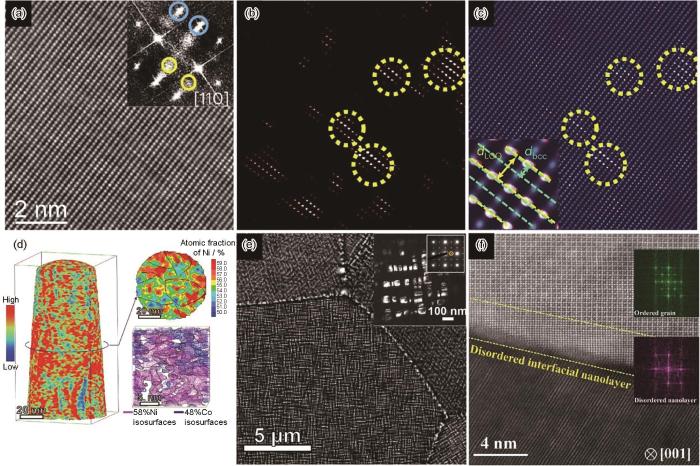

金属(包括合金)是最常见的结构材料,而屈服强度和拉伸塑性是金属结构材料的重要性能指标。高强度有助于大幅降低材料的使用量从而节约能源和降低碳排放。因此,高强金属可带来重大经济和社会效益。拉伸塑性也同样重要[1]。大拉伸塑性可提高材料服役时的安全性,而其更大工程意义是加工:拉应力下的均匀变形能力常常是材料加工之必需。遗憾的是,通常的强化机制,比如第二相析出、晶粒细化、冷加工位错增殖、固溶合金化等,在提高金属屈服强度的同时,常常造成拉伸塑性明显降低,同时实现高强度与高拉伸塑性(比如本文设定的目标:屈服强度约2 GPa,均匀延伸率约30%)是材料领域学者面临的一大挑战。本文阐述强度-塑性相互制约的内在根源,并对如何使金属材料同时实现高强度、高塑性提出新见解。

1 强度-塑性之间相互制约趋势

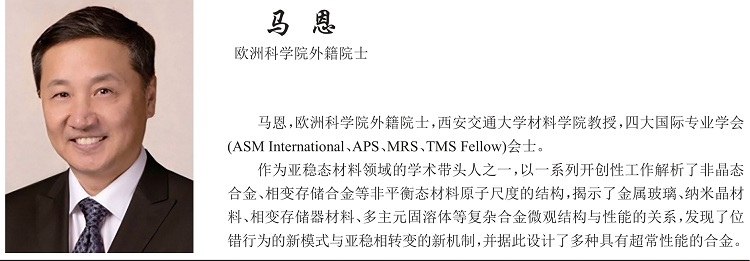

首先,合金强度的提高如果依靠的是又硬又脆的析出相,塑性大减是必然后果。对于脆性材料,塑性机制在服役应力下开动不起来,因而易于开裂并导致破坏。此外,当位错难以切过析出相而只能绕过时,会在析出相周围不断留下位错环、形成应力集中,进而萌生裂纹,断送塑性。可是,析出相并不是都脆,而且金属材料有多种的强化机制,比如教科书中列举的固溶强化、细晶强化、位错强化、相变强化等。大多数情况下,屈服强度的提升与脆性相并没有必然的联系。然而,实验中仍然经常观察到拉伸塑性随强度提高而大幅降低的情况。例如图1[2]中的几种合金,给定成分下,通过改变晶粒尺寸和冷加工条件提高合金强度的同时,强度-塑性间总是出现“香蕉状”的反向关联趋势[2]。这一趋势被称作强度-塑性倒置关系(trade-off),两者间跷跷板式的制约关系,难于规避。文献中有关打破强度-塑性倒置关系的报道,一般也难以克服给定成分合金本身的“香蕉状曲线”(图1[2])。常见的是通过改变合金成分、微观相组成和分布等,在调控强塑化机制之后,得以将强度-塑性曲线往右上角移动。这点在图1[2]中也得到了体现:“香蕉状曲线”随合金元素的加入向更强、更塑的方向提升[2]。此类通过合金设计改善强度-塑性互相掣肘的例子还有很多。新合金与其微观组织结构带来的强塑化机制改变,确实可以使强度-塑性曲线朝图1[2]中的右上角方向不断推进。

图1

图1

铜合金和钢中工程抗拉强度(Eng. UTS)和工程均匀延伸率(Eng.UE)呈相互制约的态势,曲线走向趋于“香蕉状”,加入合金元素调控成分可以降低性能间相互掣肘的程度[2]

Fig.1

Engineering ultimate tensile strength (Eng. UTS) versus engineering uniform elongation (Eng.UE), showing the strength-ductility trade-off in alloys, adapted from Ref.[2], tailoring alloy composition in Cu alloys (a, b) and in steels (c) alleviates the trade-off, shifting the banana-shaped curve to a higher level (as indicated by the arrows)

这里强调一点,上述倒置关系的改进停留在建立另一层次上的平衡(又一水平上的trade-off),而本文讨论的内容包括但超出这一范围。比如,结合了固溶强化、孪晶诱导塑性(TWIP)和相变诱导塑性(TRIP)多种强塑化机制的316LN不锈钢和CoCrNi合金的屈服强度达到0.5 GPa,而延伸率仍可高达70%左右[3];定向凝固形成的Al19Fe20Co20Ni40 (原子分数,%,下同)共晶高熵合金,拉伸时屈服强度为670 MPa,均匀延伸率仍保持在50%[4]等。因此,可以在不同层次设定目标。本文的追求,是更高层次上强度-塑性不兼容的突破。具体来说,是要将金属强化至屈服强度1 GPa以上,却基本不损失拉伸塑性。如Yang等[5]报道的fcc基体中均匀分布的极高密度纳米级L12析出相,使得(FeCoNi)86Al7Ti7合金具备1 GPa屈服强度和50%均匀拉伸应变。在此基础上,期望继续前进直至迄今块体合金中最高的屈服强度(约2.2 GPa)。换言之,在达到超高强钢(super steel)强度的同时,能够保有与未强化的单质金属类似的均匀拉伸应变(如30%)。换句话说,不再存在明显牺牲了某组元的塑性换取高强度的状况。从这个意义上来说,是要在总体上实现强度-塑性相互制约的突破,“鱼和熊掌兼得”。

2 高屈服强度、高拉伸塑性兼得的可行性

这么高的既定目标有可能实现吗?很多人认为,高强度等同于位错运动难,大塑性意味着位错运动容易。一旦要求金属材料又强又塑,陷入冲突的位错“彻底懵了”。由此得出结论,“高强高塑不可兼得,是材料变形机制的本征特性所决定的”。这种观点在国内外广为流传,变成了一个貌似无解的悖论与科学难题。

然而,以上推理存在逻辑上的漏洞:“塑”,并不是限定“位错必须容易运动”。换句话说,位错容易运动当然塑性好,但位错难运动并不代表塑性一定差。即,位错不容易运动时,并不等于它们在吉帕应力范围不能动了,以至于金属失去了塑性变形能力而变成脆性材料。可以预见,只要在高应力下能够运动的位错数量足够多,仍可以获得大塑性。事实上,即便是高强度合金,大多数情况下位错运动并没有困难到“不许动”的地步。也就是说,它们是有能力、有潜力产生大塑性的。附件1用一个类比来帮助读者理解以上分析判断。

式中,σ为真应力,ε为真应变,

3 强化与应变硬化机制

近年来,高强塑性金属材料的研发已取得明显的进展。例如,合金的异质结构可帮助提升强塑性[1]。随着成功数据点的不断出现,人们难免会产生这样的疑问:这类事例是将原有的塑性机制发挥到了极致,还是发现了新机制,或是两者的结合?

微观组织决定性能是材料科学的基本命题。可以调控的微观组织有很多,常见的包括晶体结构、晶粒/晶界、孪晶/层错、位错、空位、间隙原子、成分偏析、析出相、双相与多相等。这些微观组织可以归纳为化学(成分调控、有序化合物)与/或结构(晶粒尺寸、位错密度、孪晶界/层错等)两方面的非均匀性。需要注意的是,限制材料塑性的局域软化(应变局域化),是指产生宏观失稳, 比如实验上观察到的颈缩,与其对应的是宏观变形体积。而本文所讨论的成分或结构上的非均匀性是发生在若干纳米这种微观尺度上的非均匀性(即使浇铸样品已经过均匀化退火处理)。下文将分列这些微观组织的形态、空间分布与作用,简析它们对位错行为的影响机制。

3.1 相变诱导塑性(TRIP)

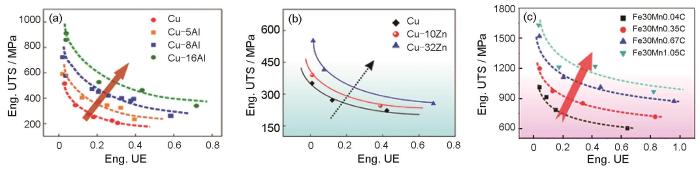

图2

图2

几种典型结构调控案例:fcc-hcp相变诱导塑性[8]、fcc-bcc相变诱导塑性[9]、层错和孪晶诱导塑性[10]和“双峰”晶粒尺寸分布[13]

Fig.2

Several typical structural regulation cases

(a) fcc-hcp transformation induced plasticity[8] (εloc—local strain, TD—tensile direction)

(b) fcc-bcc transformation induced plasticity[9] with transformation-induced plasticity (TRIP) induced rapid strain hardening in engineering stress-strain curves (ΔUTS, ΔUE, and ΔYS represent the increase in the UTS, UE, and yield strength (YS), respectively. FNAT: Fe-32.6Ni-6.1Al-2.9Ti; FNAT-m: FNAT-matrix)

(c) twinning induced plasticity with deformation twins and stacking faults (SFs)[10] (Letters M, T, and S represent the fcc-matrix, twin, and SFs, respectively)

(d) bimodal grain size distribution[13]

3.2 孪晶诱导塑性(TWIP)

TWIP机制是常与TRIP机制一同被提及的另一种有效增塑机制,也是在钢和高熵合金等金属材料中实现强度和拉伸塑性良好结合的有效机制[8]。一方面,高密度孪晶界(图2c[10])可以降低位错的平均自由程,提高屈服强度;另一方面,大量存在的界面促进位错在晶粒内的存储:随着晶粒内位错密度的提高,位错相遇并发生交互作用,位错缠绕、增殖的概率也大幅提高,应变硬化能力因而得到有效提升。通过设计合金成分,降低合金的层错能,可以有效控制合金的TWIP效应。例如,Wei等[10]将FeCoCrNiMn合金中的Mn替换为Si,研发了Fe20Co20Cr20Ni20Mn10Si10与Fe22Co22Cr22Ni22Si12合金。Si的引入加剧了合金的晶格畸变和成分不均匀,并且降低了合金的层错能,这大幅提高了合金的TRIP和TWIP能力以及相应的应变硬化能力和拉伸塑性。

3.3 晶粒/晶界调控

3.4 多主元成分调控

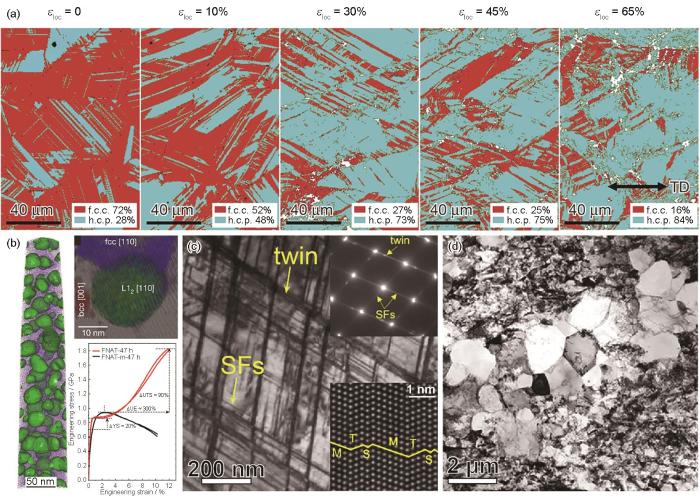

图3列举了较新的强化和应变硬化机制。近几年发展出的大量多主元合金(通常由3种及以上元素以5%~35%原子分数比例组合而成[16]),提供了许多通过调控合金成分实现高强高塑的机会[17]。在此种浓质固溶体中,元素间的相互作用(混合焓)使得组元元素存在偏好或排斥其他某些元素的倾向[18],并影响原子尺度的局域晶格畸变和成分起伏。相应地,如图3a~c[19]所示,常在多主元合金中观察到纳米尺度成分起伏(local chemical fluctuation)[20]、局域化学序(local chemical order,LCO)[21]、化学短程序(chemical short-range order,CSRO)[22]。这些化学非均匀性,在合金中引入与其他电负性、原子半径明显不同的合金元素时(它们自然会带来负混合焓),变得很明显[19~25]。例如,在Ti-30Zr-14Nb合金中添加3%O (原子分数)后,尺寸约为2 nm的有序氧复合体普遍存在,从而提升合金的强度和加工硬化能力[23]。再如,在Ti-Zr-V-Nb[19]或HfNbTiV[25]合金中添加Al,可在合金中形成从原子尺度到亚微米尺度的多级化学波动,在变形过程中有效地影响位错运动。

图3

图3

以化学/结构异质性提供强化和应变硬化机制的几个典型案例:bcc合金中的类B2局域化学序[19],纳米尺度成分起伏[26],高密度、大体积分数纳米析出相[27],及具有纳米尺度无序界面的金属间化合物[28]

Fig.3

Several typical cases of chemical/structural heterogeneities that offer mechanisms for strengthening and strain hardening

(a-c) local chemical order (LCO)[19] (dbcc—spacing of the {001} planes in the bcc lattice, dLCO—spacing of the extra LCO)

(d) nanoscale compositional undulation[26]

(e) high-volume-density of nanoprecipitation[27]

(f) intermetallic precipitate with nanoscale disordered interface[28]

以上例子的共同点是晶粒内存在明显的化学非均匀性。其对运动位错造成的影响是位错在各处的能量显著波动,而能量对距离的一阶导数便是力。换句话说,运动位错到处都感受到额外的应力。因此,位错运动的过程如同穿越一片“沼泽地”,位错段不时需要从进去后不易离开的(若干纳米尺寸)区域“脱钉” (detrapping),这便带来了强化作用。经过“沼泽地”后,位错不再保留原来的“直线”形貌,其黏滑(stick-slip)运动[21]经历的减速、停顿和位错线的拉长会使位错间相互作用、反应、增殖的机会大增,促进了位错在晶粒内部的储存。累积下来的位错越多,对后面上来的位错阻碍越大。这便带来了应变硬化作用。应变硬化效率增加使拉伸塑性提高,特别是均匀延伸率。附件3用一些比喻和图片形象地解释了这些浓质固溶体中化学非均匀性带来的强化和加工硬化新机制,以及其效果为何好于成分均匀的简单固溶体。

3.5 析出相和金属间化合物的调控

多主元合金的不断发展,不仅带来了大批的浓质固溶体,也使得析出相的调控达到了新的高度。当有序结构在基体中大量涌现时会产生丰富的畴界面,纳米尺度的析出相更使得化学异质性达到极致,可调控的范围得到了扩展,包括纳米析出相尺寸、数密度和体积分数,金属间化合物本身的成分和性能,析出物与基体的界面等。析出相尺寸仅为几到几十纳米,密集且分布均匀,可降低位错间平均自由程,从而提高屈服强度。同时,纳米尺度的析出相造成位错运动放慢、停顿、改变方向、绕过困难等,会使位错相互作用、反应、增殖的机会大增。存储下来的位错越多,对后面上来的位错阻碍越大,会提升应变硬化和拉伸塑性。例如,通过在fcc基体中引入直径为30~50 nm、体积分数为50%~55%的L12析出相,(FeCoNi)86Al7Ti7合金实现了1 GPa屈服强度和50%延伸率[5]。Han等[27]设计了Fe32.6Co27.7Ni27.7Ta5.0Al7.0多主元合金(图3e[27]),在fcc基体中形成共格的纳米析出相(约91 nm),析出相体积分数达到约55%。因此,与单相Fe35Co30Ni30Ta5合金相比,在不牺牲塑性(54%)的前提下,Fe32.6Co27.7-Ni27.7Ta5.0Al7.0多主元合金屈服强度由501 MPa提升至904 MPa。

Yang等[28]设计了一种多主元金属间化合物(Ni43.9Co22.4Fe8.8Al10.7Ti11.7B2.5), 如图3f[28]所示。其超晶格合金的晶界是固溶体结构,产生了多元素共偏析(具有纳米尺度无序化),有效抑制了沿晶断裂,使得合金具备1.6 GPa的抗拉强度和25%的室温拉伸塑性。另外,通过调控加入金属间化合物中的合金元素种类及其浓度,常常可以改变该析出相的反相畴界能[29],也就可以改变位错切过析出相的能力,而后者显然会影响强度和塑性。比如,加入Ta后的Ni3Al,反相畴界能升高[29],因而可能有利于强化。相反,加入降低Ni3Al反相畴界能的合金元素,便可能增加其塑性变形能力[30,31]。又如,较脆的NiAl-B2金属间化合物,也可能因合金元素的添加(特别是搭配加入多种元素)改变其反相畴界能[32]而塑化。这些可能性提供了一条新的思路:多组元的合金化不仅可以用来增加金属间化合物的种类和体积分数,还可以被用来有选择性地调控这些析出相本身的性能,从而优化它们对强度、塑性的贡献。这一思路在追求超高的强度(比如接近2 GPa)时尤其需要。

4 高强高塑合金设计的思路与现状

金属材料强度与塑性相互制约,特别是高强度时很难高塑性,很多时候来源于塑性流变过程中应变硬化速率的不足,这在高强材料经历高应力状态下尤为明显(见

这促使我们转向结构异质性+化学异质性[17]的设计思路和理念,据此设计的复杂合金得以综合运用第3节中所述的多项机制,包括把传统的强化机制通过高浓度、大范围合金成分的引入发挥到极致,加上利用多主元合金非均匀性增大所带来的新机制。特别是,多主元合金广阔的成分空间使材料学家得以叠加多种机制,从而实现在大幅提高材料强度的同时,保持足够的应变硬化能力以抑制塑性失稳。具体来说,第3节中讨论的位错运动过程和机制为我们设计合金成分指出了方向。例如3.1和3.2节中的例子,通过找到并加入足够量的适当元素,可以把层错能降低到所需的程度,使得TWIP、TRIP和结构异质性(应变梯度和背应力) 等传统强化机制的效果达到前所未有的程度。同时,多主元合金也引入了新的调控机制(如3.4节所述),如在Prog. Mater. Sci.综述[17]和附件3中所讨论的那样,成片又密集的非均匀性使位错以黏滑运动的方式前行,带来影响流变应力和位错增殖的新模式。近几年来许多研究都在添加与主元素具有负混合焓的合金元素(如Al、Pd、Ta等进入fcc 固溶体,Ni、O等进入bcc固溶体),以利于化学非均匀性的提高。再如3.5节所述,可以通过提高Ti、Ta等帮助金属间化合物形成的元素含量,来增加第二相的数密度、体积分数和种类,纳米析出相变得异乎寻常的密集、分布均匀。并且,调控这些金属间化合物本身的多组元成分,可以改变其塑性变形能力(有些脆性相甚至转而承载大量塑性变形),还可以改善析出相与基体的界面。当然,非均匀性(如3.4节所述)及其产生的界面(如3.5节所述)也增加位错湮灭的机会,而加工硬化过程是由位错增殖和位错湮灭共同决定的。然而,非均匀性促进的位错增殖很多是位错反应产物,其中许多是不可动而不参与动态回复的,留下的增量会多于湮灭的增量。变形中存储的位错,如果得以更均匀地分布在金属内部,可以有效减少相互湮灭的几率,积累更高的位错存储密度从而有效提升加工硬化率。

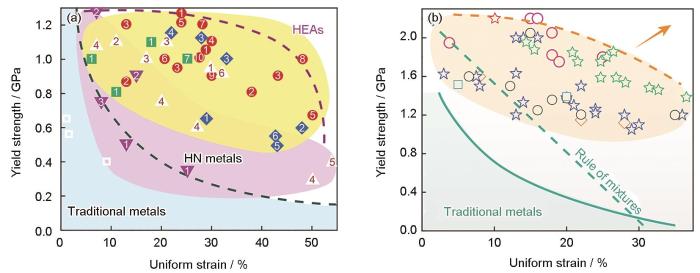

迄今为止,利用以上理念研发高强塑性金属已取得实质性进展,已初步实现屈服强度-均匀延伸率曲线由“香蕉状”向“倒置香蕉状”的转变(如图4a[17]紫色虚线所示)。一批成功案例已将金属强化至屈服强度1 GPa以上(图4a[17]),某些复杂合金(如钢)的屈服强度甚至可达约2.2 GPa (图4b),却不失足够的拉伸塑性。特别是,其中的一些高强合金,其均匀拉伸应变不比单质金属差多少。或者从另一个角度看:已有合金能做到在保有与未强化金属相似的均匀拉伸应变的前提下,强化达到超高强钢的屈服强度(> 1 GPa),甚至靠近最强的块体超级钢的2 GPa水平。图4b中数据点详细的合金成分见附件4。西安交通大学团队正在积累的数据(绿色五角星,附件4;其趋势以图4b中橙色虚线示意)正在逼近图4b中的右上角(箭头所示)。不久的将来,可以期待新开发出的块体合金能同时具有超级钢的屈服强度(约 2 GPa)和单质金属Fe的塑性(约30%均匀延伸率)。

图4

图4

屈服强度< 1.2 GPa[17]和1.2~2.2 GPa范围内金属材料拉伸屈服强度-均匀应变总图

Fig.4

Summary diagrams showing tensile yield strength vs uniform strain (elongation)

(a) the regime for yield strength < 1.2 GPa, for which the available data points thus far have already occupied the entire space, with the upper rim (dashed line) exhibiting the shape of an up-side-down banana[17] (HEAs—high-entropy alloys, HN metals—heterogeneous nanostructured metals)

(b) extended regime up to 2.2 GPa, the strength of the strongest bulk super steels (The detailed compositions for these alloys are listed in Supplementary Information 4. The upper-rim dashed line represents a currently reachable envelope, towards which our team is pushing forward with accruing experimental data (green stars). The arrow points to the future direction to go, approaching the upper-right corner where the combination of concurrent high strength and ductility is optimized)

这里有必要指出,实际的工程应用并不总是需要达到上述苛刻指标。目前,虽然尚未真正抵达图4的右上角,也已经完全跳出了多年以来徘徊于“香蕉状”区域的限制,不仅实现了强度超常,塑性也令人满意。在这个意义上,精心设计的复杂多主元合金已经摆脱了强度-塑性严重相互制约(前者达标时后者已断崖式下跌)的困境。然而,本文仍设定“鱼和熊掌兼得”为目标,更侧重的是阐述“金属材料能否同时做到高强高塑、能达到何种程度的高强高塑、怎样调控合金才能挑战高强高塑的新极限”这一基础材料科学问题。

5 总结

(1) 很多金属和合金在2 GPa以下强度范围内不会变成脆性材料。在此前提下,高屈服强度与高拉伸塑性,本征上并不是“有他没我、有我没他” (二选一)的悖论。高强度时拉伸率严重受限的原因往往是塑性失稳——特别是易于发生颈缩。

(2) 近年来实现高强高塑兼得的基本学术思想,是与传统的原理一脉相承的:通过在位错运动路线上设置有效阻碍,使位错举步维艰,从而达到高强度;同时利用这些频发障碍,增加位错反应和存储的机会,保持加工硬化率,抑制塑性失稳(颈缩)以延长拉伸率。

(3) 高强高塑合金的设计实践,近年来得益于大量涌现的多主元合金所拓展的成分空间。调控高浓度合金元素、引入大量和不同的析出相,使本文中列举的强化和应变硬化机制得到了尽可能的发挥,这些机制的叠加和综合利用得以产生简单合金体系难以企及的效果。

(4) 作为上述努力的结果,在迄今已知块体合金所及的性能范围内(屈服强度约2 GPa,均匀延伸率约30%),达到“鱼和熊掌兼得”的目标已指日可待。最后提醒一下,逐步变为现实的“高强高塑”为新的应用可能性提供了基础和机会,但工程设计上还需要更多关注合金在多种复杂载荷条件下的行为,诸如疲劳、断裂韧性、三向应力状态下的加工性能等。

文中补充材料可通过以下网址查看:

参考文献

Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals

[J].

Relationship between strength and uniform elongation of metals based on an exponential hardening law

[J].

Mechanical property comparisons between CrCoNi medium-entropy alloy and 316 stainless steels

[J].We systematically compared the mechanical properties of CrCoNi, a recently emerged prototypical medium-entropy alloy (MEA) with face-centered-cubic (FCC) structure, with hallmark FCC alloys, in particular, the well-known austenitic 316L and 316LN stainless steels, which are also concentrated single-phase FCC solid solutions and arguably next-of-kin to the MEAs. The tensile and impact properties, across the temperatures range from 373 K to 4.2 K, as well as fracture toughness at 298 K and 77 K, were documented. From room temperature to cryogenic temperature, all three alloys exhibited similarly good mechanical properties; CrCoNi increased its tensile uniform elongation and fracture toughness, which was different from the decreasing trend of the 316L and 316LN. On the other hand, the stainless steels showed higher fracture toughness than CrCoNi at all temperatures. To explain the differences in macroscopic mechanical properties of the three alloys, microstructural hardening mechanisms were surveyed. CrCoNi MEA relied on abundant mechanical twinning on the nanoscale, while martensitic transformation was dominant in 316L at low temperatures. The deformation mechanisms in the plastic zone ahead of the propagating crack in impact and fracture toughness tests were also analyzed and compared for the three alloys.

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys

[J].Alloy design based on single-principal-element systems has approached its limit for performance enhancements. A substantial increase in strength up to gigapascal levels typically causes the premature failure of materials with reduced ductility. Here, we report a strategy to break this trade-off by controllably introducing high-density ductile multicomponent intermetallic nanoparticles (MCINPs) in complex alloy systems. Distinct from the intermetallic-induced embrittlement under conventional wisdom, such MCINP-strengthened alloys exhibit superior strengths of 1.5 gigapascals and ductility as high as 50% in tension at ambient temperature. The plastic instability, a major concern for high-strength materials, can be completely eliminated by generating a distinctive multistage work-hardening behavior, resulting from pronounced dislocation activities and deformation-induced microbands. This MCINP strategy offers a paradigm to develop next-generation materials for structural applications.Copyright © 2018 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Influence of strain-rate sensitivity on necking under uniaxial tension

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

Bifunctional nanoprecipitates strengthen and ductilize a medium-entropy alloy

[J].

Metalloid substitution elevates simultaneously the strength and ductility of face-centered-cubic high-entropy alloys

[J].

High tensile ductility in a nanostructured metal

[J].

Nanodomained nickel unite nanocrystal strength with coarse-grain ductility

[J].Conventional metals are routinely hardened by grain refinement or by cold working with the expense of their ductility. Recent nanostructuring strategies have attempted to evade this strength versus ductility trade-off, but the paradox persists. It has never been possible to combine the strength reachable in nanocrystalline metals with the large uniform tensile elongation characteristic of coarse-grained metals. Here a defect engineering strategy on the nanoscale is architected to approach this ultimate combination. For Nickel, spread-out nanoscale domains (average 7 nm in diameter) were produced during electrodeposition, occupying only ~2.4% of the total volume. Yet the resulting Ni achieves a yield strength approaching 1.3 GPa, on par with the strength for nanocrystalline Ni with uniform grains. Simultaneously, the material exhibits a uniform elongation as large as ~30%, at the same level of ductile face-centered-cubic metals. Electron microscopy observations and molecular dynamics simulations demonstrate that the nanoscale domains effectively block dislocations, akin to the role of precipitates for Orowan hardening. In the meantime, the abundant domain boundaries provide dislocation sources and trapping sites of running dislocations for dislocation multiplication, and the ample space in the grain interior allows dislocation storage; a pronounced strain-hardening rate is therefore sustained to enable large uniform elongation.

Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility

[J].Grain refinement can make conventional metals several times stronger, but this comes at dramatic loss of ductility. Here we report a heterogeneous lamella structure in Ti produced by asymmetric rolling and partial recrystallization that can produce an unprecedented property combination: as strong as ultrafine-grained metal and at the same time as ductile as conventional coarse-grained metal. It also has higher strain hardening than coarse-grained Ti, which was hitherto believed impossible. The heterogeneous lamella structure is characterized with soft micrograined lamellae embedded in hard ultrafine-grained lamella matrix. The unusual high strength is obtained with the assistance of high back stress developed from heterogeneous yielding, whereas the high ductility is attributed to back-stress hardening and dislocation hardening. The process discovered here is amenable to large-scale industrial production at low cost, and might be applicable to other metal systems.

Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys

[J].

The deformation of plastically non-homogeneous materials

[J].

A critical review of high entropy alloys and related concepts

[J].

Chemical inhomogeneities in high-entropy alloys help mitigate the strength-ductility trade-off

[J].

Compositional fluctuation and local chemical ordering in multi-principal element alloys

[J].

Tailoring planar slip to achieve pure metal-like ductility in body-centred-cubic multi-principal element alloys

[J].Uniform tensile ductility (UTD) is crucial for the forming/machining capabilities of structural materials. Normally, planar-slip induced narrow deformation bands localize the plastic strains and hence hamper UTD, particularly in body-centred-cubic (bcc) multi-principal element high-entropy alloys (HEAs), which generally exhibit early necking (UTD < 5%). Here we demonstrate a strategy to tailor the planar-slip bands in a Ti-Zr-V-Nb-Al bcc HEA, achieving a 25% UTD together with nearly 50% elongation-to-failure (approaching a ductile elemental metal), while offering gigapascal yield strength. The HEA composition is designed not only to enhance the B2-like local chemical order (LCO), seeding sites to disperse planar slip, but also to generate excess lattice distortion upon deformation-induced LCO destruction, which promotes elastic strains and dislocation debris to cause dynamic hardening. This encourages second-generation planar-slip bands to branch out from first-generation bands, effectively spreading the plastic flow to permeate the sample volume. Moreover, the profuse bands frequently intersect to sustain adequate work-hardening rate (WHR) to large strains. Our strategy showcases the tuning of plastic flow dynamics that turns an otherwise-undesirable deformation mode to our advantage, enabling an unusual synergy of yield strength and UTD for bcc HEAs.© 2023. The Author(s), under exclusive licence to Springer Nature Limited.

Tuning element distribution, structure and properties by composition in high-entropy alloys

[J].

Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways

[J].

Direct observation of chemical short-range order in a medium-entropy alloy

[J].

Manipulating the ordered oxygen complexes to achieve high strength and ductility in medium-entropy alloys

[J].Oxygen solute strengthening is an effective strategy to harden alloys, yet, it often deteriorates the ductility. Ordered oxygen complexes (OOCs), a state between random interstitials and oxides, can simultaneously enhance strength and ductility in high-entropy alloys. However, whether this particular strengthening mechanism holds in other alloys and how these OOCs are tailored remain unclear. Herein, we demonstrate that OOCs can be obtained in bcc (body-centered-cubic) Ti-Zr-Nb medium-entropy alloys via adjusting the content of Nb and oxygen. Decreasing the phase stability enhances the degree of (Ti, Zr)-rich chemical short-range orderings, and then favors formation of OOCs after doping oxygen. Moreover, the number density of OOCs increases with oxygen contents in a given alloy, but adding excessive oxygen (>3.0 at.%) causes grain boundary segregation. Consequently, the tensile yield strength is enhanced by ~75% and ductility is substantially improved by ~164% with addition of 3.0 at.% O in the Ti-30Zr-14Nb MEA.© 2023. The Author(s).

Local chemical fluctuation mediated ductility in body-centered-cubic high-entropy alloys

[J].

Negative mixing enthalpy solid solutions deliver high strength and ductility

[J].

Uniting tensile ductility with ultrahigh strength via composition undulation

[J].

A mechanically strong and ductile soft magnet with extremely low coercivity

[J].

Ultrahigh-strength and ductile superlattice alloys with nanoscale disordered interfaces

[J].Alloys that have high strengths at high temperatures are crucial for a variety of important industries including aerospace. Alloys with ordered superlattice structures are attractive for this purpose but generally suffer from poor ductility and rapid grain coarsening. We discovered that nanoscale disordered interfaces can effectively overcome these problems. Interfacial disordering is driven by multielement cosegregation that creates a distinctive nanolayer between adjacent micrometer-scale superlattice grains. This nanolayer acts as a sustainable ductilizing source, which prevents brittle intergranular fractures by enhancing dislocation mobilities. Our superlattice materials have ultrahigh strengths of 1.6 gigapascals with tensile ductilities of 25% at ambient temperature. Simultaneously, we achieved negligible grain coarsening with exceptional softening resistance at elevated temperatures. Designing similar nanolayers may open a pathway for further optimization of alloy properties.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Modeling antiphase boundary energies of Ni3Al-based alloys using automated density functional theory and machine learning

[J].

Mechanism of macroalloying-induced ductility in Ni3Al

[J].

Improvement in ductility of Ni3Al by γ former doping

[A].

Effect of alloying elements on <111> dislocation in NiAl: A first-principles study

[J].