自20世纪初以来,具备低矫顽力(Hc)和高比饱和磁化强度(Ms)等优良性能的软磁材料(soft magnetic materials,SMMs)已在发电和变电领域得到广泛应用。随着对高机械负载条件下(如超高速电机中)软磁材料应用需求的提高,具有优良软磁性能的新型软磁材料也应具有良好的力学性能,如高屈服强度和高延展性等。目前广泛应用的传统软磁材料(如硅钢)无法很好地满足这些要求。多组元中/高熵合金(multicomponent medium/high-entropy alloys)具有可调控的微观结构和优异的物理化学性能,为新型金属材料的研究和开发提供了广阔的成分空间,逐渐成为众多材料科学研究者关注的热点[1~5]。单相fcc结构[6]的等原子比FeCoNi中熵合金具有良好的延展性[7],较高的Ms (160 A·m2/kg)和Curie温度(720 ℃)[8]。以FeCoNi中熵合金为基础,通过进一步合理添加合金元素而开发的多组元高熵合金(例如Fe32.6Ni27.7Co27.7Ta5.0Al7.0,%,原子分数)[9]可实现优异的磁学与力学性能匹配[9~18],有望作为高性能软磁材料发挥重要应用价值。

优良的力学与磁学性能匹配由合金的成分和微观结构共同决定。一般来说,合金的Ms主要与合金成分有关,力学性能和Hc则受到微观组织的显著影响。研究表明,通过引入Mn和Cu[11]、Mn和Al[10,14]、Cr和Si[16]、Cu和Si[17]、Al和Si[18]或Al和Cu[15,19]等元素组合来调控FeCoNi基多组元合金的微观组织可以有效地提高合金的强度,并一定程度上保留合金的软磁性能。其中,利用纳米析出相强化[5,7,9,13]或弥散氧化物强化[20]等机制可将其屈服强度提高至1 GPa以上。然而,众多非铁磁性元素的加入往往会降低合金的Ms[13],从而限制该类合金的实际应用。例如,在FeCoNi基体中引入7%Al (原子分数,下同)和5%Ta可在合金的fcc基体中诱导产生共格有序的L12纳米析出相,使合金的屈服强度(σy)和抗拉强度(σu)分别提升至1202和1526 MPa,但Ms下降近一半(88 A·m2/kg)[13]。

综合考虑上述背景,在避免外加非铁磁性元素降低合金Ms的前提下,本工作利用热机械处理方法在块体FeCoNi中熵合金中引入异构组织,在保持较低矫顽力的同时,优化强塑性匹配,实现力学与软磁性能较好的平衡。块体金属材料中的异构通常由硬度或强度差异较大的微观结构单元组成[21],主要包括层级组织[21,22]、双峰组织[23,24]和梯度组织[25]等。在部分再结晶的层级组织中,再结晶区(recrystallized zone,RZ)具有较低的位错密度,强度较低,但塑性较好;未再结晶区(non-recrystallized zone,NRZ)的高密度位错可显著提高合金强度,但会降低塑性[26]。值得注意的是,位错和晶界等缺陷往往会钉扎磁畴壁的运动,导致Hc升高,不利于实现优良的软磁性能。目前,关于异构对合金软磁和力学性能的协同影响仍然缺乏系统的认识。本工作采用微观结构表征和宏观力学与磁学性能测试,并结合对磁畴运动过程的原位动态磁光Kerr成像分析,系统研究异构等原子比FeCoNi中熵合金的软磁和力学行为,揭示与宏观行为对应的微观机理,为后续新型高强韧软磁合金的组织调控和性能优化提供参考。

1 实验方法

实验对象为等原子比FeCoNi中熵合金。采用块状纯Fe、Co和Ni (纯度约为99.9%)为原料,经真空电弧熔炼后获得铸态合金。将铸态合金在900 ℃下热轧,压下量为50% (厚度从10 mm下降到5 mm);然后将合金在1200 ℃下进行真空均匀化处理,保温2 h,水冷淬火;将均匀化处理后的合金板条在室温冷轧,压下量为60% (厚度从5 mm下降到2 mm)。利用电火花线切割机在冷轧合金板材上切取不同形状和尺寸的样品,分别在不同温度(550、600和650 ℃)下退火30 min,水冷淬火。最后对不同温度下退火的样品进行组织表征和性能测试。

采用D/max 2550 X射线衍射仪(XRD)对样品的相组成进行分析,扫描范围在30°~100°之间,扫描速率为4°/min。电子通道衬度(ECC)成像和电子背散射衍射(EBSD)分析在CLARA GMH型扫描电镜(SEM)上完成。软磁性能测试采用外径25 mm、内径20 mm、高度2 mm的圆环样品在Linkjoin MAST-2010SD型软磁直流测试装置上进行,外加最大磁场20000 A/m。磁畴运动过程的动态表征在Evico Magnetics/em-Kerr-Highres型磁光Kerr显微镜上进行,外加面内磁场范围0~70 mT。拉伸力学测试在CMT4104万能试验机上进行,拉伸应变速率为1 × 10-3 s-1,并采用数字图像关联(DIC)技术测定拉伸过程中样品上的局部应变。拉伸时采用矩形横截面试样,标距段长度8 mm、宽度2.5 mm、厚度1.5 mm。为保证数据结果的可重复性,每组实验在同等条件下重复3次。

2 实验结果与讨论

2.1 合金组织

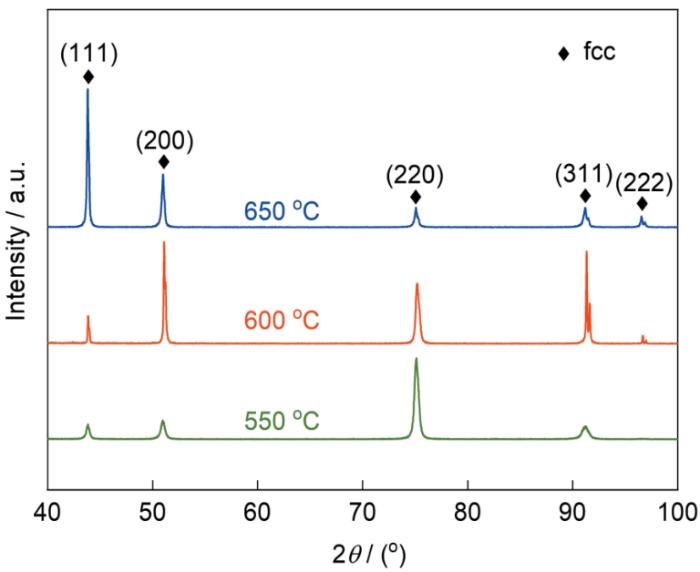

图1为等原子比FeCoNi中熵合金经不同温度退火30 min后的XRD谱。均显示出fcc结构的典型特征峰,即(111)、(200)、(220)、(311)和(222),表明合金在不同温度下退火后均保持着稳定的单相fcc结构。

图1

图1

等原子比FeCoNi中熵合金经不同温度退火30 min后的XRD谱

Fig.1

XRD spectra of the equiatomic FeCoNi medium-entropy alloy (MEA) annealed at different temperatures for 30 min

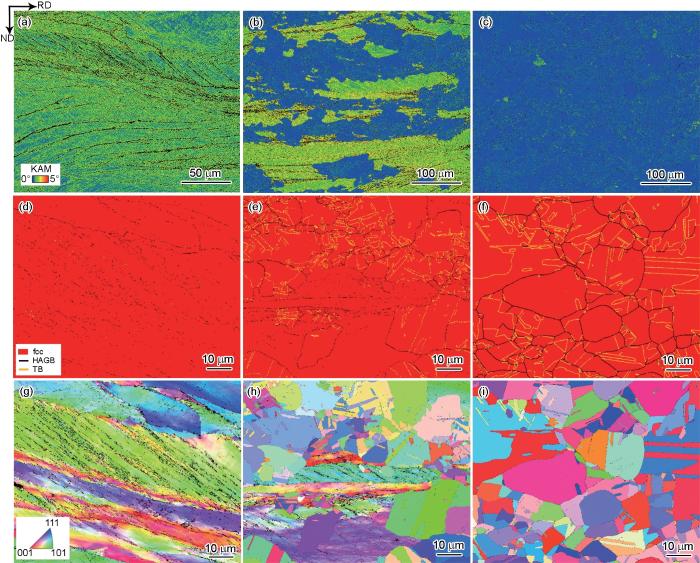

图2为FeCoNi中熵合金样品经不同温度退火后的EBSD分析结果。随着退火温度升高,合金经历了由纤维状未再结晶组织到部分再结晶组织,最后到完全再结晶组织的演变过程。如图2a所示,局部取向差(kernel average misorientation,KAM)图表明550 ℃退火后的合金组织中仍存在较高的局部应变和几何必需位错(geometrically necessary dislocations,GND)密度[23,27]。如图2d所示,相应区域的相分布图(phase map)验证了合金为单相fcc结构。此外,在退火前的冷轧过程中,不同取向的原始晶粒被严重挤压成纤维状组织,这种组织形态在550 ℃退火处理的合金样品中保留下来。如图2g所示,相应的反极图(inverse pole figure,IPF)表明合金中存在大量与轧制方向约呈45°夹角的剪切带,这进一步说明在此温度下退火的合金并未发生明显的再结晶行为。当合金经600 ℃退火后,如图2b所示的KAM图显示再结晶区具有较低的局部取向差和GND密度,而未再结晶区保持高的局部取向差和GND密度,2种区域相互堆叠分布于合金组织中,形成异构[26]。如图2e所示,该种异构中,再结晶区域存在大角度晶界和退火孪晶界。从图2h可见再结晶晶粒呈等轴状[28];对多个区域进行分析得出再结晶区的体积分数约为49%,平均晶粒尺寸约为26 μm。该异构合金样品中,再结晶区与未再结晶区体积分数相近,有利于排除2者含量对该合金样品力学和磁学性能的影响,从而便于明确该异构组织中2种结构单元各自存在的作用。当合金经650 ℃退火后,如图2c、f和i所示,整个样品呈现较低的局部取向差和GND密度,样品呈现完全再结晶组织,大角度晶界和孪晶界分布整个样品中。完全再结晶组织的平均晶粒尺寸约为28 μm,与部分再结晶的异构组织中的再结晶晶粒尺寸相近。

图2

图2

等原子比FeCoNi中熵合金样品经不同温度退火后的EBSD分析

Fig.2

EBSD analyses of the equiatomic FeCoNi MEA specimens annealed at 550 oC (a, d, g), 600 oC (b, e, h), and 650 oC (c, f, i) for 30 min (RD—rolling direction, ND—normal direction)

(a-c) kernel average misorientation (KAM) maps (d-f) phase maps overlapped with high angle grain boundaries (HAGBs) and twin boundaries (TBs) (g-i) inverse pole figure (IPFs)

2.2 软磁性能和磁畴运动行为

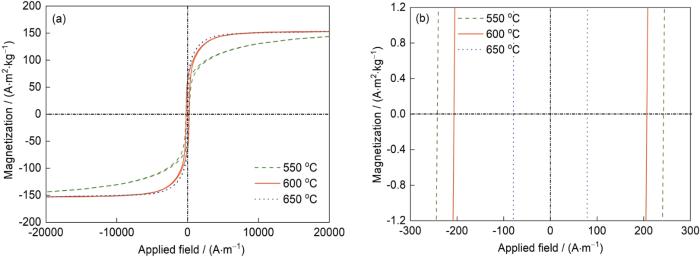

图3为不同温度退火30 min后FeCoNi中熵合金样品的磁滞回线。经550、600和650 ℃退火30 min后合金样品Hc分别为242.2、205.3和79.8 A/m,Ms分别为143.6、152.5和153.2 A·m2/kg。通常,合金的Hc与合金组织内部的缺陷含量及内应力呈正相关[29]。经550 ℃退火30 min得到的均匀未再结晶合金内位错等缺陷的密度高、晶格畸变大,可严重阻碍磁畴壁的运动,因此Hc偏高;随退火温度升高,合金内部发生再结晶形成等轴状晶粒,组织内部缺陷密度大幅降低,磁畴壁受到的钉扎作用减弱,因此Hc下降。此外,3d过渡金属元素Fe、Co和Ni均具有铁磁性,而合金的Ms主要与成分相关[30,31],因此具有不同组织特征的等原子比FeCoNi合金的Ms理论上相当。随着外加磁场增大,在600和650 ℃下退火的FeCoNi合金较快被磁化并达到饱和磁化强度;而在550 ℃下退火的合金由于缺陷密度较高,其响应外加磁场的能力较弱,在外加磁场作用下缓慢趋近饱和磁化强度。

图3

图3

等原子比FeCoNi中熵合金经不同温度退火30 min后的磁滞回线

Fig.3

Low (a) and locally high (b) magnified hysteresis loops of the equiatomic FeCoNi MEA specimens annealed at different temper-atures for 30 min

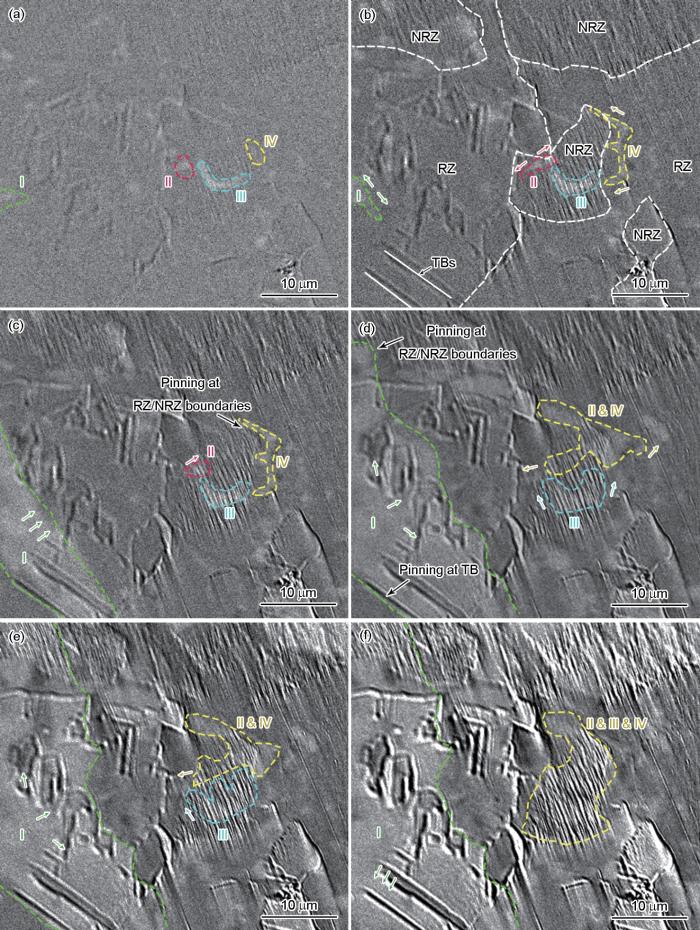

为了更直观地分析异构合金的磁化过程,利用磁光Kerr显微镜对磁畴运动过程进行研究,结果如图4所示。观察发现,再结晶区中磁畴运动较平滑,部分大角度晶界和退火孪晶界处可见磁畴钉扎现象;未再结晶区中由于存在残余应力,磁畴被细化并在外加磁场作用下沿残余应力方向分布,呈条纹状[32]。如图4a所示,当磁场强度(H)为15 mT时,仅有少量磁畴完成形核[9],其中I号和IV号磁畴处于再结晶区,II号和III号磁畴处于未再结晶区。当H = 30 mT时(图4b),更多磁畴形核并长大,各磁畴壁沿有利于磁化的方向运动。当H = 35 mT时(图4c),I号磁畴壁进一步发生显著运动,并受到退火孪晶界的钉扎作用;II号、III号和IV号磁畴变化不显著,且再结晶区与未再结晶区(RZ/NRZ)界面阻碍IV号磁畴壁的运动,这说明RZ/NRZ界面对磁畴壁的运动也具有钉扎作用。当H = 45 mT时(图4d),I号磁畴继续长大,且磁畴壁大致沿晶界和RZ/NRZ界面伸展;IV号磁畴壁因外加磁场达到足够高的强度,克服了RZ/NRZ界面的钉扎作用,并与II号磁畴内部的磁矩方向逐渐趋同,合并为II & IV号磁畴。当H = 50 mT时(图4e),I号磁畴壁也克服了RZ/NRZ边界的钉扎作用,向未再结晶区运动。值得注意的是,I号磁畴包裹区域内仍有少量未磁化区,推测这些小区域存在超细晶组织等,因此晶界密度较高,使I号磁畴壁在运动过程中绕过该区域。此外,未再结晶区内的II & IV号和III号磁畴沿箭头方向继续长大,但是速度相对较慢。这表明相较于再结晶区,未再结晶区内磁畴对外加磁场的响应相对较为迟缓,与图3的实验结果相符。当H = 70 mT时(图4f),I号磁畴壁克服了退火孪晶界的阻碍作用,继续向左下方运动;II & IV号和III号磁畴相互作用共同形成II & III & IV号磁畴。此时,大多数区域磁畴的磁矩方向趋于一致,导致样品宏观表现为磁饱和状态。磁畴运动过程的动态视频见视频1。

图4

图4

异构等原子比FeCoNi中熵合金的磁光Kerr显微成像分析

Fig.4

Kerr-microscopy images showing the growth and movement of the magnetic domain structures (marked as I-IV) in the equiatomic FeCoNi MEA with heterogenous microstructures under external magnetic fields of 15 mT (a), 30 mT (b), 35 mT (c), 45 mT (d), 50 mT (e), and 70 mT (f) (II & IV and II & III & IV are combined magnetic domains after interactions of II, III and IV domains. RZ and NRZ refer to recrystallized zone and non-recrystallized zone, respectively. Colored arrows indicate the growth directions of the corresponding magnetic domains)

2.3 力学性能测试和变形组织演化分析

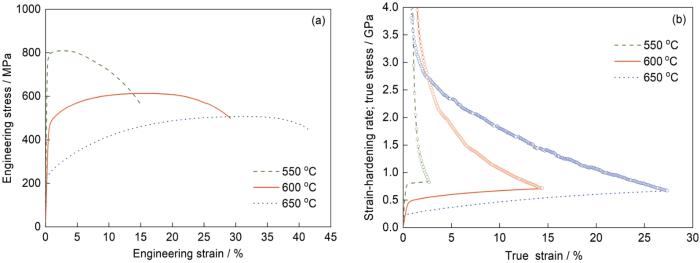

图5a为不同退火条件下FeCoNi中熵合金的工程应力-应变曲线。合金经过550 ℃退火30 min后(未再结晶组织)保持较高的σy (约为772 MPa),但延伸率(δ)较低,约为15%。这是因为低温退火难以完全消除冷轧产生的加工硬化效果,高密度缺陷严重阻碍了位错的运动,导致强度显著提高,而塑性急剧减弱。合金经过600 ℃退火30 min后(部分再结晶的异构组织),σy约为467 MPa,σu约为610 MPa,δ约为30%。当退火温度升高至650 ℃ (完全再结晶组织),合金的δ进一步提升(约为43%),但是σy随之显著降低至约232 MPa。这是因为再结晶的发生使缺陷密度显著降低,进一步改善了合金塑性,同时降低了其强度。由此可见,异质结构的引入使合金拥有更优的强塑性搭配。

图5

图5

等原子比FeCoNi 中熵合金经不同温度退火30 min后的力学性能

Fig.5

Mechanical properties of the equiatomic FeCoNi MEA specimens annealed at different temperatures for 30 min

(a) engineering stress-strain curves

(b) corresponding true stress (line plot) and strain-hardening rate (line + symbol plot) with respect to true strain

图5b为相应的应变-硬化率曲线和真应力-应变曲线。在真应变小于约5%的早期变形阶段,异质结构合金的加工硬化能力最强。此时,再结晶组织内位错的平均自由程较大,滑移和增殖相对容易[35];未再结晶组织内存在高密度不可动位错,在塑性变形时仅有少量位错开动,导致加工硬化率急剧下降[36];而异质结构中再结晶区与未再结晶区的层级分布使得可动位错适当增加,位错平均自由程适当减小,并改善局域应变分布,从而提高了合金的加工硬化能力。当真应变大于5%时,异构合金的加工硬化率比未再结晶合金高,但比完全再结晶合金低。这是因为随着形变增加,再结晶区内位错胞的出现(图6c2)可以有效地阻碍位错滑移,减小位错的平均自由程,从而减缓加工硬化率的下降。

图6

图6

异构样品不同局部应变区域的电子通道衬度(ECC)成像及局部应变分布曲线

Fig.6

Low (a1-d1) and locally high (a2-d2) magnified electron channeling contrast (ECC) images of heterostructured FeCoNi MEA with local strains of 5% (a1, a2), 20% (b1, b2), 40% (c1, c2), and 70% (d1, d2), and a typical dataset obtained by DIC method showing the local strain distribution (e) in tensile tested FeCoNi MEA specimen annealed at 600 oC for 30 min (The distance value 0 refers to the fracture surface. MBs, DT, DCs, and SBs refer to microbands, dislocation tangle, dislocation cells, and shear bands, respectively)

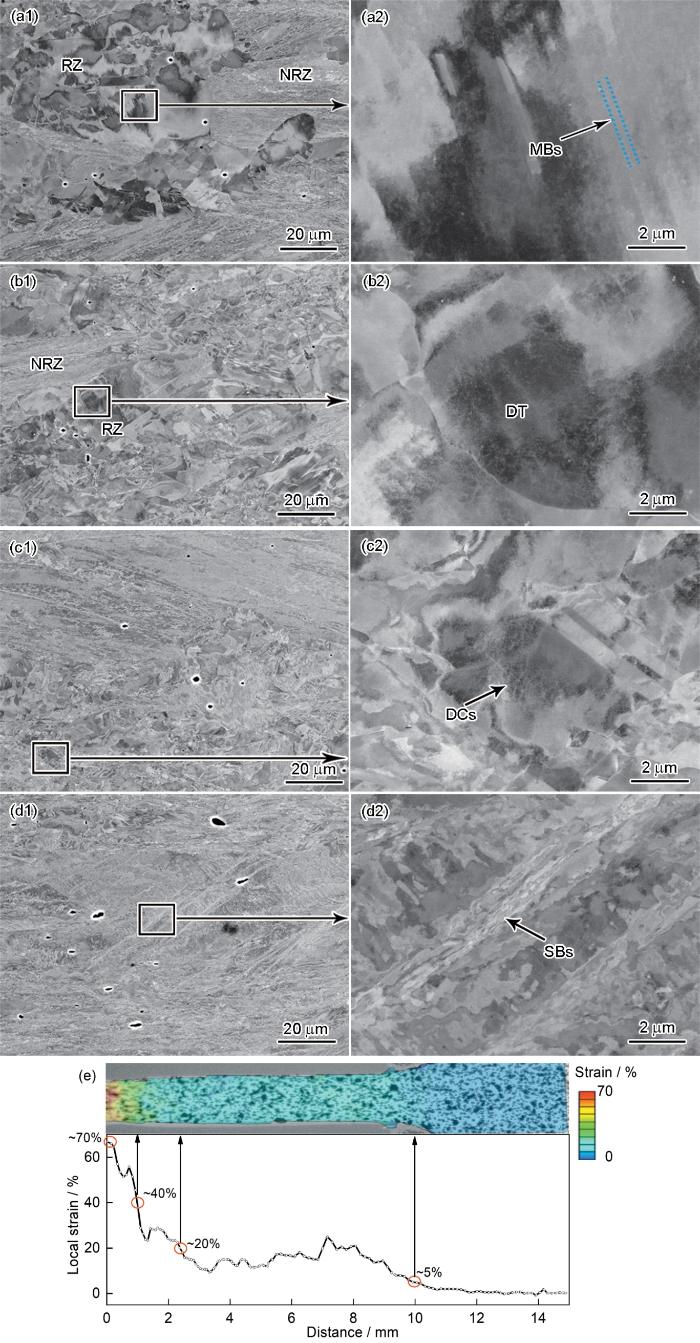

图6a1~d1和a2~d2展示了异构FeCoNi中熵合金在拉伸变形后不同局部应变(5%、20%、40%和70%)区域的组织形貌,对应样品的局部应变分布曲线如图6e所示。当局部应变为5%时,如图6a1所示,再结晶区和未再结晶区界面清晰可见,再结晶晶粒发生轻微的扭曲;图6a2显示晶粒内部存在显微变形带(蓝色虚线标记)。当局部应变增加到20%时,如图6b1所示,晶粒的塑性变形进一步增加,图6b2显示再结晶区晶粒中存在位错缠结。继续增加局部应变到40%时,如图6c1所示,再结晶区晶粒发生严重塑性变形,图6c2显示存在位错胞,这是高层错能合金严重塑性变形后的一种典型亚结构。当局部应变增加到70%时,样品在宏观上发生严重颈缩;如图6d1和d2所示,此时晶粒严重变形,出现大量与拉伸方向呈45°的剪切带,剪切带内部存在大量亚结构。由于等原子比FeCoNi中熵合金层错能高(> 100 mJ/m2)[37],位错滑移是其主要变形机制[35]。在拉伸载荷作用下,再结晶区率先发生塑性变形,逐渐产生位错缠结,并形成位错胞,最后出现与拉伸方向约呈45°的剪切带。

2.4 异构对力学与软磁性能的协同影响机理

图7

图7

异构对等原子比FeCoNi中熵合金力学和软磁性能协同影响机理示意图

Fig.7

Schematics showing the effect of heterostructure on strengthening mechanisms (a) and domain walls pinning mechanisms (b) in the equiatomic FeCoNi MEA (GBs—grain boundaries)

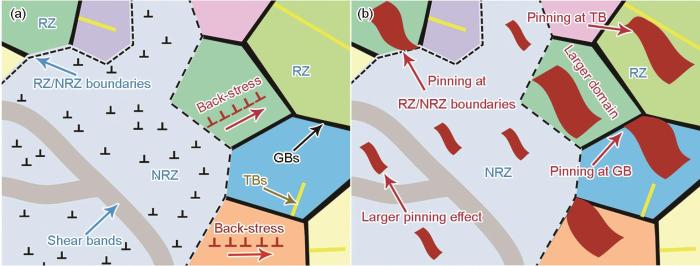

在软磁性能方面,本工作未引入非铁磁性元素,合金具有优良的Ms。如图7b所示,再结晶区域磁畴宽度较大,磁畴壁的移动较平滑,使得合金能较快地响应外磁场的变化;未再结晶区内残余应力和缺陷密度较多,磁畴被细化,且受钉扎作用更强;此外,晶界、孪晶界以及再结晶区与未再结晶区的界面也会对磁畴壁的移动有一定的钉扎作用,这些都是导致Hc升高的主要因素。值得一提的是,目前报道的很多软磁高熵合金中存在弱铁磁性或非铁磁性的第二相,且第二相与基体的晶格错配度较大,合金的Hc普遍较高[11,13,14],甚至超出软磁材料的最低标准(1000 A/m)。与之相比,本工作中异构FeCoNi合金仍保持较低的Hc (205.3 A/m),并避免了外加非铁磁性元素对Ms的不利影响。因此,本工作提出的异构设计是基于对力学和软磁性能的综合考量,即在优化力学性能的同时使其保持高Ms,并避免Hc过度增加。

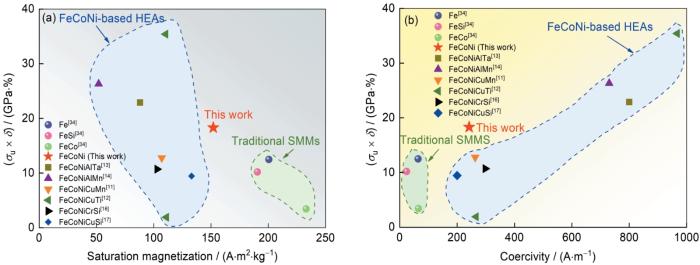

为了衡量异构FeCoNi中熵合金的力学和软磁性能,将其与传统软磁合金[34]以及软磁高熵合金[11~14,16,17]进行比较,绘制出Ashby图,如图8所示。以工业纯Fe、硅钢和FeCo合金等为代表的传统软磁合金展现出了优异的软磁性能。例如,FeCo合金的Ms可以高达233 A·m2/kg[34],硅钢的Hc可以小于20 A/m[34]。然而,传统软磁合金的力学性能较低,难以满足复杂加工成型或者高强度机械负荷的需要。近年来,软磁高熵合金概念的提出较好地弥补了传统软磁合金力学性能的不足,有望实现优良力学和软磁性能兼具的目标。值得注意的是,通过引入非铁磁性元素实现强韧化的FeCoNi基中/高熵软磁合金往往具有相对较低的Ms,不利于其实际应用。本工作中异构FeCoNi中熵合金在力学和软磁综合性能方面填补了传统软磁合金与新型软磁高熵合金之间的空缺,为后续新型软磁合金的设计与开发提供了参考。

图8

图8

异构等原子比FeCoNi中熵合金与传统软磁合金[34]以及新兴FeCoNi基高熵合金[11~14,16,17]力学-软磁性能对比

Fig.8

Mechanical and magnetic properties combined in heterostructured FeCoNi MEA compared to those of other soft magnetic alloys[34] and novel FeCoNi-based soft magnetic high-entropy alloys (HEAs)[11-14,16,17]

(a) Ashby-type map compiling room temperature ultimate tensile strength (σu) × elongation at fracture (δ) versus saturation magnetization (SMMs—soft magnetic materials)

(b) Ashby-type map showing σu × δ versus coercivity

3 结论

(1) 冷轧态等原子比FeCoNi中熵合金经550、600和650 ℃保温30 min退火后,分别呈现未再结晶组织、再结晶体积分数约为49%的部分再结晶组织和完全再结晶组织,且都保持单一fcc结构。其中,600 ℃退火后的合金具有层级组织的特点,再结晶区和未再结晶区相互堆叠,形成异构。

(2) 异构FeCoNi合金的塑性变形机制仍以位错滑移为主。未再结晶合金强度高(σy = 772 MPa)、塑性低(δ = 15%),而完全再结晶合金强度低(σy = 232 MPa)、塑性好(δ = 43%)。异构的引入实现了合金良好的强塑性搭配,使得合金屈服强度达到467 MPa,抗拉强度达到610 MPa,且δ仍能保持在30%。

(3) 异构FeCoNi合金能够较快地响应外加磁场的变化,Ms高达 152.5 A·m2/kg。异构合金中的未再结晶区、晶界、退火孪晶界以及再结晶区与未再结晶区间的界面都会对磁畴壁的运动产生钉扎作用,使合金的Hc从79.8 A/m (完全再结晶态)上升至205.3 A/m (异构态),但明显低于未再结晶态合金(242.2 A/m)。

文中视频可通过以下网址在线观看:

参考文献

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Elucidating the origination of annealing-induced hardening in an equiatomic medium-entropy alloy

[J].

Tailoring microstructures and tensile properties of a precipitation-strengthened (FeCoNi)94Ti6 medium-entropy alloy

[J].

Invar effects in FeNiCo medium entropy alloys: From an Invar treasure map to alloy design

[J].

A mechanically strong and ductile soft magnet with extremely low coercivity

[J].

Effects of Mn and Al addition on structural and magnetic properties of FeCoNi-based high entropy alloys

[J].

Exceptional combination of soft magnetic and mechanical properties in a heterostructured high-entropy composite

[J].

Influence of heat treatment on microstructure, mechanical behavior, and soft magnetic properties in an fcc-based Fe29Co28Ni29Cu7Ti7 high-entropy alloy

[J].

Ultrastrong and ductile soft magnetic high‐entropy alloys via coherent ordered nanoprecipitates

[J].

Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl) x high entropy alloys

[J].

The effects of phase constitution on magnetic and mechanical properties of FeCoNi(CuAl) x (x = 0-1.2) high-entropy alloys

[J].

A novel FeCoNiCr0.2Si0.2 high entropy alloy with an excellent balance of mechanical and soft magnetic properties

[J].A novel FeCoNiCr0.2Si0.2 (at %, thereafter, all mean atomic ratios) high-entropy alloy (HEA) was synthesized. The as-cast HEA exhibits a combination of excellent mechanical and magnetic properties with a large plastic deformation of about 60% and low coercivity (H-c) of about 187.9 A/m, which are prominent in the HEAs reported so far. Based on the large plasticity, rolling and annealing were adopted as a strategy for improving magnetic and mechanical properties of the HEA. The process of rolling followed by annealing leads to the significant enhancement of the yield strength (YS) and ultimate tensile strength (UTS) of alloy rolled at 773 K, increasing to 320 and 920 MPa respectively. Meanwhile the large plasticity and good soft magnetic properties remain. The enhancement mechanism of annealed after rolling was analyzed. Consequently, the optimal balance of magnetic and mechanical properties is achieved. The present work suggests a promising way to develop HEAs with a combination of excellent magnetic and mechanical properties.

A novel ultrafine-grained high entropy alloy with excellent combination of mechanical and soft magnetic properties

[J].

High-entropy alloys with high saturation magnetization, electrical resistivity and malleability

[J].Soft magnetic materials (SMMs) find important applications in a number of areas. The diverse requirements for these applications are often demanding and challenging for the design and fabrication of SMMs. Here we report a new class of FeCoNi(AlSi)(x) (0 <= x <= 0.8 in molar ratio) SMMsbased on high-entropy alloys (HEAs). It is found that with the compositional and structural changes, the optimal balance of magnetic, electrical, and mechanical properties is achieved at x = 0.2, for which the combination of saturation magnetization (1.15 T), coercivity (1,400 A/m), electrical resistivity (69.5 mu Omega.cm), yield strength (342 MPa), and strain without fracture (50%) makes the alloy an excellent SMM. Ab initio calculations are used to explain the high magnetic saturation of the present HEAs and the effects of compositional structures on magnetic characteristics. The HEA-based SMMs point to new directions in both the application of HEAs and the search for novel SMMs.

Effect of Ho addition on AC soft magnetic property, microstructure and magnetic domain of FeCoNi(CuAl)0.8Ho x (x = 0-0.07) high-entropy alloys

[J].

Microstructure and mechanical properties of oxide dispersion strengthened FeCoNi concentrated solid solution alloys

[J].

Hierarchical features infused heterogeneous grain structure for extraordinary strength-ductility synergy

[J].

Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility

[J].Grain refinement can make conventional metals several times stronger, but this comes at dramatic loss of ductility. Here we report a heterogeneous lamella structure in Ti produced by asymmetric rolling and partial recrystallization that can produce an unprecedented property combination: as strong as ultrafine-grained metal and at the same time as ductile as conventional coarse-grained metal. It also has higher strain hardening than coarse-grained Ti, which was hitherto believed impossible. The heterogeneous lamella structure is characterized with soft micrograined lamellae embedded in hard ultrafine-grained lamella matrix. The unusual high strength is obtained with the assistance of high back stress developed from heterogeneous yielding, whereas the high ductility is attributed to back-stress hardening and dislocation hardening. The process discovered here is amenable to large-scale industrial production at low cost, and might be applicable to other metal systems.

Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy

[J].

High tensile ductility in a nanostructured metal

[J].

Making strong nanomaterials ductile with gradients

[J].

Tailoring heterogeneities in high-entropy alloys to promote strength-ductility synergy

[J].Conventional alloys are usually based on a single host metal. Recent high-entropy alloys (HEAs), in contrast, employ multiple principal elements. The strength of HEAs is considerably higher than traditional solid solutions, as the many constituents lead to a rugged energy landscape that increases the resistance to dislocation motion, which can also be retarded by other heterogeneities. The wide variety of nanostructured heterogeneities in HEAs, including those generated on the fly during tensile straining, also offer elevated strain-hardening capability that promotes uniform tensile ductility. Citing recent examples, this review explores the multiple levels of heterogeneities in multi-principal-element alloys that contribute to lattice friction and back stress hardening, as a general strategy towards strength-ductility synergy beyond current benchmark ranges.

Awakening the metastability of an interstitial high entropy alloy via severe deformation

[J].

Magnetic properties of Co-Fe-Ni films

[J].

Amorphous and nanocrystalline materials for applications as soft magnets

[J].

A non-equiatomic FeNiCoCr high-entropy alloy with excellent anti-corrosion performance and strength-ductility synergy

[J].

A TWIP-TRIP quinary high-entropy alloy: Tuning phase stability and microstructure for enhanced mechanical properties

[J].

Stacking fault energies of face-centered cubic concentrated solid solution alloys

[J].

A numerical study of long range internal stresses associated with subgrain boundaries

[J].

Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals

[J].