计算辅助高性能增材制造铝合金开发的研究现状与展望

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review

计算辅助高性能增材制造铝合金开发的研究现状与展望 |

| 高建宝, 李志诚, 刘佳, 张金良, 宋波, 张利军 |

|

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review |

| GAO Jianbao, LI Zhicheng, LIU Jia, ZHANG Jinliang, SONG Bo, ZHANG Lijun |

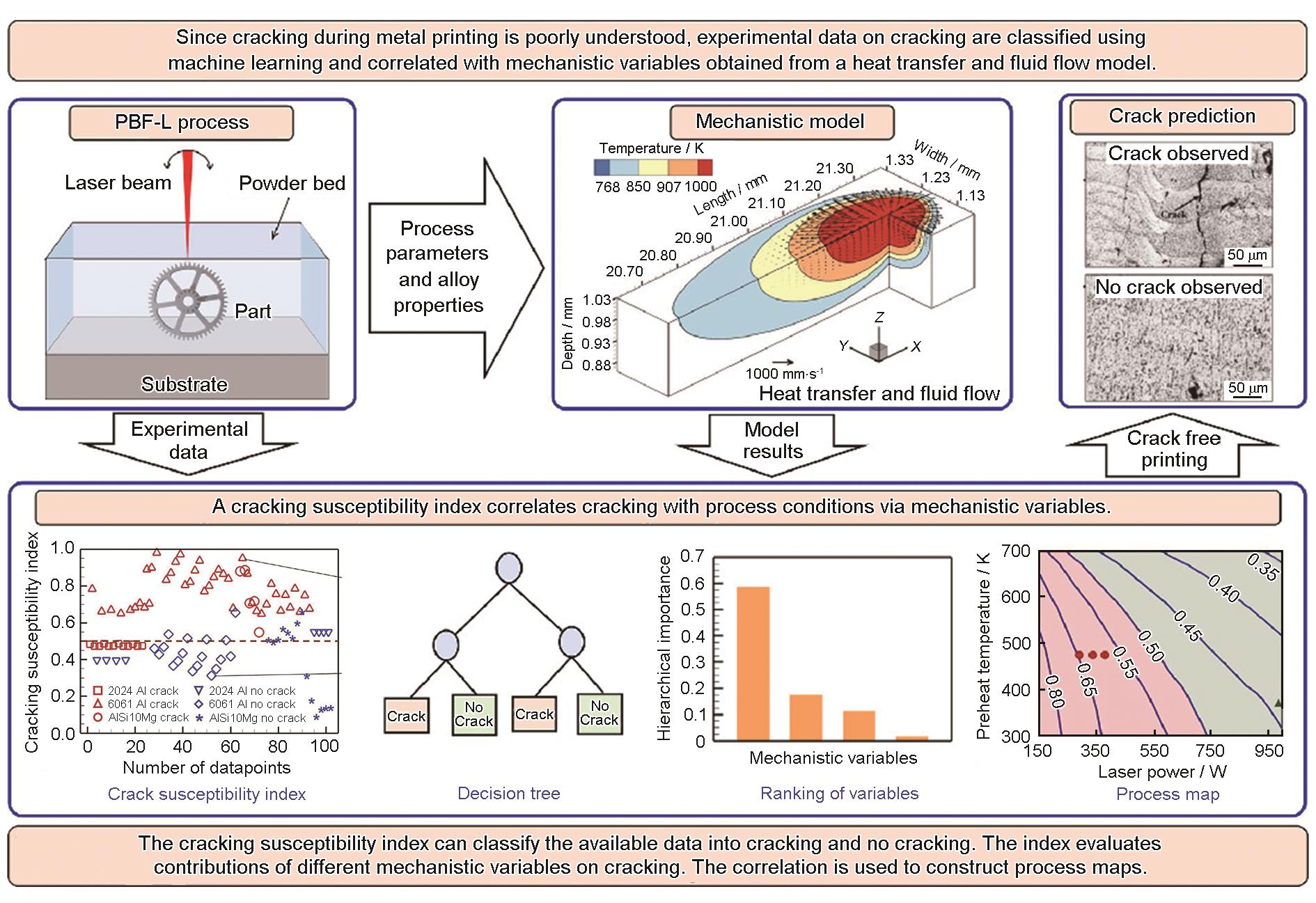

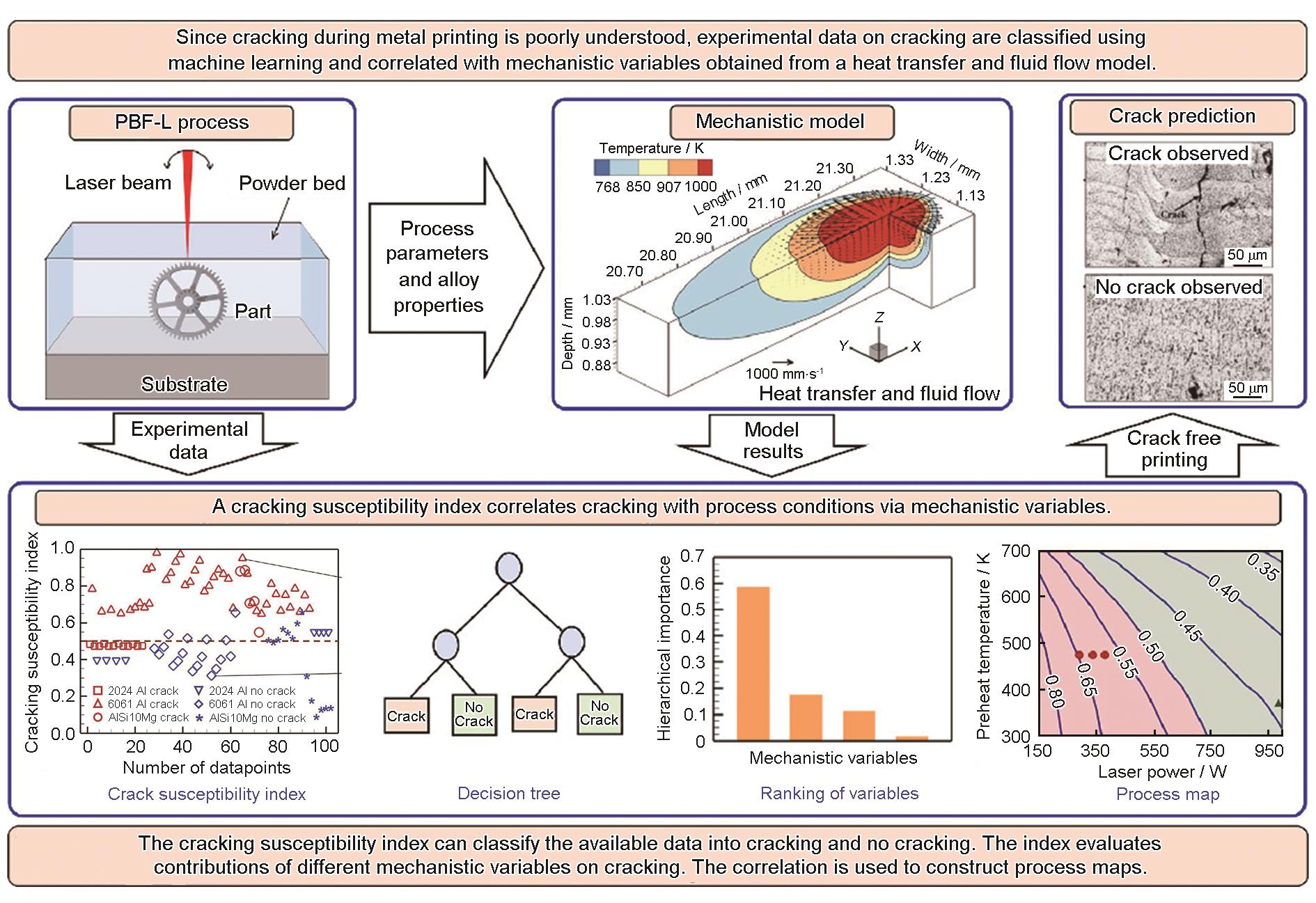

| 图11 基于物理信息的机器学习方法设计无裂纹3D打印件流程图[ |

| Fig.11 A physics-informed machine learning towards crack-free printing[ |

|