计算辅助高性能增材制造铝合金开发的研究现状与展望

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review

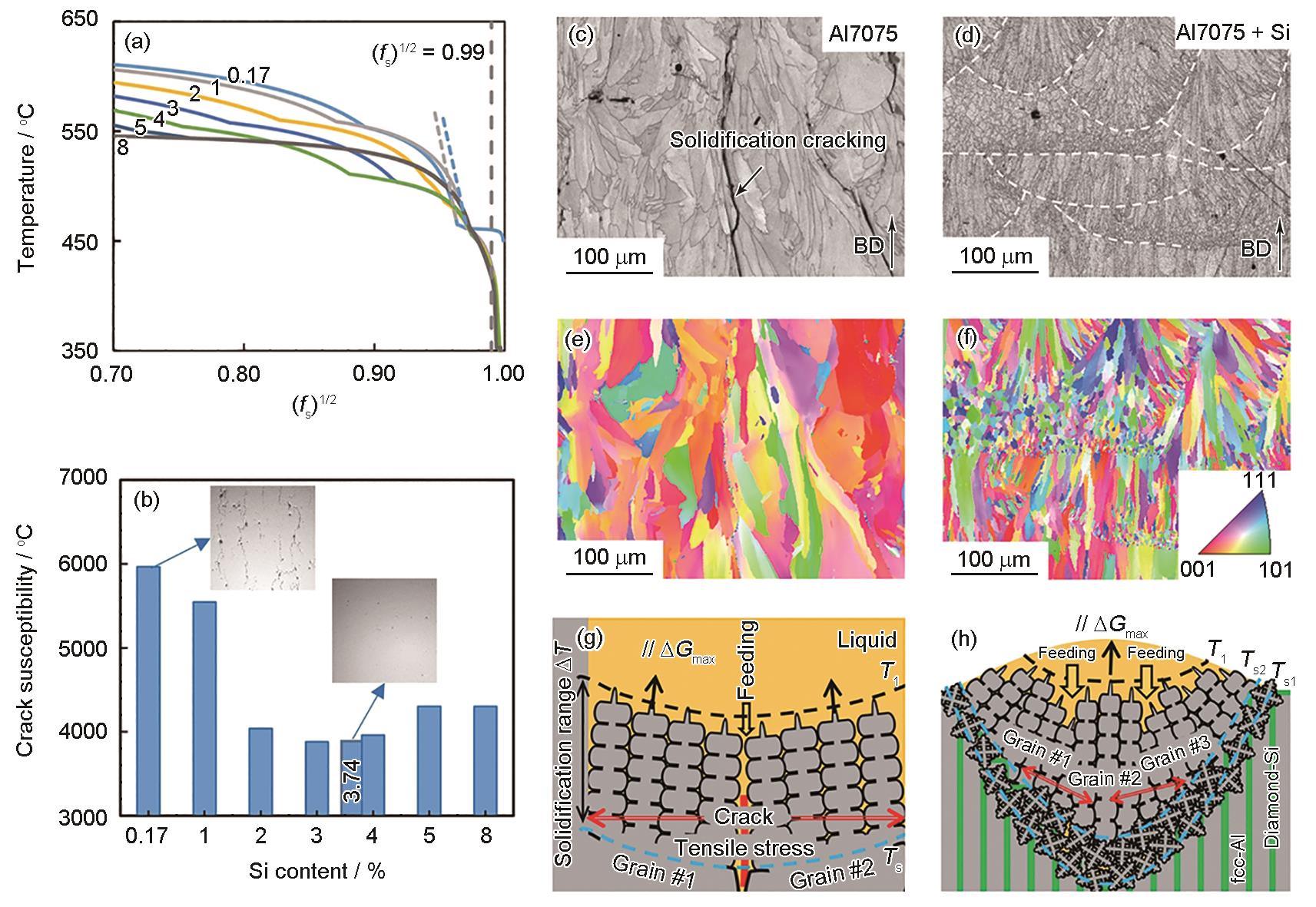

(a) T vs (fS)1/2 curves of the Al7075 alloys with 0.17% to 8% Si additions (mass fraction), the dashed vertical line indicates (fS)1/2 = 0.99

(b) variation of crack susceptibility of Al7075 alloys as a function of Si additions (Insets show the defect morphologies of Si-modified SLM processed Al7075 alloy)

(c-f) grain morphologies of SLM processed Al7075 with solidification cracks (c, e), and crack-free Si-modified Al7075 alloy (Al7075-3.74Si%) processed by SLM (d, f) (BD—building direction)

(g, h) schematics of epitaxial growth of the Al7075 alloy (g) and the solidification cracking mitigation mechanism in the Si-modified Al7075 (h) (Tl is the liquidus temperature, Ts or Ts1 is the terminal temperature of solidification, Ts2 is the temperature of full columnar grains zone, ΔT is solidification temperature range (ΔT = Tl - Ts), //ΔGmax represents that the growth direction of columnar grains is preferentially oriented parallel to the direction of the maximum temperature gradient G)