计算辅助高性能增材制造铝合金开发的研究现状与展望

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review

计算辅助高性能增材制造铝合金开发的研究现状与展望 |

| 高建宝, 李志诚, 刘佳, 张金良, 宋波, 张利军 |

|

Current Situation and Prospect of Computationally Assisted Design in High-Performance Additive Manufactured Aluminum Alloys: A Review |

| GAO Jianbao, LI Zhicheng, LIU Jia, ZHANG Jinliang, SONG Bo, ZHANG Lijun |

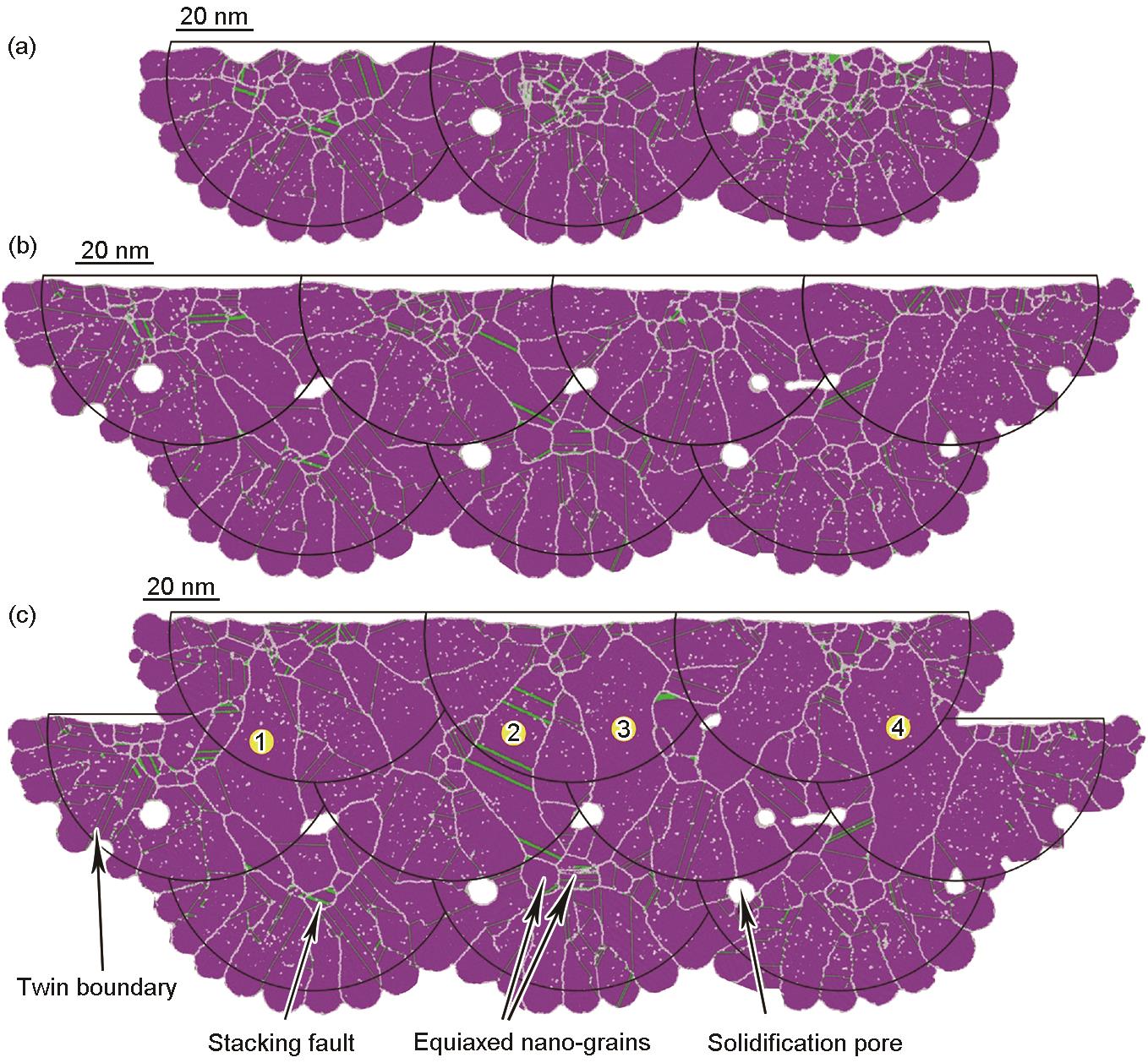

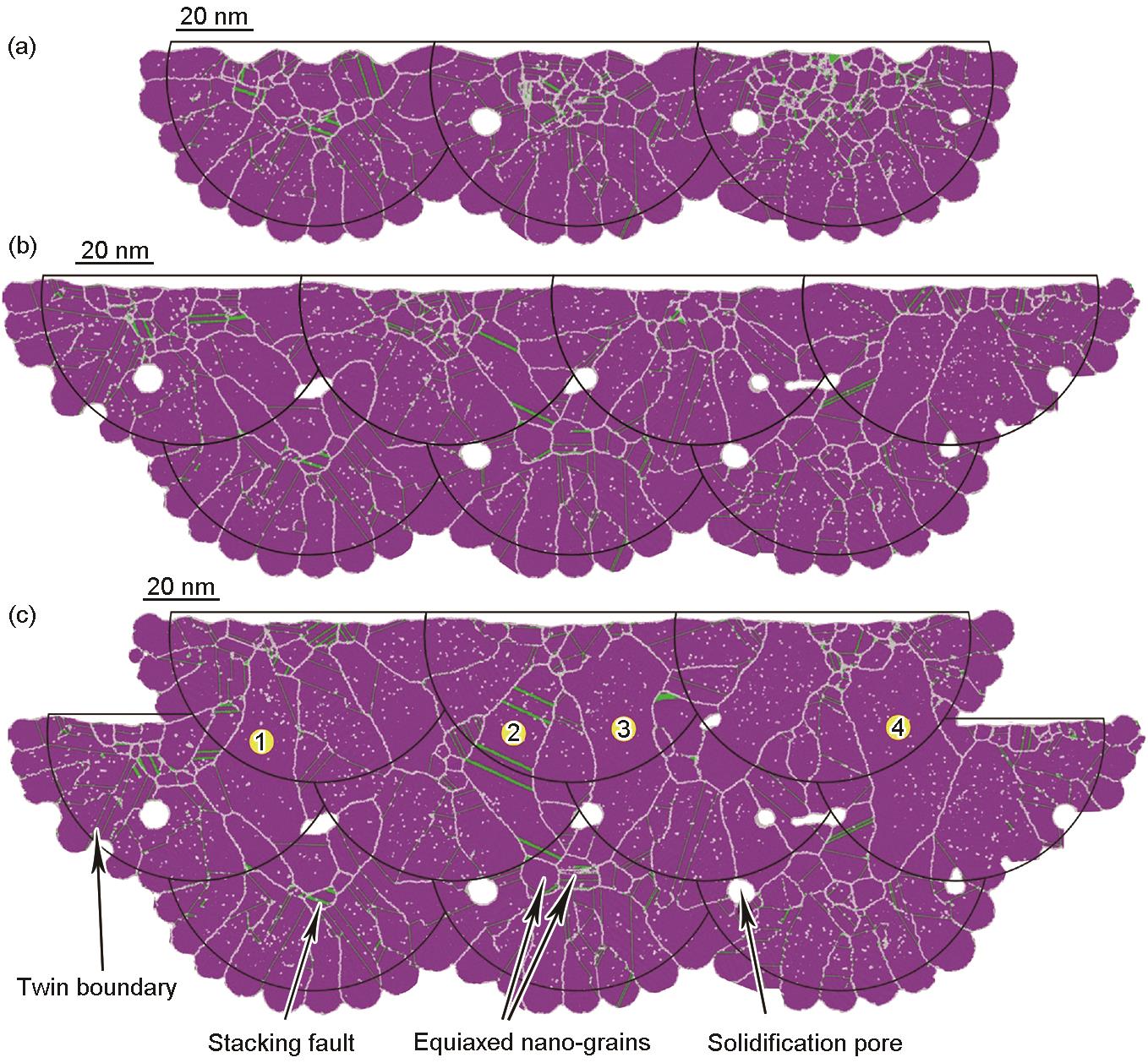

| 图2 通过分子动力学构建的微型选区激光熔化(μ-SLM)模型处理Al纳米粉末床的最终凝固结构[ |

| Fig.2 Finally solidified structures of the aluminum nano-powder bed processed by micro-selective laser melting (μ-SLM) model using molecular dynamics. Ten laser tracks have fused together a total of 453 nano-powders of average diameter 9.67 ?nm in three different layers shown in first layer (a), second layer (b), and third layer (c) (Dark semi-circles outline the contours of the melt-pool boundaries; the grains that span across the three layers are explicitly numbered in Fig.2c; the solidified nanostructure is dominated by epitaxially grown grains. Other important structural features such as equiaxed grains, nano-pores, twin boundaries, and stacking faults are labeled in Fig.2c)[ |

|