真空自耗电弧熔炼铸锭凝固行为多尺度模拟研究进展

Progress in Multiscale Simulation of Solidification Behavior in Vacuum Arc Remelted Ingot

真空自耗电弧熔炼铸锭凝固行为多尺度模拟研究进展 |

| 李俊杰, 李盼悦, 黄立清, 郭杰, 吴京洋, 樊凯, 王锦程 |

|

Progress in Multiscale Simulation of Solidification Behavior in Vacuum Arc Remelted Ingot |

| LI Junjie, LI Panyue, HUANG Liqing, GUO Jie, WU Jingyang, FAN Kai, WANG Jincheng |

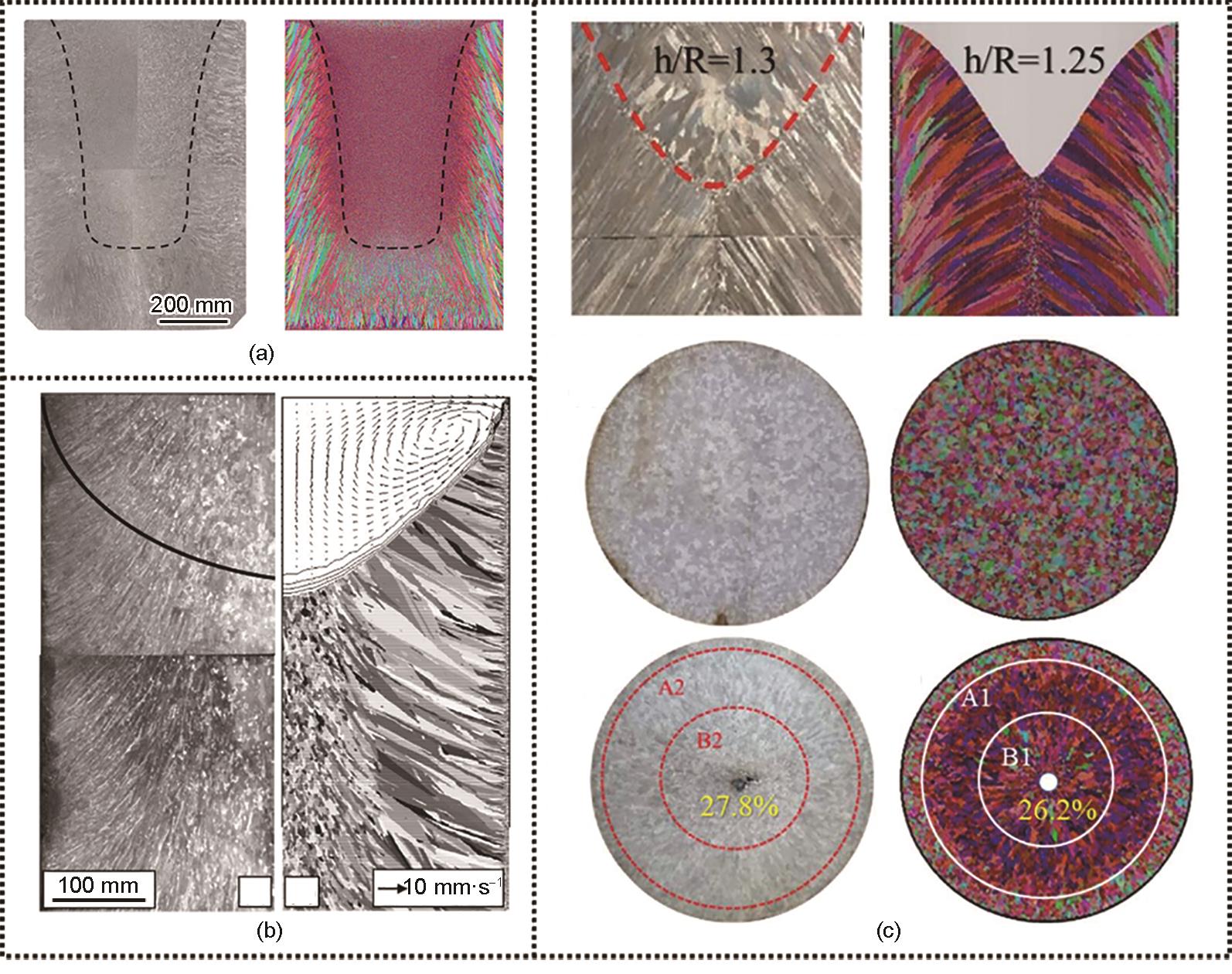

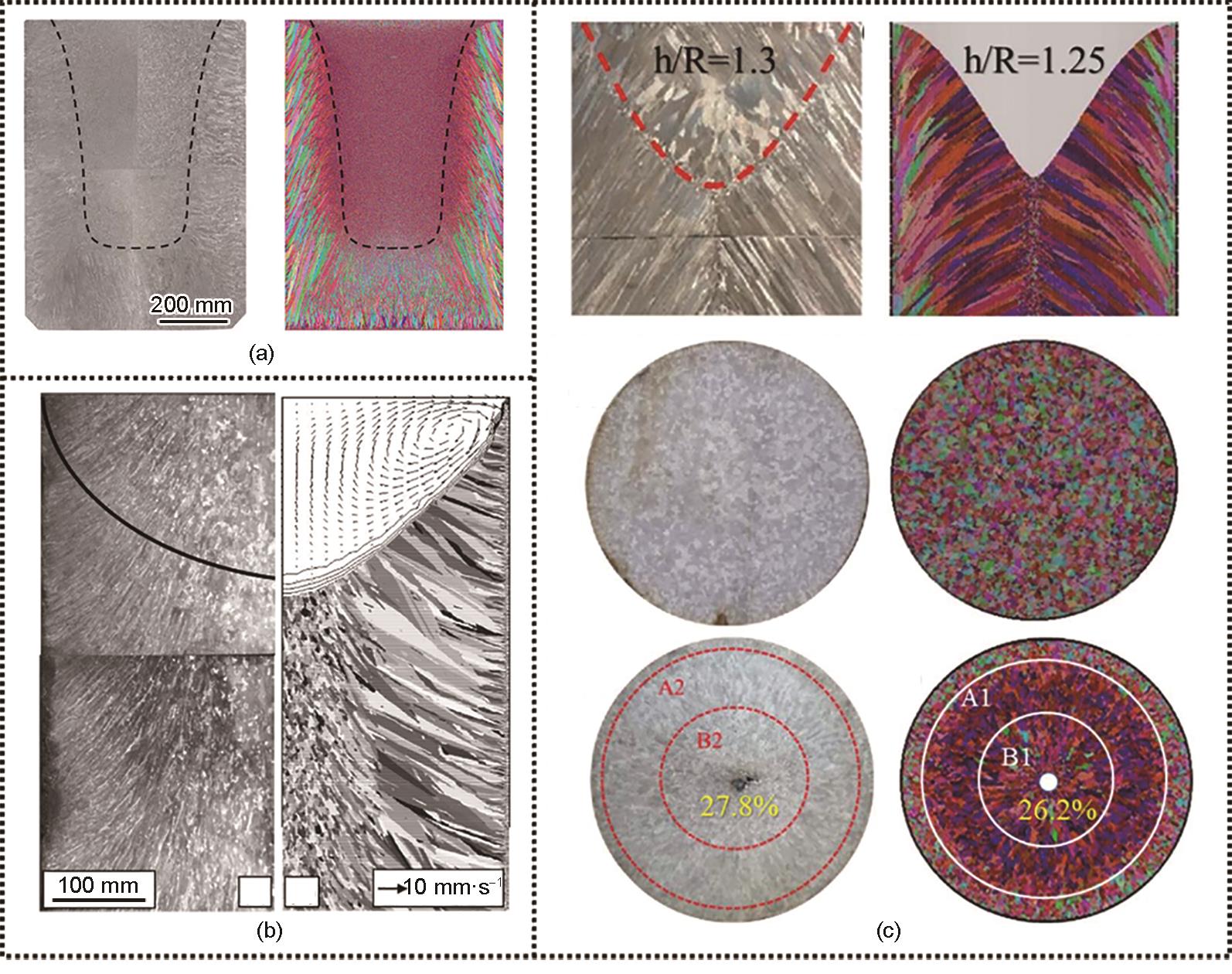

| 图9 不同合金体系中凝固晶粒组织的元胞自动机(CA)模拟与实验观测结果对比[ |

| Fig.9 Comparisons of cellular automation (CA) simulated and experimental results of solidification grain structure in titanium alloy ingot[ |

|