基于晶体塑性模型预测TA32钛合金损伤及高温成形极限

Prediction of Damage and Hot Forming Limit of TA32 Titanium Alloy Based on Crystal Plasticity Model

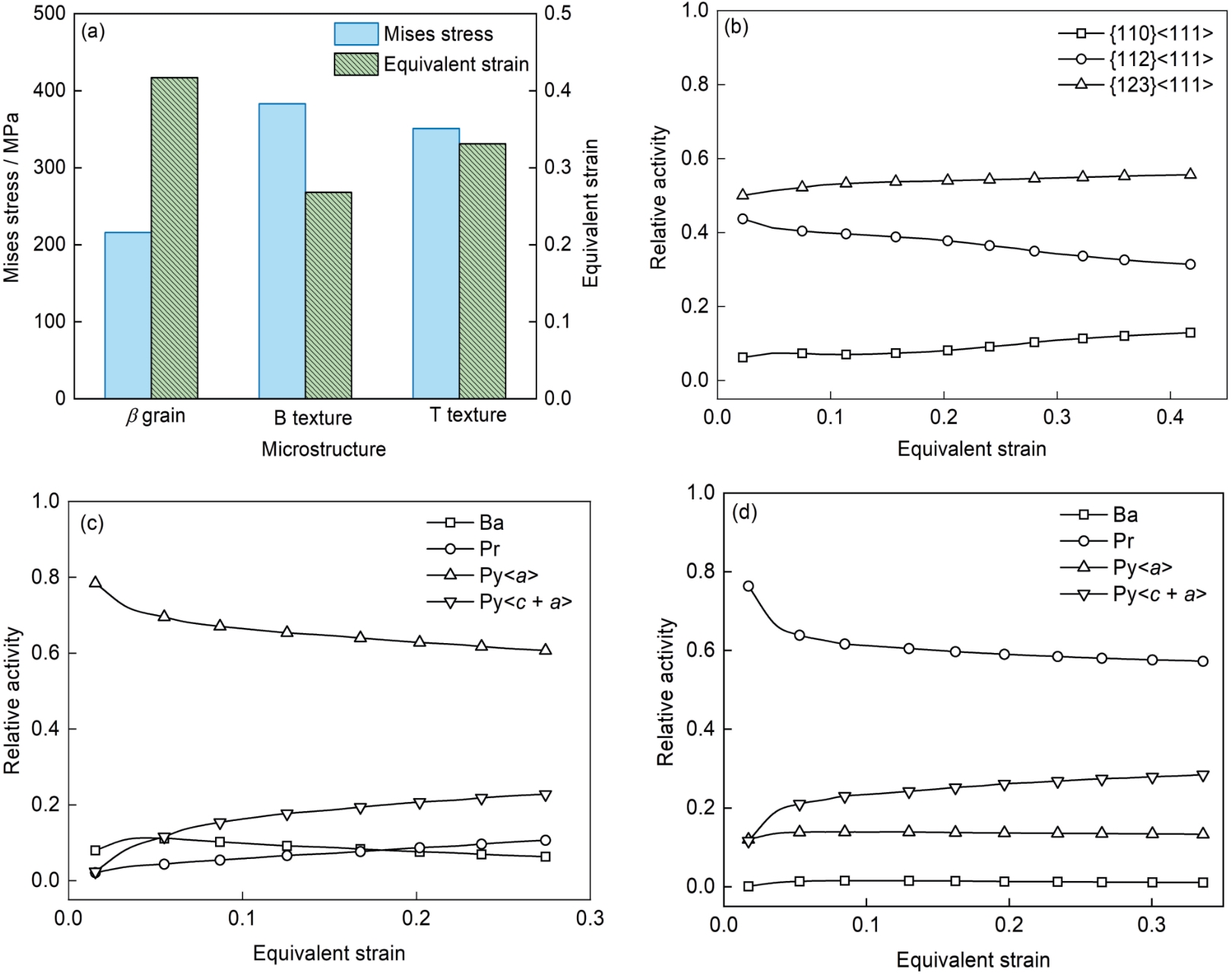

(a) stress and strain distributions (b-d) relative activities of slip systems of β grain (b), B texture (c), and T texture (d)