由于低合金钢与不锈钢在热物理性能、化学成分、微观组织特征等方面的显著差异,焊接过程及焊后热处理中会产生焊接残余应力、焊缝金属稀释、碳迁移等问题,进而影响焊接接头的性能[3,4,5,6,7,8,9,10,11,12,13]。关于奥氏体不锈钢和镍基合金充当低合金钢与不锈钢异种焊接填充金属的可行性,国内外均进行了大量的研究工作。研究[14,15]表明,与奥氏体不锈钢相比,镍基合金在抑制碳迁移、降低热应力、改善母材与焊缝间的组织不均匀性等方面的效果较为显著,被广泛应用于接管安全端的焊接。其中,ERNiCrFe-7镍基合金具有更优异的抗应力腐蚀开裂性能,是目前三代核电站接管安全端焊接的首选填充金属[5,6,7,8,9,10,11,12,13,14,15]。

本工作比较分析了2种堆焊工艺制备的接管安全端试环中堆焊层的微观组织特征,进而研究了堆焊层组织特征对焊接接头断裂行为和力学性能的影响,为优化堆焊工艺参数、提高接管安全端焊接接头的力学性能奠定理论基础。

1 实验方法

本实验中接管安全端焊接试环的制备工艺流程为:施焊现场采用不同的埋弧焊(SAW)电流、电压及焊接速率在SA508 Gr.3 Cl.2 (简称SA508)试环内壁依次带极堆焊EQ309L、EQ308L不锈钢,堆焊层总厚度≥6 mm;然后采用钨极氩弧焊(GTAW),以ERNiCrFe-7焊丝为填充金属,将带有堆焊层的SA508试环与SA182 F316LN (简称316LN)试环进行对接焊;堆焊以及对接焊完成后均对试件进行焊后热处理以消除焊接残余应力。各部分材料的化学成分如表1所示。

表1 接管安全端焊接试环件中各部分材料的化学成分 (mass fraciton / %)

Table 1

| Material | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Co | Al | Ti | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SA508 | 0.210 | 0.22 | 1.35 | 0.004 | 0.003 | 0.87 | 0.21 | - | 0.04 | - | 0.02 | - | 0.01 | Bal. |

| 316LN | 0.014 | 0.38 | 1.10 | 0.024 | 0.004 | 11.2 | 16.2 | 2.13 | - | 0.01 | - | - | 0.11 | Bal. |

| EQ309L | 0.012 | 0.37 | 1.63 | 0.013 | 0.003 | 13.2 | 24.0 | 0.06 | 0.03 | 0.04 | - | 0.007 | 0.04 | Bal. |

| EQ308L | 0.012 | 0.34 | 1.63 | 0.013 | 0.003 | 10.1 | 20.6 | 0.09 | 0.03 | 0.04 | - | 0.006 | 0.04 | Bal. |

| ERNiCrFe-7 | 0.024 | 0.16 | 0.24 | 0.003 | 0.001 | 60.4 | 28.9 | 0.01 | 0.01 | <0.01 | 0.7 | 0.5 | 0.01 | 9.09 |

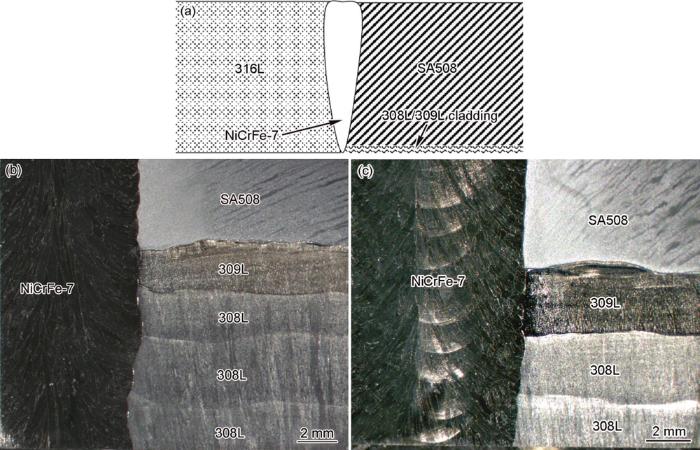

SA508试环内壁带极堆焊EQ309L不锈钢的SAW工艺参数范围为:焊接电流750~790 A,焊接电压26~29 V,焊接速率180~220 mm/min。工业生产过程中,参照工艺参数范围进行施焊,但堆焊层引起的失效现象仍时有发生。为此,本工作设计了2组SAW工艺,研究施焊工艺参数的影响规律。第一组:焊接电流为760 A、焊接电压为27 V,焊接速率为160 mm/min;第二组:焊接电流为780 A,焊接电压为27 V,焊接速率为210 mm/min。2种SAW工艺制备的接管安全端焊接试环分别标记为S1和S2,异种金属焊接接头示意图及接头中的不锈钢堆焊层形貌如图1所示。

图1

图1

接管安全端焊接试环的异种金属焊接接头示意图及不锈钢堆焊层形貌

Fig.1

Schematic of the dissimilar metal welded safe-end joint (a) and macro-morphologies of austenitic stainless steel cladding layer of S1 (b) and S2 (b)

对焊接接头中的不同材料分别选用相应的刻蚀液:SA508合金采用体积分数为4%硝酸-酒精进行腐蚀;不锈钢堆焊层采用体积分数为5%硝酸-甲醇进行腐蚀;316LN不锈钢和NiCrFe-7焊缝采用质量分数为10%铬酸-水溶液进行电解腐刻。采用GX52光学显微镜(OM)和XL-30FEG扫描电镜(SEM)观察样品微观组织。采用EPMA-1610型电子探针(EPMA)对试样中的元素分布进行分析。采用XL-30FEG型SEM上配置的电子背散射衍射(EBSD)系统分析不锈钢堆焊层的相分布。采用线切割提取出309L堆焊层,并在D/max-2400PC型X射线衍射仪(XRD)上进行物相分析,同时,采用电感耦合等离子体光谱法(ICP-OES)对提取出的309L堆焊层进行化学成分测定。

垂直于焊接接头方向切取试样进行180°侧弯实验和室温拉伸实验,试样中要包含全厚度的不锈钢堆焊层,试样示意图如图2所示。180°侧弯实验在Autograph AG-I 50万能试验机上进行,选用直径为4倍试样厚度的弯曲压头。室温拉伸实验在INSTRON 5582万能力学试验机上进行,拉伸速率为2 mm/min。采用MICROMET5103显微硬度计测量焊接接头的硬度,加载载荷100 g,保持时间15 s。

图2

图2

侧弯试样及拉伸试样示意图

Fig.2

Schematics of bending sample (a) and tensile sample (b)

Color online

2 实验结果

2.1 微观组织

图3

图3

2种埋弧焊(SAW)工艺制备接管安全端试环中309L堆焊层微观组织的OM和SEM像

Fig.3

OM (a~d) and SEM (e, f) images of microstructures of the 309L cladding layer of S1 (a, c, e) and S2 (b, d, f) (The red dashed lines in Fig.3c and d show the interfaces of martensite and austenite)

Color online

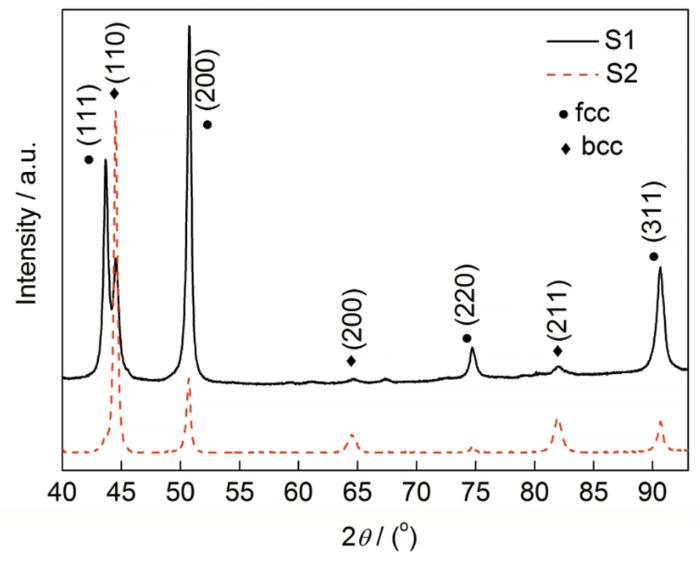

为了进一步确定309L堆焊层中的组织特征,对提取出的309L堆焊层进行XRD物相分析(图4),可见,S1、S2试环中309L堆焊层组织均为fcc和bcc的两相组织,S1试环中309L堆焊层的XRD谱上具有明显的fcc衍射峰,bcc衍射峰相对较弱;而S2试环中309L堆焊层的XRD谱上的bcc衍射峰明显增强。对比可见,S2试环中309L堆焊层内的bcc相含量显著高于S1试环。

图4

图4

2种SAW工艺制备接管安全端试环中不锈钢堆焊层的XRD谱

Fig.4

XRD spectra of the 309L cladding layers of S1 and S2

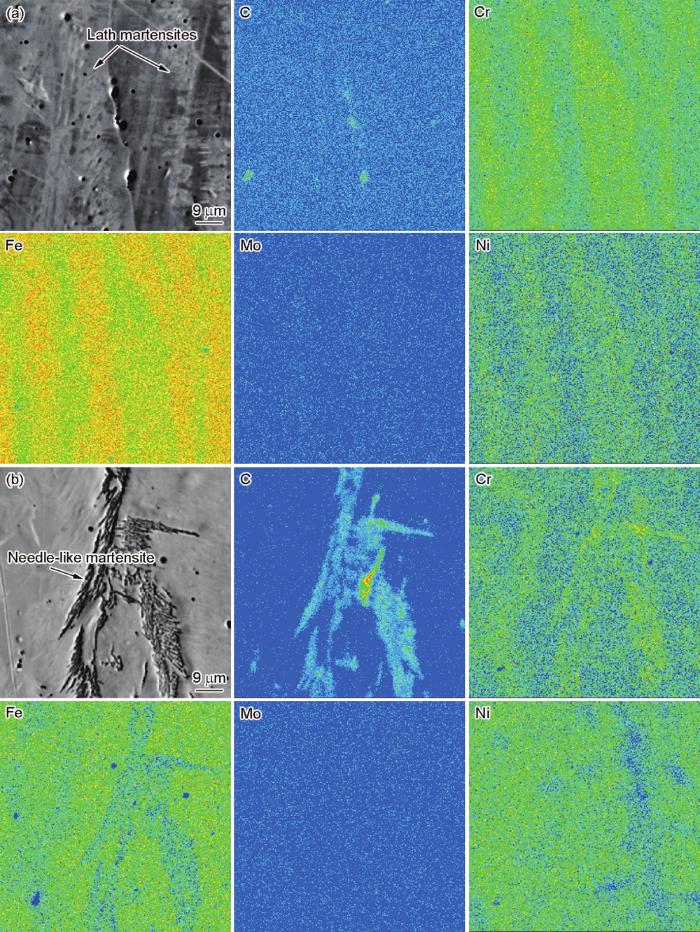

图5

图5

2种SAW工艺制备接管安全端试环中不锈钢堆焊层的元素分布

Fig.5

EPMA results of the 309L cladding layers of S1 (a) and S2 (b)

Color online

2.2 力学性能

图6

图6

2种SAW工艺制备接管安全端试环接头经180°侧弯后的宏观形貌

Fig.6

Macro-morphologies of the weld joint of S1 (a) and S2 (b) after the 180° bending test

图7

图7

2种SAW工艺制备接管安全端试环接头的拉伸应力-应变曲线

Fig.7

Tensile stress-strain curves of the weld joints of S1 and S2 at room temperature

拉伸断口侧面及断口形貌如图8所示。为确定断裂位置,对拉伸断口侧面腐刻后进行表面观察,可见2种试环的断裂位置和断裂形式不同,S1试环断裂发生在焊缝处,呈现与拉伸轴呈45°方向的剪切断裂(图8a),而S2试环沿不锈钢堆焊层以及SA508/NiCrFe-7焊缝界面开裂,断口表面基本垂直于拉伸轴(图8b)。从S2试环接头的断口形貌上可清晰地分辨出各部分材料,包括308L堆焊层、309L堆焊层、SA508、以及SA508/NiCrFe-7焊缝混合组织(图8c)。高倍SEM像显示,SA508/NiCrFe-7焊缝界面位置呈现韧窝形貌和凝固枝晶形貌(图8d);309L堆焊层位置呈现解理开裂,且存在明显的二次裂纹(图8e);308L堆焊层位置则为韧窝断裂(图8f)。

图8

图8

2种SAW工艺制备接管安全端试环接头的拉伸断口侧面和S2试环的断口形貌

Fig.8

Morphologies of side surfaces of the fractured samples of S1 (a) and S2 (b), and fracture surfaces of the weld joint of S2 (c~f)

Color online

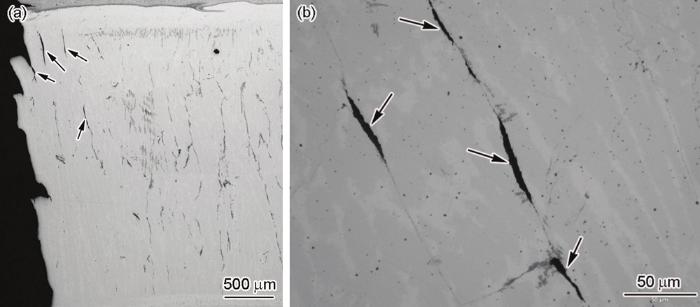

图9

图9

S2试环接头拉伸断口附近截面组织的OM像

Fig.9

Low (a) and high (b) magnified OM images of cross-sectional microstructures near the tensile fracture surface of the weld joint of S2 (The arrows show the micro-cracks)

3 分析讨论

从上述分析可见,SAW工艺参数显著影响309L堆焊层的微观组织,造成安全端试环接头力学性能的差异。SA508低合金钢表面堆焊不锈钢的过程中,常因堆焊不锈钢与SA508的局部熔化混合而发生合金元素的相互稀释,进而引起堆焊层微观组织的变化。实际施焊过程中,SAW工艺参数的变化会显著影响不锈钢与SA508之间的稀释率,造成堆焊层微观组织的差异。需要指出的是,堆焊稀释率(D)是指堆焊层金属被熔化母材所稀释的程度,即309L堆焊层中含有SA508母材的百分率。

式中,M%表示金属M的质量分数。基于309L和SA508在Schaeffler相图中的位置,SA508的焊态组织为马氏体组织,309L不锈钢的焊态组织由奥氏体和少量的δ-铁素体组成。堆焊过程中,309L与SA508经不同程度的稀释后,堆焊层的Cr/Ni当量比将处于两者之间(图10中红色线条所示),堆焊层的Cr当量[Cr]cladding和Ni当量[Ni]cladding可表示为:

式中,[Cr]SA508和[Ni]SA508分别为SA508的Cr当量和Ni当量,[Cr]309L和[Ni]309L分别为309L焊材的Cr当量和Ni当量。由

图10

图10

基于Schaeffler相图预判的309L堆焊层微观组织[18]

Fig.10

Prediction of microstructure for the cladding layer according to the Schaeffler diagram (The microstructures of the 309L cladding layer are indicated by black arrows with the increased dilution ratio (D), and microstructures of the 309L cladding layer of S1 and S2 according the chemical composition are indicated; A—austenite, M—martensite, F—ferrite)[18]

Color online

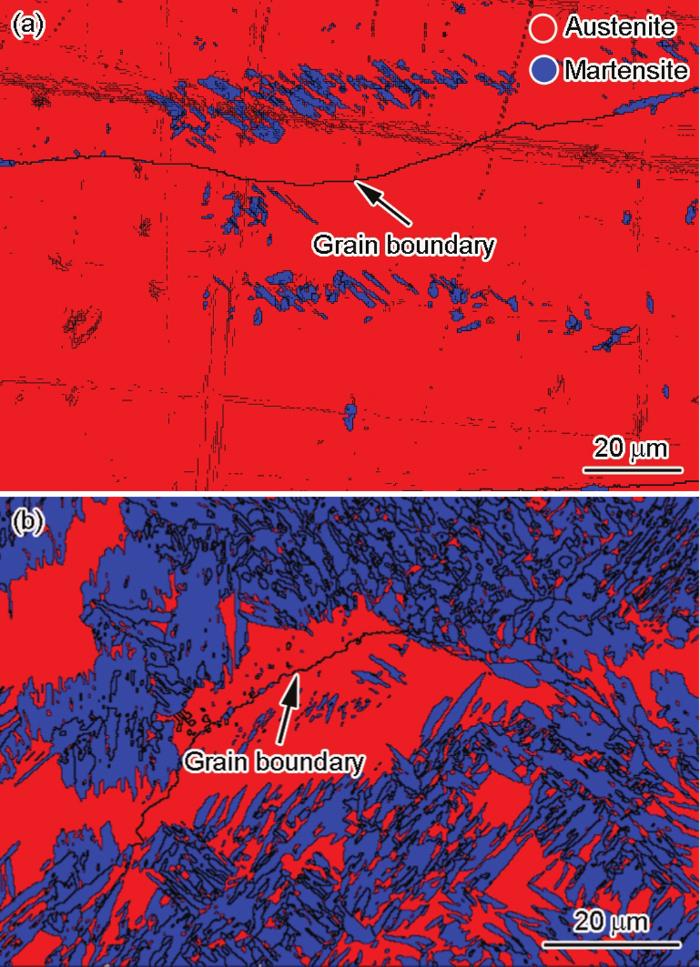

SA508表面堆焊309L过程中,靠近熔合线的区域具有较高的稀释率,造成2种试环的SA508/309L熔合线界面处均形成了薄层的马氏体区域(图3a和b),熔合线附近也会出现岛状马氏体区域[20,21,22]。远离熔合线区域的稀释率有所降低,代表的是堆焊层金属的稀释率。综合分析309L堆焊层的组织特征和Schaeffler相图计算结果可知,2个试环中309L堆焊层的稀释率均大于33%。S1试环的309L堆焊层呈现为奥氏体和板条状马氏体组织(图3c),相比之下,S2试环的309L堆焊层中的板条状马氏体含量更高,并且出现针状马氏体(图3d)。309L堆焊层的EBSD分析证实,S1试环的309L堆焊层中板条状马氏体的面积分数约为4%,主要分布在奥氏体晶内,也有少量分布在晶界上(图11a);而S2试环的309L堆焊层中含有板条状马氏体和少量的针状马氏体,马氏体的面积分数可达到约62%,马氏体界面处分布着细小的奥氏体,也存在块状奥氏体(图11b)。对比分析可见,S2试环的309L堆焊层中具有更多的马氏体,并且形成了针状马氏体,这与堆焊过程中较高的堆焊稀释率有关。为了证实上述推测,对2种试环中提取出的309L堆焊层进行化学成分分析,结果显示,S1试环和S2试环的309L堆焊层中C、Ni、Cr元素在含量上存在明显的差别(表2)。根据

图11

图11

2种SAW工艺制备接管安全端试环中309L堆焊层的相分布图

Fig.11

EBSD phase distributions of the 309L cladding layers of S1 (a) and S2 (b)

Color online

表2 2种SAW工艺制备接管安全端试环中309L堆焊层的合金元素含量及稀释率

Table 2

| Weld joint | Mass fraction of element / % | Dilution ratio % | ||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Ni | Cr | [Ni] | [Cr] | ||

| S1 | 0.076 | 0.57 | 1.38 | 8.81 | 15.72 | 11.78 | 16.58 | 36 |

| S2 | 0.091 | 0.51 | 1.33 | 7.86 | 13.69 | 11.26 | 14.46 | 45 |

2种试环中309L/NiCrFe-7/316LN对接接头的硬度测量结果表明,309L堆焊层、NiCrFe-7焊缝和316LN的显微硬度相差不大,均在(200±50) HV0.1范围内(图12)。然而,2种试环的对接接头在180°侧弯和拉伸过程中呈现出不同的断裂行为。S1试环的接头经180°侧弯后未发生开裂(图6a);拉伸变形后,断裂发生在NiCrFe-7焊缝内(图8a),接头的抗拉强度接近于NiCrFe-7焊缝的强度[7]。S2试环的接头在变形过程中,309L堆焊层中针状马氏体界面处会诱发裂纹的萌生,导致309L堆焊层成为优先开裂位置(图9)。微裂纹的出现会改变试样承受的应力水平,变形过程中微裂纹附近承受的最大应力(σmax)可表示为[23]:

图12

图12

2种SAW工艺制备接管安全端试环接头的显微硬度分布

Fig.12

Microhardness distributions across the 316LN/NiCrFe-7/309L along the dissimilar weld joints of S1 and S2

带极埋弧堆焊具有熔敷率高、焊道平整、成形美观等优点,被逐渐用于异种金属的大面积焊接,其堆焊稀释率为5%~50%不等[26]。实际施焊过程中,焊接电流、焊接电压、焊接速率等工艺参数的变化都会引起稀释率的改变。为保证接头良好的力学性能,堆焊工艺参数的选择应控制稀释率的大小,以避免针状马氏体的出现。因此,建立堆焊工艺参数与稀释率之间的理论关系是实现高性能接管安全端接头的关键工作。

4 结论

(1) 2种堆焊工艺制备试环的309L堆焊层组织均为奥氏体和马氏体,但堆焊稀释率决定了马氏体的形态和数量。较低的堆焊稀释率下,309L堆焊层组织为奥氏体和板条马氏体,而较高的堆焊稀释率会显著提高板条马氏体的含量,当稀释率超过某一临界值后,促进了针状马氏体的形成。

(2) 堆焊稀释率直接影响试环接头的力学性能。较低的堆焊稀释率下,接头经180°侧弯后未发生开裂,拉伸变形后,断裂发生在NiCrFe-7焊缝内;较高的堆焊稀释率下,接头经180°侧弯后出现309L堆焊层引起的开裂现象,拉伸变形后,呈现出沿不锈钢堆焊层以及SA508/焊缝界面的脆性断裂特征,导致接头具有较低的拉伸强度和延伸率。

(3) 变形过程中,高的堆焊稀释率下,309L堆焊层中形成的针状马氏体与奥氏体之间变形不协调,进而在界面处产生应力集中,诱发裂纹产生,导致309L堆焊层成为优先开裂位置,是造成接头力学性能下降的主要原因。

参考文献

Cracking of dissimilar metal welds in nuclear power plants and methods to evaluate its susceptibility to stress corrosion cracking

[J].

核电站异材焊接件的破裂问题与应力腐蚀评价方法

[J].

Dissimilar metal welds—Transition joints literature review

[J].

Micro-characterization of dissimilar metal weld joint for connecting pipe-nozzle to safe-end in Generation III nuclear power plant

[J].The dissimilar metal weld joint (DMWJ) in primary water system of pressurized water reactors (PWRs) has been proven to be a vulnerable component owing to its proneness to different type of flaws. Thus, maintaining integrity of such joint in case of defect presence is of great importance to the design and safe management of nuclear power plants (NPPs). For a reliable integrity analysis of DMWJ, it is essential to understand the microscopic characteristics in all regions of the joint. In this work, OM, TEM, SEM, durometer, AFM, MFM and SKPFM were utilized to investigate the microstructure, micro-hardness and the distribution of main elements, grain boundary characteristic and residual strain in the A508/52M/316L DMWJ that used for connecting the pipe safe-end and the nozzle of reactor pressure vessel in PWRs, and a comparative analysis about the microstructure and property along the radical direction of the DMWJ was obtained. The results showed that there was no region that differed from the other part of the weldment in terms of the microstructure and micro-hardness dramatically. A layer of fine grain resulting from unmelted filler metal was found in the backing weld part of the joint. The residual strain in the heat affected zone (HAZ) of 316L was higher than that in other regions. Meanwhile, drastic variations in the microstructure, chemical composition distribution and grain boundary character distribution (GBCD) in both the 316L/52Mw and the 52Mb/A508 interface regions were observed. The analyses using TEM and MFM test showed that a large number of chromium and molybdenum-rich precipitates particles distributed both along the grain boundaries and inside grains in the 316L base metal, which were identified to be precipitates with complex elementary composition rather than the normal string delta ferrite in 316L austenitic stainless steel. The SKPFM test result indicated that these precipitates were more prone to be corroded than the base metal. Therefore, further investigation about the cause of deformation and the impacts to the corrosion resistance, particularly the stress corrosion cracking (SCC) sensitivity of the precipitates needs to be carried out.

三代核电接管安全端异种金属焊接接头的显微表征

[J].利用OM, TEM, SEM, 显微硬度仪, AFM, 磁力显微镜(MFM)和扫描Kelvin探针(SKPFM)等微观分析手段, 分析了先进压水堆核电站反应堆压力容器安全端异种金属焊接接头低合金钢A508/镍基焊料52M/奥氏体不锈钢316L的金相组织、显微硬度、主要合金元素、晶界类型以及残余应变的分布, 并对比了整个焊接接头不同厚度上的组织和性能. 结果表明, 焊缝厚度方向上组织和硬度没有显著差别, 底焊位置出现一层未熔焊料形成的细小等轴晶, 在316L母材热影响区(HAZ)内残余应变较焊接件其它位置高, 熔合线附近具有复杂的微观结构、显微硬度、晶界类型、元素成分和残余应变分布. TEM和MFM分析表明, 母材316L基体内有富Cr, Mo元素的颗粒状析出相, SKPFM的结果显示该析出相Volta电势较基体更负, 因而更不耐腐蚀.

Stress corrosion cracking behavior of dissimilar metal weld A508/52M/316L in high temperature water environment

[J].The stress corrosion cracking (SCC) behavior of advanced dissimilar metal weld A508/52M/316L in simulated primary water environments of pressurized water reactor (PWR) at 290 degrees C was investigated by means of slow strain rate testing (SSRT). The tests were performed at various applied electrode potentials which correspond to the electrochemical conditions of the weld in various water environments, from low potentials with ideal water chemistry to high potentials with oxygen-contaminated water chemistry. The weld exhibits complicated microstructure and chemical composition distributions, especially, significant changes appear around the A508/52M interface and the 52M/316L interface. For tensile specimens in SSRT, sharp notches were machined at important and typical places, i.e., at the two interfaces and in the bulk parts of the low alloy steel, Ni base weld metal and stainless steel of the weld. Results showed that the specimens always failed in bulk zone of the Ni base weld metal with ductile appearances when tested in the potential range from -780 mV to -300 mV (vs SHE). When electrode potential was raised into the range from -200 mV to +200 rnV which corresponds to oxygen-contaminated water chemistry, the weld exhibits significant SCC. The area around the A508/52M interface is the weakest place, transgranular stress corrosion cracking (TGSCC) happened both along the interface and in A508 heat affected zone (HAZ), intergranular stress corrosion cracking (IGSCC) occurred in the Ni base weld metal close to the interface. The cracking mechanism and the engineering practical significance were discussed.

异材焊接件A508/52M/316L在高温水环境中的应力腐蚀破裂

[J].采用慢应变速率实验(SSRT)方法, 研究了先进的异材焊接件A508/52M/316L在模拟压水堆一回路290 ℃高温水环境中的应力腐蚀破裂(SCC)特性. 实验在-780 mV至+200 mV范围的电位下进行, 模拟一回路水化学从低O含H的理想低电位状态到溶解O$_{2}$明显超标的高电位状态的服役环境. 该焊接件显微组织和化学成分分布较复杂, 显著的变化发生在A508/52M和52M/316L 2个界面附近. 在SSRT拉伸试样的典型位置处加工了同样尺寸的尖锐缺口, 以模拟应力集中和加速实验, 并比较这些典型位置的SCC 敏感性. 结果表明, 当电位位于-780 mV至-300 mV范围时, SSRT试样总是以韧性断裂形式在镍基合金焊缝中部发生断裂. 当电位升到-200 mV至+200 mV范围时, 试样发生显著的SCC脆断, A508/52M界面区周围是该焊接件最脆弱的部位, 在该界面和附近的A508热影响区发生穿晶应力腐蚀破裂(TGSCC), 在紧邻界面的镍基合金焊缝薄层发生沿晶应力腐蚀破裂(IGSCC). 讨论了破裂机理和实验结果的工程意义.

Microstructure and local properties of a domestic safe-end dissimilar metal weld joint by using hot-wire GTAW

[J].3BO3 and 2.3 mg/L Li as LiOH with 2 mg/L dissolved oxygen at 325 ℃. A large amount of type I boundaries and type II boundaries which are susceptible to stress corrosion cracking (SCC) exist in 52Mb near the SA508/52Mb interface and result in the highest SCC susceptibility of this interface. Microstructure transition was found in the SA508 heat affected zone (HAZ). In 316LN HAZ, increasing the distance from the fusion boundary, the number fraction of CSL boundaries increase while the residual strain decreases, resulting in the second-highest SCC susceptibility of 316LN HAZ. In 52M, residual strain distributes randomly but not uniformly, the residual strain is prone to accumulate at the grain boundaries. Dramatic changes of mechanical properties are observed across the joint, especially at the SA508/52M interface. The differences of the local microstructure and chemical composition lead to the differences of the local properties of the weld joint.]]>

国产核电安全端异种金属焊接件的微观结构及局部性能研究

[J].利用OM、SEM、显微硬度仪、微小试样拉伸实验及慢应变速率拉伸实验对国产带热丝隔离层核电安全端焊接件不同部位的微观结构及局部的力学性能和应力腐蚀敏感性进行了研究。发现,在SA508/52Mb界面处的52Mb中具有大量的对应力腐蚀敏感的I型晶界及II型晶界,导致此界面具有最高的应力腐蚀敏感性;SA508热影响区存在明显的组织过渡;316LN热影响区中随着距熔合线距离的增加,重位点阵(CSL)晶界的数量分数逐渐增大,Σ3晶界与理想的Σ3晶界的偏差角减小,残余应变逐渐减小,残余应变的最高值出现在对接焊底焊位置处的316LN热影响区中,导致316LN的热影响区也具有较高的应力腐蚀敏感性。焊接件不同部位的力学性能存在较大的差异。对于硬度分布而言,显微硬度变化最剧烈的位置在SA508/52Mb界面附近,且此界面附近的52Mb具有最高的硬度,此界面附近的SA508脱C区具有最低的硬度。强度的变化趋势与硬度的变化趋势类似。一般强度高的地方断裂应变低。焊接件不同位置的性能差异主要取决于不同部位的微观结构(包含组织、成分等)差异。

Characterization of microstructure of A508III/309L/308L weld and oxide films formed in deaerated high-temperature water

[J].

Stress corrosion cracking of a low alloy steel to stainless steel transition weld in PWR primary waters at 292 ℃

[J].

Fracture mechanism of a dissimilar metal welded joint in nuclear power plant

[J].In this paper, fracture tests and microscopic observations were conducted on an Alloy52M dissimilar metal welded joint (DMWJ) between A508 ferritic steel and 316L stainless steel in nuclear power plant. The fracture mechanism of different regions within the joint was investigated, and the relationship between fracture mechanism in local microstructures and local fracture resistance of the DMWJ was analyzed. The results show the fracture mechanism of A508 and 316L base metals and heat-affected-zone (HAZ) of 316L is typical ductile fracture of nucleation, growth and coalescence of voids, and different crack growth resistance is mainly related to microstructures of them. The fracture mode in A508 HAZ and A508/52Mb interface region with predominant martensite microstructure is mixed brittle and ductile fracture, which leads to lower crack growth resistance. The columnar austenite crystal orientation relative to main crack growth direction apparently affects fracture mechanism and crack growth resistance of buttering Alloy52Mb and weld Alloy52Mw. The cracks in Alloy52Mb propagate across columnar crystal boundaries in a ductile mode, and higher fracture resistance is produced. While the cracks in weld Alloy52Mw propagate along the weak columnar crystal boundaries in a brittle mode, which leads to lower crack growth resistance. The cracks in interface regions and HAZs generally grow towards the material sides with lower strength, which is caused by local strength mismatch and affects local crack growth resistance. (C) 2012 Elsevier Ltd.

Evaluation of residual stresses in dissimilar weld joints

[J].

Local fracture behavior in an alloy 52M dissimilar metal welded joint in nuclear power plants

[J].

核电52M镍基合金异种金属焊接接头的局部断裂行为

[J].

Microstructure, local mechanical properties and stress corrosion cracking susceptibility of an SA508-52M-316LN safe-end dissimilar metal weld joint by GTAW

[J].

A comparative evaluation of welding consumables for dissimilar welds between 316LN austenitic stainless steel and Alloy 800

[J].

Three-dimensional thermomechanical simulation and experimental validation on failure of dissimilar material welds

[J].

Studies on the shedding behavior of the surfacing layer on the inner wall of the safety and nozzle of the steam generator nozzle

[J].

蒸汽发生器下封头接管内壁堆焊层脱落问题的研究

[J].

Research on microstructure evolution and interfacial disbonding mechanism during dissimilar weld between 18MND5 and 309L

[J].

18MND5/309L焊接过程中组织演变以及界面剥离机理研究

[J].

Constitution diagram for stainless steel weld metal

[J].

WRC-1992 constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram

[J].

Microstructural characterization of an SA508-309L/308L-316L domestic dissimilar metal welded safe-end joint

[J].

Technical note: Martensite formation in austenitic/ferritic dissimilar alloy welds

[J].

Microstructure and stress corrosion cracking behavior of the weld metal in alloy 52-A508 dissimilar welds

[J].

δ-Ferrite formation and its effect on the mechanical properties of heavy-section AISI 316 stainless steel casting

[J].

Effect of hardness of martensite and ferrite on void formation in dual phase steel

[J].

Effect of Fe2Zr phase on the mechanical properties and fracture behavior of Fe-Cr-W-Zr ferritic alloy

[J].