耦合热力学相变路径预测Fe-C包晶合金宏观偏析

|

|

冯苗苗, 张红伟, 邵景霞, 李铁, 雷洪, 王强

|

Prediction of Macrosegregation of Fe-C Peritectic Alloy Ingot Through Coupling with Thermodynamic Phase Transformation Path

|

|

FENG Miaomiao, ZHANG Hongwei, SHAO Jingxia, LI Tie, LEI Hong, WANG Qiang

|

|

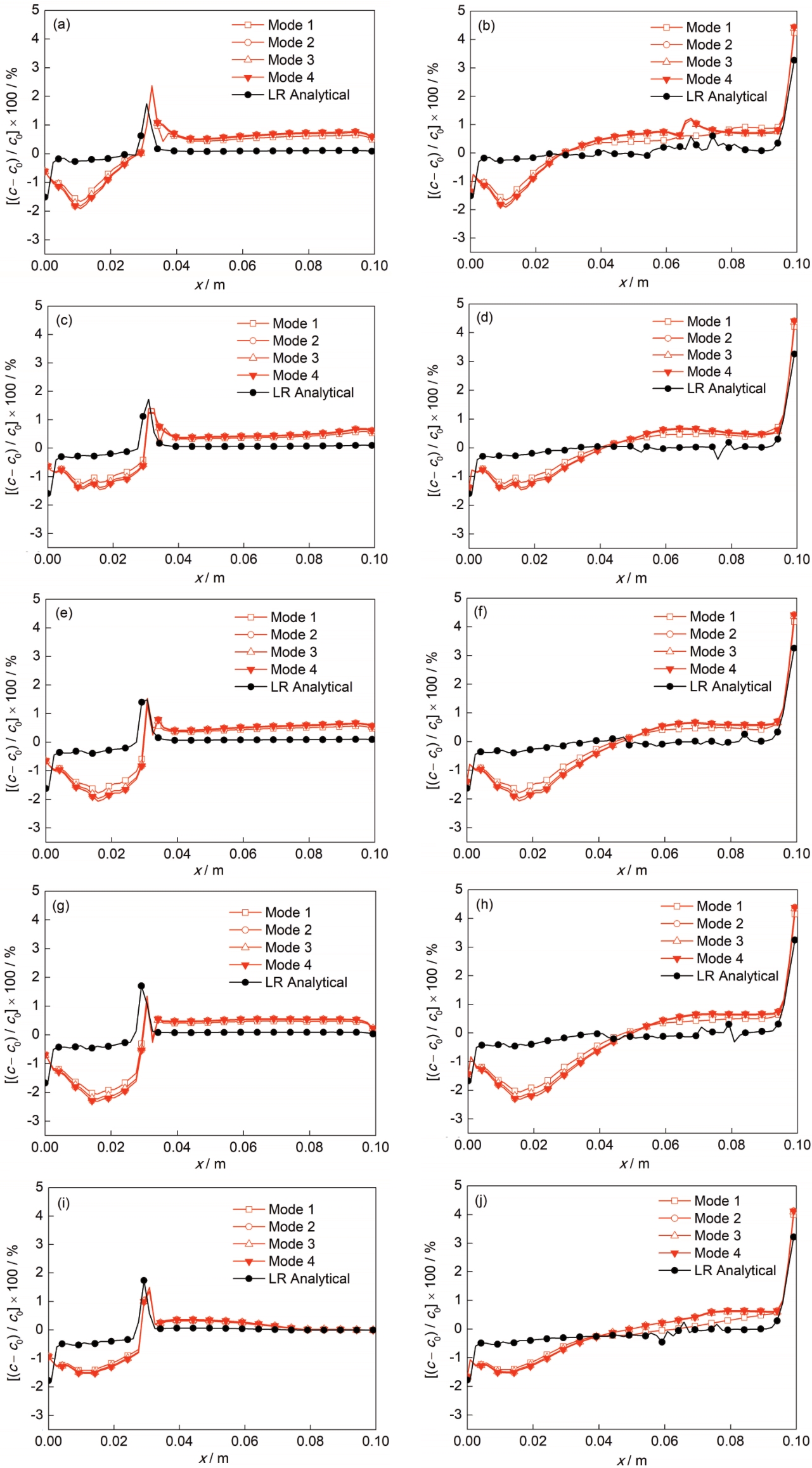

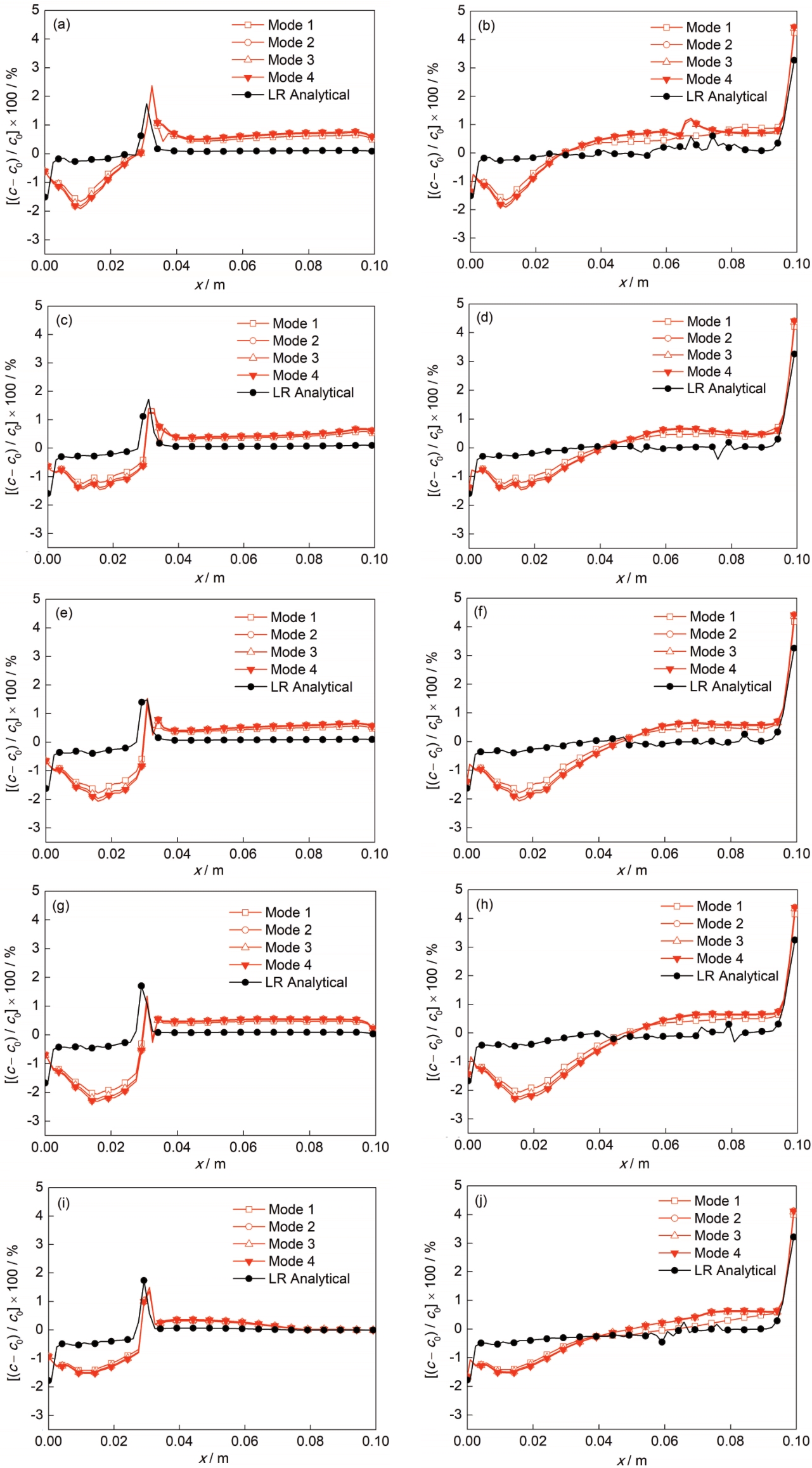

图13 数据表温度数据存储方式对Fe-0.1%C合金截面C的相对溶质成分分布的影响

(a) y = 5 mm, t = 110 s (b) y = 5 mm, calculation end

(c) y = 25 mm, t = 110 s (d) y = 25 mm, calculation end

(e) y = 35 mm, t = 110 s (f) y = 35 mm, calculation end

(g) y = 45 mm, t = 110 s (h) y = 45 mm, calculation end

(i) y = 55 mm, t = 110 s (j) y = 55 mm, calculation end

|

Fig.13 Influences of storage mode of temperature in tabulation on distributions of [(c - c0) / c0] × 100 for solute C at cross section of the Fe-0.1%C alloy ingot (Mode 1—intitial temperature Tini = Tliq (int type) + overheat 30oC, temperature step ΔT = -1oC; Mode 2—Tini = Tliq (real type) + overheat 30oC, ΔT = -1oC; Mode 3—Tini = Tliq (int) + overheat 30oC, ΔT = -1oC, with L/δ, L + δ/γ, γ/α, γ + α/CEM phase transformation points in tabulation; Mode 4—Tini = Tliq (real) + overheat 30oC, with temperature reset at each phase transformation point (real type) while keeping ΔT = -1oC in tabulation)

|

|

|

|

|