperature of austenite formation during heating, Ms—martensite start temperature)

通过对末端淬火曲线(图1)和U曲线(图2)的分析可知,Al、Ti、B元素的配合添加使得实验用钢的淬透性明显增加。Al在钢中的存在形式主要是氧化物Al2O3和氮化物AlN以及固溶Al,当Al以难熔化合物形式存在时,一般起细化晶粒作用,此时降低了钢在加热时奥氏体晶粒长大的倾向性,使得钢的淬透性降低;但Al以固溶形式存在于钢中时,则能提高钢的淬透性。B在钢中固溶量达到0.0007%~0.0015%时,可代替大量的合金元素强烈提高钢的淬透性,这是由于B在冷却过程中在晶界偏聚,抑制珠光体的形核。由于Al和B都是强氮化物形成元素,研究[24]表明TiN或Ti(C, N)的析出温度在1440 ℃,因此在2#钢中添加0.028%Ti进行固氮,使Al可以充分固溶于钢中;但由于TiN的析出温度较高,容易形成粗大的析出相降低材料的性能,因此考虑到Al添加含量较高时析出温度升高,可用来在含B钢中固氮,同时多余的Al固溶于钢中提高钢的淬透性。

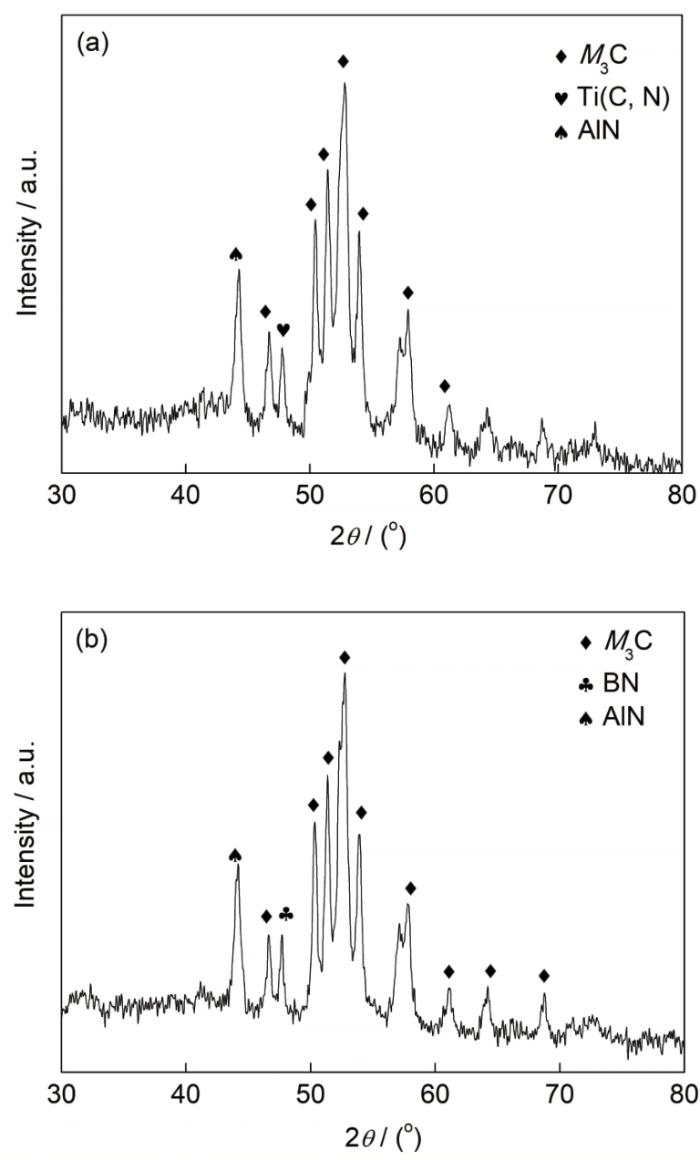

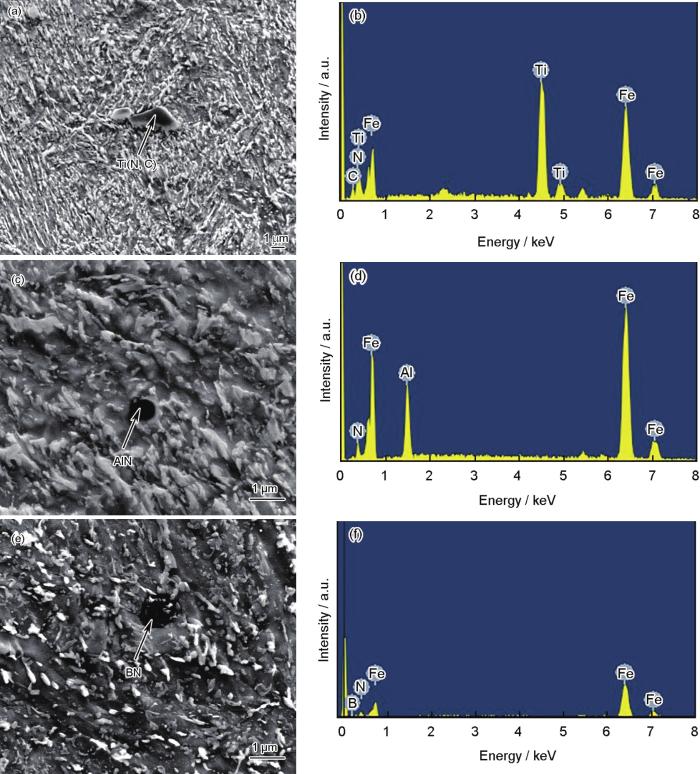

通过XRD定性分析可知,2#钢中析出相主要为M3C、M(C, N)和AlN,其中M3C相组成结构式为(Fe0.973Mn0.008Cr0.015Mo0.004)3C,M(C, N)相组成结构式为(Ti0.869Mo0.085Cr0.046)(C0.249N0.751);3#钢中的析出相主要为M3C、BN和AlN,其中M3C相组成结构式为(Fe0.971Mn0.007Cr0.016Mo0.006)3(C0.999B0.001),如图8所示。析出相的SEM像如图9所示。2#钢中的Ti(C, N)析出相呈不规则形状,有2条较为平直的边,长边尺寸约1.8 μm,短边约1.3 μm,形成的析出相尺寸较大;3#钢中AlN和BN析出相均呈圆形,尺寸约500 nm。

图8

图9

图9

2#和3#钢析出相形貌和EDS分析

Fig.9

SEM images (a, c, e) and EDS analyses (b, d, f) of Ti(C, N) (a, b), AlN (c, d), BN (e, f) precipitated in 2# steel (a, b) and 3# steel (c~f)

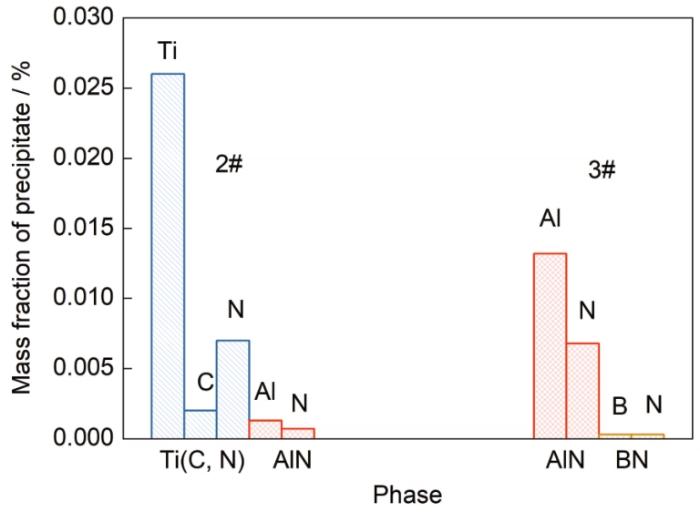

相的定量分析结果如图10所示。2#钢中,Ti(C, N)中有质量分数为0.0026%的Ti用于固氮,固溶的Al含量为0.0387%,占钢中Als含量的94%;3#钢中,参与形成析出相的Al含量为0.0132%,固溶的Al含量为0.0608%,参与形成析出相的B含量为0.0004%,固溶的B含量为0.0008%,占添加B含量的66.7%,可显著提高钢的淬透性。

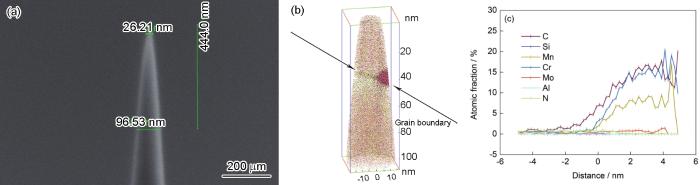

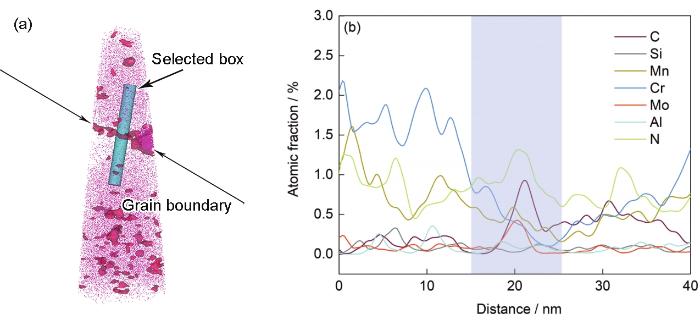

图10

3DAP可以在原子层面上对材料中不同元素进行分析,得出金属样品在纳米尺度空间的不同元素的分布图,定性、定量考察元素分布变化[42,43]。为进一步研究合金元素对钢淬透性的作用,通过3DAP测得针尖处金属元素分布(不含Fe)及含量,如图11所示,其中单个元素的原子空间分布如图12所示。图11a为针尖试样SEM像,图11b为试样采集区(30 nm×30 nm×100 nm)除Fe之外其它元素的分布,样品中C、Si、Mn、Cr、Mo、Al、N的原子分数分别为0.46%、0.06%、0.87%、1.19%、0.12%、0.08%、0.63%,在针尖中上部包含一条晶界,且在晶界处右上部出现元素大规模偏聚,其中C、Mn、Cr偏聚最为明显,Mo次之;这是由于Cr、Mo均为强碳化物形成元素,容易与C发生共偏聚,形成碳化物析出相。而Si、Al、N原子由于是非碳化物形成元素,故偏聚于析出相外。由图11c可知,在碳化物存在处C、Mn、Cr的原子浓度最大值分别为20.0%、17.5%、20.4%。

图11

图11

含晶界针尖试样以及通过3DAP测得针尖处金属元素含量

Fig.11

Needle tip samples with grain boundary (a) and three-dimensional spatial distribution of alloy element atoms (b), metal element content at the needle tip (c) measured by 3DAP

Color online

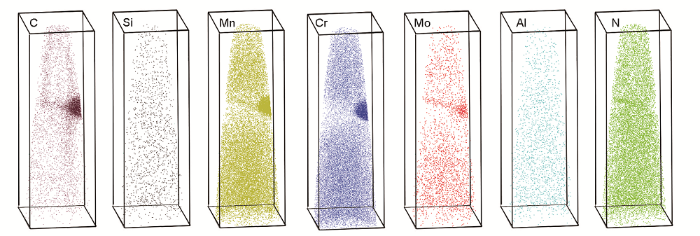

图12

图12

2#钢各元素在3D空间的分布

Fig.12

Element distributions of 2# steel in 3D space

Color online

对图12中Mo原子分布进行三维原子重构,得到Mo原子分数为0.4%的等浓度面空间分布,如图13a所示。在图13a取穿过晶界的直径5 nm×40 nm的微区进行分析,各元素含量分布如图13b所示,横坐标20 nm附近即晶界所在区域,可见在晶界处N、Mn、Mo、C原子含量升高,存在偏聚现象,与图12的元素在三维空间的分布情况吻合。Mn、Mo元素在晶界处偏聚,抑制铁素体珠光体的形核与长大,导致过冷奥氏体等温转变曲线铁素体珠光体区C曲线显著右移,使得42CrMo钢具有良好的淬透性能。而Al元素在钢中未见明显偏聚,弥散分布于基体中,可以抑制基体C的扩散,从而抑制贝氏体的转变[44],进一步提高42CrMo钢的淬透性。

图13

图13

晶界处元素在3D空间的分布

Fig.13

Distribution of elements at grain boundaries in 3D space

Color online

(a) isoconcentration surface with 0.4%Mo (atomic fraction)(b) content of each element in the diameter 5 nm×40 nm micro-region across the grain boundary

4 结论

(1) 在钢中配合添加Al-Ti、Al-B元素,明显提高了钢的淬透性,可实现大截面试样56 mm之内全部淬透,心部获得90%以上马氏体组织,并获得良好的拉伸性能(Rm≥1220 MPa)和低温冲击性能(KV2≥27 J)。

(2) Ti的添加可以发挥固氮的效果,使94%Al固溶于钢中,提高钢的淬透性;Al在钢中添加含量为0.074%,有0.0132%的Al参与AlN形成,使有效添加B含量达到0.0008%,其余Al固溶于钢中,与B共同提高钢的淬透性。

(3) 3DAP实验结果显示,Mn、Mo元素在晶界处的偏聚抑制铁素体珠光体转变,从而使钢具有良好的淬透性;Al在钢中弥散分布,抑制钢中C的扩散,从而抑制了贝氏体的转变,提高钢的淬透性。

参考文献

Analysis of tempering treatment on material properties of DIN 41Cr4 and DIN 42CrMo4 steels

[J].

Study of the effects of high temperatures on the engineering properties of steel 42CrMo4

[J].

Embrittlement of bolts made of the 25Cr2Mo1V steel after long exposure at 540 ℃

[J].Bolts made of the 25Cr2Mo1V steel become gradually embrittled with increas-ing fraction of intercrystalline fracture after long exposure (more than 40000hours) at 540℃. This is found to be caused by the segregation of phosphorus upto 8 at% at austenitic grain boundaries accompanying the depletion of molybdenumin ferrite down to about 0.3% owing to the formation of a molybdenum-contain-ing carbide Fe_3Mo_3C (M_6C). Reheating of the embrittled bolts to 680℃ removes the segregation of phos-phorous at the grain boundaries and therefore also the intercrystalline embrittle-ment. However, the molybdenum content of ferrite is further lowered to about 0.2%and its scavenging effect for phosphorous is thus greatly lost, therefore the embrit-tling tendency of these bolts during reuse is enhanced. Even after requenchingand tempering, the service life of these bolts is still shortened, owing possibly tothe inhomogeniety of molybdenum in austenite not removed by the reaustenitizingtreatment.

25Cr2Mo1V钢螺栓在540℃长期使用中变脆的研究

[J].25Cr2Mo1V钢螺栓在540℃长期使用(40000h以上)中变脆是由于含Mo的Fe_3Mo_3C(M_6C)缓慢析出,使铁素体中的Mo含量降低到0.3%Mo左右,不足以抑制P向晶界扩散并富集到8at-%P的程度,从而产生沿晶脆断. 已经变脆了的螺栓经680℃保温处理虽然可以消除P在晶界的富集及沿晶脆断,但是由于铁素体中Mo含量进一步降低到0.2%左右,螺栓在二次使用过程中的变脆倾向加剧.即使再次进行淬火回火处理,可能由于淬火并不能完全去除奥氏体中Mo的不均匀性,螺栓在二次使用时寿命较短.

Ultra-high cycle fatigue behavior of a novel 1.9 GPa grade super-high-strength maraging stainless steel

[J].

A novel low cost 2000 MPa grade ultra-high strength steel with balanced strength and toughness

[J].

Development and application of high strength steel for bolts

[J].

高强度螺栓钢的研制与应用

[J].

Tensile stress relaxation of turbine bolt steels at high temperature

[J].

Effect of heat treatment on delayed fracture resistance of structural steel 42CrMo

[J].

热处理对42CrMo钢的耐延迟断裂性能的影响

[J].对42CrMo钢进行了淬火回火处理和等温淬火处理,探讨热处理工艺对高强度钢的耐延迟断裂性能的影响.缺口拉伸实验表明,与淬火回火相比,等温处理后42CrMo钢在抗拉强度为1500 MPa级时具有优良的耐延迟断裂性能.组织观察发现,42CrMo钢等温处理后由下贝氏体组成,ε-碳化物分布在贝氏体板条内部,原奥氏体晶界无碳化物,因而耐延迟断裂性能较好.随等温温度的降低,贝氏体板条变细,强度增加,耐延迟断裂性能也提高.可见,通过等温处理获得下贝氏体组织是改善1500 MPa级合金结构钢的耐延迟断裂性能的一种有效途径.

Fatigue properties and failure analysis of connection bolt in wind power application

[D].

风电连接螺栓疲劳性能及其失效分析

[D].

Hot deformation behavior of a new nuclear use reduced activation ferritic/martensitic steel

[J].

Fracture analysis of high strength bolt for wind power unit

[J].

风电机组用高强度螺栓断裂分析

[J].

Effect of aluminizing on hardenability of steel (S45C)

[J].

Influence of alloying elements and microstructure on the hardness of 42CrMo steel

[J].

合金元素及显微组织对42CrMo钢硬度的影响

[J].

Influence of microalloying elements on microstructure and mechanical properties of 42CrMo steel

[J].

微合金化元素对42CrMo钢组织与性能的影响

[J].

Influence of tempering temperature on the microstructure and mechanical properties of a Cr-Ni-Mo-alloyed steel for rock drill applications

[J].

Arrangement of collective B12 atoms in the crystal structure of γ-Fe and effect of boron on the hardenability of Steel

[J].

Microstructure and mechanical properties of the microalloyed 42CrMo steels with Ti and B

[J].

Ti、B微合金化42CrMo钢的组织与性能

[J].

Improvement of hardenability and toughness of SCM440 with addition of Al

[J].

Alを活用したSCM440の焼入性ならびに焼入焼戻し材の靭性の改善

[J].

Effect of wTi/wN and wAl on hardenability and mechanical properties of B-containing steels

[J].

wTi/wN和wAl对含B钢淬透性及力学性能的影响

[J].针对具有不同wTi/wN的低Al- Ti- B系列和高Al- B试验钢进行末端淬火试验和调质热处理试验,通过淬透性曲线、热力学计算、组织和力学性能的对比分析,研究了wTi/wN和Al含量对含B调质钢淬透性及力学性能的影响。结果表明,低Al- Ti- B系列钢的wTi/wN大于342时,Ti能有效地固N保B提高淬透性,但过高的wTi/wN又容易形成粗大的TiN颗粒降低韧性;wTi/wN小于342时,Ti固N的能力有限,多余的N易与B结合形成BN降低淬透性;试验钢中较合适的wTi/wN为393,保证了较高的淬透性和综合力学性能。高Al- B钢中较高的Al含量(0083%,质量分数)起到了固N保B的效果,其淬透性最好,能获得全厚度马氏体组织,具有高的强韧性。此外,钢中过高的N含量易与Ti、B结合形成对淬透性和韧性不利的粗大TiN和BN颗粒,为确保含B调质钢的淬透性和强韧性,应严格控制钢中的N含量。

Effect of alloying element Al on hardenabilitity and mechanical properties of micro-B treated ultra-heavy plate steels

[J].Utilizing Jominy end quenching test, chemical phase analysis and thermo- dynamical calculation, study of the effect of alloying elements on hardenability and mechanical properties of a B-bearing ultra-heavy plate steel was carried out. The results showed that small amount of Ti addition could form TiN for its much higher bonding ability than B, fixing N element and thus making B free. Normal Al content failed to prevent BN from precipitating due to the weaker competition for N than B. However, when Al content was increased as high as 0.07%, the competition of Al for N was distinctly improved, making solid-solution B increased. For proper chemical combination of B and N- fixing element, hardenability was increased and accordingly both microstructure and mechanical properties were improved so that the quantity and size of martensite/austenite (M/A) islands and granular bainite were decreased markedly, and low-temperature impact toughness and tensile properties were improved by a large degree. The calculation was in a good accord with experimental results.

合金元素Al对微B处理特厚钢板淬透性及力学性能的影响

[J].采用顶端淬火、化学相分析和热力学计算, 研究了合金元素对含B特厚钢板淬透性和力学性能的影响. 结果表明, 由于Ti与N的结合力远高于B, 微量Ti的加入(0.015%, 质量分数, 下同)可形成TiN, 固定N元素, 使B游离, 提高淬透性. 常规Al含量(0.02%)对N的竞争力略低于B, 无法阻止BN的析出; 增加Al含量至0.07%以上, 可提高Al对N的结合力, 固溶B含量增加, 可同样起到提高淬透性的作用. 通过B和固氮元素的组合, 促进淬透性的提高, 可使含B特厚钢板心部的显微组织状态显著改善, 粒状贝氏体数量降低, 马氏体/奥氏体(M/A)岛组分尺寸减小, 低温冲击韧性和强度均有明显提高.

Applications of TEM and 3DAP to measurement of phase diagrams

[J].

EBSD study on the significance of carbon content on hardenability

[J].

Coincidence doppler broadening and 3DAP study of the pre-precipitation stage of an Al-Li-Cu-Mg-Ag alloy

[J].AbstractPre-precipitation solute clustering in Al–Li–Cu–Mg–Ag and Al–Cu–Mg–Ag alloys has been investigated by coincidence Doppler broadening (CDB) spectroscopy of positron annihilation and three-dimensional atom probe (3DAP) analysis. Although Ag–Mg co-clusters form in the Al–Cu–Mg–Ag alloy in the early stage of aging, no evidence for the co-cluster formation was obtained from the Li containing alloy using 3DAP. While CDB spectra indicated that vacancies are associated with Ag after aging for 15 s in the Al–Cu–Mg–Ag alloy, vacancy–Ag association is suppressed in the Li containing alloy. Based on the 3DAP and CDB results, the reasons for the completely different clustering behaviors observed in these two similar alloys are discussed.]]>

Study on Cu precipitate of the low C high strength steel containing Cu and Ni during isochronal tempering

[J].followed by water quenching, and tempered isochronally for 60 min at different temperatures. The hardness was conducted, the microstructure and Cu precipitate were analyzed by HRTEM and APT. During tempering, Cu precipitation happened, Cu precipitate Moire fringe formed and the Cu precipitate transformed to fcc structure; the lath boundary gradually bulged out and migrated, a repeat of bulging and migration of local parts of lath boundary resulted in migration of the whole boundary, and lath martensite transformed to equiaxed ferrite finally. At 500℃, the strengthening peaked by Cu precipitates. During 400-500℃, the number of Cu clusters changed greatly when the Cu isoconcentration set at different values, this indicated that the Cu precipitates were on the stage of nucleation; while the number of Cu clusters changed little during 500-650 ℃, this indicated that the Cu precipitates were on the stage of coarsening. The Cu, C, Mo and P segregated at the grain boundary. The boundary could provide Cu solutes and nucleation sites for Cu precipitation, leading to the segregation of Cu clusters at the grain boundary. The Ni, Mn and Al segregated at the heterophase interface between Cu precipitate and ferrite matrix forming a core-shell structure.]]>

含Cu和Ni低碳高强度钢等时回火析出富Cu相的研究

[J].HRTEM和三维原子探针(3DAP)对含Cu和Ni低碳高强度钢等时回火析出的富Cu相进行了研究.结果表明: 回火过程中,基体发生软化, 富Cu相析出, 板条状马氏体逐渐转变成多边形状铁素体; 在500 ℃时富Cu相强化作用达到最大值; 设置不同的Cu等浓度值时, 在400-500 ℃富Cu相的数量变化幅度大, 在500-650 ℃富Cu相的数量基本不变; 在晶界处发生C, Mo, P和Cu的偏聚; 晶界处Cu浓度高于基体, 为富Cu相的形核和长大提供了有利条件; 在析出的富Cu相与基体的过渡层上发生Ni, Mn和Al的偏聚, 这些偏聚元素与富Cu相核心共同形成核-壳结构.]]>

TEM and 3DAP characterization of an age-hardened Mg-Ca-Zn alloy

[J].

Application of hardenability concepts in heat treatment of steel

[J].

Solid-state diffusion bonding of NbSS/Nb5Si3 composite using Ni/Al and Ti/Al nanolayers

[J].

Element segregation and solidification behavior of a Nb, Ti, Al Co-strengthened superalloy ЭК151

[J].

Effect of grain size on hardenability of gear steel

[J].

齿轮钢晶粒尺寸对淬透性的影响

[J].

Effect of trace Co on the hardenability of 7085 aluminum alloy

[J].

The effect of stress on bainite transformation, microstructure, and properties of a low-carbon bainitic steel

[J].

Austenitizing temperature and hardenability of low-carbon boron steels

[J].

Incomplete bainite transformation accompanied with cementite precipitation in Fe-1.5(3.0)%Si-0.4%C alloys

[J].Steels containing bainite microstructure are widely applied in various industrial areas. Incomplete bainite transformation is frequently used to control volume fraction of retained austenite as well as its stability and is also closely related to bainite growth mechanism. It is generally accepted that incomplete bainite transformation could occur when carbide precipitation is absent. On the other hand, some new studies revealed that carbide with very fine size were observed in “carbide-free” bainite in Si added steels. Our previous study on bainite isothermal transformation kinetics together with its microstructural evolution with Fe-1.5(3.0)%Si-0.4%C alloys (mass fraction) at 400~500 ℃ found incomplete bainite transformation phenomenon for the 3.0Si alloy at 450 ℃ and for two alloys at 400 ℃. In contrast with the generally accepted view, cementite precipitation with Si depletion was observed at the beginning of incomplete transformation stage. Further analysis on three dimension atom probe results revealed that the carbide volume fraction as well as amount of C atoms in carbide hardly changes during incomplete transformation stage. Thermodynamic analysis revealed that small chemical driving force for cementite precipitation and/or the necessity of Si partition are two factors accounting for the extremely slow cementite precipitation kinetics. It is thus proposed that incomplete bainite transformation and carbide precipitation could co-exist. Conditions for incomplete bainite transformation are modified as follows. Firstly, bainitic ferrite growth is stopped before reaching equilibrium fraction. In addition, carbide precipitation should be absent or its kinetics should be slow enough.

Fe-1.5(3.0)%Si-0.4%C合金贝氏体不完全转变现象及伴随的渗碳体析出

[J].从热力学、动力学角度对Fe-1.5(3.0)%Si-0.4%C (质量分数)合金在400~500 ℃等温贝氏体相变过程中的贝氏体不完全转变阶段可以出现渗碳体析出的现象进行了深入分析。结果表明,贝氏体不完全转变阶段渗碳体的析出动力学非常缓慢。热力学分析表明,缓慢的渗碳体析出动力学与其很小的化学驱动力和/或渗碳体析出需要Si原子配分有关。证实了贝氏体不完全转变现象可以伴随有碳化物析出,但碳化物析出动力学在贝氏体不完全转变阶段需要非常缓慢。

Effects of tempering temperature on the impact toughness of steel 42CrMo

[J].42CrMo heat-resistant steel is a kind of structural steel, which is widely used in structural components such as crane weight-on-wheel; automobile crank shaft, locomotive gear hub and so on, for its good hardening ability, high temperature strength, good creep resistance, and little quenching deformation. However; in industry application; mismatching between the strength and the toughness always occurs for 42CrMo structure components. In order to solve the problem that the strength does not match the toughness in the manufacturing process for the polar crane for the nuclear power station; the effect of tempering temperature on the morphology and distribution of carbides and the impact toughness has been investigated for steel 42CrMo in this study. The experimental results indicated that the microstructure of the quenched steel 42CrMo after 500-650 degrees C tempering was characterized by tempering sorbite. As the tempering temperature increased, the Charpy absorbed energy at -12 degrees C initially increased and then decreased. The flake carbides after 500 and 530 degrees C tempering are not evenly distributed on the original martensite boundaries, the Charpy absorbed energy are 26 and 44 J, respectively. While the granular carbides are evenly distributed in the microstructure after 600 degrees C tempering; the Charpy absorbed energy reaches a maximum value of 104 J. When the tempering temperature is higher than 600 degrees C, granular carbides coarsened obviously and the Charpy absorbed energy reduced notably. The morphology and distribution of carbides is the key factor that influences the impact toughness of steel 42CrMo. Morphology and structure analysis for the carbide was carried out by TEM together with EDS analysis, the results showed that the carbide after tempering treatment is (Fe, M)(3)C and Fe, Cr, Mo are the main alloy element in the carbide. When the tempering temperature is in the range of 560-600 degrees C, the uniformly-distributed granular carides forrns on the matrix and the impact toughness is over 60 J. As the tempering temperature continues increasing, the carbides will coarsen and the impact toughness will decrease. In order to obtain the good strength and toughness matching, for 42CrMo structure, it is recommended that the tempering temperature should be in the range of 550-590 degrees C.

回火温度对42CrMo钢冲击韧性的影响

[J].以核电站环形起重机用42CrMo耐热钢为研究对象, 分析了显微组织中碳化物形貌和分布随回火温度的变化及其对冲击韧性的影响.结果表明, 42CrMo钢经水淬后在500-650 ℃区间回火, 显微组织均为回火索氏体.随回火温度上升, -12 ℃冲击功先增加后减小; 经500和530 ℃回火后, 片状碳化物不均匀分布于原马氏体板条界上, 冲击功分别为26和44 J; 600 ℃回火后碳化物呈颗粒状弥散分布, 冲击功达到峰值104 J; 600 ℃以上回火, 颗粒状碳化物明显粗化,冲击功下降.碳化物的形貌和分布是影响42CrMo钢冲击性能的关键因素.

Investigation of the correlation between thermal properties and hardenability of Jominy bars quenched with air-water mixture for AISI 1050 steel

[J].

3DAP investigation of precipitation behavior of Cu-rich phase in Super304H heat resistant steel

[J].Super304H austenitic heat resistant steel is based on 18/8 Cr-Ni stainless steel alloyed mainly with 3%Cu and a small amount of Nb combined with N, which is used as superheater/reheater tubes in ultra-super critical (USC) power plants all over the world, due to its good combination of elevated temperature strength with hot corrosion resistance. The excellent high temperature strengths of this steel are mainly contributed by the precipitation strengthening effect of fine Cu-rich phase. Comprehensive study of the characteristic of Cu-rich phase is very important to understand strengthening effect on this steel. However, the Cu-rich phase is very fine< and difficult to be detected at the beginning of precipitation. In this paper, three dimensional atom probe (3DAP) was used to study the early stage of precipitation behavior and the composition change in Cu-rich phase of Super304H aged at 650℃ for different times after solution treatment at high temperature. Cu-rich phase is formed from Cu-rich segregated rigion by the concentration of Cu atoms in it at very beginning stage of aging. Homogeneously distributed Cu-rich phase precipitates with about 1 nm radius are obviously detected after aging at 650℃ for 5 h. With increasing aging time, Cu-rich phase is growing slowly while other elements in the Cu-rich phase decreased obviously. The copper element has almost concentrated to 90\% in the center part of Cu-rich phase after 500 h aging. The homogenous distribution of fine Cu-rich phase in austenitic matrix effects excellent hardening with increasing aging time. The stability of fine Cu-rich phase is one of the most important reasons for keeping good strength of Super304H heat resistant steel at high temperature.

3DAP研究Super304H耐热不锈钢中富Cu相的析出行为

[J].利用三维原子探针(3DAP)研究了超超临界电站锅炉过热器/再热器管材Super304H在650℃时效富Cu相的析出行为. 结果表明, 富 Cu相的析出经历了富Cu原子偏聚区的快速形成以及Cu原子不断聚集到富Cu偏聚区中而渐变形成富Cu相. 富Cu相的析出速率极快, 时效仅5 h富Cu相已明显析出. 随时效时间的延长在富Cu相中逐步排斥出其它元素, 使Cu原子成为富Cu相的主要组成元素. 时效500 h富Cu相中Cu原子的浓度已经达到90%, 时效1000 h富Cu相仍然保持纳米级的尺度且均匀分布, 对Super304H耐热不锈钢具有非常好的强化作用.

Carbon segregation behavior of high-carbon high-alloy steel during deep cryogenic treatment using 3DAP

[J].23C6 carbide combined with other alloy element. This is one of the main reasons increasing the wear resistance of tool steels.]]>

3DAP研究高碳高合金钢深冷处理过程的C偏聚行为

[J].23C6型碳化物.]]>