计算辅助高性能增材制造铝合金开发的研究现状与展望

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review

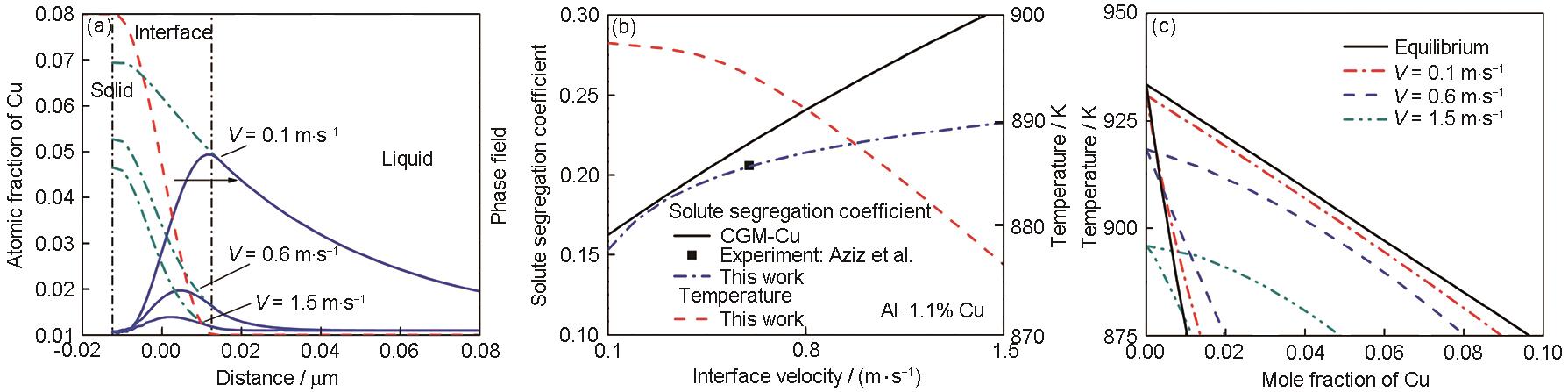

(a) phase-field simulated steady-state concentration profiles with three different interface moving velocities (or solidification rate) V in Al-Cu system (The red dash line denotes the phase field, the bule solid lines denote the overall concentrations, while the dotted lines denote the liquid concentrations)

(b) phase-field simulated solute segregation coefficient and solidification temperature as a function of interface velocity (or solidification rate) in Al-1.1%Cu (atomic fraction) alloy

(c) model-predicted kinetic phase diagrams at different interface velocities (or solidification rate) due to the 1-D phase-field simulation using the time-elimination relaxation scheme of the Al-Cu system