Corrosion of metallic materials fabricated by selective laser melting

1

2019

... 增材制造(additive manufacturing,AM)是20世纪90年代新兴的制造技术,可精密快速地制造出复杂形状的结构件,实现“自由制造”,解决了复杂结构件的成形问题,且大幅度减少了加工工序,缩短了加工周期[1].增材制造技术近年来发展迅速,在许多领域得到广泛应用,并在不断拓展. ...

Corrosion behavior of selective laser melted Ti-6Al-4V alloy in NaCl solution

1

2016

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Anisotropic response in mechanical and corrosion properties of hastelloy X fabricated by selective laser melting

1

2019

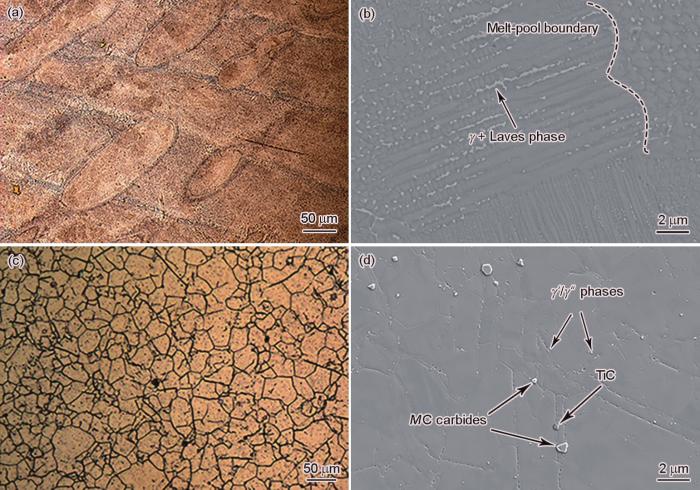

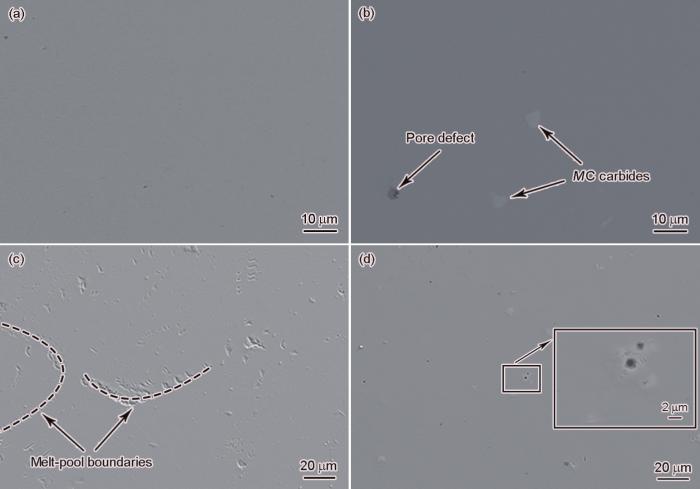

... 图4为SLM Inconel 718合金和R Inconel 718合金腐蚀前后的表面形貌.可见,未腐蚀的SLM Inconel 718合金表面未观察到金属碳化物(图4a),而未腐蚀的R Inconel 718合金表面存在金属碳化物和孔隙缺陷(图4b).在0.1 mol/L NaOH溶液中腐蚀后,2种合金均发生点蚀.SLM Inconel 718合金点蚀优先发生在熔池边界和孔隙部位[3] (图4c),其点蚀形貌与R Inconel 718合金(图4d)存在明显区别. ...

Local Corrosion behavior of additive manufactured AlSiMg alloy assessed by SEM and SKPFM

1

2016

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Investigations of γ′, γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting

1

2018

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting

1

2015

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Selective laser melting of Inconel 718 under high laser power

2

2020

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

... [7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Correlation between depassivation and repassivation processes determined by single particle impingement: Its crucial role in the phenomenon of critical flow velocity for erosion-corrosion

0

2021

Electrochemical behavior of Inconel 718 fabricated by laser solid forming on different sections

2

2018

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

... [9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Microstructural, corrosion and mechanical properties of additively manufactured alloys: A review

2

2022

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

... 目前,增材制造Inconel 718的腐蚀行为研究主要集中于中性氯离子环境,在酸性环境中也有少量的研究[10],但是,增材制造Inconel 718合金在碱性环境中的腐蚀行为研究尚未见文献报道.本工作研究了SLM Inconel 718合金在0.1 mol/L NaOH溶液中的腐蚀行为,以期为SLM Inconel 718合金在碱性介质下的应用提供理论参考和数据支撑. ...

Effect of microstructural constituents on mechanical properties and fracture toughness of Inconel 718 with anomalous deformation behavior at 650oC

0

2020

A review of mechanical properties of additively manufactured Inconel 718

1

2019

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Effect of heat treatment on the δ phase distribution and corrosion resistance of selective laser melting manufactured Inconel 718 superalloy

1

2018

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Studies on heat treatment and electrochemical behaviour of 3D printed DMLS processed nickel-based superalloy

1

2019

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Effect of solution heat treatment on microstructure and electrochemical behavior of electron beam smelted Inconel 718 superalloy

0

2018

Corrosion behavior of a selective laser melted Inconel 718 alloy in a 3.5 wt.% NaCl solution

6

2021

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

... 增材制造Inconel 718合金采用SLM工艺制造而成,成形参数为:激光功率138 W、扫描速率429 mm/s、层厚0.04 mm,整个制备过程在高纯度Ar气保护下进行,以避免合金内部产生气孔.对比材料为商用轧制态Inconel 718合金 (R Inconel 718).2种合金的主要化学成分见表1[16],2种合金的成分近似,主要由Ni、Cr、Nb、Mo、Fe等元素构成.所有样品均切割成直径为10 mm、高度为5 mm的圆柱体,一底面为工作面,除了工作面外,其余面用环氧树脂密封.样品的工作面依次用400#、800#和1000#的SiC砂纸逐级打磨,先后用去离子水、无水乙醇清洗后,冷空气吹干待用. ...

... 激光选区熔化(SLM)和轧制(R)态Inconel 718合金的化学成分[16] (mass fraction / %) ...

... Chemical compositions of selective laser melted (SLM) and rolled (R) Inconel 718 alloys[16] ...

... 钝化膜的载流子密度是影响材料耐蚀性的重要因素之一.钝化膜的载流子密度可以通过测量空间电荷层的电容(CSC)与电极电位(E)的函数曲线来分析.根据Mott-Schottky理论,CSC与E之间的关系可表示为[16,29]: ...

... 式中,ε是钝化膜的介电常数(取12[16,30]);ε0是真空介电常数(8.854 × 10-14 F/cm);e是电子电荷的绝对值(1.6021 × 10-19 C);Nq是电荷载流子密度,由Mott-Schottky曲线斜率进行计算,斜率为正呈n-型半导体特征,斜率为负呈p-型半导体特征;Efb是平带电位;kB是Boltzmann常数(1.38 × 10-23 J/K);T是热力学温度. ...

Corrosion behavior of wire arc additive manufactured Inconel 718 superalloy

3

2020

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

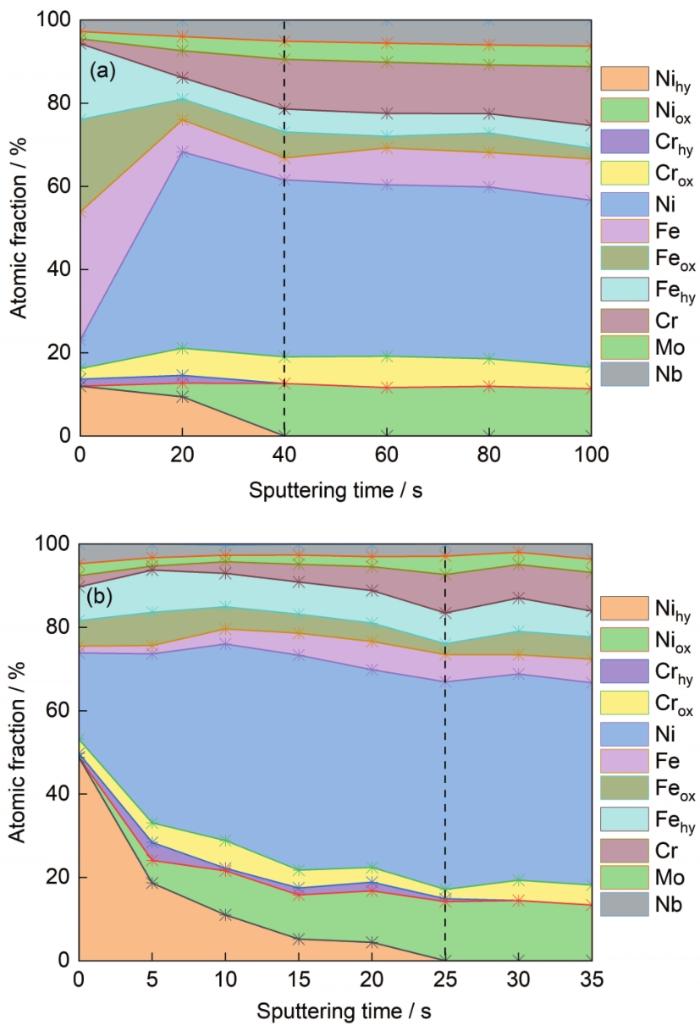

... 对钝化膜不同深度的XPS谱进行拟合处理,计算出钝化膜中不同成分的原子分数,结果如图11所示.与R Inconel 718合金相比,SLM Inconel 718合金钝化膜中NiO的含量较低,Cr2O3的含量较高,NiO是多孔的[17,24],Cr2O3是致密且保护性良好[38];另外,R Inconel 718合金的钝化膜中金属Nb含量降低,导致Ni的活性增加和Cr的活性降低,促使形成多孔钝化膜[17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...

... [17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...

Microstructural evolution and corrosion behaviors of Inconel 718 alloy produced by selective laser melting following different heat treatments

2

2019

... 随着增材制造技术的应用越来越广泛,其腐蚀性能得到越来越多的关注.一般来说,增材制造金属零构件存在孔隙和熔池边界等缺陷,导致其耐蚀性低于传统方法制造的金属零构件[2~4].Inconel 718合金是一种具有优异的机械性能、抗氧化性、耐高温和耐腐蚀性的镍基高温合金[5~7],已广泛应用于化工、航空航天、石油、舰船、核反应堆等众多领域[7~9].Inconel 718合金是增材制造领域应用最为广泛的合金材料,其性能得到了大量的研究[6,10~12].腐蚀性能是其重要的性能指标之一,研究人员[9,13~18]对其腐蚀性能也做了相关的研究.Raj等[14]研究了直接金属激光烧结(DMLS)成形的Inconel 718在1.0 mol/L H2SO4溶液中的电化学行为,发现DMLS Inconel 718的耐蚀性高于商业Inconel 718,而且经过热处理的DMLS Inconel 718比商业合金具有更低的电流密度和更高腐蚀电位.Tang等[16]研究了激光选区熔化(SLM)增材制造Inconel 718合金在3.5%NaCl (质量分数)溶液中的腐蚀行为.研究发现,与轧制Inconel 718相比,SLM Inconel 718合金表面形成多孔的钝化膜,耐蚀性更差.Zhang和Ojo[17]研究了电弧增材制造(WAAM)和锻造Inconel 718热处理后(HT)的腐蚀行为.结果表明,与锻造HT Inconel 718相比,WAAM HT Inconel 718在1.0 mol/L HNO3和1.0 mol/L H2SO4溶液中耐蚀性相对较差,主要原因在于其钝化膜含有较少Cr2O3和较多NiO.Luo等[18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

... [18]研究了SLM Inconel 718在3.5%NaCl溶液中的腐蚀行为.结果表明,SLM Inconel 718和轧制Inconel 718表面出现明显的裂纹,但轧制样品表面钝化膜光滑,其耐蚀性优于SLM Inconel 718. ...

Performance of different microstructure on electrochemical behaviors of laser solid formed Ti-6Al-4V alloy in NaCl solution

1

2021

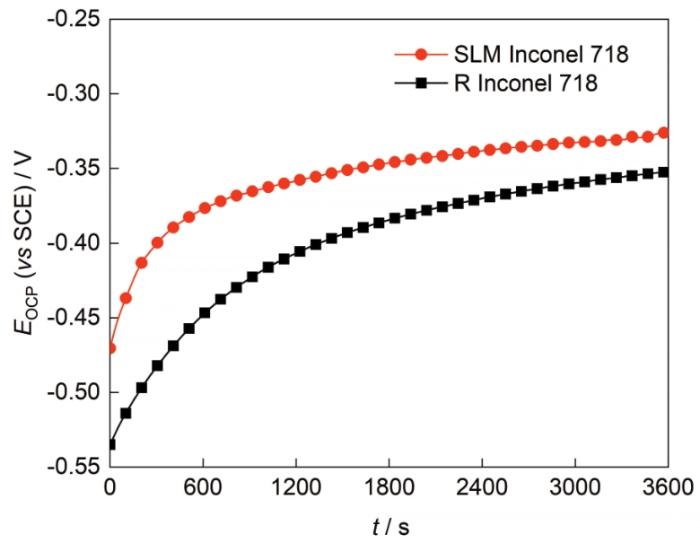

... 图2为2种合金在0.1 mol/L NaOH溶液中的开路电位(EOCP)变化趋势.可以看出,2种材料的EOCP均随着时间的增加而正移,表明2种材料表面生成钝化膜,处于自发钝化状态[19].SLM Inconel 718合金的开路电位正于R Inconel 718合金的开路电位,SLM Inconel 718合金的活性较R Inconel 718合金更低,更难发生腐蚀[20,21]. ...

Local electrochemistry of reinforcement steel-distribution of open circuit and pitting potentials on steels with different surface condition

1

2015

... 图2为2种合金在0.1 mol/L NaOH溶液中的开路电位(EOCP)变化趋势.可以看出,2种材料的EOCP均随着时间的增加而正移,表明2种材料表面生成钝化膜,处于自发钝化状态[19].SLM Inconel 718合金的开路电位正于R Inconel 718合金的开路电位,SLM Inconel 718合金的活性较R Inconel 718合金更低,更难发生腐蚀[20,21]. ...

Relationship of corrosion behavior between single-phase equiatomic CoCrNi, CoCrNiFe, CoCrNiFeMn alloys and their constituents in NaCl solution

1

2021

... 图2为2种合金在0.1 mol/L NaOH溶液中的开路电位(EOCP)变化趋势.可以看出,2种材料的EOCP均随着时间的增加而正移,表明2种材料表面生成钝化膜,处于自发钝化状态[19].SLM Inconel 718合金的开路电位正于R Inconel 718合金的开路电位,SLM Inconel 718合金的活性较R Inconel 718合金更低,更难发生腐蚀[20,21]. ...

Passivation behavior of 2507 super duplex stainless steel in simulated concrete pore solution

2

2020

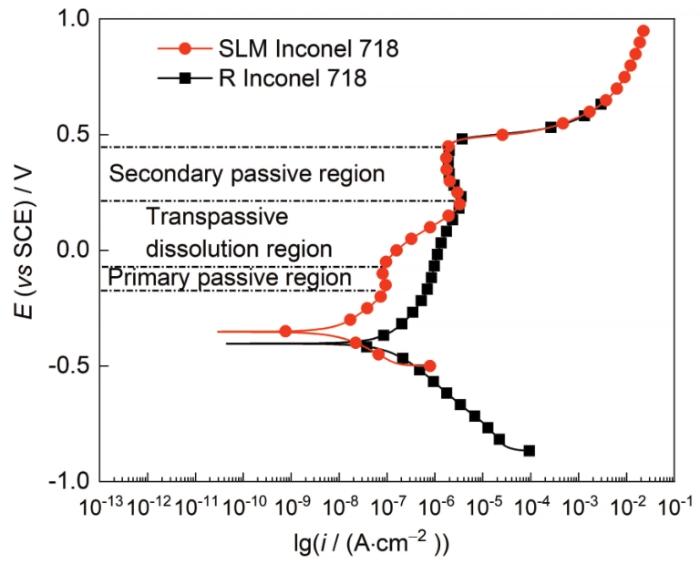

... 图3为SLM Inconel 718合金和R Inconel 718合金在0.1 mol/L NaOH溶液中的动电位极化曲线.可以看出,2种合金均发生点蚀,但SLM Inconel 718合金的腐蚀速率要低于R Inconel 718合金,SLM Inconel 718合金的耐蚀性更优.与R Inconel 718合金不同,SLM Inconel 718合金的阳极极化曲线可以分为初级钝化区(-0.17~-0.07 V)、过钝化溶解区(-0.07~0.22 V)、二次钝化区(0.22~0.44 V)和点蚀(> 0.44 V) 4个阶段.在过钝化溶解区,SLM Inconel 718合金的钝化电流密度(ip)由(9.18 ± 0.05) × 10-8 A/cm2变化为(3.51 ± 0.02) × 10-6 A/cm2,这归因于钝化膜中部分氧化物的转变或溶解[22,23]. ...

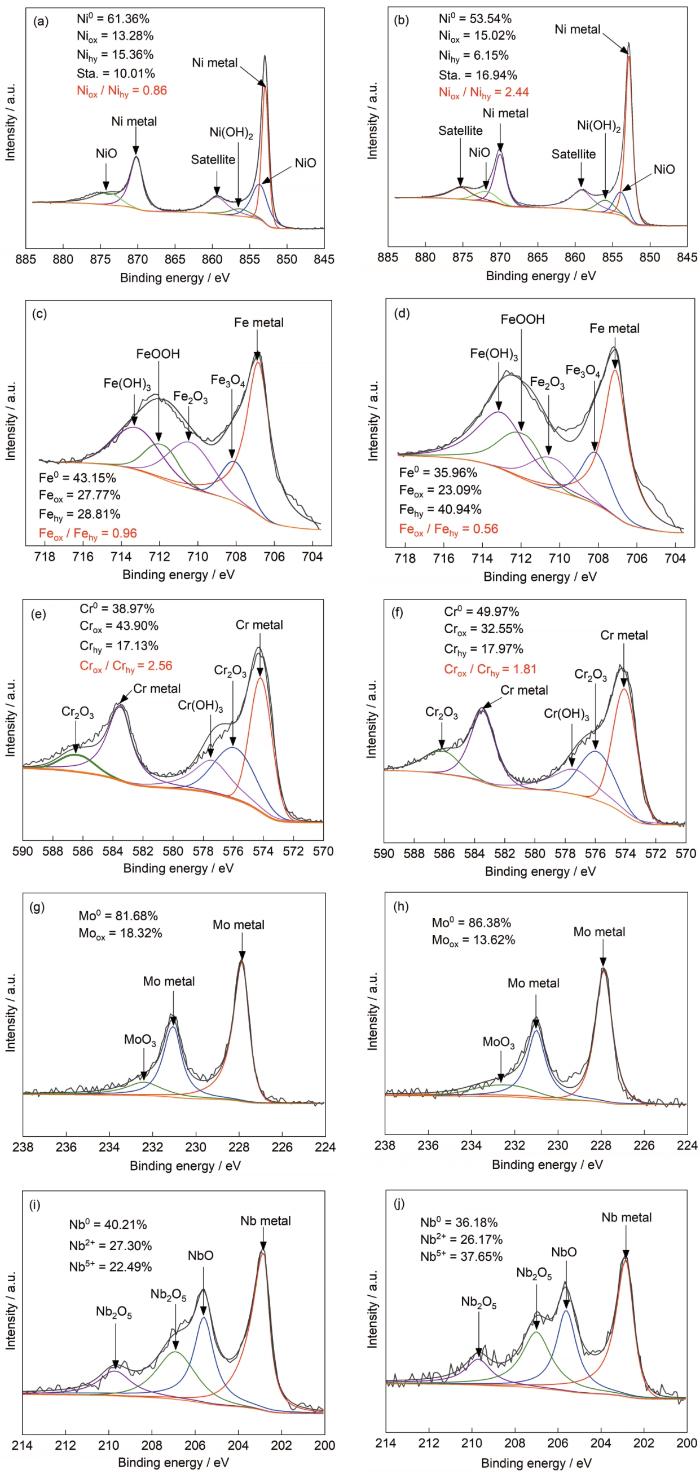

... 钝化膜的成分是决定钝化膜稳定性和保护性能的最主要因素.图9给出了2种合金钝化膜的Ni2p、Fe2p、Cr2p、Mo3d和Nb3d的XPS谱.由图可知,SLM Inconel 718合金和R Inconel 718合金的钝化膜成分组成一致,均由Ni、Fe和Cr的氧化物和氢氧化物以及Mo和Nb的氧化物构成.Ni2p光谱划分为Ni0、Ni2+和卫星峰[34,35],其中Ni2+以NiO和Ni(OH)2形式存在,SLM Inconel 718合金的NiO/Ni(OH)2比值大约是R Inconel 718合金的1/3 (图9a和b).Fe2p光谱划分成5个峰,分别为金属Fe、Fe3O4、Fe2O3、FeOOH和Fe(OH)3.Fe2O3和Fe(OH)3作为钝化膜的主要成分,在SLM Inconel 718合金和R Inconel 718合金中都具有较高的峰面积比.在二次钝化区域,Fe的氧化物容易转化为FeOOH[22] (图9c和d).Cr2p光谱划分为金属Cr、Cr2O3和Cr(OH)3,SLM Inconel718合金的Cr2O3/Cr(OH)3比值为2.56,R Inconel 718合金则下降到1.81 (图9e和f).Mo3d光谱划分为金属Mo和MoO3 (图9g和h).Cwalina等[36]指出MoO3可以改善钝化膜的性能,从而进一步降低钝化电流密度,但2种合金表面生成的钝化膜中MoO3的含量很少.Nb3d光谱划分为金属Nb、NbO和Nb2O5 (图9i和j). ...

Corrosion and cavitation erosion resistance enhancement of cast Ni-Al bronze by laser surface melting

1

2021

... 图3为SLM Inconel 718合金和R Inconel 718合金在0.1 mol/L NaOH溶液中的动电位极化曲线.可以看出,2种合金均发生点蚀,但SLM Inconel 718合金的腐蚀速率要低于R Inconel 718合金,SLM Inconel 718合金的耐蚀性更优.与R Inconel 718合金不同,SLM Inconel 718合金的阳极极化曲线可以分为初级钝化区(-0.17~-0.07 V)、过钝化溶解区(-0.07~0.22 V)、二次钝化区(0.22~0.44 V)和点蚀(> 0.44 V) 4个阶段.在过钝化溶解区,SLM Inconel 718合金的钝化电流密度(ip)由(9.18 ± 0.05) × 10-8 A/cm2变化为(3.51 ± 0.02) × 10-6 A/cm2,这归因于钝化膜中部分氧化物的转变或溶解[22,23]. ...

Influence of micro-structure on corrosion behavior of a Ni-based superalloy in 3.5% NaCl

2

2007

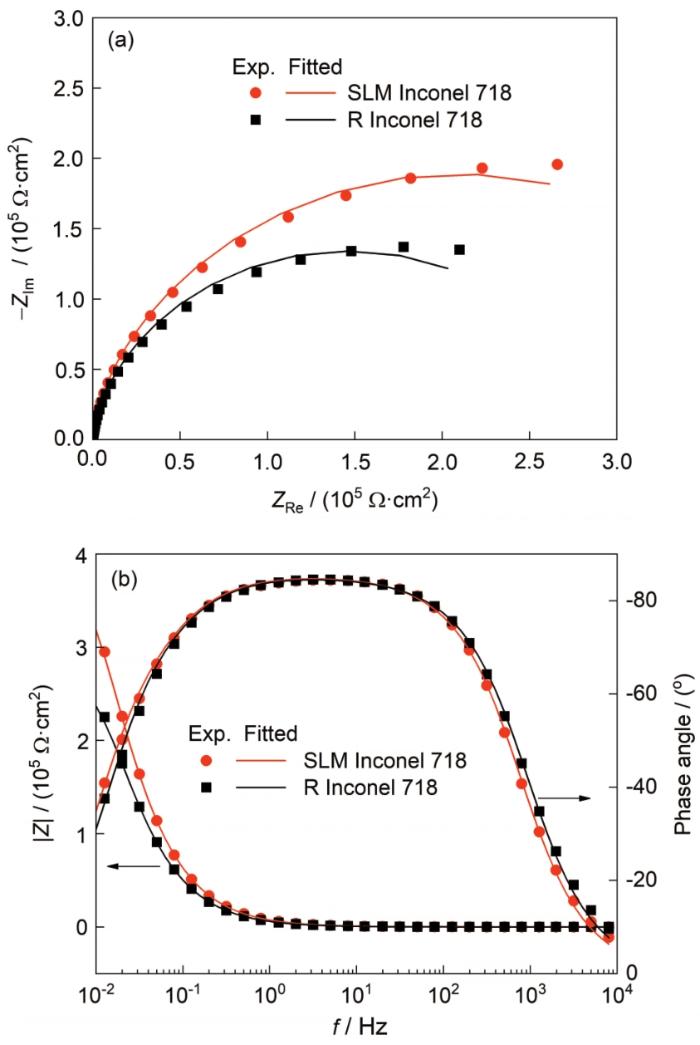

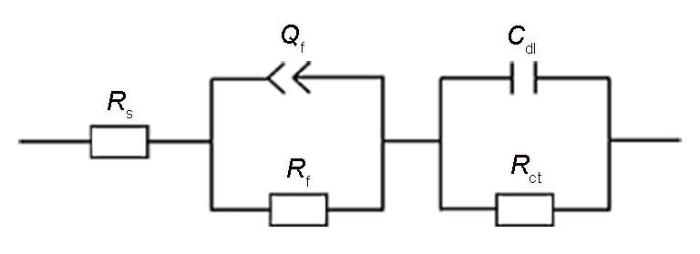

... 采用EIS进一步分析了SLM Inconel 718合金的腐蚀行为,结果如图5所示.从图5a可知,2种合金均呈现出不完整的单容抗弧,这是由于电极/电解质界面中的电荷转移过程,并且与钝化膜性质的变化有关[24].与R Inconel 718相比,SLM Inconel 718的容抗弧更宽,耐蚀性更好[25].Bode图如图5b所示,在较宽的频率范围内,2种合金的相位角均大于80°,合金表面都形成较稳定的无源膜[26].在中低频区,SLM Inconel 718合金表面形成的钝化膜获得了比R Inconel 718合金更大的阻抗模值.图6是EIS的等效电路,图中Rs是溶液电阻,Rf是钝化膜电阻,Qf表示钝化膜电容,Cdl是双电层电容,Rct是电荷转移电阻.EIS数据拟合结果如表2所示.可知,SLM Inconel 718合金的Rf和Rct均大于R Inconel 718合金,SLM Inconel 718合金的钝化膜保护性能更强,腐蚀速率更低,耐蚀性更优异. ...

... 对钝化膜不同深度的XPS谱进行拟合处理,计算出钝化膜中不同成分的原子分数,结果如图11所示.与R Inconel 718合金相比,SLM Inconel 718合金钝化膜中NiO的含量较低,Cr2O3的含量较高,NiO是多孔的[17,24],Cr2O3是致密且保护性良好[38];另外,R Inconel 718合金的钝化膜中金属Nb含量降低,导致Ni的活性增加和Cr的活性降低,促使形成多孔钝化膜[17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...

Comparison of electrochemical behavior between coarse-grained and fine-grained AISI 430 ferritic stainless steel by Mott-Schottky analysis and EIS measurements

1

2015

... 采用EIS进一步分析了SLM Inconel 718合金的腐蚀行为,结果如图5所示.从图5a可知,2种合金均呈现出不完整的单容抗弧,这是由于电极/电解质界面中的电荷转移过程,并且与钝化膜性质的变化有关[24].与R Inconel 718相比,SLM Inconel 718的容抗弧更宽,耐蚀性更好[25].Bode图如图5b所示,在较宽的频率范围内,2种合金的相位角均大于80°,合金表面都形成较稳定的无源膜[26].在中低频区,SLM Inconel 718合金表面形成的钝化膜获得了比R Inconel 718合金更大的阻抗模值.图6是EIS的等效电路,图中Rs是溶液电阻,Rf是钝化膜电阻,Qf表示钝化膜电容,Cdl是双电层电容,Rct是电荷转移电阻.EIS数据拟合结果如表2所示.可知,SLM Inconel 718合金的Rf和Rct均大于R Inconel 718合金,SLM Inconel 718合金的钝化膜保护性能更强,腐蚀速率更低,耐蚀性更优异. ...

The passivity of selective laser melted 316L stainless steel

1

2020

... 采用EIS进一步分析了SLM Inconel 718合金的腐蚀行为,结果如图5所示.从图5a可知,2种合金均呈现出不完整的单容抗弧,这是由于电极/电解质界面中的电荷转移过程,并且与钝化膜性质的变化有关[24].与R Inconel 718相比,SLM Inconel 718的容抗弧更宽,耐蚀性更好[25].Bode图如图5b所示,在较宽的频率范围内,2种合金的相位角均大于80°,合金表面都形成较稳定的无源膜[26].在中低频区,SLM Inconel 718合金表面形成的钝化膜获得了比R Inconel 718合金更大的阻抗模值.图6是EIS的等效电路,图中Rs是溶液电阻,Rf是钝化膜电阻,Qf表示钝化膜电容,Cdl是双电层电容,Rct是电荷转移电阻.EIS数据拟合结果如表2所示.可知,SLM Inconel 718合金的Rf和Rct均大于R Inconel 718合金,SLM Inconel 718合金的钝化膜保护性能更强,腐蚀速率更低,耐蚀性更优异. ...

Influence of nanocrystallization on passive behavior of Ni-based superalloy in acidic solutions

2

2007

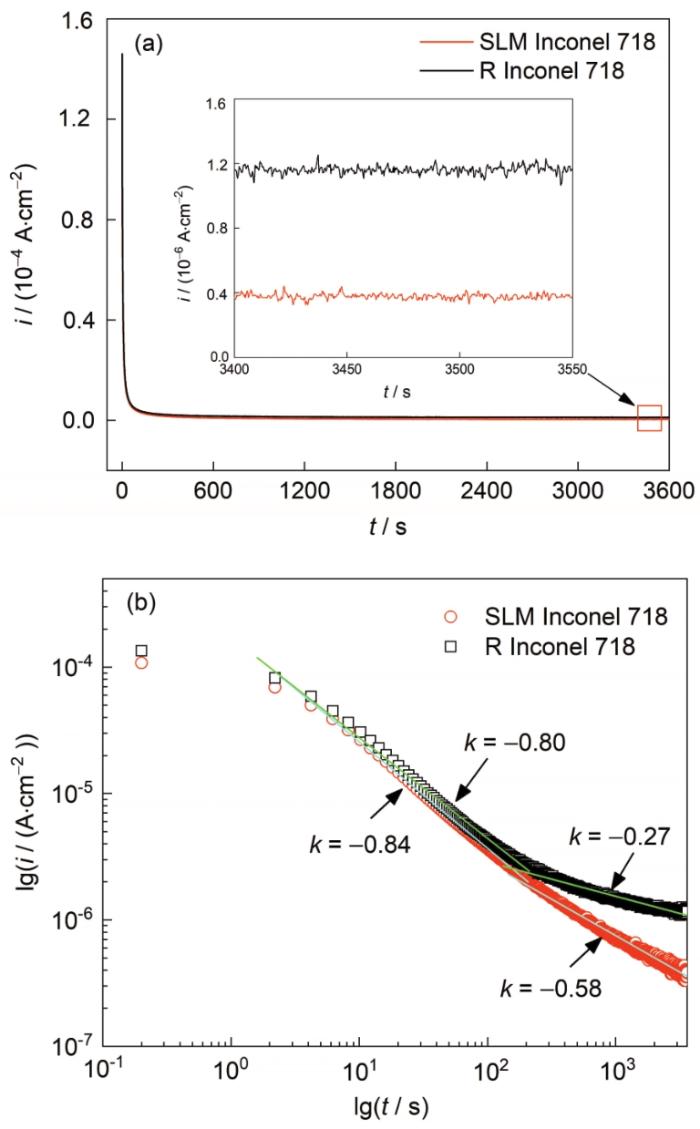

... 图7a和b分别为SLM Inconel 718和R Inconel 718在0.1 mol/L NaOH溶液中的电流密度随时间变化的关系曲线以及与其对应的双对数曲线.从图7a可知,前100 s时,电流密度随着时间的增加急剧下降,表明合金表面形成了钝化膜.钝化膜形成和溶解同时进行,但钝化膜的厚度随着成膜时间的增加而逐渐增加,电流密度缓慢下降,并最终趋于稳定,SLM Inconel 718合金和R Inconel 718合金的电流密度稳定值分别为(3.74 ± 0.10) × 10-7和(1.16 ± 0.02) × 10-6 A/cm2.与R Inconel 718合金相比,SLM Inconel 718合金电流密度更低,钝化膜更稳定,保护性更好.如果忽略双层电荷的贡献,电流密度的最初下降与电极表面的钝化膜生长有关.电流密度(i)随时间(t)下降[27]: ...

... 式中,A为常数;k为电流密度-时间双对数曲线的斜率(k = -1.0,表示形成了高场控制的钝化膜,钝化膜的致密性较好,保护性能较强;k = -0.5,表示形成了扩散控制的钝化膜,钝化膜疏松多孔,致密性较差,保护性能较弱[27]).由图7b看出,初始时,SLM Inconel 718合金和R Inconel 718合金的电流密度-时间双对数曲线的斜率分别为-0.84和-0.80,接近于-1,此时生成了相对致密、保护性良好的钝化膜;随着时间的延长,曲线的斜率分别变化为-0.58和-0.27,此时,由于溶解和重新形成过程而形成了多孔的钝化膜[28]. ...

Pitting corrosion of aluminum

1

1999

... 式中,A为常数;k为电流密度-时间双对数曲线的斜率(k = -1.0,表示形成了高场控制的钝化膜,钝化膜的致密性较好,保护性能较强;k = -0.5,表示形成了扩散控制的钝化膜,钝化膜疏松多孔,致密性较差,保护性能较弱[27]).由图7b看出,初始时,SLM Inconel 718合金和R Inconel 718合金的电流密度-时间双对数曲线的斜率分别为-0.84和-0.80,接近于-1,此时生成了相对致密、保护性良好的钝化膜;随着时间的延长,曲线的斜率分别变化为-0.58和-0.27,此时,由于溶解和重新形成过程而形成了多孔的钝化膜[28]. ...

Effect of aging treatment on microstructure and corrosion behavior of a Fe-18Cr-15Mn-0.66N stainless steel

1

2022

... 钝化膜的载流子密度是影响材料耐蚀性的重要因素之一.钝化膜的载流子密度可以通过测量空间电荷层的电容(CSC)与电极电位(E)的函数曲线来分析.根据Mott-Schottky理论,CSC与E之间的关系可表示为[16,29]: ...

Electronic properties of the passive films formed on CoCrFeNi and CoCrFeNiAl high entropy alloys in sodium chloride solution

1

2020

... 式中,ε是钝化膜的介电常数(取12[16,30]);ε0是真空介电常数(8.854 × 10-14 F/cm);e是电子电荷的绝对值(1.6021 × 10-19 C);Nq是电荷载流子密度,由Mott-Schottky曲线斜率进行计算,斜率为正呈n-型半导体特征,斜率为负呈p-型半导体特征;Efb是平带电位;kB是Boltzmann常数(1.38 × 10-23 J/K);T是热力学温度. ...

Passivity of 316L stainless steel in borate buffer solution studied by Mott-Schottky analysis, atomic absorption spectrometry and X-ray photoelectron spectroscopy

1

2010

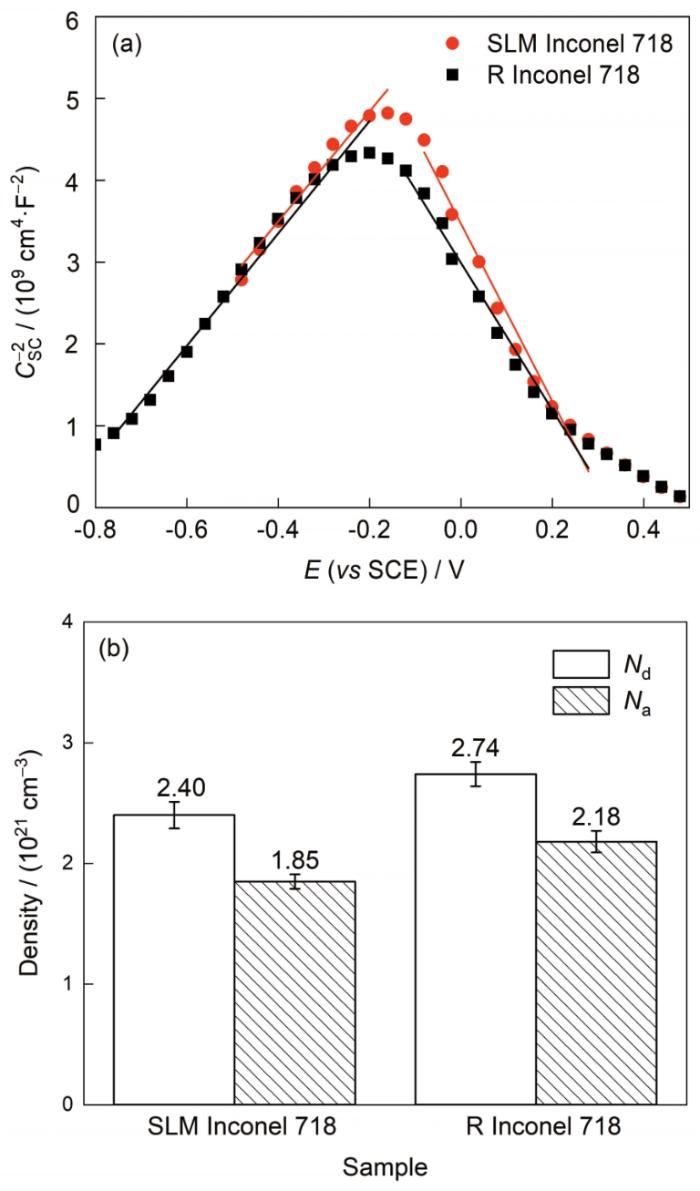

... 图8a显示了SLM Inconel 718合金和R Inconel 718合金在0.1 mol/L NaOH溶液中的Mott-Schottky曲线.可以看出,2种合金的钝化膜均呈现p-n异质结联接结构,这与钝化膜中Ni、Cr和Fe的氧化物和氢氧化物的半导体类型有关.在负电位区域,线性区域的斜率是正值,SLM Inconel 718合金和R Inconel 718合金的钝化膜呈n-型半导体行为,这是由于钝化膜中存在Fe2O3、Fe3O4和FeOOH[31].随着电极电位的增加,的值逐渐增大,即电容逐渐减小,这是由于电子耗尽层厚度增加和电荷载流子(n-型半导体的供体)数量减少.随着电位的正移,因阴离子的吸附作用,电容增加与价带中空穴浓度增加有关[32].SLM Inconel 718合金和R Inconel 718合金钝化膜的主要成分由Fe的氧化物和氢氧化物转变为Cr2O3和NiO等氧化物,从而表现出p-型半导体行为[33].图8b是2种合金表面钝化膜的施主/受主密度,可以看出,2者均达到了1021 cm-3数量级.与R Inconel 718合金相比,SLM Inconel 718合金表面钝化膜的载流子密度(供体密度Nd和受体密度Na)下降12%~15%,钝化膜的保护性更好. ...

Semiconducting properties of thermally grown oxide films on AISI 304 stainless steel

1

2000

... 图8a显示了SLM Inconel 718合金和R Inconel 718合金在0.1 mol/L NaOH溶液中的Mott-Schottky曲线.可以看出,2种合金的钝化膜均呈现p-n异质结联接结构,这与钝化膜中Ni、Cr和Fe的氧化物和氢氧化物的半导体类型有关.在负电位区域,线性区域的斜率是正值,SLM Inconel 718合金和R Inconel 718合金的钝化膜呈n-型半导体行为,这是由于钝化膜中存在Fe2O3、Fe3O4和FeOOH[31].随着电极电位的增加,的值逐渐增大,即电容逐渐减小,这是由于电子耗尽层厚度增加和电荷载流子(n-型半导体的供体)数量减少.随着电位的正移,因阴离子的吸附作用,电容增加与价带中空穴浓度增加有关[32].SLM Inconel 718合金和R Inconel 718合金钝化膜的主要成分由Fe的氧化物和氢氧化物转变为Cr2O3和NiO等氧化物,从而表现出p-型半导体行为[33].图8b是2种合金表面钝化膜的施主/受主密度,可以看出,2者均达到了1021 cm-3数量级.与R Inconel 718合金相比,SLM Inconel 718合金表面钝化膜的载流子密度(供体密度Nd和受体密度Na)下降12%~15%,钝化膜的保护性更好. ...

Passive film on 2205 duplex stainless steel studied by photo-electrochemistry and ARXPS methods

1

2019

... 图8a显示了SLM Inconel 718合金和R Inconel 718合金在0.1 mol/L NaOH溶液中的Mott-Schottky曲线.可以看出,2种合金的钝化膜均呈现p-n异质结联接结构,这与钝化膜中Ni、Cr和Fe的氧化物和氢氧化物的半导体类型有关.在负电位区域,线性区域的斜率是正值,SLM Inconel 718合金和R Inconel 718合金的钝化膜呈n-型半导体行为,这是由于钝化膜中存在Fe2O3、Fe3O4和FeOOH[31].随着电极电位的增加,的值逐渐增大,即电容逐渐减小,这是由于电子耗尽层厚度增加和电荷载流子(n-型半导体的供体)数量减少.随着电位的正移,因阴离子的吸附作用,电容增加与价带中空穴浓度增加有关[32].SLM Inconel 718合金和R Inconel 718合金钝化膜的主要成分由Fe的氧化物和氢氧化物转变为Cr2O3和NiO等氧化物,从而表现出p-型半导体行为[33].图8b是2种合金表面钝化膜的施主/受主密度,可以看出,2者均达到了1021 cm-3数量级.与R Inconel 718合金相比,SLM Inconel 718合金表面钝化膜的载流子密度(供体密度Nd和受体密度Na)下降12%~15%,钝化膜的保护性更好. ...

X-ray photoelectron spectroscopy study of the passive films formed on thermally sprayed and wrought Inconel 625

1

2010

... 钝化膜的成分是决定钝化膜稳定性和保护性能的最主要因素.图9给出了2种合金钝化膜的Ni2p、Fe2p、Cr2p、Mo3d和Nb3d的XPS谱.由图可知,SLM Inconel 718合金和R Inconel 718合金的钝化膜成分组成一致,均由Ni、Fe和Cr的氧化物和氢氧化物以及Mo和Nb的氧化物构成.Ni2p光谱划分为Ni0、Ni2+和卫星峰[34,35],其中Ni2+以NiO和Ni(OH)2形式存在,SLM Inconel 718合金的NiO/Ni(OH)2比值大约是R Inconel 718合金的1/3 (图9a和b).Fe2p光谱划分成5个峰,分别为金属Fe、Fe3O4、Fe2O3、FeOOH和Fe(OH)3.Fe2O3和Fe(OH)3作为钝化膜的主要成分,在SLM Inconel 718合金和R Inconel 718合金中都具有较高的峰面积比.在二次钝化区域,Fe的氧化物容易转化为FeOOH[22] (图9c和d).Cr2p光谱划分为金属Cr、Cr2O3和Cr(OH)3,SLM Inconel718合金的Cr2O3/Cr(OH)3比值为2.56,R Inconel 718合金则下降到1.81 (图9e和f).Mo3d光谱划分为金属Mo和MoO3 (图9g和h).Cwalina等[36]指出MoO3可以改善钝化膜的性能,从而进一步降低钝化电流密度,但2种合金表面生成的钝化膜中MoO3的含量很少.Nb3d光谱划分为金属Nb、NbO和Nb2O5 (图9i和j). ...

镍基合金CMSX-4在3.5 wt.% NaCl溶液中的腐蚀行为

1

2020

... 钝化膜的成分是决定钝化膜稳定性和保护性能的最主要因素.图9给出了2种合金钝化膜的Ni2p、Fe2p、Cr2p、Mo3d和Nb3d的XPS谱.由图可知,SLM Inconel 718合金和R Inconel 718合金的钝化膜成分组成一致,均由Ni、Fe和Cr的氧化物和氢氧化物以及Mo和Nb的氧化物构成.Ni2p光谱划分为Ni0、Ni2+和卫星峰[34,35],其中Ni2+以NiO和Ni(OH)2形式存在,SLM Inconel 718合金的NiO/Ni(OH)2比值大约是R Inconel 718合金的1/3 (图9a和b).Fe2p光谱划分成5个峰,分别为金属Fe、Fe3O4、Fe2O3、FeOOH和Fe(OH)3.Fe2O3和Fe(OH)3作为钝化膜的主要成分,在SLM Inconel 718合金和R Inconel 718合金中都具有较高的峰面积比.在二次钝化区域,Fe的氧化物容易转化为FeOOH[22] (图9c和d).Cr2p光谱划分为金属Cr、Cr2O3和Cr(OH)3,SLM Inconel718合金的Cr2O3/Cr(OH)3比值为2.56,R Inconel 718合金则下降到1.81 (图9e和f).Mo3d光谱划分为金属Mo和MoO3 (图9g和h).Cwalina等[36]指出MoO3可以改善钝化膜的性能,从而进一步降低钝化电流密度,但2种合金表面生成的钝化膜中MoO3的含量很少.Nb3d光谱划分为金属Nb、NbO和Nb2O5 (图9i和j). ...

镍基合金CMSX-4在3.5 wt.% NaCl溶液中的腐蚀行为

1

2020

... 钝化膜的成分是决定钝化膜稳定性和保护性能的最主要因素.图9给出了2种合金钝化膜的Ni2p、Fe2p、Cr2p、Mo3d和Nb3d的XPS谱.由图可知,SLM Inconel 718合金和R Inconel 718合金的钝化膜成分组成一致,均由Ni、Fe和Cr的氧化物和氢氧化物以及Mo和Nb的氧化物构成.Ni2p光谱划分为Ni0、Ni2+和卫星峰[34,35],其中Ni2+以NiO和Ni(OH)2形式存在,SLM Inconel 718合金的NiO/Ni(OH)2比值大约是R Inconel 718合金的1/3 (图9a和b).Fe2p光谱划分成5个峰,分别为金属Fe、Fe3O4、Fe2O3、FeOOH和Fe(OH)3.Fe2O3和Fe(OH)3作为钝化膜的主要成分,在SLM Inconel 718合金和R Inconel 718合金中都具有较高的峰面积比.在二次钝化区域,Fe的氧化物容易转化为FeOOH[22] (图9c和d).Cr2p光谱划分为金属Cr、Cr2O3和Cr(OH)3,SLM Inconel718合金的Cr2O3/Cr(OH)3比值为2.56,R Inconel 718合金则下降到1.81 (图9e和f).Mo3d光谱划分为金属Mo和MoO3 (图9g和h).Cwalina等[36]指出MoO3可以改善钝化膜的性能,从而进一步降低钝化电流密度,但2种合金表面生成的钝化膜中MoO3的含量很少.Nb3d光谱划分为金属Nb、NbO和Nb2O5 (图9i和j). ...

Revisiting the effects of molybdenum and tungsten alloying on corrosion behavior of nickel-chromium alloys in aqueous corrosion

1

2019

... 钝化膜的成分是决定钝化膜稳定性和保护性能的最主要因素.图9给出了2种合金钝化膜的Ni2p、Fe2p、Cr2p、Mo3d和Nb3d的XPS谱.由图可知,SLM Inconel 718合金和R Inconel 718合金的钝化膜成分组成一致,均由Ni、Fe和Cr的氧化物和氢氧化物以及Mo和Nb的氧化物构成.Ni2p光谱划分为Ni0、Ni2+和卫星峰[34,35],其中Ni2+以NiO和Ni(OH)2形式存在,SLM Inconel 718合金的NiO/Ni(OH)2比值大约是R Inconel 718合金的1/3 (图9a和b).Fe2p光谱划分成5个峰,分别为金属Fe、Fe3O4、Fe2O3、FeOOH和Fe(OH)3.Fe2O3和Fe(OH)3作为钝化膜的主要成分,在SLM Inconel 718合金和R Inconel 718合金中都具有较高的峰面积比.在二次钝化区域,Fe的氧化物容易转化为FeOOH[22] (图9c和d).Cr2p光谱划分为金属Cr、Cr2O3和Cr(OH)3,SLM Inconel718合金的Cr2O3/Cr(OH)3比值为2.56,R Inconel 718合金则下降到1.81 (图9e和f).Mo3d光谱划分为金属Mo和MoO3 (图9g和h).Cwalina等[36]指出MoO3可以改善钝化膜的性能,从而进一步降低钝化电流密度,但2种合金表面生成的钝化膜中MoO3的含量很少.Nb3d光谱划分为金属Nb、NbO和Nb2O5 (图9i和j). ...

Passivation behavior and surface chemistry of 2507 super duplex stainless steel in artificial seawater: Influence of dissolved oxygen and pH

2

2019

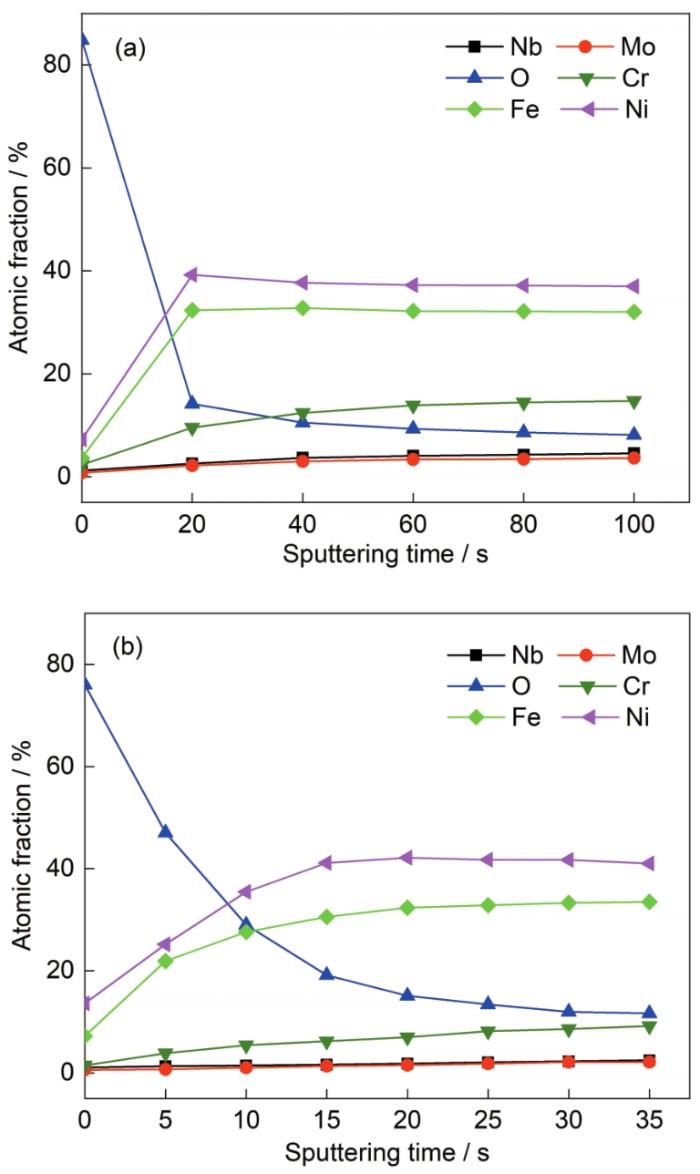

... 图10是2种合金表面钝化膜中Ni、Fe、Cr、Mo、Nb和O的深度分布.可以看出,Ni、Fe和Cr含量随溅射时间增加而增加.与R Inconel 718合金相比,SLM Inconel 718合金形成钝化膜的表层具有更低的Ni、Fe和Cr含量以及较高的O含量,表明SLM Inconel 718合金形成的钝化膜更厚[37]. ...

... 对钝化膜不同深度的XPS谱进行拟合处理,计算出钝化膜中不同成分的原子分数,结果如图11所示.与R Inconel 718合金相比,SLM Inconel 718合金钝化膜中NiO的含量较低,Cr2O3的含量较高,NiO是多孔的[17,24],Cr2O3是致密且保护性良好[38];另外,R Inconel 718合金的钝化膜中金属Nb含量降低,导致Ni的活性增加和Cr的活性降低,促使形成多孔钝化膜[17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...

The electrochemical behaviour of 2205 duplex stainless steel in alkaline solutions with different pH in the presence of chloride

1

2012

... 对钝化膜不同深度的XPS谱进行拟合处理,计算出钝化膜中不同成分的原子分数,结果如图11所示.与R Inconel 718合金相比,SLM Inconel 718合金钝化膜中NiO的含量较低,Cr2O3的含量较高,NiO是多孔的[17,24],Cr2O3是致密且保护性良好[38];另外,R Inconel 718合金的钝化膜中金属Nb含量降低,导致Ni的活性增加和Cr的活性降低,促使形成多孔钝化膜[17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...

A study of the passive films on chromium by capacitance measurement

1

2003

... 对钝化膜不同深度的XPS谱进行拟合处理,计算出钝化膜中不同成分的原子分数,结果如图11所示.与R Inconel 718合金相比,SLM Inconel 718合金钝化膜中NiO的含量较低,Cr2O3的含量较高,NiO是多孔的[17,24],Cr2O3是致密且保护性良好[38];另外,R Inconel 718合金的钝化膜中金属Nb含量降低,导致Ni的活性增加和Cr的活性降低,促使形成多孔钝化膜[17].因此,SLM Inconel 718合金表面生成的钝化膜较R Inconel 718合金相对致密,保护性更好.此外,钝化膜中氢氧化物的原子分数由表及里逐渐减少,氢氧化物的消失表示钝化膜的终止[37],在SLM Inconel 718合金中,Ni(OH)2和Cr(OH)3的消失时间是一致的,均为40 s,而R Inconel 718仅需要25 s,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的消失时间更长,钝化膜更厚,阻挡介质传输的能力更强,保护性更好.值得注意的是,与R Inconel 718合金相比,SLM Inconel 718合金的钝化膜中Ni(OH)2和Cr(OH)3的含量更低,导致钝化膜中的水含量减小,载流子密度降低[39],很好地解释了钝化膜半导体特性的研究结果. ...