基于界面追踪-动网格技术模拟凝固收缩下Fe-C合金宏观偏析

Numerical Simulation on Macrosegregation in Fe-C Alloy Under Solidification Shrinkage Through Interface Tracking-Dynamic Mesh Technique

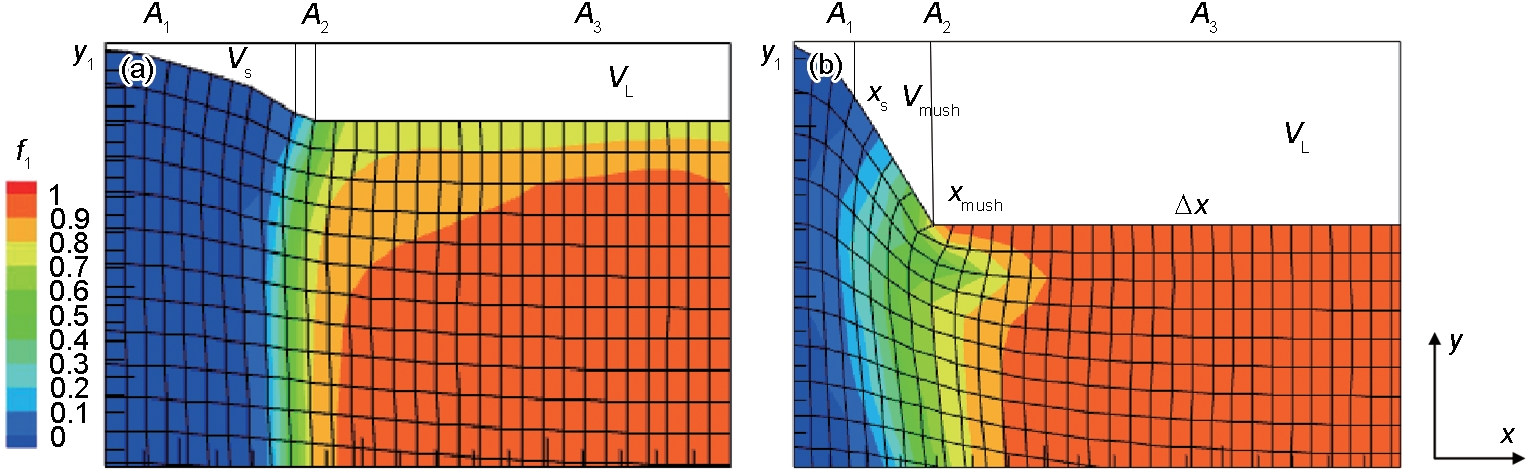

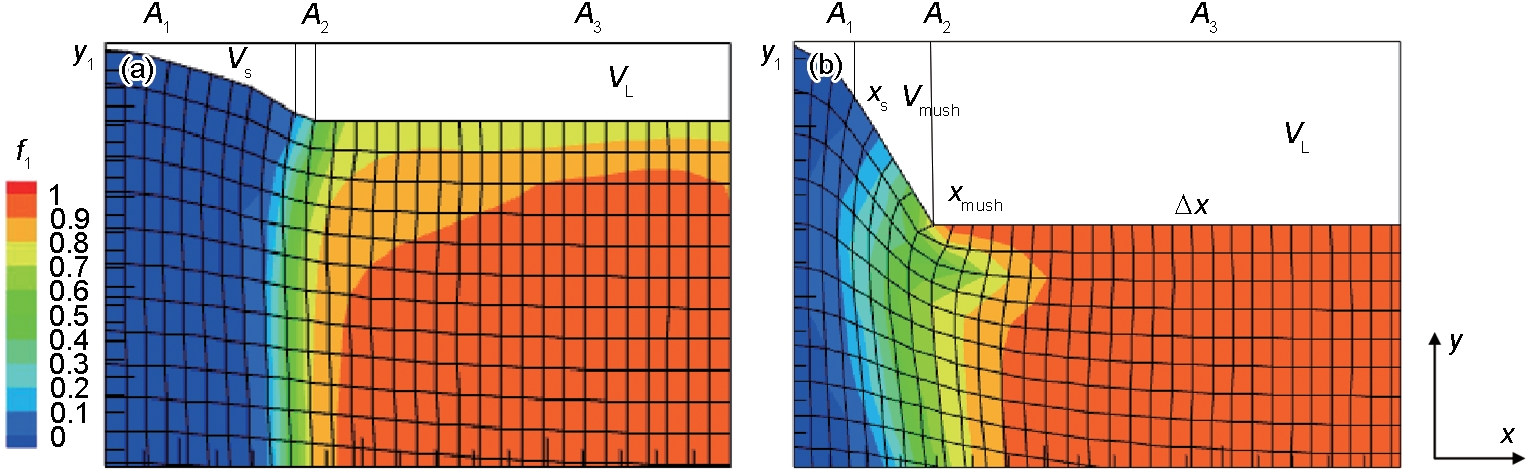

(a) N = 1 (b) N = N(0 < fl < 0.9)

基于界面追踪-动网格技术模拟凝固收缩下Fe-C合金宏观偏析 |

| 董士虎, 张红伟, 吕文朋, 雷洪, 王强 |

|

Numerical Simulation on Macrosegregation in Fe-C Alloy Under Solidification Shrinkage Through Interface Tracking-Dynamic Mesh Technique |

| DONG Shihu, ZHANG Hongwei, LÜ Wenpeng, LEI Hong, WANG Qiang |

| 图2 凝固收缩第II阶段铸锭顶端体积变化关系 |

| Fig.2 Layouts of volume evolution at ingot top during solidification shrinkage stage II (Δx—cell size in x-direction, xs—maximum of x-coordinate in solid zone at ingot top, xmush—maximum of x-coordinate in mushy zone at ingot top, A1—solidified zone, A2—mushy zone, A3—liquid zone, Vs—volume shrinkage at solidified zone, Vmush—volume shrinkage at mushy zone, VL—volume shrinkage at liquid zone, y1—maximum of y-coordinate for ingot at end of stage I, N—number of shrinkage mesh, fl—liquid volume fraction) (a) N = 1 (b) N = N(0 < fl < 0.9) |

|