基于晶体塑性模型预测TA32钛合金损伤及高温成形极限

|

|

范荣磊, 陈明和, 吴迪鹏, 武永

|

Prediction of Damage and Hot Forming Limit of TA32 Titanium Alloy Based on Crystal Plasticity Model

|

|

FAN Ronglei, CHEN Minghe, WU Dipeng, WU Yong

|

|

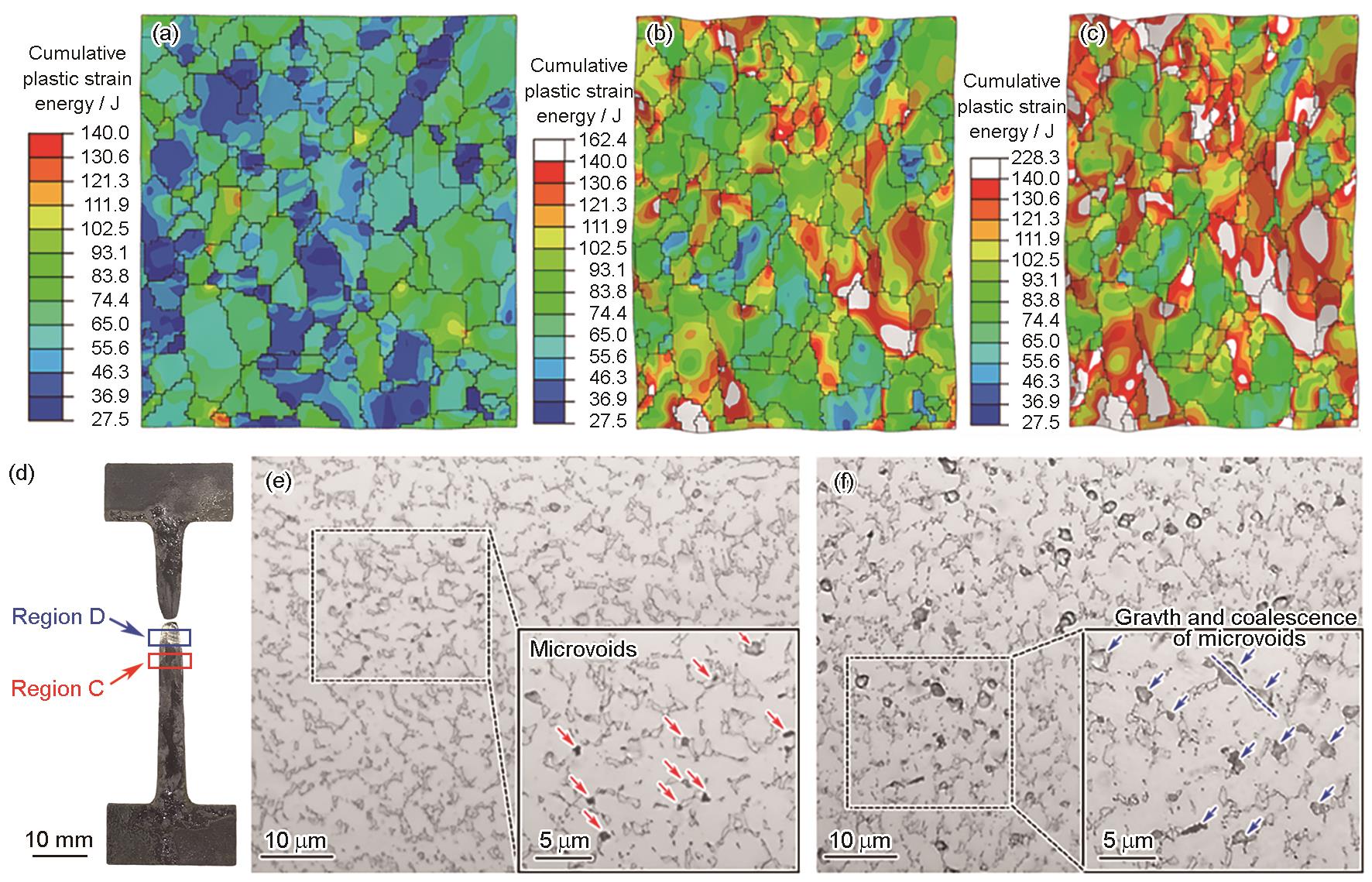

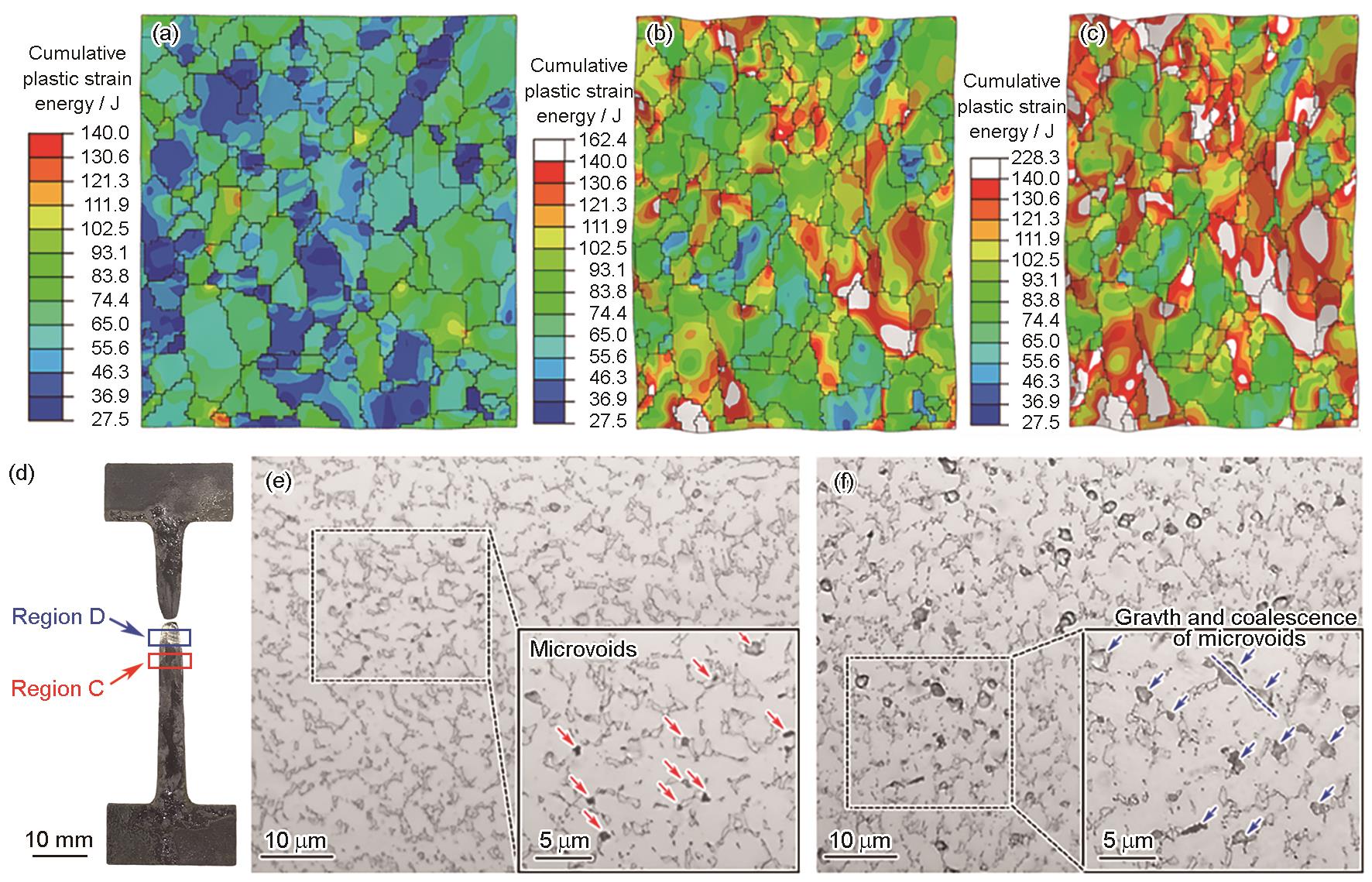

图8 TA32板材以0.01 s-1应变速率单轴拉伸时微孔洞的模拟与实验结果

|

Fig.8 Simulation results by RVE (a-c) and experimental results (d-f) of microvoids under uniaxial tension at a strain rate of 0.01 s-1 (Insets in Figs.8d and e are enlarged views)

(a-c)at the strains of ε = 0.1 (a), ε = 0.3 (b), and ε = 0.4 (c) (d-f) the specimen (d) and microstructures of region C (e) and region D (f) in Fig.8d

|

|

|

|

|