金属基复合材料(MMCs)具有高强度、高硬度和抗磨损等优异的综合性能,在航空航天、电子科技和国防军工等领域的应用日益增多。然而,微米级增强体在提高金属基体强度的同时,往往牺牲了其塑性,且导致MMCs的可加工性变差[1,2]。近年来,纳米增强体强化轻合金复合材料以其轻质、高强、耐热以及减震、吸声、光催化[3]、电磁屏蔽等多功能特性成为研究热点。然而,由于纳米增强体尺寸小、比表面能高,与微米尺寸的增强体相比,更容易发生团聚,难以在金属基体中实现均匀分散。因而,实现纳米增强体的构型设计和可控制备更加困难,严重限制了纳米增强体强化轻合金复合材料的应用[4,5]。提升纳米增强体分散性和实现构型调控的同时,改善纳米增强体与基体的界面结合,是纳米增强体强化轻合金复合材料研究的重要挑战。

1 纳米陶瓷颗粒增强体

1.1 外加法

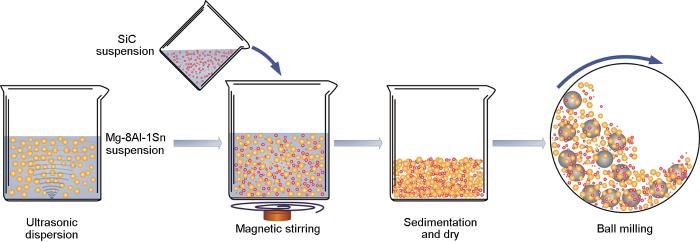

Li等[8]和Wang等[9,10]采用溶剂辅助加机械球磨的方法(图1),成功将纳米SiCp均匀分散于Mg-8Al-1Sn (体积分数,%)基体中。通过较低的制备温度,抑制界面处Al4C3脆性相的产生,实现SiC和基体的紧密结合。所得复合材料在室温下的拉伸强度(381 MPa)和延伸率(8.3%)分别提升了19.8%和84.4% (表1[8,10,11,12,13,14,15,16,17,18,19])。Mobasherpour等[11]对纳米Al2O3颗粒和7075Al复合粉末进行高能球磨处理,破坏增强体表面的氧化膜,同时有效提升了Al2O3在基体中的分散性,同时将Al基体晶粒细化至32 nm。所得复合材料Brinell硬度由128 HB提升到204 HB,同时拉伸强度(443 MPa)较7075Al合金提升了60.5%。

图1

图1

溶剂辅助分散加机械球磨法制备SiC/Mg-8Al-1Sn纳米复合粉末示意图

Fig.1

Schematic of the fabrication procedure for SiC/Mg-8Al-1Sn nanomaterials reinforced light metal matrix composites (LMMCs) powers by the combination of solvent-assistant dispersion and mechanical ball milling

表1 不同纳米增强体强化轻合金复合材料的力学性能[8,10,11,12,13,14,15,16,17,18,19]

Table 1

Architecture | Material (volume fraction / %) | Processing | E GPa | UTS MPa | YS MPa | δ % | Ref. |

|---|---|---|---|---|---|---|---|

| Homogeneous | 0.5SiC/Mg-8Al-1Sn | PM+hot extrusion | - | 381 | 239 | 8.3 | [8] |

| Mg-8Al-1Sn | - | - | 318 | 175 | 4.5 | [8] | |

| 0.8SiC/2014Al | PM+hot extrusion | 73.5 | 573 | 378 | 9.0 | [10] | |

| 2014Al | PM+hot extrusion | 71.6 | 513 | 310 | 12.5 | [10] | |

| 5Al2O3/7075Al | Mechanical alloying | - | 443 | - | 2.1 | [11] | |

| 3CNT/Al | FPM+HEBM | 91.0 | 406 | - | 8.8 | [12] | |

| Al | FPM | 70.6 | 245 | - | 15.8 | [12] | |

| 1.5CNT/Al-Zn-Mg-Cu | FPM-SSBM | 78.0 | 698 | 695 | 4.4 | [13] | |

| (8.15TiB+1.25TiC+0.59La2O3)/Ti | In situ synthesized | 129.5 | 1298.5 | 1170.8 | 4.2 | [14] | |

| Ti | In situ synthesized | 112.8 | 1051.1 | 934.3 | 10.2 | [14] | |

| (1.2TiC+2.5TiB+1.3Nd2O3)/Ti | In situ synthesized | - | 1150 | - | 1.0 | [15] | |

| Laminated | 5TiBw/Ti | Reaction hot pressing | - | 617 | 497 | 24.5 | [16] |

| 1.5RGO/Al | FPM | 87 | 302 | - | 5.3 | [17] | |

| 3D network | (5TiB+5TiC)/Ti64 | Reaction hot pressing | - | 1267 | 1153 | 6.1 | [18] |

| Ti64 | Reaction hot pressing | - | 944 | 823 | 13.0 | [18] | |

| Two-scale network | (4Ti5Si3+3.4TiBw)/Ti64 | Reaction hot pressing | - | 1180 | 1050 | 5.0 | [19] |

需要指出的是,优化球磨工艺参数可以提升纳米陶瓷增强体的分散性,破坏增强体表面的氧化膜,是解决外加法中纳米增强体分散性和界面问题的有效方法。

1.2 原位内生法

Song等[22]采用自蔓延高温合成(SHS)法制备了增强体尺寸小于200 nm的TiC/Al复合材料。发现增加Al粉含量会在点火过程中消耗更多的热量,从而降低燃烧温度,避免了温度过高导致的TiCp粗化。Zhou等[23]选用碳纳米管(carbon nanotube,CNTs)作C源以增强C的扩散,用Al-Cu合金代替纯Al作为基体以降低SHS制备过程中的温度,成功获得了尺寸小于100 nm且均匀弥散分布的TiCp。所得复合材料拉伸强度(540 MPa)和延伸率(19.0%)较基体合金分别提升了11%和188%。Xiao等[21]采用Al-K2TiF6-KBF4反应体系制备了TiB2/AZ91复合材料,所得TiB2平均尺寸小于100 nm,且分布均匀、界面结合良好,因而复合材料的拉伸强度(237 MPa)和延伸率(11.8%)较基体金属分别提升了25.5%和51.1%。Nampoothiri等[20]将原位法制得的Al-4.4Cu/TiB2合金进行重熔,之后进行高能超声处理,成功将TiB2尺寸由800 nm细化至23 nm。由于增强体尺寸下降,复合材料的压缩屈服强度(119 MPa)提升至Al-Cu合金的2倍。

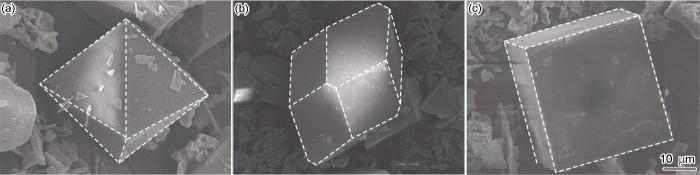

图2

图2

Al-20%Mg2Si (质量分数)中初生Mg2Si三维形貌图

Fig.2

Typical FESEM images of primary Mg2Si in Al-20%Mg2Si (mass fraction) alloys

(a) octahedron (b) truncated octahedron (c) cube

总之,控制增强体的尺寸是原位法制备纳米陶瓷强化轻合金复合材料的关键问题,通过使用新型C源提升C的扩散,提升基体含量或引入第二金属相以降低反应温度,可以防止制备过程中增强体粗化,获得纳米级陶瓷颗粒增强体。

2 碳纳米材料增强体

Fan等[12]针对CNTs/Al复合材料,通过片状粉末冶金的方式增加Al表面积以引入高含量(3%,体积分数)的CNTs;采用亲水聚乙烯醇(PVA)对纳米Al片进行表面改性,改善界面结合;通过短时(2 h)高能球磨减少对CNTs结构的破坏。复合材料拉伸强度(406 MPa)和延伸率(8.8%)较浆料分散所得复合材料分别提升了36%和363% (表1[8,10,11,12,13,14,15,16,17,18,19]),强度提升的同时,极大地保证了材料的塑性。Xu等[13]采用片状粉末冶金-变速球磨法相结合的方式制备了CNTs/Al复合材料。高速球磨过程中的粉末冷焊增强了界面结合;纳米Al片有利于位错运动,提升了合金的位错存储和加工硬化能力。所得复合材料的屈服强度为695 MPa,同时延伸率仍可保持在4.4% (表1[8,10,11,12,13,14,15,16,17,18,19])。Gao等[30]使用表面富含阴离子的氧化石墨烯(graphene oxide,GO)和阳离子表面活性剂(CABT水溶液)改性后的纳米Al片制备了GN/Al复合材料,通过静电自组装实现GO在纳米Al片表面均匀弥散分布。0.3%GN/Al (质量分数)复合材料的拉伸强度(110 MPa)较纯Al提升了30%。

可见,通过表面改性改善增强体和基体的界面结合,同时使用片状粉末冶金法配合湿磨法、变速球磨、短时高能球磨等方式在保持碳纳米增强体分散性的同时,避免破坏其纳米结构,是制备高强韧碳纳米材料强化轻合金复合材料的有效途径。

3 多元多尺度复合增强

Yang等[14,15]采用熔铸法制备了微米级TiBw和TiCp以及纳米级La2O3颗粒协同强化的钛基复合材料。由于纳米增强体的Orowan强化和晶须的增韧作用,复合材料的拉伸强度(1170.8 MPa)比单一TiC强化的复合材料提升了13% (表1[8,10,11,12,13,14,15,16,17,18,19])。Saba等[31]使用机械搅拌和火花等离子烧结(SPS)技术制备了TiC/CNTs双重强化铝基复合材料,在基体中均匀分散的CNTs和纳米TiCp显著提高了复合材料的Vickers硬度(88 HV),与基体金属相比提升了149%。TiC/CNTs双重强化可将陶瓷颗粒的强化优势与CNTs裂纹桥联、抑制裂纹扩展、限制位错运动等强化特点相结合,产生双重强化效果。

设计颗粒/颗粒、颗粒/晶须、颗粒/CNTs、纳/微双尺度等混杂增强的复合材料时,选择合适的增强体含量配比,调控不同形貌增强体的分布,有可能最大限度地发挥各组元的增强优势;另外,将碳纳米增强体与纳米陶瓷颗粒增强体的优势结合,可制备出更高性能的轻合金复合材料。

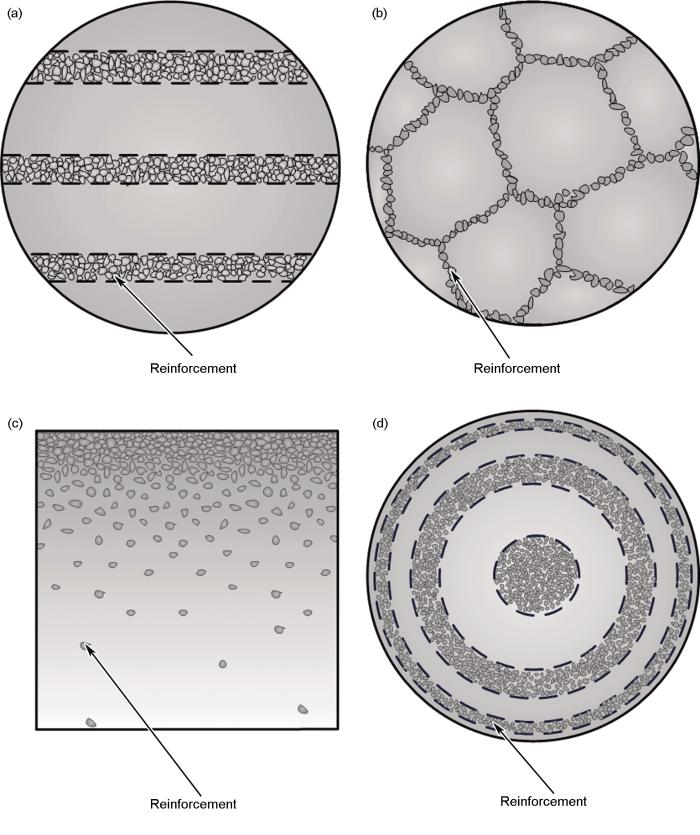

4 复合材料构型设计

设计复合材料微观构型可以突破纳米增强体强化轻合金复合材料的强韧性倒置关系瓶颈,获得高韧性复合材料,或制备满足特殊工况的多功能轻合金复合材料[7]。常见的纳米增强体强化轻合金复合材料构型设计包括层状构型、网状构型、梯度构型以及在此3种构型基础上构建的环状构型、仿砖构型等。

4.1 层状构型

图3

图3

4种典型的纳米增强体强化轻合金复合材料构型设计

Fig.3

Schematics of nanomaterials reinforced LMMCs with different architecture designs

(a) laminated (b) 3D network (c) functionally graded (d) macro-ring

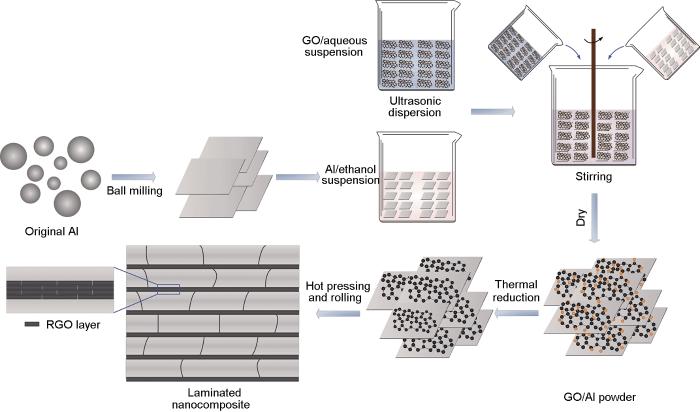

Launey等[35]模仿贝壳结构,使用冰膜法和定向冷冻法,将冰/Al2O3悬浮液定向凝固,预先制备陶瓷支架,随后浸渗Al-Si合金熔体,成功制备了Al2O3/Al-Si仿生微叠层复合材料。Zhang等[36]和Wang等[32]使用同样的方式制备了TiC/Al层状复合材料,发现层状结构中的多重裂纹可以阻碍裂纹扩展,且粗糙陶瓷层表面的树突有效协调了层间的剪切应力,复合材料具有优异的弯曲强度(500 MPa),较纯Al提升了356%。Jiang等[33]采用片状粉末冶金法制备了Al2O3/Al复合粉末,通过粉末自组装使片状复合粉末定向排列为纳米微叠层结构。片状Al晶粒不易长大,因而叠层结构较为稳定。长条状Al有利于位错的存储和运动,可同时提升复合材料的强度(拉伸强度262 MPa)和塑性(延伸率22.9%)。与冰膜法相比,片状粉末冶金法可以通过灵活调控Al片厚度和增强体分布,简单有效地实现复合材料强韧化。Wu等[34]采用反应热压烧结法制备了TiBw/Ti层状复合材料。发现拉伸过程中复合材料内部形成的高密度、离散分布的微裂纹,能有效抑制应变局部化,降低复合材料对早期裂纹的敏感性,延伸率(8%)较均质构型提升了约20倍。反应热压法制备层状复合材料时,层片间原位合成的TiBw可以钉扎和桥接界面,形成强界面结合,但在层厚小于400 μm时容易造成层厚不均匀,需准确调控层厚,以获得良好的强塑性匹配[17]。Li等[17]使用纳米Al片吸附GO,通过氧化还原法和粉末自组装法制备了仿生微叠层构型的还原氧化石墨烯(RGO)/Al复合材料(图4)。微叠层可以减少RGO的结构破坏,且界面结合良好,有利于载荷传递和位错运动,复合材料具有良好的强塑性匹配(拉伸强度302 MPa,延伸率5.3%)。

图4

图4

片状粉末冶金法制备层状构型还原氧化石墨烯/Al纳米复合材料示意图

Fig.4

Schematic of the fabrication of RGO/Al nanocomposites with a bioinspired nanolaminated structure by flack power metallurgy (GO—graphene oxide)

层状构型可以很好地协调纳米增强体强化轻合金复合材料的强塑性,采用冰膜法、片状粉末冶金法、反应热压烧结法等调控微叠层层厚,强化界面结合,充分实现材料致密性,是制备高性能层状构型纳米增强体强化轻合金复合材料的有效途径。

4.2 网状构型

Yang等[37]使用SPS烧结制备了增强体呈连续三维网状分布的Ti2AlC/TiAl纳米复合材料,发现晶界处增强体富集可以提升复合材料的强度;同时晶内大量塑性良好的基体金属区域可以保证材料的塑性。复合材料压缩变形时,屈服强度、断裂强度分别高达2058 MPa和2217 MPa,远高于均质构型复合材料(表1[8,10,11,12,13,14,15,16,17,18,19])。Huang等[18]将纳米B4C颗粒嵌入大尺寸Ti6Al4V颗粒(40~70 μm)的周围,呈准连续网状分布在基体周围,SPS烧结后形成三维网状构型的(TiBw+TiC)/Ti6Al4V复合材料。由于纳米TiBw的增韧效应及其对晶界的强化效应,复合材料拉伸强度达到1267 MPa,延伸率保持在6.1%,较好地实现了强塑性匹配的问题。

网状构型的纳米增强体强化轻合金复合材料可以实现复合材料强塑性理想匹配,提高复合材料的高温承载能力。晶须贯穿相邻晶粒从而形成三维网状构型复合材料是构型设计的新思路,通过调控晶须的种类和体积分数,可以制备出高强度、耐高温的网状构型轻合金复合材料,提高合金的极限使用温度。另外,由于纳米增强体在高温下依然具有高的稳定性,在大变形过程中对金属基体晶粒长大有较强的抑制作用,因而复合材料表现出良好的组织稳定性[39]。

4.3 梯度构型

Watanabe等[3]通过离心混合粉末法(CMPM),使纳米SiC和TiO2陶瓷颗粒集中分布在材料表面,制备了SiC/Cu和TiO2/Al梯度复合材料。表面富集的增强体有效提高了复合材料的表面硬度;由于纳米级TiO2颗粒的光催化效应,复合材料可应用于生物医学或建筑材料等领域。Jamian等[40]在大离心力条件下使用CMPM方法制备了Al/SiC梯度空心圆柱,实现了SiC从圆柱内表面到外表面的梯度分布。CMPM或重力铸造是制备功能梯度复合材料的有效方法,但增强体与金属基体的界面结合较差。Watanabe等[3]指出,SHS配合CMPM可以制备界面结合良好的梯度复合材料。重力铸造、增材制造、磁力搅拌等方法也可以用于制备梯度纳米增强体强化轻合金复合材料[41]。

由于纳米增强体优异的强化效果以及电、光、热等方面的物理化学特性,梯度构型可以实现纳米增强体强化轻合金复合材料的局部强化或功能化,或使2种金属、构型自然过渡。在更多构型设计中引入梯度复合强化的思路,是实现纳米增强体强化轻合金复合材料结构功能一体化的重要方式。

4.4 其它构型

基于仿生设计新的复合材料构型,通过搭建纳米微柱、多尺度增强、局部强化等方式优化已有的构型或将几种构型相叠加,制备层状-网状、网状-梯度等构型的复合材料,可以进一步提升复合材料的强塑性。

5 展望

随着纳米技术的不断进步和轻量化的迫切需求,纳米增强体强化轻合金复合材料的研究和应用领域也逐步扩大。从材料的应用层面来看,纳米增强体强化轻合金复合材料是纳米材料、信息技术、能源技术、先进制造等领域不可或缺的组成部分。为进一步提升纳米增强体强化轻合金复合材料的综合性能,推进其研发和产业化,研究者仍需从以下方面做出努力:

(1) 高强塑纳米增强体强化轻合金复合材料的可控制备。目前纳米增强体强化轻合金复合材料的研究主要集中在提升增强体的分散性和界面结合等方面,针对轻金属基体组织的关注较少,使用等通道挤压(ECAP)、高压扭转(HPT)、搅拌摩擦(FSP)、大压下量控轧等变形方法,将金属基体细化为超细晶或纳米晶组织,研究超细晶基体的高强度、超塑性和组织稳定性。发展以纳米材料作为增强体、以超细晶或纳米晶轻金属为基体的复合材料,有望开发具有高温超塑性、室温高强度的轻质金属基复合材料。

(2) 开发新型多元多尺度混杂增强轻合金复合材料。目前在混杂增强的轻合金复合材料中,增强体的引入多依赖外加法,对于原位混杂强化轻合金复合材料的研究仍局限于现象观察。另外,对于混杂强化过程中增强体之间耦合作用和混杂强化机理等仍需进一步探索。采用原位法实现混杂增强轻合金复合材料的可控制备,揭示混合增强中增强体的协同强化机理,是制备更高性能、更多新功能的纳米增强体强化轻合金复合材料的重要设计思路。

(3) 优化已有构型纳米增强体强化轻合金复合材料。目前已有复合材料构型中在致密性、界面结合、耐磨性等方面仍然存在挑战。针对已有构型中的共性问题,通过先进的表征手段,如透射电镜、聚焦离子束、三维原子探针等技术,研究局部增强体含量以及构型设计中结构参数对协调变形和强韧性的影响规律,设计和优化现有的复合材料构型,是纳米增强体强化轻合金复合材料的重要研究方向。

(4) 发展具有新型构型纳米增强体强化轻合金复合材料。发展新的制备技术,使复合材料构型更接近自然结构。采用增材制造等方式构建分层支架,制备具有定制微结构的复合材料。将构型设计和纳米增强体特有的电、光、热学特性相结合,通过涂层、多层叠加、梯度复合等方式实现纳米增强体强化轻合金复合材料局部强化和功能化,实现复合材料的结构功能一体化是新型纳米复合材料发展的重要趋势。

参考文献

Microstructural and mechanical characteristics of in situ metal matrix composites

[J].During the past decade, considerable research effort has been directed towards the development of in situ metal matrix composites (MMCs), in which the reinforcements are formed in situ by exothermal reactions between elements or between elements and compounds. Using this approach, MMCs with a wide range of matrix materials (including aluminum, titanium, copper, nickel and iron), and second-phase particles (including borides, carbides, nitrides, oxides and their mixtures) have been produced. Because of the formation of ultrafine and stable ceramic reinforcements, the in situ MMCs are found to exhibit excellent mechanical properties. In this review article, current development on the fabrication, microstructure and mechanical properties of the composites reinforced with in situ ceramic phases will be addressed. Particular attention is paid to the mechanisms responsible for the formation of in situ reinforcements, and for creep failure of the aluminum-based matrix composites.

Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets

[J].One-dimensional carbon nanotubes and two-dimensional graphene nanosheets with unique electrical, mechanical and thermal properties are attractive reinforcements for fabricating light weight, high strength and high performance metal-matrix composites. Rapid advances of nanotechnology in recent years enable the development of advanced metal matrix nanocomposites for structural engineering and functional device applications. This review focuses on the recent development in the synthesis, property characterization and application of aluminum, magnesium, and transition metal-based composites reinforced with carbon nanotubes and graphene nanosheets. These include processing strategies of carbonaceous nanomaterials and their composites, mechanical and tribological responses, corrosion, electrical and thermal properties as well as hydrogen storage and electrocatalytic behaviors. The effects of nanomaterial dispersion in the metal matrix and the formation of interfacial precipitates on these properties are also addressed. Particular attention is paid to the fundamentals and the structure roperty relationships of such novel nanocomposites.

A Novel fabrication method for functionally graded materials under centrifugal force: The Centrifugal mixed-powder method

[J].One of the fabrication methods for functionally graded materials (FGMs) is a centrifugal solid-particle method, which is an application of the centrifugal casting technique. However, it is the difficult to fabricate FGMs containing nano-particles by the centrifugal solid-particle method. Recently, we proposed a novel fabrication method, which we have named the centrifugal mixed-powder method, by which we can obtain FGMs containing nano-particles. Using this processing method, Cu-based FGMs containing SiC particles and Al-based FGMs containing TiO2 nano-particles on their surfaces have been fabricated. In this article, the microstructure and mechanical property of Cu/SiC and Al/TiO2 FGMs, fabricated by the centrifugal mixed-powder method are reviewed.

Interfacial reaction mechanism between matrix and reinforcement in B4C/6061Al composites

[J].61Complicated interfacial reactions occurred in B4C/6061Al composites.61Reactions involving Mg and Si were divided into oxidation of Mg and other reactions.61Al/B4C reaction produced free B and then activated B/Mg reactions.61B/Mg reactions rather than Mg oxidation were main reasons for Mg consumption.61Interfacial reactions definitely deteriorate age-hardening ability of composites.

Strain partitioning behavior of in situ Ti5Si3/TiAl composites

[J].For a particle-reinforced composite, strain attribute at both sides of the interface is a critical factor influencing the mechanical properties. Here, we applied transmission electron microscope (TEM) and geometrical phase analysis (GPA) to Ti 5 Si 3 /TiAl composites, and demonstrated that strain compatibility and geometric continuity of these two components primarily relied on interfacial shear deformation. This approach is expected to be applied in other traditional composites for nanoscale strain analysis and performance optimization.

Grain refinement and superplastic behavior of carbon nanotube reinforced aluminum alloy composite processed by cold rolling

[J].

Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal?

[J].Since the 1960s, it has been a common practice worldwide to pursue a homogeneous distribution of reinforcements within a matrix material, discontinuous metal matrix composites (DMMCs) in particular. Taking an overview of the worldwide activities in DMMC research, despite many favourable attributes such as improved specific strength, stiffness and superior wear resistance, DMMCs with a homogeneous microstructure tend to exhibit a very low room temperature damage tolerance even with a highly ductile matrix material such as aluminium. In this review, a range of uniquely multi-scale hierarchical structures have been successfully designed and fabricated by tailoring reinforcement distribution for DMMCs in order to obtain superior performance. A variety of specific microstructures that were developed in Al, Mg, Cu, Fe, Co and TiAl matrices indicate that there must be adequate plastic regions among the reinforcements to blunt or deflect cracks if one wants to toughen DMMCs. Following this path, aided by theoretical analyses, the most recent success is the design and fabrication of a network distribution of in situ reinforcing TiB whiskers (TiBw) in titanium matrix composites (TMCs), where a tailored three-dimensional (3D) quasi-continuous network microstructure displays significant improvements in mechanical properties. This resolves the brittleness surrounding TMCs fabricated by powder metallurgy. It is the large reinforcement-lean regions that remarkably improve the composite ductility by bearing strain, blunting the crack and decreasing the crack-propagation rate. The fracture, strengthening and toughening mechanisms are comprehensively elucidated in order to further understand the advantages of such an inhomogeneous microstructure, and to justify the development of novel techniques to produce such inhomogeneous microstructures. This approach opens up a new horizon of research and applications of DMMCs and can be easily extended to general multi-phase composites with enhanced physical and mechanical properties.

Fabrication of nano-SiC particulate reinforced Mg-8Al-1Sn composites by powder metallurgy combined with hot extrusion

[J].Nano-SiC particulates (n-SiCp) reinforced Mg-8Al-1Sn (AT81) composites with different volume fractions (0, 0.25, 0.5 and 1.002vol.%) were fabricated by powder metallurgy process (P/M) combined with hot

Aging behavior of nano-SiC/2014Al composite fabricated by powder metallurgy and hot extrusion techniques

[J].The aging-hardening kinetics of powder metallurgy processed 2014Al alloy and its composite have been studied. The existence of n-SiC particulates leads to the increase of peak hardness. Interestingly, the aging-hardening peak of the composite takes place at earlier time than that of the unreinforced alloy. Transmission electron microscopy (TEM) studies indicated that the major precipitation phases are Al5Cu2Mn3and θ′ (Al2Cu). Besides, Ω phase appeared in both specimens at peak hardening condition, which has been rarely observed previously in aluminum metal matrix composites without Ag. Accelerated aging kinetics and increased peak hardness may be attributed to the higher dislocation density resulted from the mismatch of coefficients of thermal expansion between n-SiC and 2014Al matrix. The results are beneficial to fabricating high performance composites for the application in automobile field such as pistons, driveshaft tubes, brake rotors, bicycle frames, railroad brakes.

Effect of nano-SiC content on mechanical properties of SiC/2014Al composites fabricated by powder metallurgy combined with hot extrusion

[J].Nano-SiC particulates (n-SiCp) reinforced 2014Al matrix composites with different reinforcement volume fractions (0, 0.25, 0.5 and 1 vol.-%) were fabricated by powder metallurgy combined with hot extrusion. The effect of volume fraction of n-SiCp on mechanical properties of composites was studied at both ambient and elevated temperatures. The increase of n-SiCp content led to an increase in yield strength (YS) and ultimate tensile strength (UTS) and a slight decrease in elongation which is much better than the composites reinforced with micro-SiCp. The 0.5 vol.-% n-SiCp/2014Al composite observed the highest YS and UTS of 090804378 and 090804573 MPa at room temperature and of 090804303 and 090804409 MPa at 473 K. The enhancement of the properties is suggested to be induced by uniformly dispersed and well-bonded n-SiCp reinforcements as well as the age-hardening effect of the more and finer precipitates.

Effect of nano-size Al2O3 reinforcement on the mechanical behavior of synthesis 7075 aluminum alloy composites by mechanical alloying

[J].Reinforcing aluminum matrix with much smaller particles, submicron or nano-sized range, is one of the key factor in producing high-performance composites, which yields improved mechanical properties. High-energy ball milling was successfully employed to synthesize nano-crystalline Al7075 alloy powders reinforced with 1, 3 and 5 vol.% Al2O3 at nano-size level. Hot pressing was employed to consolidate the green powder metallurgy products. The nano-composite powders were characterized by SEM, TEM, and XRD. Using Williamson-Hall equation, crystallite size and lattice strain of various Al7075 composite powders were estimated with broadening of XRD peaks. XRD results showed that the crystallite size of aluminum reached 42.30, 36.25 and 32.22 nm, respectively, after 20 h milling in case of Al7075/1, 3, and 5 vol.% Al2O3 nano-composite powder with uniform particle size distribution. TEM observation confirmed the nano-crystalline nature of Al7075/5 vol.% Al2O3 milled powder. Mechanical measurements showed that the hardness and ultimate tensile strength of the Al7075-nano Al2O3 tend to increase with increasing nano Al2O3 volume content at the expense of tensile ductility. (C) 2012 Elsevier B.V. All rights reserved.

Enhanced interfacial bonding and mechanical properties in CNT/Al composites fabricated by flake powder metallurgy

[J].A flake powder metallurgy route consists of a slurry based dispersion process and a short time ball milling process was proposed to fabricate strong and ductile CNT/Al composites reinforced with high content CNTs. To improve the interfacial bonding, the CNT/Al nanoflake powders prepared through slurry based dispersion process would go through a short time high energy ball milling process to break native Al 2 O 3 skin and embed CNTs into Al matrix. With the dispersion homogeneity and well-maintained structural integrity of CNTs achieved by the slurry based dispersion, and improvement of interfacial bonding from non-bonding to physical bonding/diffusion assisted bonding and partial reaction bonding through the short time ball milling, an enhancement of tensile strength from 298 to 40662MPa and ductility from 1.9 to 8.8% was obtained for the 262h ball-milled 362vol.% CNT/Al composites, compared to the composites fabricated by sole slurry based dispersion process. It also outperformed that fabricated by direct high energy ball milling, indicating the flake powder metallurgy method could provide a good coordination between the CNT dispersion homogeneity, structural integrity and interfacial bonding.

High-strength CNT/Al-Zn-Mg-Cu composites with improved ductility achieved by flake powder metallurgy via elemental alloying

[J].The uniform dispersion of carbon nanotubes (CNTs) is usually accompanied by severe grain refinement of Al matrix, which leads to the low ductility of CNT/Al alloy composites. To accommodate this dilemma, a flake powder metallurgy route via elemental alloying was proposed to fabricate CNT/Al-Zn-Mg-Cu composites with improved ductility and high strength. CNT/Al flake powders were firstly obtained by ball milling at a low speed to achieve uniform dispersed of CNTs, and then milled with Zn, Mg and Cu elemental flake powders at a high speed to achieve lamellar CNT/Al-Zn-Mg-Cu particles, which were consolidated and homogenized to obtain bulk CNT/Al-Zn-Mg-Cu composites. Compared with the CNT/AA7075 counterparts fabricated by directly using CNTs and atomized AA7075 powders, the CNT/Al-Zn-Mg-Cu composites exhibited improved ductility with high modulus and strength, due to the well-protected and uniformly aligned CNTs, and good dislocation storage capability of the elongated ultrafine grains.

Microstructure and mechanical property of in situ synthesized multiple-reinforced (TiB+TiC+La2O3)/Ti composites

[J].

In situ synthesis of hybrid and multiple-dimensioned titanium matrix composites

[J].A novel hybrid and multiple-dimensioned ceramic particles (TiB, TiC and Nd 2O 3) reinforced titanium matrix composites were in situ synthesized utilizing the reaction between Ti, C, Nd and B 2O 3 through homogeneously melting in a non-consumable vacuum arc remelting furnace. The thermodynamic of in situ synthesis reaction was analyzed. The phases in the composites were identified by X-ray diffraction (XRD). The microstructures of the composites were observed by means of scanning electron microscopy (SEM), backscattered electron microscopy and second-electron microscopy. Three kinds of reinforcements were found in the titanium matrix: micron-sized TiB whiskers, micron-sized TiC particles and both micron-sized and nano-sized Nd 2O 3 particles. Reinforcements were homogeneously distributed in the matrix. (TiB + TiC + Nd 2O 3)/Ti composites obtained higher mechanical property than TiC/Ti composites.

Fracture behaviors and microstructural failure mechanisms of laminated Ti-TiBw/Ti composites

[J].A range of laminated Ti–TiBw/Ti composites with layer thicknesses of 300μm, 400μm and 500μm were successfully fabricated by reaction hot pressing. The stress–strain curve of the laminated composites with 300μm layer thickness exhibits superior tensile elongation (24.5%) and similar strength compared with the laminated composites with 400μm and 500μm layer thicknesses. The higher elongation is characterized by a prolonged strain softening stage and “non-catastrophic fracture” behavior. The fractography of laminated Ti–TiBw/Ti composites comprises two fracture modes; Ti layers exhibit shear fracture with many shear bands accompanying with micro-voids. However, TiBw/Ti composite layers reveal ductile fracture initiated by nucleation, growth and coalescence of micro-cracks. The difference on fracture mechanisms between Ti layer and TiBw/Ti composite layer is determined by the TiBw reinforcement, while high elongation of the laminated Ti–TiBw/Ti composites with thinner layer thickness is probably attributed to the effective size effect. Meanwhile, with the increase of stress and strain during the plastic deformation process, Ti layer and TiBw/Ti composite layer reveal interaction and mutual competing fracture damage behaviors.

Enhanced mechanical properties of graphene (reduced graphene oxide)/aluminum composites with a bioinspired nanolaminated structure

[J].

High tensile-strength and ductile titanium matrix composites strengthened by TiB nanowires

[J].A three-dimensional network-woven architecture made of TiB nanowires has been designed and realized in the matrix of a Ti6Al4V alloy. The architecturally nanostructured design was achieved by dispersing nanoparticles of B 4 C or B onto the surfaces of spherical Ti6Al4V powder particles via mechanical mixing and subsequent consolidation by spark plasma sintering. The as-sintered nanostructured Ti6Al4V-TiB composites demonstrated excellent tensile strengths and ductility that are required for critical applications. The in situ formed TiB nanowires with aspect ratios up to 300 contributed to the high tensile strengths while the architectural design of the TiB nanowires ensured the good tensile ductility.

Effects of Ti5Si3 characteristics adjustment on microstructure and tensile properties of in-situ (Ti5Si3+TiBw)/Ti6Al4V composites with two-scale network architecture

[J].

Post in-situ reaction ultrasonic treatment for generation of Al-4.4Cu/TiB2 nanocomposite: A route to enhance the strength of metal matrix nanocomposites

[J].

Microstructure, mechanical properties and strengthening mechanisms of Mg matrix composites reinforced with in situ nanosized TiB2 particles

[J].In this work, Mg matrix composites reinforced with 2.5 wt% nanosized TiB2 particles are fabricated by adding Al-TiB2 master alloy prepared by the chemical reaction of Al-K2TiF6-KBF4 system into molten magnesium. The size distribution of TiB2 particles extracted from the master alloy and their effects on the microstructure and mechanical properties of AZ91 matrix are investigated. The results show that the TiB2 particles display a dominant number of particles less than 100 nm and a uniform distribution in the composites. Also, the grain size of composites is decreased compared with AZ91 alloy. The high resolution TEM reveals that the interface between nanosized TiB2 particles and matrix is clear and bonds well. Besides, the yield strength, ultimate tensile strength and elongation to fracture of composites are improved by 49.4%, 25.5% and 51.1% respectively. Among the strengthening mechanisms of nanosized particles reinforced Mg matrix composites, dislocation strengthening and Orowan strengthening play a more important role in increasing the strength. It is noteworthy that the elongation to fracture of the composites is higher than that of AZ91 matrix, which is contrary to other works.

In situ fabrication of TiC particulates locally reinforced aluminum matrix composites by self-propagating reaction during casting

[J].TiC ceramic particulates locally reinforced aluminum matrix composites were successfully fabricated via self-propagating high-temperature synthesis (SHS) reaction of Al–Ti–C system during aluminum melt casting. The SHS reaction could be initiated when Al contents in the green compacts ranged from 20 wt.% to 40 wt.%. With increasing Al contents, the ignition delay time was prolonged and the adiabatic combustion temperature was lowered. Using XRD and DSC analysis, the SHS reaction characteristic was discussed. The result showed that Al serves not only as a diluent but also as an intermediate reactant participating in the SHS reaction, determining the reaction process and its final producsts. The SEM images revealed a relatively uniform distribution and nearly spherical morphology of TiC particulates in the locally reinforced region, and excellent adhesion and gradient distribution between the TiC particulates reinforced region and Al-matrix. The size of the TiC particulates decreased obviously with increasing Al contents in the blends.

The nano-sized TiC particle reinforced Al-Cu matrix composite with superior tensile ductility

[J].The high mechanical properties of the TiC particle reinforced Al–Cu matrix composites are highly desirable for a wide range of critical applications. However, a long-standing problem for these composites is that they suffer from low ductility and limited formability. Here we fabricated the nano-sized TiC particle reinforced Al–Cu matrix composites by dispersing the nano-sized TiC particles into molten Al–Cu alloy. The tensile strength and ductility were significantly improved with the addition of the nano-sized TiC particles. The tensile strength and elongation of the 0.5wt% nano-sized TiC particle reinforce Al–Cu matrix composite can reach to 540MPa and 19.0%, increased by 11.08% and 187.9% respectively, than those of the Al–Cu matrix alloy (485MPa and 6.6%).

Morphology evolution of primary Mg2Si in Al-20Mg2Si-0.1Ca alloys prepared with various solidification cooling rates

[J].

Refinement and modification of primary Mg2Si in an Al-20Mg2Si alloy by a combined addition of yttrium and antimony

[J].

The influence of Li on the tensile properties of extruded in situ Al-15%Mg2Si composite

[J].

Enhanced ductility in an Al-Mg2Si in situ composite processed by ECAP using a modified BC route

[J].A modified BC route, noted as BC-m, was designed and employed to process an Al g2Si composite in an effort to improve the ductility of the composite. The modification was implemented to improve the effectiveness of particle redistribution of the conventional BC route while maintaining its high grain refinement efficiency. The experimental results demonstrated that route BC-m was strongly effective in redistributing particles while maintaining a comparable microstructural refinement efficiency relative to route BC, which led to an increase in ultimate tensile strength and much higher ductility in the composite. Additionally, the use of route BC resulted in higher yield strength because of its stronger work-hardening effect compared to route BC-m.

Effect of heat treatment on microstructure and mechanical property of Al-10%Mg2Si alloy

[J].

Progress on multi-dimensional carbon nanomaterials reinforced aluminum matrix composites: A review

[J].以铝基复合材料为代表的金属基复合材料,具有高的比强度、比模量及优异的导热、导电性能,在航空航天、汽车制造、机械电子及其它民用领域具有广泛的应用前景。近年来,碳纳米相作为复合材料的增强体凭借其优异的力学性能和物理性能以及自身结构特点,引起人们极大关注而成为铝基复合材料研究领域的新热点。本文从不同维度结构的碳纳米相(零维碳纳米洋葱、一维碳纳米管、二维石墨烯等)为增强相的角度,概述了这些碳纳米相增强铝基复合材料的制备方法及其在力学性能方面的研究进展,阐述了从单一相增强到多元多维度混杂增强的铝基复合材料在力学性能方面的优势,旨在阐明通过碳纳米相的结构设计和空间构筑实现高强韧性铝基复合材料的设计思路,并展望了高强韧轻金属基复合材料未来的研究趋势。

多维度碳纳米相增强铝基复合材料研究进展

[J].以铝基复合材料为代表的金属基复合材料,具有高的比强度、比模量及优异的导热、导电性能,在航空航天、汽车制造、机械电子及其它民用领域具有广泛的应用前景。近年来,碳纳米相作为复合材料的增强体凭借其优异的力学性能和物理性能以及自身结构特点,引起人们极大关注而成为铝基复合材料研究领域的新热点。本文从不同维度结构的碳纳米相(零维碳纳米洋葱、一维碳纳米管、二维石墨烯等)为增强相的角度,概述了这些碳纳米相增强铝基复合材料的制备方法及其在力学性能方面的研究进展,阐述了从单一相增强到多元多维度混杂增强的铝基复合材料在力学性能方面的优势,旨在阐明通过碳纳米相的结构设计和空间构筑实现高强韧性铝基复合材料的设计思路,并展望了高强韧轻金属基复合材料未来的研究趋势。

Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites

[J].The development of novel nanomaterials brings new opportunity and challenge for high sensing detection of biomolecules. The authors describe the preparation of 3-dimentional hollow graphene balls (3D HGBs) using nickel nanoparticles (Ni-NPs) as the template. The Ni-NPs were synthesized by chemical reduction of nickel chloride and then graphene was coated onto their surface via carburization... [Show full abstract]

Exploring the reinforcing effect of TiC and CNT in dual-reinforced Al-matrix composites

[J].

Developing high toughness and strength Al/TiC composites using ice-templating and pressure infiltration

[J].

A flake powder metallurgy approach to Al2O3/Al biomimetic nanolaminated composites with enhanced ductility

[J].O/Al composites. Nanoflake Al powders with native AlO skins were used as building blocks to rapidly assemble into biomimetic nanolaminated structures via compacting and extrusion, giving rise to strong and ductile composites with tensile strength of 26202MPa and plasticity of 22.9%. Thus, it is evidenced that well-balanced strength and ductility can be achieved in biomimetic metal–matrix composites by flake PM.

Fracture behavior and strain evolution of laminated composites

[J].Laminated composites consisting of alternating layers of TiB w /Ti and Ti(Al) were prepared, and exhibited a superior elongation to fracture that is nearly 20 times higher than that of bulk TiB w /Ti composites. Coupling two- and three-dimensional fracture characterizations of TiB w /Ti-Ti(Al) laminated composites show distinct fracture characteristics including crack distribution, formation of tunnel cracks, and suppression of crack propagation. These experimentally observed fracture characteristics are intimately correlated with in situ monitored strain evolution process, by which we observed that strain localization is effectively suppressed by laminated structure, thus lowering the stress intensity near the crack tip as well as the driving force for crack propagation. As a consequence, laminated composites are not so sensitive to the early cracking, and exhibit a good strength-ductility combination.

A novel biomimetic approach to the design of high-performance ceramic-metal composites

[J].Abstract The prospect of extending natural biological design to develop new synthetic ceramic-metal composite materials is examined. Using ice-templating of ceramic suspensions and subsequent metal infiltration, we demonstrate that the concept of ordered hierarchical design can be applied to create fine-scale laminated ceramic-metal (bulk) composites that are inexpensive, lightweight and display exceptional damage-tolerance properties. Specifically, Al(2)O(3)/Al-Si laminates with ceramic contents up to approximately 40 vol% and with lamellae thicknesses down to 10 microm were processed and characterized. These structures achieve an excellent fracture toughness of 40 MPa radicalm at a tensile strength of approximately 300 MPa. Salient toughening mechanisms are described together with further toughening strategies.

Preparation of nacre-like composites by reactive infiltration of a magnesium alloy into porous silicon carbide derived from ice template

[J].

Effect of spark plasma sintering temperature on the microstructure and mechanical properties of a Ti2AlC/TiAl composite

[J].The effect of spark plasma sintering (SPS) temperature on the microstructure and mechanical properties of a bulk ultrafine structured Ti 2AlC/TiAl composite prepared by SPS of a mixture of mechanically alloyed Ti–Al powder with a composition of Ti–50Al (at%) and 10 vol% carbon nanotubes (CNTS) has been investigated. X-ray diffraction analysis showed that the sintered bulk material mainly composed of γ-TiAl and Ti 2AlC phases. The microstructures of the samples were examined using scanning electron microscopy and transmission electron microscopy. It was found that when an SPS temperature of 950 °C was used, the bulk Ti 2AlC/TiAl composite had a high density of 98.3%, and a microstructure consisting of a continuous interpenetrating network of Ti 2AlC phase and equiaxed TiAl grains with an average size of 300 nm. The compressive yield strength and hardness of the sintered samples reached 2058 MPa and 6.12 GPa respectively. With increasing the SPS temperature up to 1150 °C, the TiAl grains became significantly coarsened, leading to clearly reduced mechanical properties.

Effects of volume fraction on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with novel network microstructure

[J].In order to better understand the relationship of structure echanical properties of TiBw/Ti6Al4V (TiBw/Ti64) composites with a network microstructure and deduce the upper limit of TiBw volume fraction, the effects of volume fraction on the microstructure and tensile properties were further investigated. The equation calculating the optimal and maximum volume fractions of reinforcement for the composites with a network microstructure was deduced. For the present system, the optimal and maximum volume fractions were verified to be 5.1vol.% and 10.2vol.%, respectively, by calculation, microstructure observation, tensile properties. When the volume fraction was equal and lower than 5.1vol.%, the coarse TiBw formed, or else, the fine TiBw, the cluster TiBw and the block TiBw, even unhealed pores formed. The tensile strength of TiBw/Ti64 composites increases and then hastily decreases, while the ductility keeps on decreasing with increasing volume fractions of TiBw reinforcement.

Current research and future prospect on microstructure stability of superplastic light alloys

[J].金属材料超塑性一般要求具有均匀细小的等轴晶粒,并且在高温超塑变形过程中能够保持晶粒尺寸稳定性,避免晶粒快速长大。轻合金的超塑性不仅要具备等轴细晶组织,还需要通过引入第二相或合金元素等来保证材料的高温组织稳定性,这也是当前金属材料超塑性的研究热点之一。目前提高超塑性材料细晶组织稳定性的策略主要包括:析出第二相粒子钉扎晶界,双相合金的相结构之间抑制彼此生长,复合材料的增强体抑制晶粒长大以及单相合金的溶质原子偏聚等。本文概述了含析出第二相合金、双相合金、金属基复合材料和单相合金等轻合金超塑性组织稳定性的研究现状,并从工业应用需求及降低生产成本的角度,提出了超塑性材料的发展趋势。

超塑性轻合金组织稳定性的研究进展及展望

[J].金属材料超塑性一般要求具有均匀细小的等轴晶粒,并且在高温超塑变形过程中能够保持晶粒尺寸稳定性,避免晶粒快速长大。轻合金的超塑性不仅要具备等轴细晶组织,还需要通过引入第二相或合金元素等来保证材料的高温组织稳定性,这也是当前金属材料超塑性的研究热点之一。目前提高超塑性材料细晶组织稳定性的策略主要包括:析出第二相粒子钉扎晶界,双相合金的相结构之间抑制彼此生长,复合材料的增强体抑制晶粒长大以及单相合金的溶质原子偏聚等。本文概述了含析出第二相合金、双相合金、金属基复合材料和单相合金等轻合金超塑性组织稳定性的研究现状,并从工业应用需求及降低生产成本的角度,提出了超塑性材料的发展趋势。

Formation of compositional gradient in Al/SiC FGMs fabricated under huge centrifugal forces using solid-particle and mixed-powder methods

[J].

Design for additive manufacturing with site-specific properties in metals and alloys

[J].[Display omitted]

Using Mg and Mg-nanoAl2O3 concentric alternating macro-ring material design to enhance the properties of magnesium

[J].The overall aim of engineering design is to improve on technology and way of life. Here, we show how the tensile properties of magnesium have been improved using concentric alternating macro-ring design. Specifically, Mg-nanoAl 2O 3 layered hybrid nano-composites were fabricated. These nano-composites were then hot extruded into fairly concentric hybrid alternating Mg and Mg-nanoAl 2O 3 macro-ring structures (having stressed micro-interface). We also show the first instance of mechanical property improvement by careful simultaneous design of macrostructure and microstructure in a composite. Here, we focus on the effects of varying the thickness of the pre-extrusion layers. The 0.2%YS, UTS and ductility of the ring structured hybrid nano-composites peaked at 3 mm pre-extrusion layer thickness, where the corresponding properties of monolithic Mg were significantly inferior in comparison. Further, our method of ring structured hybrid composite synthesis may possibly enable significant reduction in time and cost of manufacturing superconducting cables. [All rights reserved Elsevier].

Strengthening and toughening mechanisms in graphene-Al nanolaminated composite micro-pillars

[J].Uniaxial compression tests were carried out on micro-pillars fabricated from nanolaminated graphene (reduced graphene oxide, RGO)-Al composites of different RGO concentrations and laminate orientations (the angle between laminate planes and the pillar axis). It was found that the strengthening capability of RGO can be enhanced by either orienting the RGO layers parallel with the loading direction or raising the RGO concentration. The stress train response of the micro-pillars was populated with discrete bursts, and the stress increments of the bursts scaled with the RGO concentration, regardless of the laminate orientation relative to the loading direction. These observations were interpreted by the variation in the load-bearing capacity of RGO in different laminate orientations, the dislocation annihilation at the RGO/Al interface, and a crack deflection mechanism provided by the robust RGO/Al interface that toughened the composites. This work underscores the importance of structural design and control in the stiffening, strengthening, and toughening of metal matrix composites, and the methodology developed may be applied to other composites with microstructural heterogeneity to probe their specific mechanical behaviors and structure-property correlations.