基于热力学计算与机器学习的增材制造镍基高温合金裂纹敏感性预测模型

Modeling of Crack Susceptibility of Ni-Based Superalloy for Additive Manufacturing via Thermodynamic Calculation and Machine Learning

基于热力学计算与机器学习的增材制造镍基高温合金裂纹敏感性预测模型 |

| 穆亚航, 张雪, 陈梓名, 孙晓峰, 梁静静, 李金国, 周亦胄 |

|

Modeling of Crack Susceptibility of Ni-Based Superalloy for Additive Manufacturing via Thermodynamic Calculation and Machine Learning |

| MU Yahang, ZHANG Xue, CHEN Ziming, SUN Xiaofeng, LIANG Jingjing, LI Jinguo, ZHOU Yizhou |

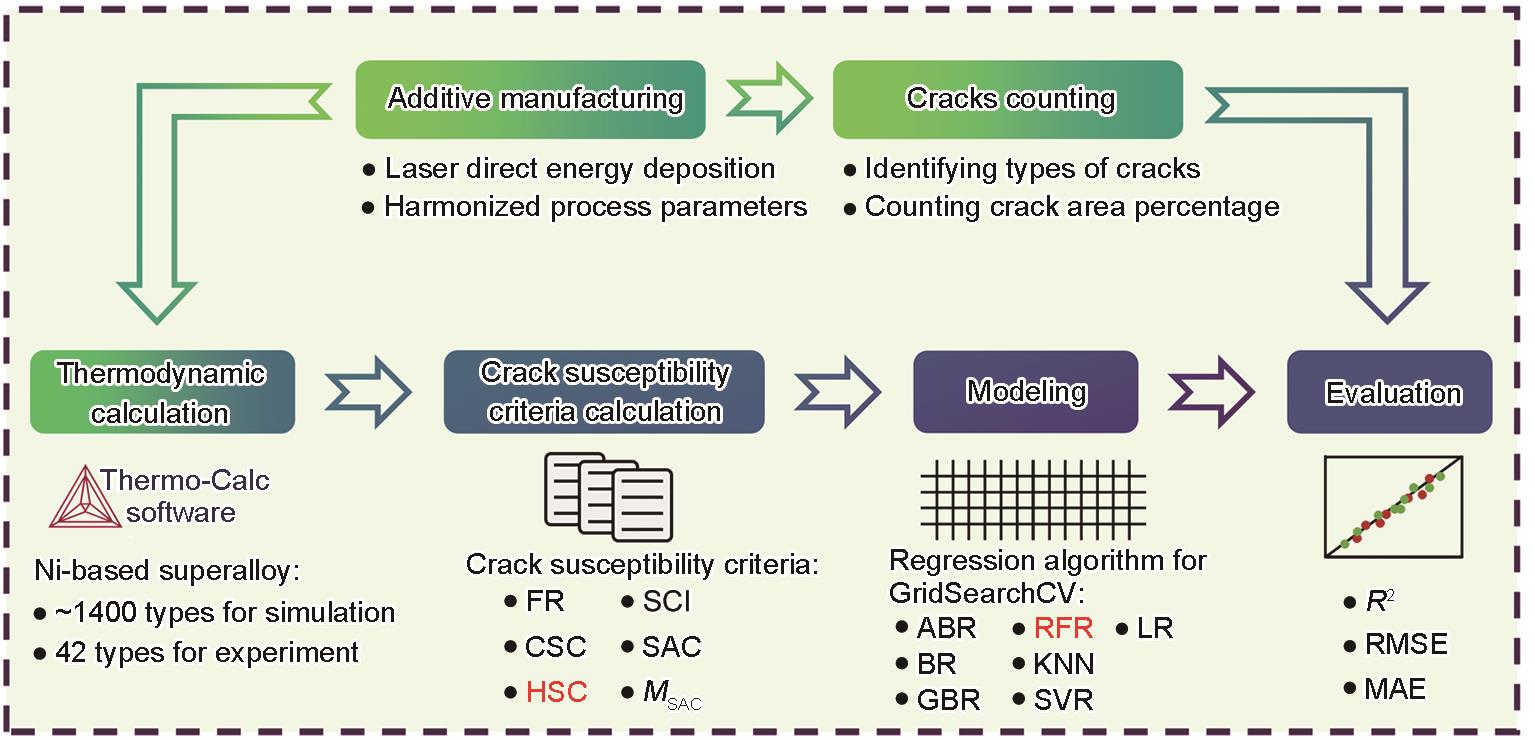

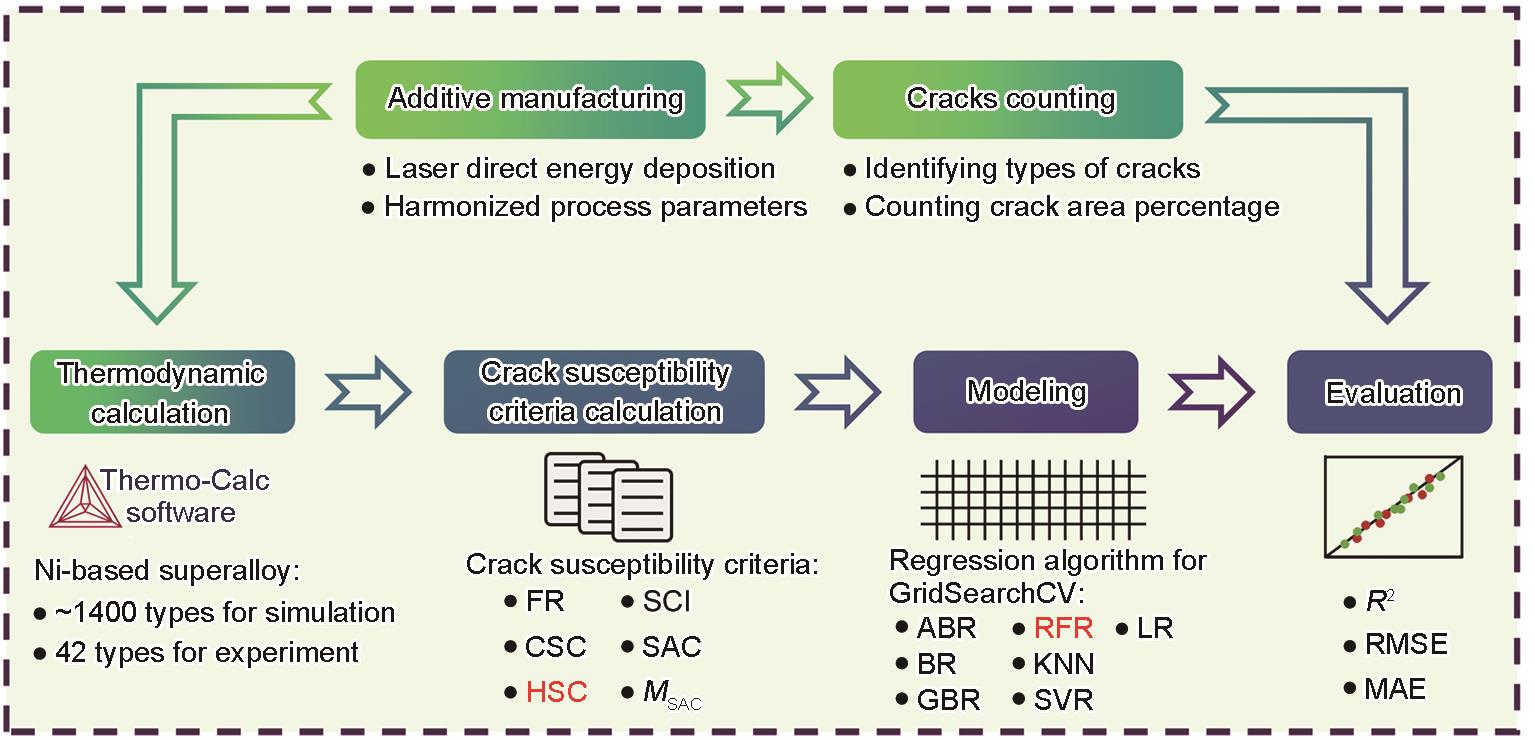

| 图1 镍基合金裂纹敏感性预测模型建立流程 |

| Fig.1 Workflow for crack susceptibility prediction of Ni-based superalloy (FR—freezing range, CSC—crack susceptibility criterion, HSC—hot-tearing susceptibility criterion, SCI—solidification cracking index, SAC—strain age cracking index, MSAC—index of strain age cracking by mass-percentage, ABR—AdaBoost regression, BR—Bagging regression, GBR—gradient boosting regression, RFR—random forest regression, KNN—K-nearest neighbors, SVR—support vector regression, LR—linear regression, R2—correlation coefficient, RMSE—root mean squared error, MAE—mean absolute error) |

|