高铌TiAl合金具有较低的密度、优良的抗氧化性、良好的高温比强度和抗蠕变等性能,其使用温度比常规TiAl合金高60~100 ℃,是具有发展前景的新一代高温轻质结构材料,在航天领域具有重大应用潜力,可用于航空飞行器的热防护蒙皮、喷嘴和翼舵系统等[1,2,3,4,5]。然而,由于TiAl合金的本征脆性、高温变形能力差,其板材制备难度很大。尤其对于薄板材料,轧制过程强烈的热散失和应变敏感性使得大规格板材较难制备,该过程强烈依赖于轧制条件。目前,通常采用包套轧制的方法进行TiAl板材制备,从而防止热量散失、界面氧化和裂纹萌生扩展等问题[6],保证TiAl合金的轧制可以在传统普通轧机上进行,进而大幅降低TiAl合金薄板材的加工成本。但对于包套轧制过程中包套结构、工艺参数和板材传输等工况条件对TiAl板材成形过程的影响等问题,相关的研究工作仍然较少,缺乏实践经验。除了不断改进、优化轧制技术,通常还采用优化的合金设计以及热加工铸锭或合金化粉末板坯进行TiAl合金板材制备[2,7],其中成分均匀、组织细小的预轧制板坯有利于满足高温热变形的要求。如Kim等[8]报道的β型TiAl合金成分范围为Ti-(40~45)Al-(2~8)Nb-(1~8)(Cr, Mn, V, Mo)-(0~0.5)(B, C) (原子分数,%,下同),其铸态组织细小均匀、流变应力低、高温变形能力良好。Kong等[9]采用近等温包套轧制的方法进行Ti-43Al-9V-Y合金的制备,获得了最大尺寸(700 mm×200 mm×(1.5~3.0) mm)的板材。德国GKSS、奥地利Plansee公司和中南大学在粉末冶金(PM)法制备TiAl板材方面取得了卓有成效的成果。GKSS利用PM法制备出性能优异的TNB系列合金板材,其中γ-MET PX (Ti-45Al-(5~10)Nb-X(B, C)合金板材的尺寸可达1000 mm×450 mm×1 mm或750 mm×350 mm×0.25 mm,并具有良好的室温塑性。

目前,针对高铌TiAl合金的板材轧制工艺设计及组织调控的研究相对较少,尤其是针对铸态合金直接进行轧制的研究。溶质Nb元素在TiAl合金中具有较高的溶解度,可有效阻碍位错运动与溶质扩散,显著提高TiAl合金的高温强度及组织稳定性[10]。此外,溶质Nb可降低TiAl合金的层错能,进一步影响其再结晶过程、变形抗力和流变软化行为。但是,高铌TiAl合金的热变形工艺参数和加工窗口尚不明晰。Wang等[11]采用特殊设计的不锈钢包套结构和每道次大变形量的轧制工艺制备了较大变形量的高铌TiAl合金板材,并分析了轧制和热处理工艺对组织演化过程的影响,获得了厚度约为1.9 mm、组织均匀的板材,该研究促进了短流程高效率板材制备工艺的开发。Chen等[12]和Liu等[13]分析了高铌TiAl合金铸锭中溶质元素的偏析行为,结果表明,主要存在S型、β型和α型3种溶质偏析,其中溶质Nb和Al元素的偏析会严重影响TiAl合金的层错能,热-力耦合作用下导致复杂的局域流变、层片分解和再结晶过程,进而造成组织和力学性能的分散性。同时,本文作者前期工作[14]发现溶质Nb会显著阻碍位错运动并促进机械孪晶的形成,而溶质Al的富集容易导致组成相的不均匀分布,导致局域软化行为和复杂的再结晶组织分布。因此,高铌TiAl合金的软化过程和组织演化与轧制工艺参数密切相关。综上所述,研究高铌TiAl合金的热变形行为及热变形过程的组织演化规律,有利于铸态合金直接轧制的工艺设计和再结晶组织调控,促进高铌TiAl合金的板材制备及其工程化应用。

本工作研究了Ti-46Al-8Nb合金的热加工图及直接包套轧制过程的组织特征和软化行为。通过分析功率耗散图、失稳图和应变速率敏感因子,结合热变形过程的组织演化规律,获得了该合金的热加工区间。通过包套轧制进行高铌TiAl合金的板材制备,明确了该过程的组织特征及流变软化行为,为高铌TiAl合金的轧制工艺制定及组织调控提供指导。

1 实验方法

采用水冷铜坩埚感应熔炼制备成分为Ti-46Al-8Nb合金铸锭,并对铸锭进行950 ℃保温40 h后随炉冷却的退火处理。采用电火花线切割技术在铸锭心部切取直径8 mm、高度15 mm的圆柱形试样,试样的高度方向沿铸锭的轴向。将切取的圆柱形试样表面车光亮后,使用MMS-300热力模拟试验机对圆柱形试样进行单道次热压缩实验。单道次压缩实验在Ar气气氛保护下进行,样品以5 ℃/s的速率升温至1100~1250 ℃,保温5 min后开始变形,变形量为真应变0.6,应变速率范围为0.001~1 s-1,变形后立刻淬火。

从铸锭心部切取方形轧制板坯,板材厚度方向沿铸锭的轴向,打磨板坯的各个表面并用丙酮清洗。采用包套轧制的方法对Ti-46Al-8Nb合金板坯进行热轧。使用TC4钛合金与304不锈钢制作复合包套,通过氩弧焊的方式进行封焊后,获得包套轧制预板坯。Ti-46Al-8Nb合金的具体轧制工艺为:将包套板坯随炉加热至1250 ℃,保温30 min后轧制,道次变形量不大于15%,轧制速率为0.15~0.20 m/s,每道次回炉保温5~10 min。达到总变形量后,将板材置于加热炉中,在950 ℃保温4 h后随炉冷却至室温。从轧态板材切取试样,用来观察该合金的热变形行为及组织演变。应用ULTRA55扫描电子显微镜(SEM)的背散射电子像(BSE)和电子背散射衍射(EBSD)技术及Tecnai G2 F20透射电子显微镜(TEM)进行微观组织观察和分析。

2 实验结果及分析讨论

2.1 热加工图

Prasad等[15]建立的动态材料模型(dynamic material modeling,DMM)假定机加工过程为一个系统,其中的工件为能量耗散体,在某温度和应变下,外力输入给工件的能量(P)主要作用于2个方面,如下式所示:

式中,G代表由塑性变形引起的能量耗散,其中大部分转化为热量;J代表组织演变引起的能量耗散,用于动态回复、动态再结晶、变形诱发相变、塑性流变或材料失效等;

上述两部分能量G和J所占的比例,可通过应变速率敏感指数(m)决定:

式中,T为变形温度。

如果材料符合本构关系

对于理想的线性耗散状态,m=1,则能量J=Jmax=

η描述了材料在不同T和

在动态材料模型中,基于Ziegler的最大熵产生率原理建立的材料流变失稳判据为[16]:

图1

图1

Ti-46Al-8Nb合金在不同真应变(ε)下的热加工图

Fig.1

Hot processing maps of Ti-46Al-8Nb alloys at ε=0.1 (a), ε=0.2 (b), ε=0.3 (c), ε=0.4 (d) and ε=0.5 (e) (ε—true strain,

图1中等值线上的数值代表η,阴影区域为失稳区,加工图中的不同区域对应着不同的热变形机制[17]。失稳区主要出现在较低η值区域。在应变小于0.3时,热加工图中有2个失稳区,其中一个出现在低温、高应变速率区域,温度为1100~1225 ℃、应变速率为0.06~1 s-1,另一个出现在温度为1150 ℃、应变速率为0.001 s-1附近。当应变增加到0.4时,在温度1250 ℃、应变速率0.006 s-1附近也出现了失稳。在应变不大于0.3时,随着应变的增加失稳区变化不明显,当应变达到0.4时,随着应变的增加失稳区迅速扩大。不同真应变下对应的热加工图中η的数值随真应变增加整体略有下降,但其等值线的分布规律基本相同。去除失稳区,将真应变为0.5时的加工图划分成了3个区域,如图1e所示的区域1~3,η值范围分别为0.25~0.38、0.38~0.45和0.45~0.65,一般认为η值在0.30~0.50范围内材料会发生大量的动态再结晶(DRX),η值高于0.60材料可能会出现超塑性[16]或涉及相变过程。

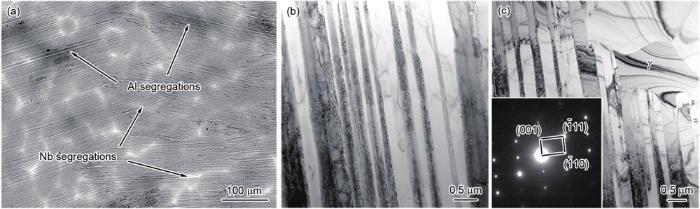

为了解释热加工图中失稳区的分布和η值的基本演变规律,对热压缩前后的Ti-46Al-8Nb合金进行了显微组织观察分析,图2为铸态Ti-46Al-8Nb合金的微观组织和相组成。铸态Ti-46Al-8Nb合金为近片层组织,如图2a所示,片层团尺寸为200~250 μm,α2/γ层片间距约为0.2~0.8 μm,片层团晶界分布着尺寸为5~10 μm的γ相晶粒,分别如图2b和c所示。该合金铸态组织中存在着严重的网状偏析,在层片团界面上存在深色的溶质Al偏析以及在层片团内存在白亮的Nb偏析(图2a)。根据平衡相图,其凝固路径为L→L+βprimary→βprimary (βprimary即初生β相),初生β相(低Al高Nb)在凝固过程中会导致枝晶间液相形成Al元素的偏析,Al偏析显示为黑色衬度;在β→α的固态转变过程中,多个α晶粒会在β晶粒内形核长大,该过程中溶质Al元素会向α相内部扩散而Nb元素则是向着相反的方向扩散,最终导致Nb元素在层片团界面富集,形成Nb偏析,显示白亮衬度。上述Ti-46Al-8Nb合金的层片组织特征及溶质偏析将对其热变形行为及热轧组织产生重要影响。

图2

图2

铸态Ti-46Al-8Nb合金的微观组织和相组成

Fig.2

SEM-BSE image of as-cast Ti-46Al-8Nb alloys (a), TEM images of the lamellar colonies (b), and γ grains at colony boundaries and the corresponding selected area electron diffraction (SAED) pattern (inset) (c)

样品发生失稳主要是由于产生绝热剪切带或发生局域流变等,在失稳区内进行热加工,样品会产生开裂或变形缺陷。图3为不同变形条件下Ti-46Al-8Nb合金微观组织的SEM像。如图3a所示,在1100 ℃、1 s-1条件下,组织中出现了明显的剪切带,片层团发生了剧烈的弯曲和扭折,甚至出现了宏观可见的裂纹缺陷(图3a中插图),在此变形条件下外部能量输入主要用于剪切带的形成和片层界面处裂纹的形成和扩展,导致η较小,引发材料失效和流变应力下降。除此之外,在1150 ℃、0.001 s-1条件下也发生了失稳,如图3b所示,组织中的Al偏析区域存在大量异常长大的晶粒。图4a~c分别为1150 ℃、0.001 s-1条件下变形的图像质量(IQ)图、相+晶界分布图和晶粒图,该变形组织以保留变形特征的残余片层为主,其中存在着大量的小角度晶界(约为32.7%),且全部存在于残余片层内部。在片层团晶界,即虚线框内,为尺寸非常不均匀的γ晶粒,这说明在此变形条件下,发生了严重的局域流变,变形易集中在Al偏析区域,而片层则保持着初始的变形特征。在非常缓慢的变形速率下,部分再结晶γ晶粒快速长大。在实际热加工过程中需要避免以上情况的产生,从而提高组织均匀性并保持合金较好的变形能力。

图3

图3

不同变形条件下Ti-46Al-8Nb合金微观组织的SEM像

Fig.3

SEM images showing deformed microstructures in hot compression tests of Ti-46Al-8Nb alloys with different deformation conditions

(a) 1100 ℃, 1 s-1 (Inset shows the crack defects)

(b) 1150 ℃, 0.001 s-1

(c) 1200 ℃, 0.1 s-1 (Region 1, inset shows the high magnified image of kinked lamellae)

(d) 1150 ℃, 0.01 s-1 (Region 2)

(e) 1200 ℃, 0.01 s-1 (Region 2)

(f) 1250 ℃, 0.001 s-1 (Region 3)

图4

图4

Ti-46Al-8Nb合金典型微观组织的EBSD表征

Fig.4

EBSD maps showing the deformed microstructure of Ti-46Al-8Nb alloys under deformation conditions of 1150 ℃,0.001 s-1 (Dotted boxes show grains in Al-segregation regions at colony boundaries) (a~c) and 1200 ℃, 0.1 s-1 (d~f)

Color online

(a, d) image quality (IQ) maps (b, e) phase maps with grain boundary misorientation angles (GB—grain boundary) (c, f) grain distribution maps

如图3c所示为1200 ℃、0.1 s-1 (区域1)条件下变形的片层结构,此时η值约为0.25,可以观察到明显的片层弯折(图3c中插图),片层内部是大量细小的再结晶γ晶粒和球化的α2晶粒,晶粒尺寸约为1 μm。该区域的EBSD测试结果如图4d~f所示。可见,板条结构较为清晰,尤其是α2板条,并未完全破碎,而γ板条内部已经产生了大量细小的晶粒,这些晶粒为Ti-46Al-8Nb合金在较高的应变速率下新形成的再结晶晶粒,若升高变形温度或降低应变速率,这些晶粒将迅速长大,使片层充分破碎。1150 ℃、0.01 s-1和1200 ℃、0.01 s-1条件下(区域2)的组织如图3d和e所示,此时组织的再结晶和均匀程度明显提高,呈现等轴晶形态。随温度从1150 ℃升至1200 ℃,晶粒尺寸从约5 μm增至15 μm,在1150 ℃仍存在少量残余片层,而在1200 ℃已经全部转变为等轴晶。区域2的η值较区域1略微增加,此时外部输入的能量多用于再结晶晶粒的形核和长大。1250 ℃、0.001 s-1条件下(区域3)的η值较其它2个区域明显增加,相应的微观组织如图3f所示,α2相体积分数较区域1和2明显增加,组织中存在大量片层间距细小的等轴片层晶,这说明在1250 ℃、0.001 s-1条件下可能发生了γ+α→α相变,由此产生的细小α晶粒在随后的冷却过程中析出了γ片层,此过程使η达到较高的数值。此情况下α相体积分数明显增加,而高温α相的变形能力相对较差,会增加变形抗力,因此,为了提高Ti-46Al-8Nb合金的变形能力应该尽量避免在此工艺下变形。

图5所示为不同真应变下Ti-46Al-8Nb合金的m随温度和应变速率的变化趋势。m通过

图5

图5

不同真应变下Ti-46Al-8Nb合金的应变速率敏感指数(m)随温度(T)和应变速率(

Fig.5

Variations of strain rate sensitivity exponent (m) with T and

基于上述的热加工图、热变形组织观察以及应变速率敏感指数的分析,为避免板材在轧制过程中开裂失效和晶粒异常长大等,促进TiAl合金发生均匀的塑性流变和充分再结晶,最终选择轧制温度范围为1150~1200 ℃、应变速率0.01~0.03 s-1,每道次的变形量约为18% (真应变0.2),有望获得具有良好板型板厚以及无裂纹缺陷的TiAl合金板材。

2.2 包套轧制Ti-46Al-8Nb合金的组织演化

图6a显示了包套轧制Ti-46Al-8Nb合金板材法向-轧向(ND-RD)面的宏观组织。采用机加工的方法去除复合包套后,TiAl合金板材的厚度大约为0.85 mm (变形量约80%),板材厚度较为均匀,厚度差别不大于5 μm,包套材料与TiAl合金没有发生反应,界面光滑,板材表面质量良好,表明复合包套设计对板材起到了明显的保护作用。从整体上观察,相比于铸态组织,Ti-46Al-8Nb合金在轧制变形后,组织明显变得细小,由于铸态组织中成分偏析的影响,热轧组织局域流变较为严重,但无Nb元素偏析,而Al元素偏析仍较为明显。轧制变形带明显存在,表现为再结晶与条状残余片层的交替组织。由于Nb元素大量固溶,残余片层稳定性大幅提高,从而导致轧制变形后仍有残余片层存在。

图6

图6

包套轧制Ti-46Al-8Nb合金板材微观组织演变的SEM-BSE像

Fig.6

SEM-BSE images of the as-rolled microstructure evolutions of Ti-46Al-8Nb alloy

(a) macro-structure (ND—normal direction, RD—rolling direction) (b1, b2) decomposition of lamellar colonies at low rolling reduction (c1, c2) decomposition of lamellar colonies at higher rolling reductions (d1, d2) fully DRXed microstructure (DRX—dynamic recrystallization)

随着包套轧制的继续进行,经过大变形量的轧制后,尺寸较大的残余片层完全分解,形成如图6d1和d2所示的完全再结晶组织,组织中仅剩余少量残余片层。这些残余片层内部存在一些块状的γ相,这些γ晶粒跨越多个α2/γ板条,打断了片层的连续性。残余片层中储存着变形能,如果对其继续变形或者热处理,可能会完全转变为等轴晶组织。

2.3 包套轧制Ti-46Al-8Nb合金的流变软化机制分析

为了进一步说明Ti-46Al-8Nb合金轧制板材的微观组织特征和流变软化机制,对其进行了TEM观察,如图7所示。在变形初期,片层板条中首先发生的是位错的堆垛和塞积。γ-TiAl相为L10结构[20],c/a=1.02 (c和a为晶格常数),存在各向异性,但考虑到c轴仅比a轴长2%,差别较小,可将其近似为fcc结构,滑移系相对较多,在应变能的激发作用下,γ相可通过{111}滑移面上Burgers矢量b=1/2<110]的普通位错和b=<101]、b=1/2<112]的超位错进行变形。由于Nb元素的固溶,γ相层错能降低,不易发生位错的交滑移或攀移,故γ相晶粒中塞积了大量位错,如图7a所示。大量堆垛的位错可为亚晶的形成提供驱动力,促进变形亚结构的形成,图7b显示了γ晶粒中弯曲的亚晶界及大量亚晶粒的存在,亚晶界的形成消耗了大量的位错,其周围位错的数量明显减少。如果随着变形的进行,即继续增加轧制道次或提升每道次的变形量,这些亚结构会逐渐向大角度晶界转化,从而促进再结晶晶粒的形成,即发生动态再结晶和再结晶晶粒的长大,最终使片层的连续性遭到破坏。

图7

图7

包套轧制Ti-46Al-8Nb合金板材的TEM分析

Fig.7

TEM analyses of the as-rolled microstructure of Ti-46Al-8Nb alloy

(a) dislocations in γ grains

(b) sub-structures in γ grains

(c) twinning in γ grains at colony boundaries

(d) twinning lamellae and the corresponding SAED patterns (inset)

(e) interactions of dislocations and deformation twins (f, g) decomposition of lamellar colonies (Inset in Fig.7f shows the SAED patterns of γ grains) (h) fully DRXed microstructure (Inset shows the SAED patterns of α2 grains)

除了位错诱导再结晶晶粒形成的机制,孪生变形也是轧制Ti-46Al-8Nb合金中典型的变形机制,如图7c~f所示。Ti-46Al-8Nb合金轧制组织中存在着大量不同形态的孪晶,图7c为宽度较大的孪晶,这些孪晶大多出现在片层团的晶界处,其周围不存在位错,主要形成于轧制道次间反复的回炉保温过程中,属于退火孪晶。在后续轧制过程中,这类孪晶会诱导不连续动态再结晶晶粒的形成,从而提高片层团晶界的变形能力。图7d为间距极细的孪晶片层结构及其选区电子衍射(SAED)花样(图7d中插图),这种结构在片层厚度方向表现出纳米尺度,片层间距不足50 nm,从SAED结果可知其内部同时存在着α2/γ片层和γ相孪晶[21]。此外,图7e所示是轧制态Ti-46Al-8Nb合金中的另一种孪晶形态,这些孪晶界与片层界面呈一定的角度,且大多与位错缠绕在一起。低层错能的γ-TiAl容易发生孪生变形,且仅有一个明显的孪生剪切方向,即{111}滑移面上的b=1/6<

包套坯料从箱式炉中取出时的温度为1250 ℃,在从加热炉转移至轧机和在轧制过程中,包套内部TiAl合金板材的温度会不可避免地有所降低,这将导致TiAl合金在包套热轧过程中并不是持续恒温的。在温降及变形应力的共同作用下,TiAl合金的α2/γ层片组织容易发生相变分解,即L(α/γ)→γ+α+B2/β,在片层完全分解的区域内,γ、α2和B2三相同时存在,片层分解的同时还伴随着α→γ转变。上述转变的发生将产生多相组织,包括大量的再结晶γ晶粒、α相和残余层片组织。

高铌TiAl合金具有较高的变形抗力和层片稳定性、低的层错能和元素扩散能力,在热变形过程中容易发生局域流变行为,其软化过程主要以γ相动态再结晶和L(α/γ)片层的相变分解为主。其中,层片团以及晶界处的变形差异容易导致变形不均匀,导致粗大的残余层片以及分散的组织产生,溶质偏析加剧了这个过程的发生,尤其是Al的偏析导致粗大的再结晶γ相形成。针对高铌TiAl合金,细小均匀的原始组织容易提高热变形能力[25]。采用1200~1250 ℃范围内高速、大变形量的复合包套轧制工艺有利于获得均匀细小的再结晶组织,从而保证合金的均匀塑性流变,显著提高TiAl合金包套轧制板材组织和性能的均匀性。

3 结论

(1) 根据动态材料模型计算并绘制Ti-46Al-8Nb合金的热加工图,在应变小于0.3时,热加工图中有2个失稳区,当应变增加到0.4时,在温度1250 ℃、应变速率0.006 s-1附近也出现了失稳,在此范围内易发生合金的开裂和组织的异常长大。通过功率耗散因子(η)和应变速率敏感指数(m)随温度和应变速率的变化趋势分析,并结合热变形组织的观察,将温度范围1150~1200 ℃,应变速率0.01~0.03 s-1和每道次的变形量约为18% (真应变0.2)确定为最终的轧制工艺。

(2) 通过复合包套轧制,获得了厚度约为0.85 mm的Ti-46Al-8Nb合金板材,板材厚度均匀、无裂纹。在轧制变形过程中,首先会发生片层团的弯曲和扭折,在片层偏转的同时,L(α2/γ)板条会出现明显的宽化;随后,片层团将在晶界和弯折处优先发生分解,并逐渐向片层内部扩展;随着包套轧制的继续进行,组织发生局域流变软化,存在明显的轧制变形带,表现为再结晶与条状残余片层的交替组织,其中晶界处溶质Al的偏析区存在再结晶γ晶粒。

(3) Ti-46Al-8Nb合金在高温热变形过程中的流变软化以γ相的动态再结晶为主,主要通过位错塞积诱导亚晶界形成完成小角度晶界向大角度晶界的转化,此外,反复回炉保温过程中产生的退火孪晶和轧制过程中产生的大量孪晶片层结构,对于不连续动态再结晶晶粒的形成有极大的促进作用;除了动态再结晶,L(α/γ)→γ+α+B2/β和α→γ转变过程也是片层团分解的主要途径,表现为α2板条细化、γ板条粗大和片层结构破碎成多相组织等。

参考文献

Advances and challenges of TiAl base alloys

[J].γ-TiAl intermetallic alloys was outlined and divided into 4 stages: starting (1974~1985), revolutionary (1986~1995), emerging (1996~2005) and specialty materials (2006~). Major events and landmarks at the different stages were recounted to provide a framework for understanding scientific and technological progress. Key advances in the following 6 areas were reviewed: alloying, microstructure type, primary processing (melting), secondary processing (hot working), properties (including creep, fracture and fatigue, and oxidation), and tertiary processing (forming, covering both investment casting and near-net shape powder metallurgy). Future challenges were identified as follows: improvement of centrifugal casting technology, low-cost wrought process, development of third-generation alloys that meet design specifications, new applications based on new technologies, and viability of new forming routes such as additive manufacturing。]]>

钛铝金属间化合物的进展与挑战

[J].按照起步(1974~1985年), 热潮(1986~1995年), 兴起(1996~2005年)和特定应用(2006年~) 4个阶段回顾了钛铝金属间化合物的研发历程, 评述了各阶段对钛铝合金发展起到主导作用的里程碑事件, 简要总结了在合金化、显微组织类别、一次加工(熔炼)、二次加工(热加工)、性能、三次加工(成形)等6个方面的主要进展. 提出了钛铝合金未来发展面临的5方面挑战: 铸造合金与技术的进一步发展、低成本变形合金技术、第三代合金研制、基于新制备技术的新应用以及新成形工艺研发。

Review of alloy and process development of TiAl alloys

[J].

Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials

[J].

A newly developed hot worked TiAl alloy for blades and structural components

[J].

Development and evaluation of TiAl sheet structures for hypersonic applications

[J].

Temperature transients during hot pack rolling of high temperature alloys

[J].

Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase γ-TiAl based alloy

[J].Advanced intermetallic multi-phase gamma-TiAl based alloys, such as TNM alloys with a nominal composition of Ti-43.5Al-4Nb-1Mo-0.1B (in at.%), are potential candidates to replace heavy Ni-base superalloys in the next generation of aircraft and automotive combustion engines. Aimed components are turbine blades and turbocharger turbine wheels. Concerning the cost factor arising during processing, which - additionally to material costs significantly influences the final price of the desired components, new processing solutions regarding low-cost and highly reliable production processes are needed. This fundamental study targets the replacement of hot-working, i.e. forging, for the production of turbine blades. But without forging no grain refinement takes place by means of a recrystallization process because of the lack of stored lattice defects. Therefore, new heat treatment concepts have to be considered for obtaining final microstructures with balanced mechanical properties in respect to sufficient tensile ductility at room temperature as well as high creep strength at elevated temperatures. This work deals with the adjustment of microstructures in a cast and heat-treated TNM alloy solely by exploiting effects of phase transformations and chemical driving forces due to phase imbalances between different heat treatment steps and compares the mechanical properties to those obtained for forged and heat-treated material. (C) 2013 Elsevier Ltd.

High temperature deformation behavior of beta-gamma TiAl alloy

[J].

Microstructures and mechanical properties of hot-pack rolled Ti-43Al-9V-Y alloy sheet

[J].

Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys

[J].AbstractThe influence of Nb and Al contents on the microstructure and yield strength of high Nb containing TiAl base alloys was investigated. The experimental results show that the yield strength at 900 °C of the alloys with the same type of microstructure, such as fully lamellar (FL), nearly lamellar (NL) and degraded fully lamellar (DFL), increases with increasing Nb content and decreasing Al content in the composition range of 0–10 at.% Nb and 44–49 at.% Al. DFL is the degraded form of FL microstructure after exposure at 1050 °C for 30 h. It is shown that the Nb addition in the alloys increases the value of the σ0 term in the Hall–Petch relation of yield stress vs. lamellar spacing. This result has been related to TEM observations of dislocation structure in deformed specimens. The observations indicated that high level of Nb solute in the γ-TiAl matrix leads to a high critical resolved shear stress (CRSS) of dislocation loops. High Nb addition also reduces the degradation rate of FL microstructure after exposure at 1050 °C for 30 h. Both effects of high Nb addition are related to the change of the directionality of Ti–Ti (Nb) and Nb–Al bonds in the lattice. The decrease in Al content results in an increase in the volume fraction of α2 phase, which leads to a decrease in the lamellar spacing of the lamellar structure. The high temperature strength of the alloys is determined by the lamellar spacing λ through the Hall–Petch equation kλλ−1/2.]]>

Hot packed-rolling process of high-Nb TiAl alloy and its microstructure evolution

[J].

高铌TiAl基合金板材制备包套热轧工艺及组织控制

[J].

Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale

[J].

Microstructure, microsegregation pattern and the formation of B2 phase in directionally solidified Ti-46Al-8Nb alloy

[J].

Microstructures and high temperature tensile properties of Ti-43Al-4Nb-1.5Mo alloy in the canned forging and heat treatment process

[J].β phase, α2/γ lamellae decomposition and the dynamic recrystallization induced by dislocation slipping and twinning in γ phase, and the final microstructure is composed of remnant α2/γ lamellae and equiaxed α2, γ and B2 phases. With the increasing heat treatment temperature, the microstructure changes from the multi-phase structure (remnant α2/γ lamellar, equiaxed α2, γ and B2 phases) at 1250 ℃ to the α2/γ lamellar and γ phase at 1285 ℃, and then the fully α2/γ lamellar structure at 1300 ℃, during which the B2 phase is gradually dissolved due to the solution diffusion, and the remnant α2/γ lamellae change to equiaxed α2/γ colonies according to the α2/γ→γ+α2+B2 transition, and the final fully α2/γ lamellar structure is promoted by γ→α transition at high temperature. Moreover, the tensile tests of the hot isostatic pressed (HIPed) samples, canned forged and heat treated samples at 800 ℃ are conducted, in which the fully lamellar structure shows the high properties with the ultimate strength of 663 MPa and the elongation of 26%. The deformation process of the fully α2/γ lamellar can be strengthened by the lamellae twisting, microvoid inhibition and wavy growth of the cracks, leading to the optimal high temperature performance. Moreover, the disordered bcc β phase can promote the deformation during the hot working process at the high temperature (≥1200 ℃), while the hard-brittle B2 phase severely deteriorates the service properties, which should be controlled accurately for the high mechanical properties during the thermo-mechanical processing.]]>

Ti-43Al-4Nb-1.5Mo合金包套锻造与热处理过程的微观组织及高温拉伸性能

[J].β相协调变形、片层相变分解、γ相内位错滑移以及孪晶诱导的动态再结晶为主,最终组织为残余α2/γ层片和等轴α2、γ、B2相的混合组织。随热处理温度的升高,热变形组织由残余α2/γ层片和多相混合组织转变为α2/γ层片+γ相组织,在较高的温度下(1300 ℃)转变为全层片组织。其中,B2相随着溶质扩散程度的增加逐渐消失,残余层片组织发生分解转变为等轴α2/γ层片团,同时发生γ→α转变,形成全层片组织。对热等静压、锻态和热处理试样的高温(800 ℃)拉伸性能进行比较,经热处理后获得的全片层组织具有最佳的综合性能,抗拉强度为663 MPa,延伸率达到26%。分析该样品的断裂行为可知,由于存在层片扭曲拉长、微孔钝化以及裂纹曲折延伸的断裂机制,全层片组织具有良好强度-塑性的综合力学性能。另外,热加工过程中(高温) bcc结构B2相能够协调变形,但服役条件下硬脆的B2相作为裂纹源容易引起裂纹萌生,对力学性能极其不利。因此,TiAl合金在热变形和服役过程中需要对组成相进行严格控制,从而获得良好的力学性能。]]>

Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242

[J].

Study on globularization of lamellar a structure in TC17 titanium alloy during hot deformation using processing map

[J].

应用热加工图研究TC17合金片状组织球化规律

[J].

Hot deformation behaviors and processing maps of as-cast TiAl based alloy

[J].

铸造TiAl基合金的热变形行为及加工图

[J].

Effect of pack rolling on microstructures and tensile properties of as-forged Ti-44Al-6V-3Nb-0.3Y alloy

[J].The microstructures and tensile properties of Ti-44Al-6V-3Nb-0.3Y (at. %) alloy before and after hot rolling were investigated systematically. SEM results indicated that the as-rolled TiAl sheet was characterized by completely dynamically recrystallizated microstructures, except some refined lamellar colonies in the back end, which are primarily caused by the temperature drop during canned forging and subsequent pack rolling. By TEM analysis, the coarsening of gamma lamellae by alpha lath decomposition during hot rolling are found. Meanwhile, by EBSD measurements, the phase composition and grain features of the as-forged and the as-rolled conditions were characterized and compared. Additionally, the tensile properties were tested to find that the room temperature tensile strength decreased obviously after hot rolling, with yield strength decreasing from 620 MPa to 520 MPa along transverse direction (TD) and to 485 MPa in rolling direction (RD), and the UTS from 680 MPa to 598 MPa and 556 MPa respectively. The reason for the degradation of the tensile strength is interpreted detailedly. After being heat-treated in single a phase field, beta phase was eliminated from current deformed TiAl alloy and the tensile properties were enhanced obviously. Crown Copyright (C) 2011 Published by Elsevier Ltd.

Experimental study and numerical simulation of dynamic recrystallization behavior of TiAl-based alloy

[J].

Microstructure and deformation of two-phase γ-titanium aluminides

[J].

Flow stress prediction and hot deformation mechanisms in Ti-44Al-5Nb-(Mo, V, B) alloy

[J].

Study on the microstructure, phase transition and hardness for the TiAl-Nb alloy design during directional solidification

[J].

Morphology and competitive growth during the development of the parallel lamellar structure by self-seeding in directionally solidified Ti-50Al-4Nb alloy

[J].

Hot forging design and microstructure evolution of a high Nb containing TiAl alloy

[J].

Microstructure, mechanical properties, and crack propagation behavior in high-Nb TiAl alloys by directional solidification

[J].