镍基单晶高温合金的研发进展

Recent Progress in Research and Development of Nickel-Based Single Crystal Superalloys

镍基单晶高温合金的研发进展 |

| 张健, 王莉, 谢光, 王栋, 申健, 卢玉章, 黄亚奇, 李亚微 |

|

Recent Progress in Research and Development of Nickel-Based Single Crystal Superalloys |

| ZHANG Jian, WANG Li, XIE Guang, WANG Dong, SHEN Jian, LU Yuzhang, HUANG Yaqi, LI Yawei |

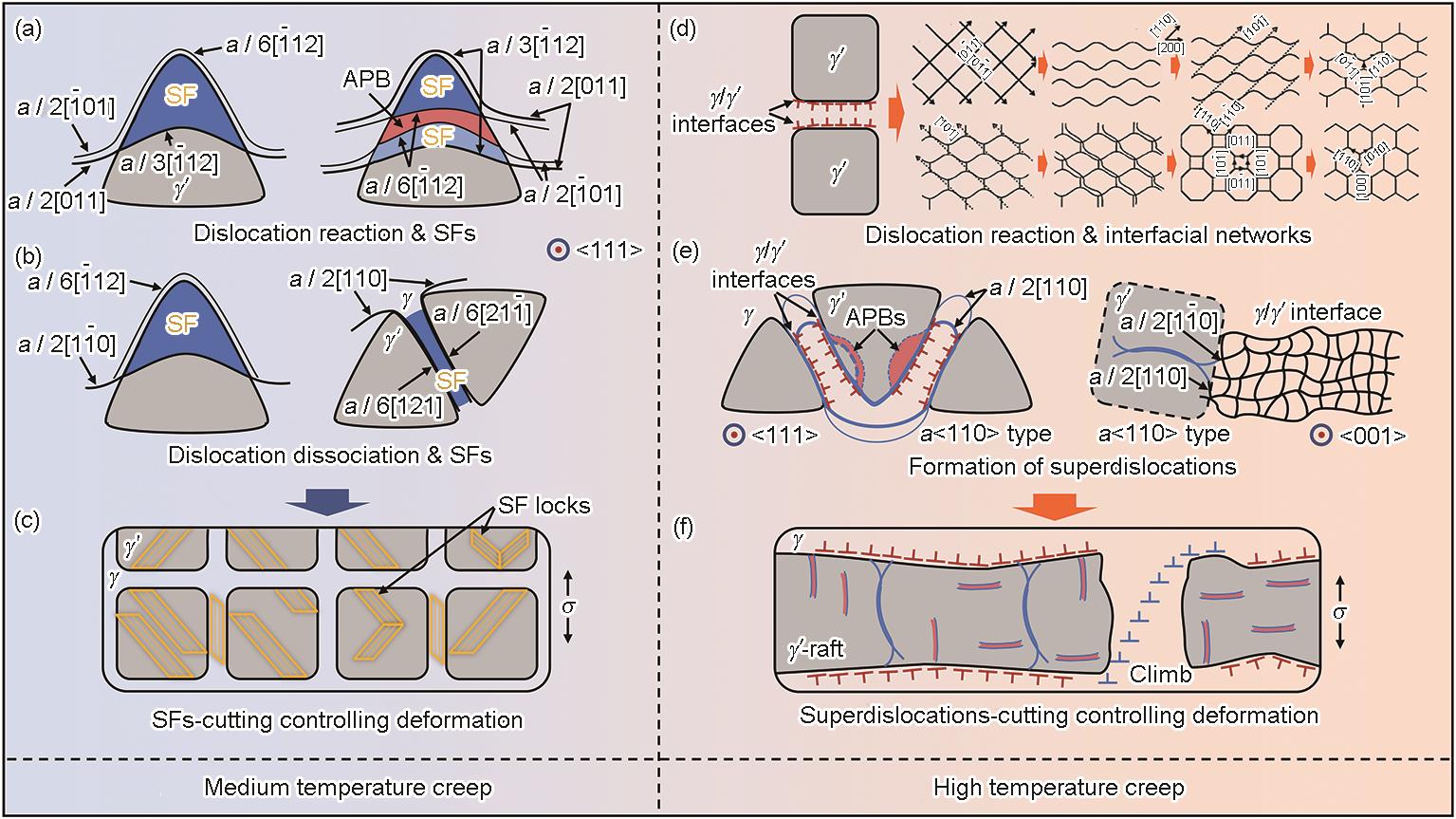

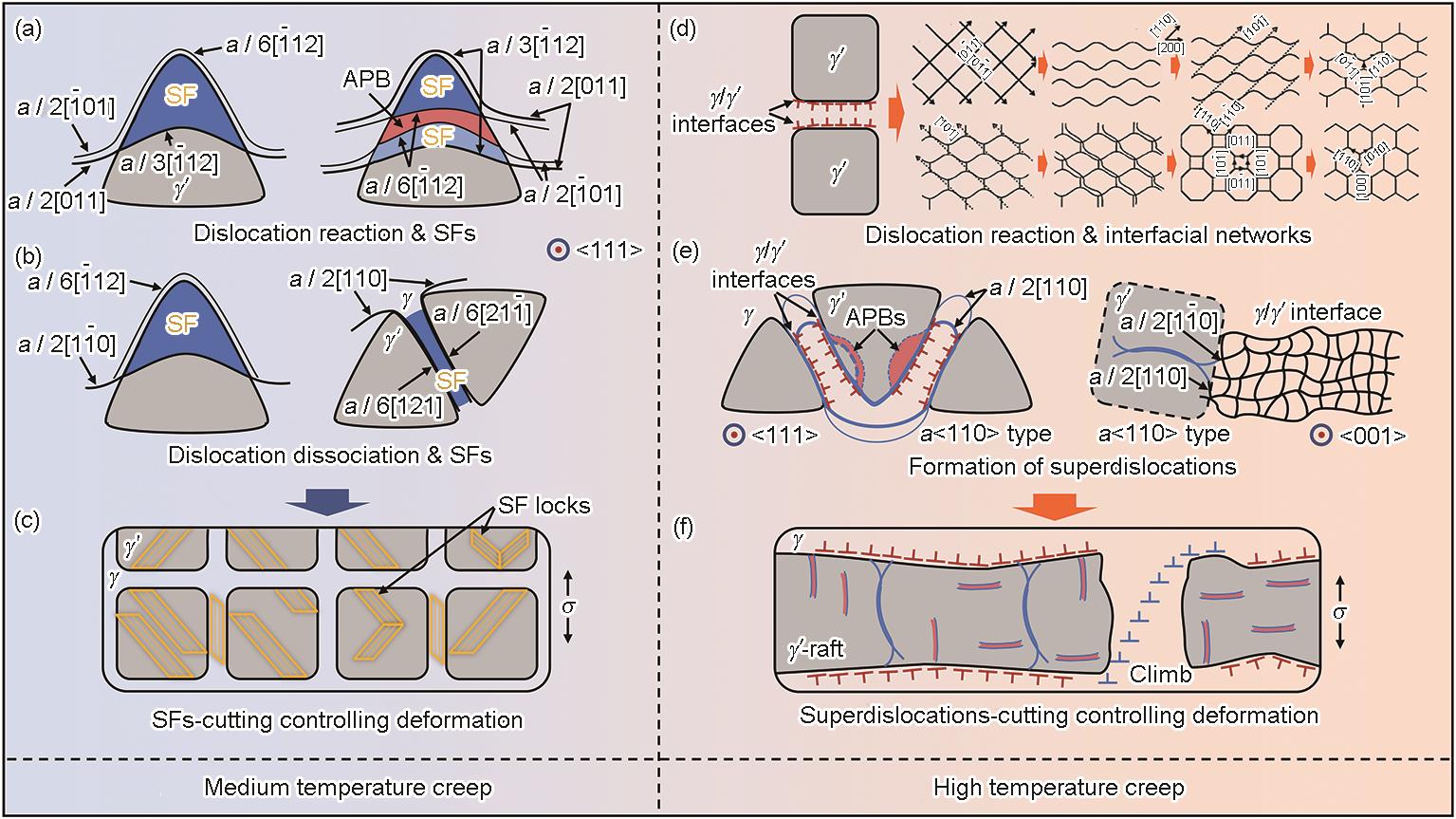

| 图2 单晶高温合金蠕变变形机制示意图 |

| Fig.2 Schematics of temperature dependence of creep deformation mechanisms for single crystal superalloys (a-c) at medium temperature, the main deformation mechanism is matrix dislocation reaction (a), and at higher stress, dislocation dissociation is also activated (b), both mechanisms in Figs.2a and b lead to the formation of stacking faults (SFs) (c) (σ—applied stress) (d-f) at high temperature, the applied stress and misfit stress impel matrix dislocation reaction at γ/γ' interface during primary creep, and then dislocation networks generate (d), as creep in progress, high local stress and interaction of interfacial dislocations result in the formation of superdislocations, including a<110> type and a<100> type (e), the former is antiphase boundary (APB) coupled with dislocation pair, and the latter is dislocation pair with non-compact core originating from interfacial dislocations. In latter stage, γ'-raft cutting by superdislocations occurs (f) |

|