金属增材制造是一个多尺度耦合问题[5],涉及复杂传热传质、相变和凝固组织演化等物理现象[6],其在宏观尺度上表现为移动熔池在多物理场耦合作用下温度场和流场分布演化、固/液界面能量与质量输运以及凝固参数在空间和时间域的变化问题,在微观尺度上表现为凝固组织演化和溶质元素再分配问题。因此,掌握多场耦合下热质输运及组织演化机制是揭示工艺-组织-性能内禀关系的基础[7]。在金属增材制造过程中,高能束作用在熔池内产生超高温度梯度和极高冷却速率,使得传统实验手段难以对熔池内传热传质、晶粒生长进行原位观察与测量[8]。此外,由于物理过程复杂、工艺变量繁多,传统试错法调整工艺参数只能针对单一目标,效率低、周期长、成本高,因此数值模拟逐渐成为一种重要且高效的手段。例如,在电弧熔丝工艺中,电弧作为热源对温度场分布和凝固参数起决定性作用,根据电弧形态和参数以解析法获得熔池凝固参数,并假定微观流场初始值,代入相场模型即可计算其微观组织演化过程[9,10]。通过基于连续体假设的宏观热传导模型与微观相场模型耦合是金属增材制造中最常用的跨尺度模拟方法[11],能够充分考虑因热源参数、材料物性和散热条件对凝固参数的影响,提取凝固参数代入微观组织演化模型从而精确预测微观结构。

通过合理的数值模拟方法,可以准确再现增材制造过程中热过程、熔池内热质输运以及凝固组织生长演化情况。利用宏观热传导模型可以实现增材制造过程熔池流动特性、熔体铺展凝固行为的模拟[12],阐明多场耦合下移动熔池热-流场分布演化特性,揭示工艺变量对沉积效率和沉积层表面质量的影响规律[13];多物理场(温度场、流场、合金浓度场等)耦合的微观组织数值模型能够再现凝固参数对组织演化与溶质再分配的影响[14],探明多场耦合下组织形成与显微偏析的调控机制;同时结合金相组织实验验证,能够阐明多能场、多重热循环下沉积样件组织-性能的内禀关系[15]。数值模拟的应用很大程度上减少了工艺实验的工作量,极大地节约了时间成本、原料成本和人力成本,加快了增材构件的高效、高性能、一体化成形进程。

本工作利用跨尺度模拟方法,将宏观有限元模型与微观相场模型耦合,开展了铝合金熔滴复合电弧增材凝固过程微观组织生长与演化研究,在工艺实验基础上建立有限元模型并计算温度场,分析并提取凝固界面前沿温度梯度与凝固速率,代入相场模型计算熔池不同位置枝晶生长情况,同时描述了凝固过程从柱状晶向等轴晶转变行为和外延生长特性,研究结果为组织和性能的主动控制提供了理论依据。

1 实验条件及数值模型

1.1 实验方法

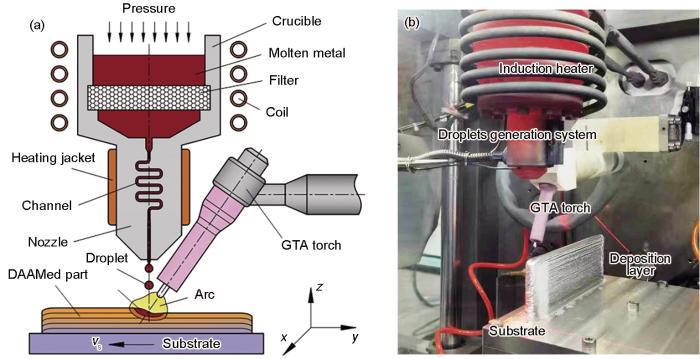

图1

图1

熔滴复合电弧增材制造工艺原理图与实验平台

Fig.1

Schematic of droplet and arc additive manufacturing (DAAM) process (a) and experimental platform (b) (Vs—substrate moment velocity, GTA—tungsten inert gas)

实验中,将2319铝合金铸锭在坩埚内加热至熔化,并使熔体温度恒定为760℃。为避免沉积层内部氧化物夹杂,采用Magic Wave 3000焊接电源作为变极性钨极气体保护弧焊的热源,采用交流方波脉冲波形的焊接电流以及时、有效地清除成形基板表面或预铺展区域表面的氧化膜,实验中电流脉冲频率设定为50 Hz,熔滴直径3 mm,熔体流量控制在100 mm3/s左右。为实现微观组织的主动控制,选取可良好成形的工艺参数进行沉积实验,研究沉积过程中的组织演化特性。

1.2 宏观数值传热模型

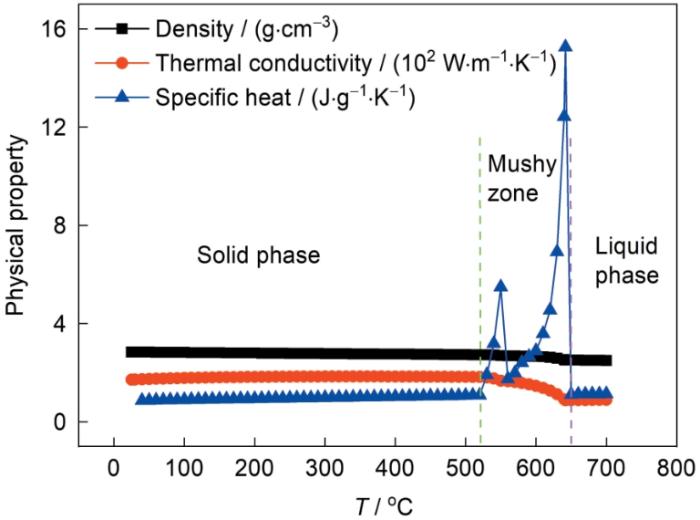

图2

图2

2319铝合金随温度变化的物性参数

Fig.2

Temperature (T)-dependent physical properties of 2319 aluminum alloy

后半椭球体热源控制方程为:

式中,qf、qr分别为前、后半个椭球的热流密度;qarc为电弧有效功率(W);ff、fr分别为前、后椭球能量分配系数,本工作ff = 0.6,fr = 1.4;af、ar分别为前、后椭球半轴长度;bl、cl分别为前后椭球共享宽度和深度尺寸;x、y、z为直角坐标系中坐标。。

1.3 微观组织相场模型

在熔池底部会产生较大温度梯度,底部微小区域内温度场T(Z, t)控制方程为[21]:

式中,T0为参考温度,t为枝晶生长的时间,G为温度梯度,Z为平行于枝晶生长方向的坐标值,Z0为参考点坐标,V为凝固速率,c和c∞分别表示浓度和远离固/液界面处的浓度,k为溶质平衡分配系数,μ为中间变量,

考虑弛豫时间τ:

式中,

在熔池上部同时存在对流辐射和热传导,凝固环境与熔池底部不同,易产生较大过冷度。无量纲过冷度

其温度场控制方程为:

式中,Tm为合金熔点,L为潜热,κ为热扩散系数,cp 为比热容。为保证计算的收敛性,W取0.27 μm,单个网格尺寸dx = 0.8W,

在相场模拟中,假设晶粒的择优生长取向(preferred orientation)与温度梯度方向相同;而温度梯度的方向是由选取点在熔池中的位置决定的,其方向垂直于等温线方向。但是在实际凝固过程中,熔池底部晶粒的择优生长取向可能与温度梯度不平行,因为高温熔体会依附于未熔化的基板材料表面进行凝固,新凝固的晶粒择优生长方向将与基板晶粒的择优生长方向相同,呈现外延生长(epitaxial growth)特性[23]。

式中,f(θ0)为仅关于θ0的函数;g = 1.249 ± 0.004[25];Pe为Peclet数,是传热与传质中的无量纲数,指传热中对流与扩散热量、或传质中对流与扩散质量之比。

在相场方程中,为了引入晶粒的择优取向方向,界面能各向异性项ε修正为:

式中,ε0为界面宽度常数;r为各向异性强度系数;

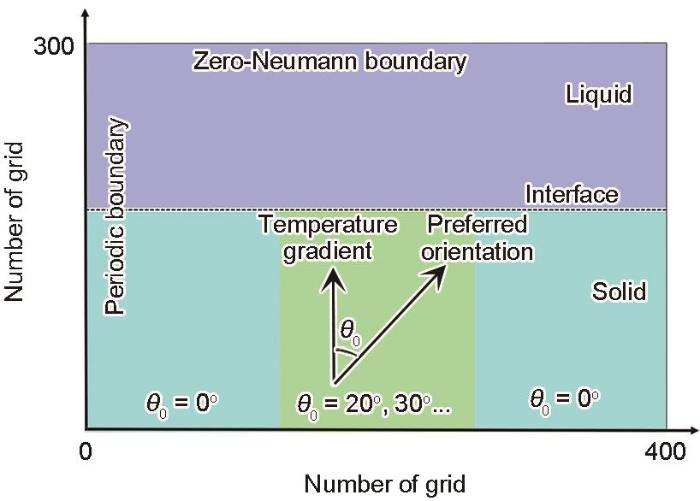

模型初始条件如图3所示,在计算域底部设置20个网格厚度的固相层,在计算域中间部分,设置一定的取向偏差角,两侧区域取向偏差角为0,即枝晶生长方向与温度梯度平行,上下边界为Zero-Neumann边界条件,左右为周期性边界条件。

图3

图3

外延生长相场模型初始条件

Fig.3

Initial conditions of epitaxial growth phase field model (θ0—misorientation angle)

2 结果与讨论

2.1 单层单道沉积温度场演变及凝固参数的提取

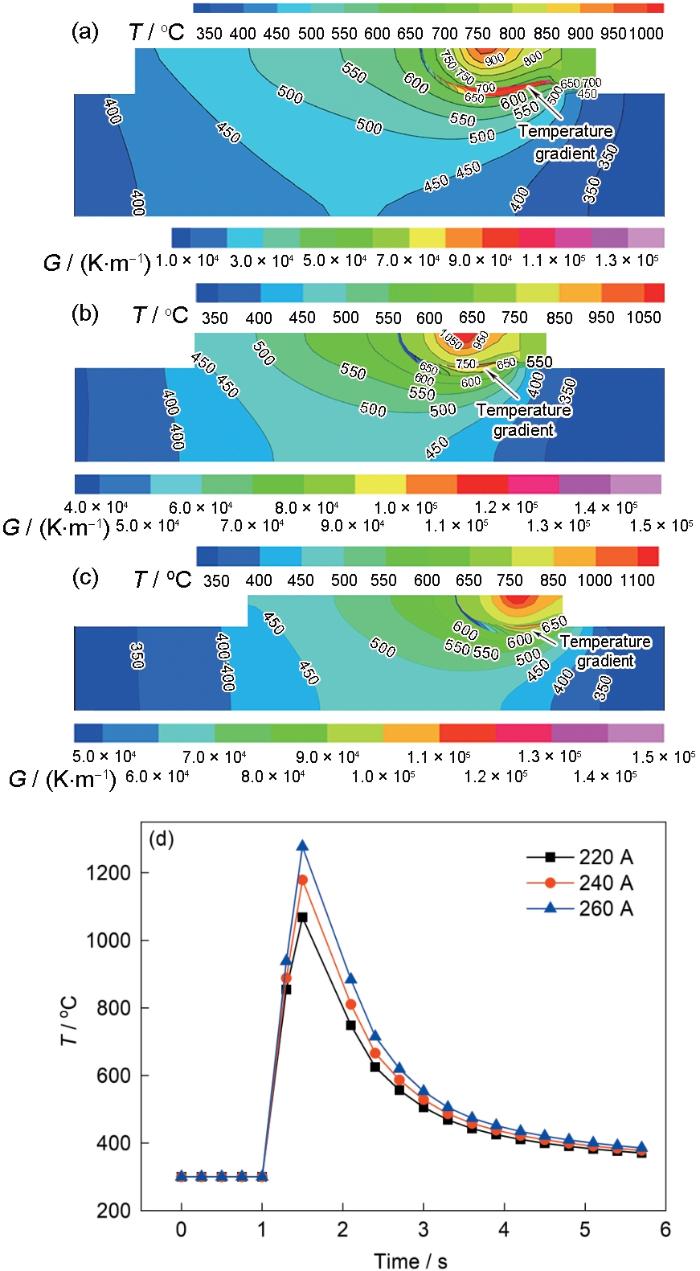

图4

图4

不同电流下沉积层温度场分布情况及沉积层中心点处温度变化曲线

Fig.4

Temperature field distributions of deposition layer under currents of 220 A (a), 240 A (b), and 260 A (c); and temperature change curves at the center point of the layer under different currents (d) (G—temperature gradient)

温度梯度为单位长度内温度的改变,即:

凝固速率V为[26]:

式中,

双椭球热源所形成的固/液界面在(x0, y0)点法线斜率l与夹角的关系为

式中,a和b分别为椭球的长短轴距离,将椭圆整体平移至第一象限,然后计算凝固前沿所在的椭圆方程,得:

联立以上公式即可求出V:

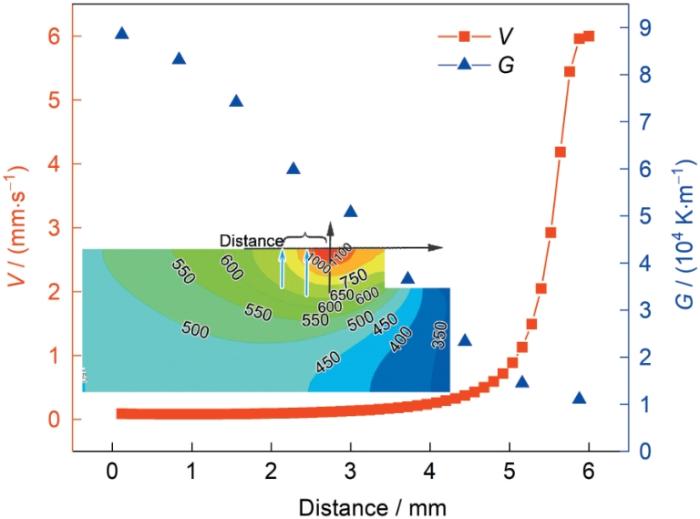

根据数值模拟结果和以上推导得出电弧电流260 A时凝固界面上G和V的变化曲线,如图5所示。以热源所在位置为原点,提取熔合线上温度梯度和凝固速率并向基板移动方向投影,投影点到热源距离为横坐标。可以看出,温度梯度在熔池底部最大,约为9 × 104 K/m,沿凝固前沿向上,温度梯度逐渐减小,凝固速率的变化趋势正好相反,在熔池底部最低,然后沿熔合线逐渐增大,在熔池顶部凝固速率等于Vs。

图5

图5

熔池内温度梯度(G)和凝固速率(V)分布

Fig.5

Temperature gradient and solidification velocity distribution in the molten pool (V—solidification speed; inset shows the temperature field, and two blue arrows represent the projection process of the selected points on the fusion line)

2.2 熔池不同位置微观组织的影响

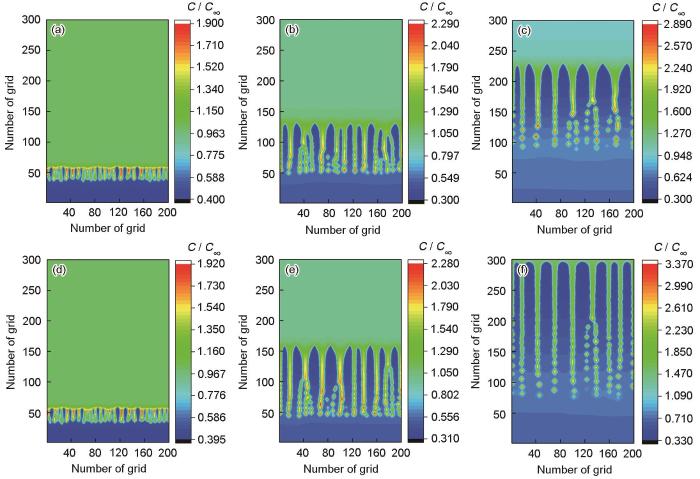

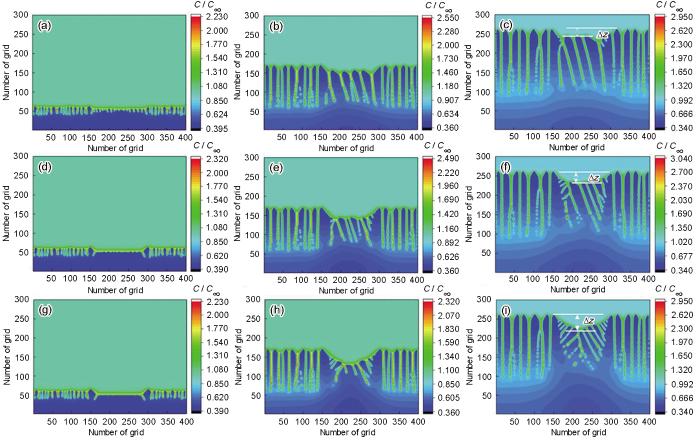

图6

图6

熔池底部与中部微观组织生长过程

Fig.6

Microstructure growth processes at the bottom (a-c) and the middle part (d-f) of molten pool (c— concentration, c∞—concentration far away from the interface, c / c∞—relative concentration, t—time, Δt—time step. One grid size is 0.216 μm)

(a) t = 2500Δt (b) t = 8500Δt (c) t = 24500Δt

(d) t = 2500Δt (e) t = 8500Δt (f) t = 19500Δt

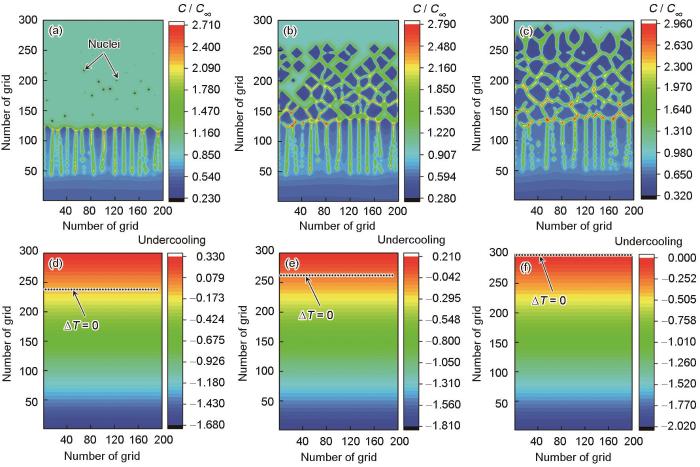

图7

图7

凝固过程中柱状晶向等轴晶转变(CET)过程的微观组织生长状况及对应时刻温度场分布演化过程

Fig.7

Columnar to equiaxed transition (CET) processes during solidification showing the microscopic microstructure growths (a-c) and corresponding temperature field distributions (d-f) at different time (ΔT—undercooling)

(a, d) t = 5100Δt (b, e) t = 5700Δt (c, f) t = 6700Δt

熔池底部和中部微观组织类似,都是柱状晶结构,这是由于这部分区域温度梯度较大,而凝固速率较小导致。微观组织都经历了平面生长、竞争生长和稳定生长3个阶段。初始条件为在计算域底部设置薄的固相层,随着凝固的进行,固/液界面向前推进,进入平面生长阶段,由于界面前端溶质富集和过冷的共同作用,界面逐渐失稳,产生许多细小晶粒,这些晶粒沿温度梯度方向不断长大,进入竞争生长阶段[27],由于在垂直枝晶生长方向的空间有限,大部分在竞争中被淘汰,只有少数几个晶粒生存下来,进入到最后的稳定生长阶段。

式中,Γ为与材料有关的参数。从有限元结果可以看出,从熔池底部到中部,温度梯度呈减小趋势,凝固速率逐渐增大,所以一次枝晶臂间距会逐渐减小,从而验证了相场模拟结果的正确性。

图7为熔池凝固过程的中上部区域微观组织转变和对应温度场演化过程。可以看出,在凝固前期凝固组织以柱状晶形式向前推进,由于凝固速率较快,一次枝晶臂间距明显低于熔池中部的组织,而且随着凝固的进行,无量纲过冷度为0的等温线向前推进的速率高于柱状晶枝晶尖端生长速率,从而使柱状晶前方液相区域整体处于过冷状态,如图7d所示。由于温度梯度在此处较小,约为40000 K/m,其影响作用降低,在过冷熔体中逐渐形成一些细小的晶核,然后逐渐长大形成等轴晶(图7a和b)。这些等轴晶出现在柱状晶上方,占用了柱状晶向前推进的空间,抑制了柱状晶的继续生长;同时无量纲过冷度为0的等温线继续向前推进,直到计算域顶端(图7d~f),在新的过冷熔体中产生新的晶核继续长大为等轴晶。最终凝固组织呈现为下方柱状晶区域和上方的等轴晶区域,即为微观组织从柱状晶向等轴晶进行转变(columnar to equiaxed transition,CET)。

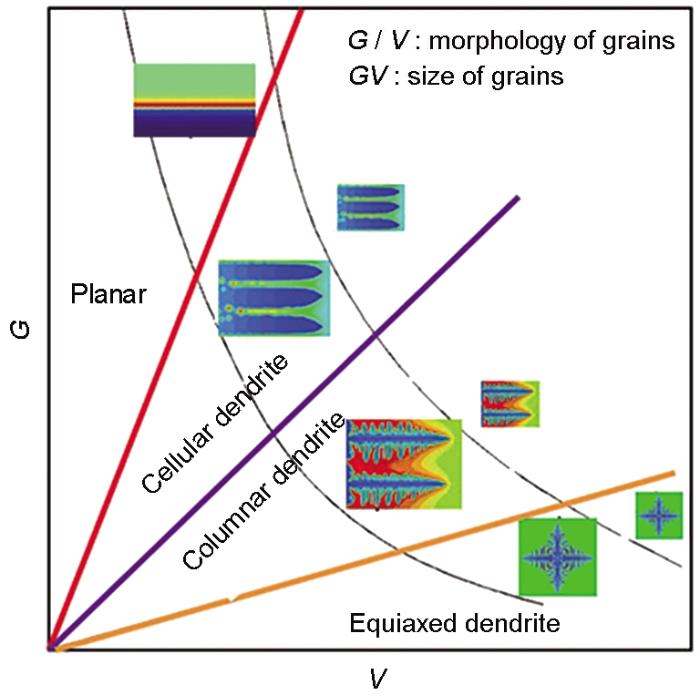

图8

图8

晶粒微观形貌与凝固条件的关系

Fig.8

Relationship between micromorphology and solidification conditions of grains (For an alloy of a given composition, the morphology and size of the grains are mainly determined by G and V in the molten pool)

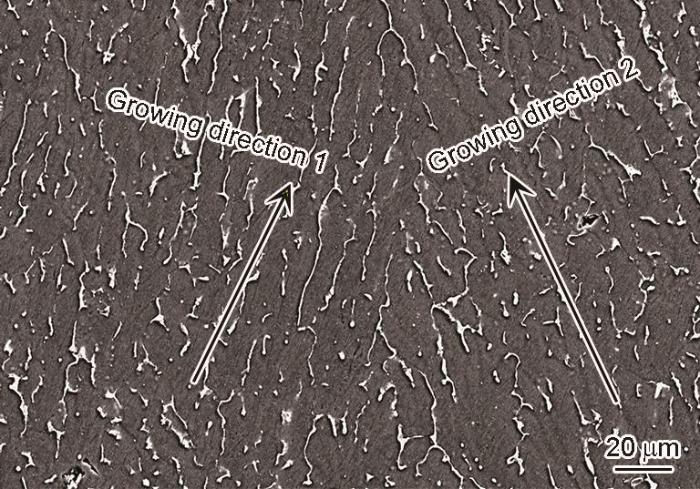

2.3 外延生长特性

在材料沉积过程中,高温熔体在固态基板上遇冷开始凝固,一方面,晶粒的形成往往会依附于母材晶粒的既有表面而继续生长;另一方面,晶粒生长具有严格的择优取向,铝合金择优取向为<100>方向,当择优方向与熔池内温度梯度平行时最有利于柱状晶的生长,而当2者存在一定角度时,柱状晶生长受到抑制,在竞争生长阶段更容易被淘汰[31]。

为研究外延生长对微观组织的影响,选取3个不同取向偏差角(

图9

图9

不同取向偏差角下凝固组织的生长过程

Fig.9

Growth processes of solidification microstructure at the misorientation angles of 20° (a-c), 30° (d-f), and 40° (g-i) (ΔZ is the grain height difference with different misorientation angles) (a, d, g) t = 2500Δt (b, e, h) t = 7500Δt (c, f, i) t = 12500Δt

总体来说,微观组织所受影响随取向偏差角的增大而愈发明显。当θ0 = 20°时,计算区域中间部分柱状晶生长方向略微倾斜,与两侧没有取向偏差角的柱状晶相互影响不明显,如图9c所示。当θ0 = 30°时,柱状晶生长倾斜角度增大,在右侧取向偏差角过渡区域,柱状晶上长出明显的二次枝晶臂,并不断向左前方倾斜生长。另外在右侧过渡区域,某些已经形成的一次枝晶在竞争生长过程中遭到淘汰,如图9e所示。当θ0 = 40°时,存在取向偏差角的区域枝晶生长所受影响较大,出现二次枝晶臂交错生长现象,而且在生长过程中更多的枝晶在竞争生长中遭到淘汰,如图9i所示。由此说明,小的取向偏差角会使枝晶倾斜生长,当取向偏差角逐渐增大时,使枝晶生长倾斜角度增大,竞争生长过程更为激烈,更多的枝晶被淘汰。所以在微观组织观测时偶尔可见部分柱状晶倾斜生长,且倾斜角度较小。

式中,C0为合金的原始浓度。由上式可知,凝固速率减小,组分过冷倾向减小,即界面稳定性增加,由此说明了取向偏差角增大导致界面更不容易失稳,从而枝晶形成相对滞后。

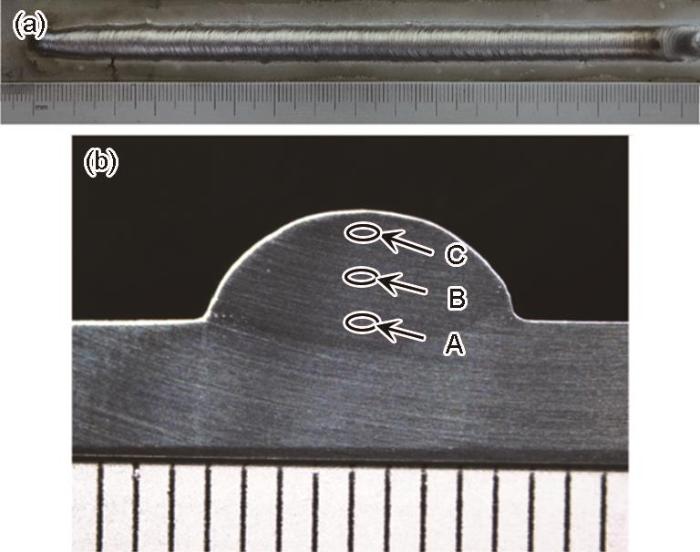

3 实验验证

熔滴复合电弧增材沉积铝合金单层单道沉积层宏观形貌和横截面如图10所示,在电弧电流为260 A、基板移动速率为6 mm/s时,沉积层表面形貌较为光滑平整,在横截面上未观察到空隙裂纹等缺陷。为了对微观组织模拟进行验证,首先对试样进行打磨抛光去掉划痕,采用Keller试剂(95 mL H2O + 2.5 mL HNO3 + 1.5 mL HCl + 1.0 mL HF)对试样表面腐蚀5~10 s,放在Nikon MA200显微镜(OM)下观察其微观组织。选取横截面上沉积层底部、中部和上部(即A、B、C 3个区域)进行金相观测,获取其微观形貌与演化规律。

图10

图10

熔滴复合电弧增材沉积层与横截面形貌

Fig.10

Deposition layer (a) and cross-sectional morphology (b) obtained by droplet and arc additive manufacturing

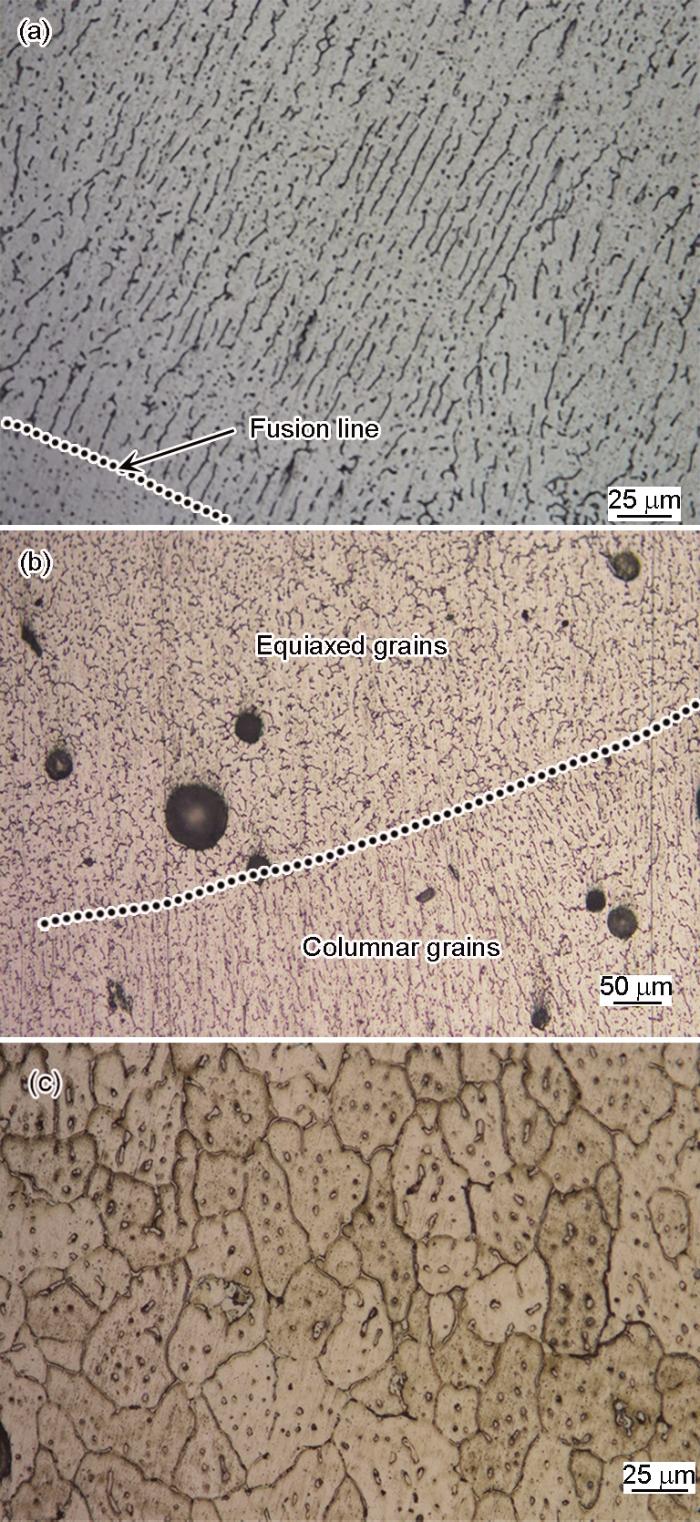

图11

图11

沉积层不同位置微观组织的OM像

Fig.11

Microscopic structures of the deposition layer at different positions

(a) bottom (zone A in Fig.10b)

(b) middle (zone B in Fig.10b)

(c) upper part (zone C in Fig.10b)

图12

4 结论

(1) 通过有限元法计算了熔滴复合电弧增材沉积过程中熔池内的温度场分布,并提取推导凝固参数随位置变化的控制方程,分析得到温度梯度在熔池底部最大,为9 × 104 K/m,并沿凝固前沿向上逐渐减小;凝固速率变化趋势相反,从熔池底部到顶部逐渐增大,直到与基板移动速率相等。

(2) 由于熔池内凝固环境的差异,导致凝固后微观组织不同。在熔池底部和中部,产生柱状晶组织,底部柱状晶一次枝晶臂间距大于熔池中部的柱状晶;到熔池中上部区域,凝固速率的增大和温度梯度的减小会使柱状晶向等轴晶转变,即CET转变。

(3) 沉积过程中高温熔体在基板上凝固时会继承基板晶粒的择优取向,当择优取向与温度梯度不完全一致时,会使柱状晶生长方向与温度梯度方向呈现一定角度。通过引入取向偏差角对外延生长过程进行模拟,发现随着取向偏差角的增大,凝固初期界面越不容易失稳,后期枝晶生长形貌所受影响越大,并且越容易在竞争生长阶段被淘汰。

参考文献

Microstructure and mechanical properties of 2024 aluminum alloy prepared by wire arc additive manufacturing

[J].Owing to its outstanding advantages, such as low specific gravity, high specific strength, and good machinability, 2024 aluminum alloy has been used as various load components in the aerospace field and has become an important lightweight material. The properties of the 2024 aluminum alloy are highly correlated with its microstructures. Accordingly, in this study, 2024 aluminum alloy deposited specimens were fabricated using wire arc additive manufacturing. Further, the microstructures and mechanical properties of the deposited specimens were investigated in different regions. The layered characteristics could be observed macroscopically in the deposited specimens, and a single deposition layer was divided into two regions: interlayer and innerlayer. The grain morphology changed from equiaxed grains in the innerlayer region to columnar grains in the interlayer region. The deposited specimens mainly included α-Al, θ-Al2Cu, and S-Al2CuMg phases. In the nonequilibrium solidification process of additive manufacturing, the deposited specimens presented element segregation. The distribution of Mg in the Al matrix was uniform for the innerlayer region. However, Cu was segregated as eutectics at the grain boundary in the interlayer region. The average tensile strength, yield strength, and elongation of deposited specimens were (323.5 ± 6.6) MPa, (178.7 ± 6.2) MPa, and (9.03 ± 0.67)%, respectively, which were higher than those of cast annealing 2024 aluminum alloy. Owing to the difference in the microstructure, the innerlayer and interlayer regions showed different crack propagation behavior. The cracks in the interlayer region propagated along the distribution path of eutectics, showing intergranular fracture, and the crack propagation mode in the innerlayer region changed to transgranular fracture.

电弧增材制造2024铝合金的微观组织与力学性能

[J].采用电弧增材制造工艺制备了三元Al-Cu-Mg (2024)铝合金成形试样,并对试样的晶粒形貌、物相组成、元素分布与力学性能进行研究。结果表明,2024铝合金成形试样宏观上表现出层状特征,单一沉积层可以分为层间区域与层中区域2部分,晶粒形貌由层中区域的等轴晶转变为层间区域的柱状晶;成形试样微观组织主要包括α-Al、θ-Al<sub>2</sub>Cu与S-Al<sub>2</sub>CuMg相;由于增材制造非平衡凝固过程,成形试样出现元素偏析,层中区域Mg元素在Al基体中均匀分布;电弧重熔作用下,层间区域元素偏析严重,Cu元素以共晶组织的形式在晶界偏析,Mg元素出现局部富集;成形试样的平均抗拉强度、屈服强度与断后伸长率分别为(323.5 ± 6.6) MPa、(178.7 ± 6.2) MPa和(9.03 ± 0.67)%,高于铸造退火态2024铝合金的力学性能;由于微观组织的不同,层中区域与层间区域出现不同的裂纹扩展行为,层间区域裂纹沿着共晶组织分布路径扩展,表现为沿晶断裂,层中区域裂纹扩展模式变为穿晶断裂。

Wire and arc additive manufacturing of lightweight metal components in aeronautics and astronautics

[J].

航空航天轻质金属材料电弧熔丝增材制造技术

[J].

Materials' fundamental issues of laser additive manufacturing for high-performance large metallic components

[J].

高性能大型金属构件激光增材制造: 若干材料基础问题

[J].简要介绍了高性能大型金属构件激光增材制造的技术特点、国内外研究进展及技术发展面临的挑战,分析了大型金属构件激光增材制造的"高性能材料制备"与"复杂结构直接制造"有机融合、"控形/控性"一体化的独特特征。指出高性能大型关键金属构件激光增材制造技术的发展和工程应用,将在很大程度上取决于人们对激光增材制造过程中对激光/金属交互作用行为及能量吸收利用机制、内部冶金缺陷形成机制及力学行为、移动熔池约束快速凝固行为及构件晶粒形态演化规律、非稳态循环固态相变行为及显微组织形成规律、内应力演化规律及构件变形开裂预防方法等材料基础问题的深入研究。

Laser additive manufacturing of high-performance metallic aerospace components

[J].

航空航天高性能金属材料构件激光增材制造

[J].

Numerical simulation on metallic additive manufacturing

[J].

金属增材制造数值模拟

[J].

Phase-field study on the evolution of microstructure of the molten pool for additive manufacturing

[J].

面向增材制造的熔池凝固组织演变的相场研究

[J].

Modeling of additive manufacturing processes for metals: Challenges and opportunities

[J].

A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium

[J].

Phase-field simulation of dendrite growth under forced flow conditions in an Al-Cu welding molten pool

[J].

Phase field modeling of solidification microstructure evolution during welding

[J].

Multiscale modelling of microstructure, micro-segregation, and local mechanical properties of Al-Cu alloys in wire and arc additive manufacturing

[J].

Numerical simulation of arc-droplet-weld pool behaviors during the external magnetic field-assisted MIG welding-brazing of aluminum to steel

[J]

A novel method for the molten pool and porosity formation modelling in selective laser melting

[J].

Multi-scale numerical simulation of molten pool evolution process for electron beam selective melting

[J].

电子束选区熔化增材制造熔池演化多尺度模拟

[J].

A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies

[J].

Molten pool dynamics and particle migration Behavior during TIG-assisted droplet deposition manufacturing of SiC particle-reinforced aluminum matrix composites

[J].A transient three-dimensional (3D) numerical model based on computational fluid dynamics is developed to simulate the molten pool behaviors during the tungsten inert gas (TIG) welding arc-assisted droplet deposition manufacturing (DDM) of silicon carbide (SiC) particle-reinforced aluminum matrix composites (AMCs). The factors, such as arc forces, the interaction between SiC particles and liquid Al matrix, and surface tension, are considered in the model. The model was validated by comparing the simulation data and results obtained from DDM on the cross-sectional profile and particle distribution of deposits. The evolution law of the peak temperature in molten pool is discussed, the impact-induced molten pool characteristics and the migration behaviors of SiC particles are investigated. The results showed that the TIG-assisted DDM process can be broken down into four phases, including droplet impacting, coalescing, spreading and recoiling. The remelting is observed near the impacting point, a V-shaped depression is formed at the molten pool center, a crown-like hump is generated at the edge of the molten pool. Most of the reinforcements are deposited at the both sides of deposits due to the melt's dragging force. The deposition of the reinforcements toward the bottom of the molten pool is suppressed by the impact-induced local elevated pressure and the convection within the molten pool.

TIG电弧辅助熔滴沉积增材制造SiCp增强铝基复合材料中的熔池动力学与颗粒迁移行为

[J].

Investigation of droplet + arc deposition additive manufacturing with WCP simultaneous reinforcement for aluminum alloy

[J].

铝合金熔滴复合电弧沉积同步WC颗粒强化增材制造工艺研究

[J].针对铝基复合材料高效率、低成本增材制造,提出了铝合金熔滴复合电弧沉积同步颗粒强化增材制造新方法。实验研究中,以倾斜变极性电弧为热源,2024铝合金为基体材料,球形WC颗粒为增强相。成形过程中,由熔滴发生系统产生的铝合金熔滴,竖直落入倾斜电弧产生的熔池,与此同时WC颗粒以气载粉的方式送入熔池后沿,并随着电弧和基板的相对运动分散在铝合金基体中。单道多层沉积实验结果表明,送粉位姿、载气流量和WC颗粒直径均对WC<sub>P</sub>/Al沉积过程影响显著。保持送粉方向平行于钨针轴线,且粉末流汇聚于熔池后沿时,有利于在沉积过程中保持电弧形态的稳定并获得较高的颗粒植入比例。金相分析显示,WC<sub>P</sub>/Al沉积层内WC颗粒分布总体均匀,且颗粒与基体结合可靠;WC颗粒的存在会抑制柱状晶的生长,并且当WC颗粒直径小于40μm时,具有显著的晶粒细化效果。

Modeling metal deposition in heat transfer analyses of additive manufacturing processes

[J].

A new finite element model for welding heat sources

[J].

On the interaction between welding residual stresses: A numerical and experimental investigation

[J].

Phase-field modeling of binary alloy solidification with coupled heat and solute diffusion

[J].

Quantitative phase-field model of alloy solidification

[J].

Epitaxial-growth-induced junction welding of silver nanowire network electrodes

[J].In this study, we developed a roll-to-roll Ag electroplating process for metallic nanowire electrodes using a galvanostatic mode. Electroplating is a low-cost and facile method for deposition of metal onto a target surface with precise control of both the composition and the thickness. Metallic nanowire networks [silver nanowires (AgNWs) and copper nanowires (CuNWs)] coated onto a polyethylene terephthalate (PET) film were immersed directly in an electroplating bath containing AgNO. Solvated silver ions (Ag ions) were deposited onto the nanowire surface through application of a constant current via an external circuit between the nanowire networks (cathode) and a Ag plate (anode). The amount of electroplated Ag was systematically controlled by changing both the applied current density and the electroplating time, which enabled precise control of the sheet resistance and optical transmittance of the metallic nanowire networks. The optimized Ag-electroplated AgNW (Ag-AgNW) films exhibited a sheet resistance of ∼19 Ω/sq at an optical transmittance of 90% (550 nm). A transmission electron microscopy study confirmed that Ag grew epitaxially on the AgNW surface, but a polycrystalline Ag structure was formed on the CuNW surface. The Ag-electroplated metallic nanowire electrodes were successfully applied to various electronic devices such as organic light-emitting diodes, triboelectric nanogenerators, and a resistive touch panel. The proposed roll-to-roll Ag electroplating process provides a simple, low-cost, and scalable method for the fabrication of enhanced transparent conductive electrode materials for next-generation electronic devices.

Impact of fluid flow on the dendrite growth and the formation of new grains in additive

[J].

Growth directions of microstructures in directional solidification of crystalline materials

[J].

Phase-field simulations and microstructural analysis of epitaxial growth during rapid solidification of additively manufactured AlSi10Mg alloy

[J].

Recent progresses in competitive grain growth during directional solidification

[J].Competitive growth between different structures including phases, dendrites and grains is a common phenomenon existing in various microstructure evolution processes. The overgrowth outcome of competitive growth has a paramount influence on final solidification microstructures and mechanical behaviors of materials. The competitive grain growth during directional solidification is a key factor for microstructures controlling, especially for the preparation of single crystal turbine blades. In recent years, the competitive grain growth during directional solidification becomes a hot spot due to an increasing demand for the single crystal preparation and inconsistent experimental results with the classical Walton-Chalmers model. In this paper, the mechanism of competitive grain growth based on the classical Walton-Chalmers model and its challenges were firstly discussed, and then some recent research progresses in converging growth and diverging growth in two dimensional spaces, and non-uniplanar growth in three dimensional spaces were reviewed. Furthermore, the recent works of our group on competitive grain growth during directional solidification by using the phase field method were introduced. Finally, the outlooks of future studies on competitive grain growth during directional solidification are presented.

定向凝固晶粒竞争生长的研究进展

[J].竞争生长是材料微观组织演化过程中普遍存在的现象,不同组织间(包括相、枝晶、晶粒等)均可能存在竞争生长,这些竞争作用对最终微观组织的形成及力学性能具有重要影响。不同取向晶粒间的竞争生长控制是材料微观组织调控的重要环节,尤其是对定向单晶叶片的制备,不同取向晶粒间的竞争生长是决定能否成功获得完整单晶结构的关键因素。近年来,一方面单晶材料制备要求的不断提高,迫切需要有关晶粒竞争生长机制及规律方面的理论性指导,另一方面经典晶粒竞争生长理论预测结果与实验观测并不相符,有时甚至可能完全相反,这使得定向凝固过程中不同取向晶粒间的竞争生长问题日益成为一个热门的研究课题。本文首先回顾了Walton-Chalmers模型的晶粒竞争生长机制及其所受到的严重挑战,然后分别对定向凝固二维条件下汇聚生长和发散生长及三维条件下晶粒竞争生长的研究现状进行了述评,并介绍了本课题组近年来基于相场法数值模拟在定向凝固晶粒竞争生长研究方面的工作进展,最后对定向凝固过程中不同取向晶粒之间的竞争生长研究进行了总结与展望。

Simulation of the columnar-to-equiaxed transition in directionally solidified Al-Cu alloys

[J].

Columnar to equiaxed transition in additively manufactured CoCrFeMnNi high entropy alloy

[J].

Modeling columnar to equiaxed transition in directional solidification of Inconel 718 alloy

[J].

Phase-field modeling of grain evolutions in additive manufacturing from nucleation, growth, to coarsening

[J].