零热膨胀金属材料研究进展

Research Progress on Zero Thermal Expansion Metallic Materials

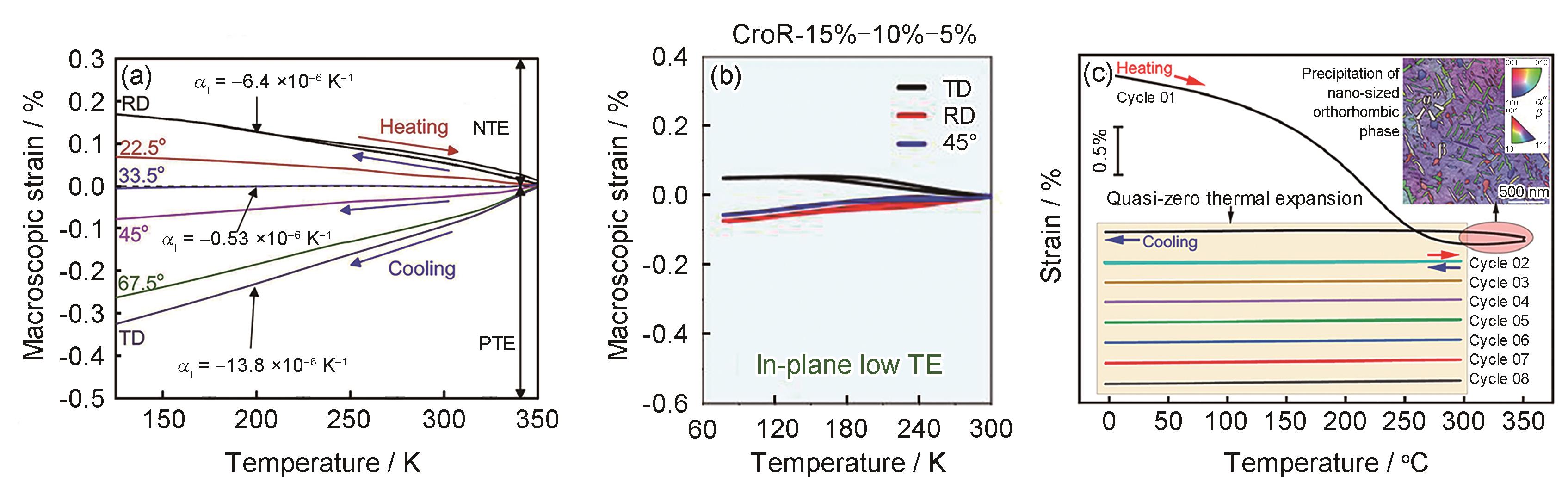

(a) evolution of macroscopic strain with temperature of rolled 60% (thickness reduction rate) Ti50.6Ni49.4 alloy sheet along RD, 22.5°, 33.5°, 45°, 67.5°, and TD after annealing for 60 min at 523 K[

(b) Ni50.8Ti49.2 alloy through three steps rolling (CroR-15%-10%-5%: the thickness of the first rolling direction is reduced by 15%-the thickness in the vertical direction from the first rolling direction is reduced by 10%-thickness is reduced by 5% along the first rolling direction) to a thickness of 30% of the total thickness after the internal macroscopic thermal expansion change[

(c) Ti22Nb CR (cold-rolled) plate along the rolling direction in eight cycles (cycle 01 Tmax (maximum temperature) = 350 oC, thermomechanical analyzer measurements were performed in cycle 02-08 at Tmax = 300 oC)[